Method for measuring impurity content in methylhydrazine

A technology for rapid determination of impurity content, applied in the field of analytical chemistry, can solve problems such as inability to measure the impurity content of methyl hydrazine, and achieve the effects of overcoming long time, small relative error and accurate determination results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ① Instrument: The gas chromatograph is equipped with a thermal conductivity detector, a split / splitless inlet, and a capillary column of 60m×0.32mm×5μm.

[0024] ②Test conditions: manual injection; injection volume 1 μL; oven temperature 60°C, rear inlet temperature 250°C, rear detector temperature 250°C; split ratio 25:1; column temperature 60°C for 9 Minutes, the temperature was programmed to rise to 150°C at 20°C / min, and the temperature was kept constant for 2 minutes; the flow rate of the chromatographic column was 3ml / min; the carrier gas was high-purity helium.

[0025] ③ Gas phase detection of methylhydrazine sample 1 was carried out by the area percentage method.

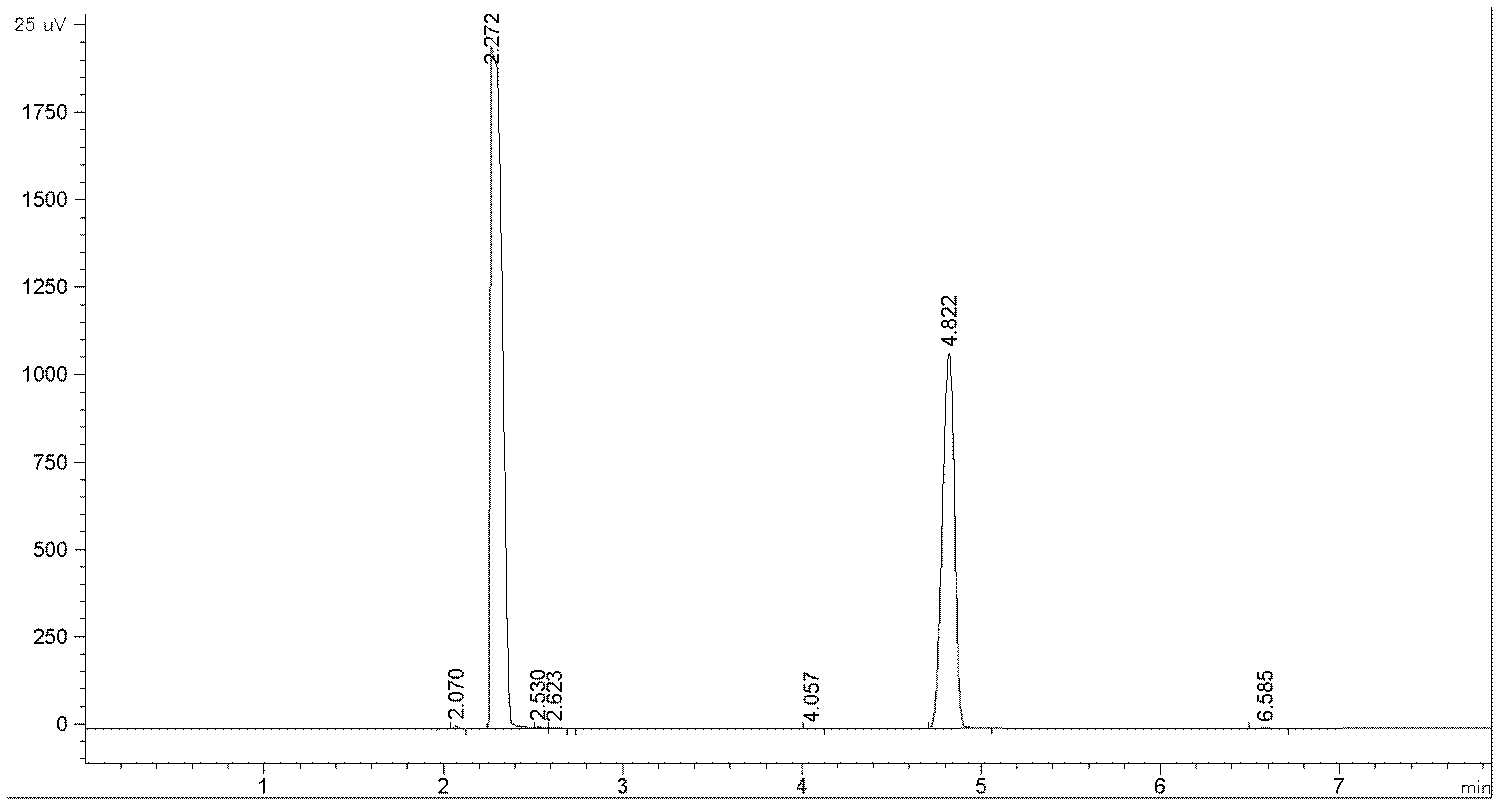

[0026] Chromatograms such as figure 1 As shown, the results are shown in Table 1, and each component and retention time are shown in Table 1.

