Analysis method of N,N-dimethylhydroxylamine

A dimethylhydroxylamine and analysis method technology, applied in the field of nuclear fuel reprocessing, can solve the problems of contamination, uneconomical and practical, high price of gas chromatography or ion chromatography instruments, and achieve the effect of avoiding precipitation and hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

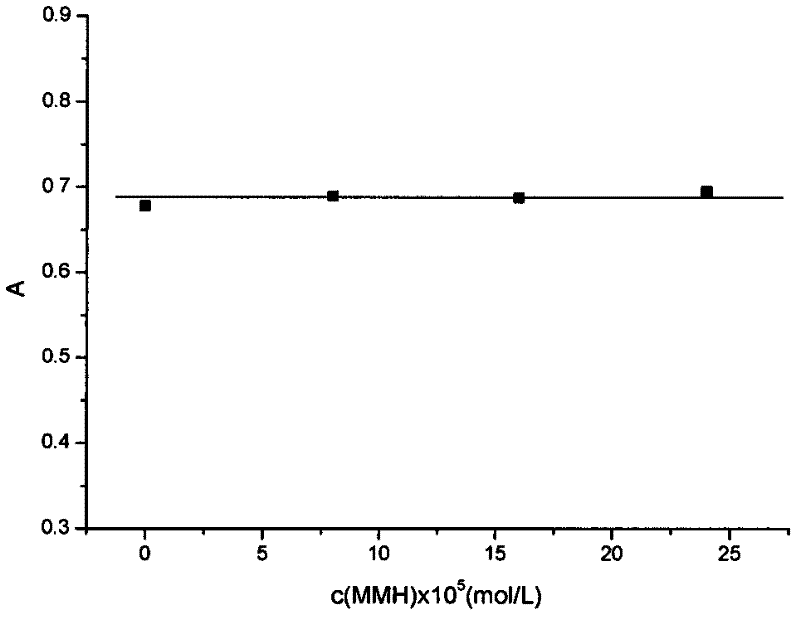

[0033] This embodiment is Pu 3+ , Methanol, formaldehyde, formic acid, methylamine, dimethylamine, ethanol, methylhydrazine and N, N-dimethylhydroxylamine, the analysis method of N,N-dimethylhydroxylamine coexists.

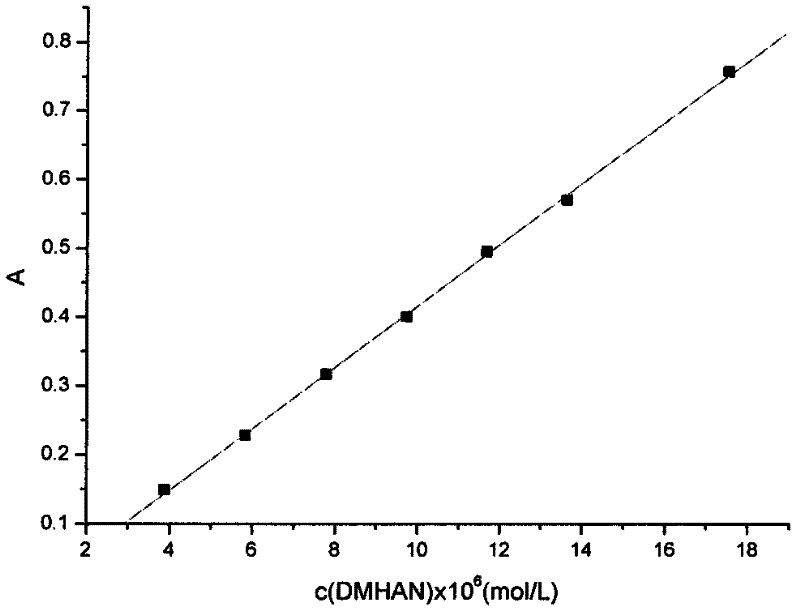

[0034] (1) The configuration concentration is 3.89×10 -4mol / L N,N-dimethylhydroxylamine aqueous solution, as a standard solution.

[0035] (2) Weigh 0.5112g of phenanthroline + 0.45mL of 11.10mol / L hydrochloric acid + 0.4995g of ferric ammonium sulfate into a 250.00ml volumetric flask, dilute with water to the mark, shake well, and use it as a developer.

[0036] (3) Prepare a 0.05 mol / L potassium hydrogen phthalate solution, add a small amount of NaOH solution to adjust the pH to 5.0, and use it as a buffer solution.

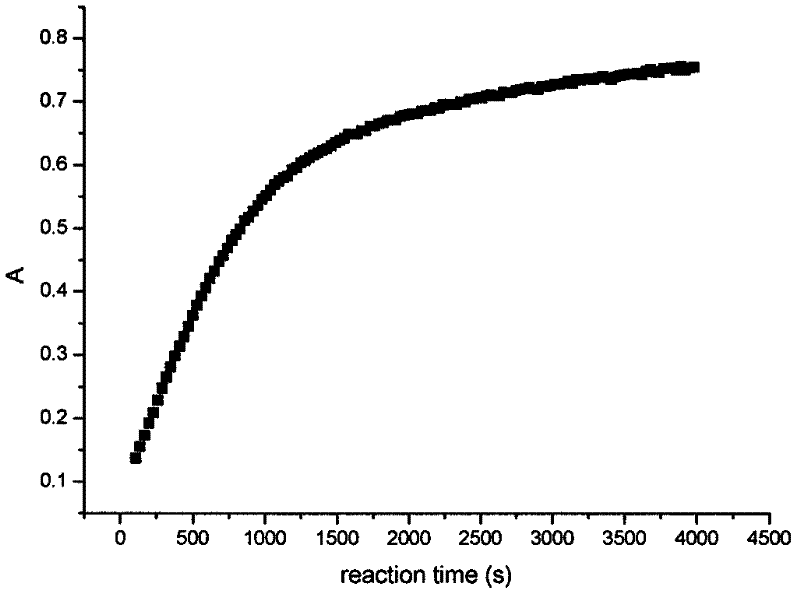

[0037] (4) Add 2.00 mL of buffer solution and 1.2 mL of chromogen to eight 10.00 mL volumetric flasks respectively; 400.00 μL with a concentration of 3.89×10 -4 mol / L standard solution of N,N-dimethylhydroxylamine. Dilute it with water to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com