Microwave integrated machine for production of aerogel material and method for continuous production of aerogel material

An airgel and all-in-one technology, applied in airgel preparation, colloid chemistry, colloid chemistry, etc., can solve problems such as long production cycle, decline in thermal insulation performance, collapse of internal skeleton structure, etc., to save energy and ensure production safety , the effect of reducing the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

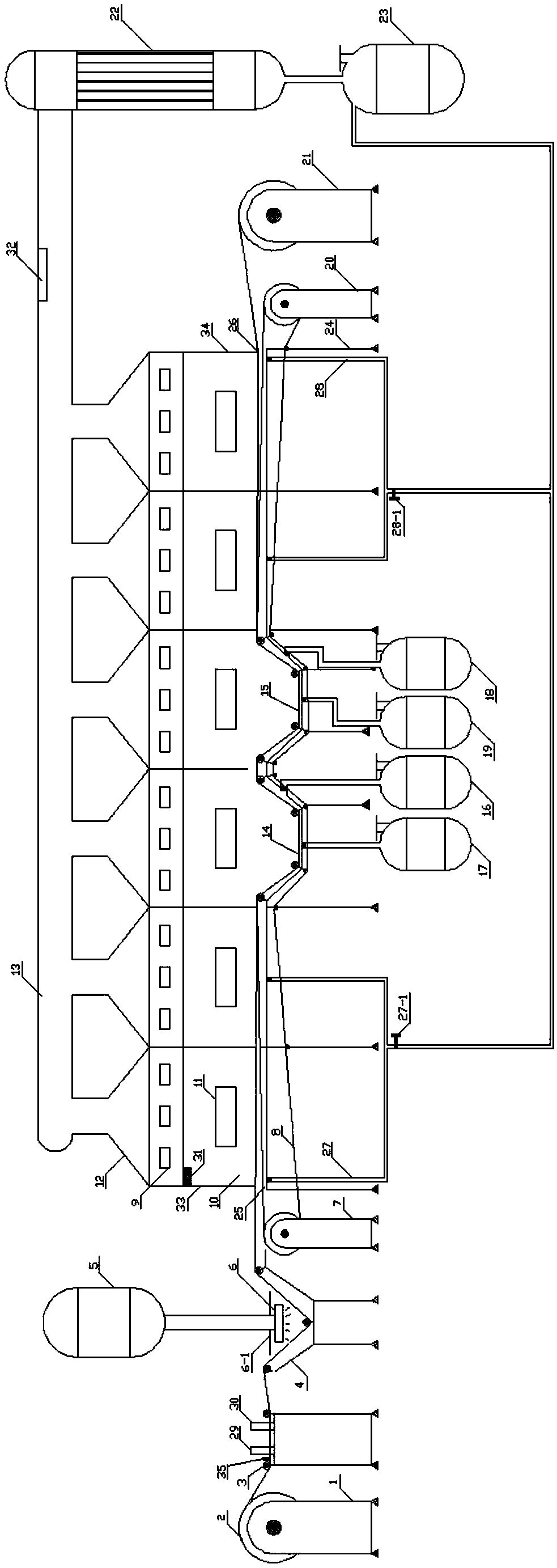

specific Embodiment approach 1

[0037] Embodiment 1: In this embodiment, the microwave integrated machine for producing airgel materials includes an unwinder 1, a shielding cover 6-1, a roller 3, a dipping pool 4, an airgel precursor liquid storage tank 5, and a high-pressure nozzle 6. Front transmission device 7, PTFE conveyor belt 8, microwave generator 9, microwave cavity 10, observation and maintenance window 11, wind collecting hood 12, dehumidification pipe 13, solvent replacement device 14, hydrophobic modification device 15, replacement liquid Raw material storage tank 16, replacement residual liquid storage tank 17, modified liquid raw material storage tank 18, modified residual liquid collection storage tank 19, rear transmission device 20, winder 21, tubular condenser 22, condensate receiver Tank 23, microwave equipment bracket 24, raw material inlet 25, product outlet 26, front inert gas protection device 27, first gas valve 27-1, rear inert gas protection device 28, second gas valve 28-1, magneti...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the front inert gas protection device 27, the rear inert gas protection device 28 and the oxygen content online monitoring device 32 are interlocked. When the microwave cavity 10, the oxygen When the content exceeds 6vol.%, the front inert gas protection device 27 and the rear inert gas protection device 28 will automatically inject inert gas to reduce the oxygen content. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: adopt the method for the continuous production of airgel material of the microwave all-in-one machine that produces airgel material according to the following steps:

[0040] 1. Introduce the nano-absorbing factor into the airgel precursor: mix and stir 500kg of the airgel precursor and 0.05-0.5kg of the nano-absorbing factor for 5-10min under the condition that the speed of the high-speed disperser is 100-1000r / min After being uniformly dispersed, the airgel precursor solution containing the nano-absorbing factor is obtained, and the airgel precursor solution containing the nano-absorbing factor is loaded into the airgel precursor solution storage tank 5 and heated to 20-60° C.;

[0041] Under the condition that the speed of the high-speed disperser is 100-1000r / min, mix and stir 500kg of replacement liquid and 0.5-5kg of flame retardant for 5-10 minutes to obtain the treated replacement liquid, and put the treated replacement liquid into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com