[0027] Table 1

[0028]

Embodiment 2

[0030] Utilize the content of impurity in the rapid determination of methylhydrazine by gas chromatography, comprising the following steps:

[0031] ① Instrument: The gas chromatograph is equipped with a thermal conductivity detector; the inlet is a split / splitless inlet; the capillary column is 60 m long, with an inner diameter of 0.32 mm and a film thickness of 5 μm.

[0032] ②Test conditions: manual injection; injection volume 1 μL; column oven temperature 70°C, rear inlet temperature 250°C, rear detector temperature 270°C; split ratio 25:1; column temperature 70°C for 9 Minutes, the temperature was programmed to rise to 150°C at 20°C / min, and the temperature was kept constant for 2 minutes; the flow rate of the chromatographic column was 3ml / min; the carrier gas was high-purity helium.

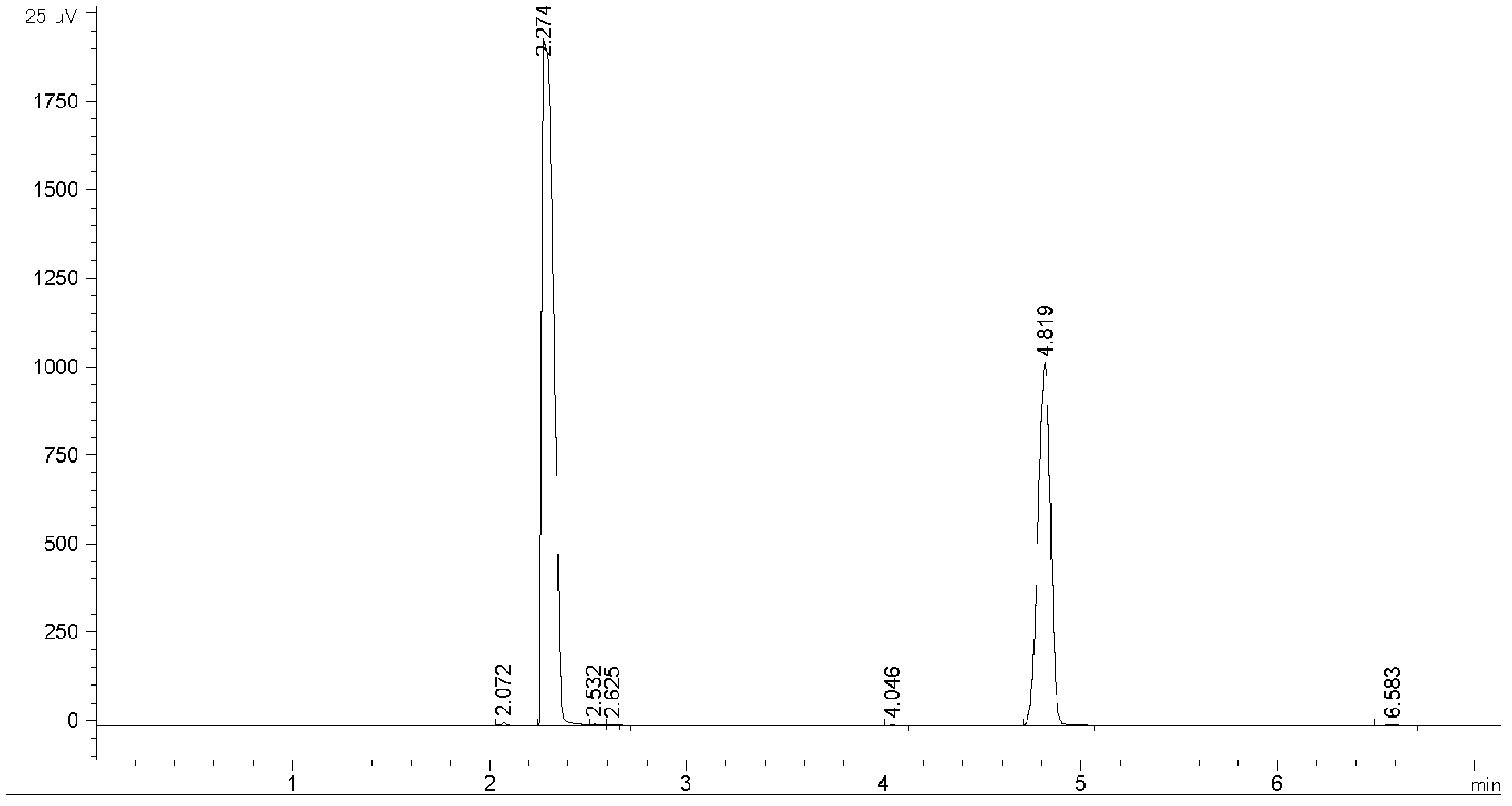

[0033] ③Using the area percentage method to quantitatively analyze the impurities therein.

