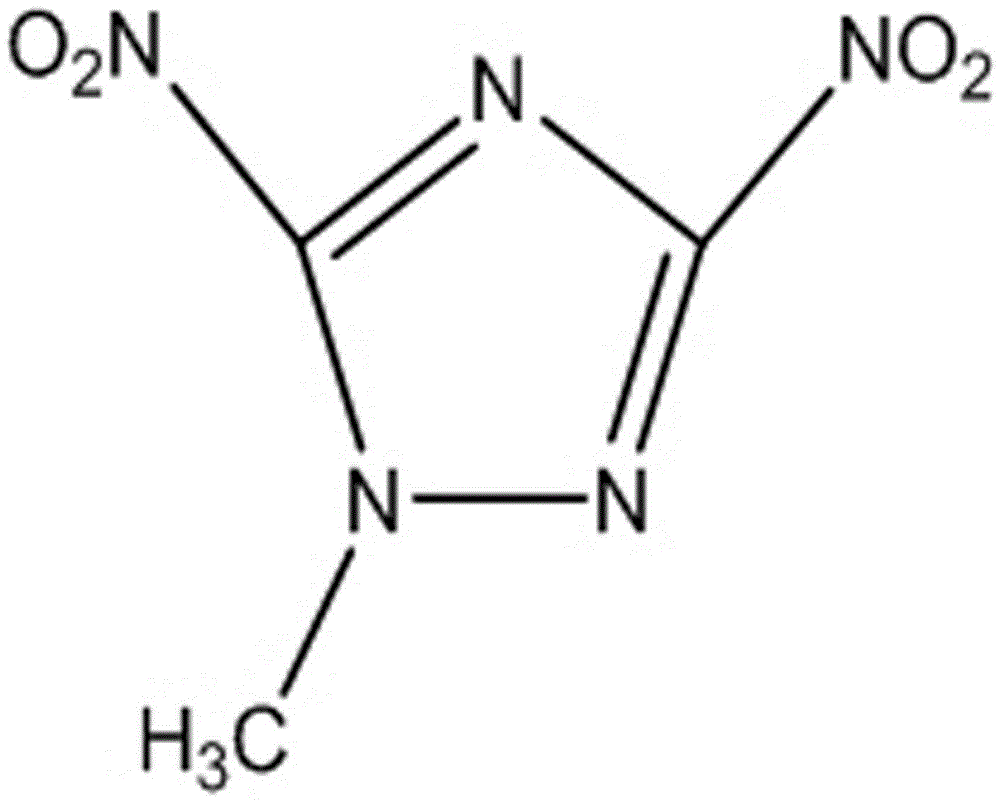

Preparation method of 1-methyl-3,5-binitro-1,2,4-triazole

A technology of dinitro and methyl groups, applied in the direction of organic chemistry, etc., can solve the problems of difficult treatment of wastewater components, low yield of final products, potential safety hazards, etc., and achieve the effects of saving raw materials, low prices, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, a kind of preparation method of 1-methyl-3,5-dinitro-1,2,4-triazole comprises the following steps:

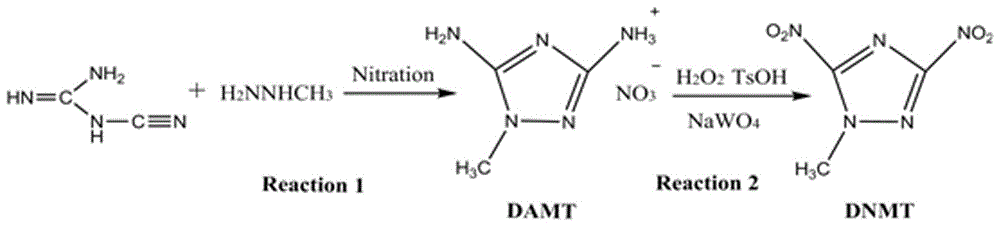

[0045] The first step, the preparation of 1-methyl-3,5-diamino-1,2,4-triazole nitrate (DAMT)

[0046] Put the three-neck flask equipped with a stirrer in an ice-water bath, and after fixing, pour 300mL of water and 260mL of methylhydrazine solution (40%) into the reaction vessel slowly in sequence, stir, cool to -10°C, and then prepare the 310mL of concentrated nitric acid (65%) solution was slowly added dropwise to the aqueous solution of methylhydrazine. The entire feeding process of concentrated nitric acid took 30 minutes, and the temperature was controlled at -10°C, and stirred until completely mixed. After the concentrated nitric acid is added dropwise, 225g of dicyandiamide is added to obtain a mixed solution; the mixed solution is placed at 10°C and stirred for 0.5h. At this time, the dicyandiamide is not completely dissolved, and then the temperatu...

Embodiment 2

[0049] Example 2, in the first step of this example, the amount of water is 350mL, the amount of methylhydrazine is 220mL, cooled to -5°C, the amount of concentrated nitric acid is 250mL, the entire nitration process is 45min, and the temperature is controlled at -5°C, The dosage of dicyandiamide is 260g, the mixed solution is placed at 15°C and stirred for 0.8h, then heated to 85°C and stirred for 3h4h, and then placed at 0°C for 10h after the reaction is completed, and the rest is the same as in Example 1. The obtained product 1 was 324.7g, the yield of the first step reaction was 82.0%, the total reaction yield was 41.18%, and the purity of the target product was 98.40%.

Embodiment 3

[0050] Example 3, in the first step of this example, the amount of water is 400mL, the amount of methylhydrazine is 300mL, cooled to 0°C, the amount of concentrated nitric acid is 350mL, the entire nitration process is 60min, and the temperature is controlled at 0°C, dicyandiamide The amount of amine used was 300g. The mixed solution was placed at 20°C and stirred for 1 hour, then heated to 95°C and stirred for 5 hours. After the reaction was completed, it was placed at 5°C for 11 hours. The rest was the same as in Example 1. The obtained product 1 was 340.55g, the yield of the first step reaction was 86.0%, the total yield of the reaction was 43.19%, and the purity of the target product was 98.63%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com