[0034] The chromatogram of the methylhydrazine sample separated by the chromatographic column ...

Embodiment 3

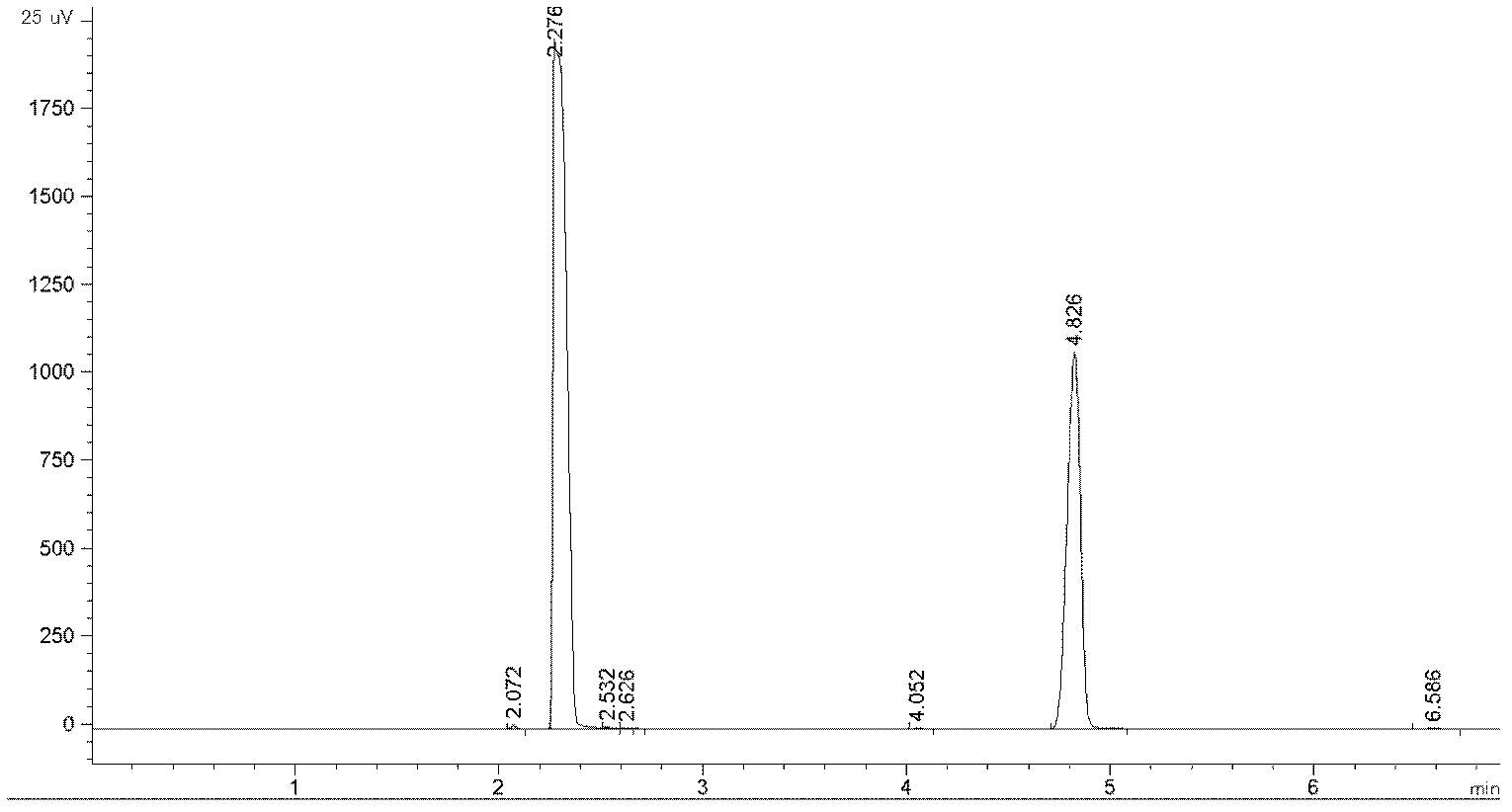

[0038] ① Instrument: The gas chromatograph is equipped with a thermal conductivity detector, a split / splitless inlet, and a capillary column of 60m×0.32mm×5μm.

[0039] ②Test conditions: manual injection; injection volume 1 μL; column oven temperature 80°C, rear inlet temperature 250°C, rear detector temperature 300°C; split ratio 25:1; column temperature 80°C for 9 Minutes, the temperature was programmed to rise to 160°C at 20°C / min, and the temperature was kept constant for 2 minutes; the flow rate of the chromatographic column was 5ml / min; the carrier gas was high-purity helium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com