Shielded metal arc welding method used for phase welding of X7Ni9 steel and S30408 steel

An electrode arc welding and electrode technology, which is applied in arc welding equipment, welding/welding/cutting items, welding medium, etc., can solve the problems of complex joint structure and difficulty, achieve high strength, good low temperature toughness, and avoid excessive internal stress. concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a kind of electrode arc welding method that is used for X7Ni9 steel and S30408 steel phase welding, and this method comprises the following steps:

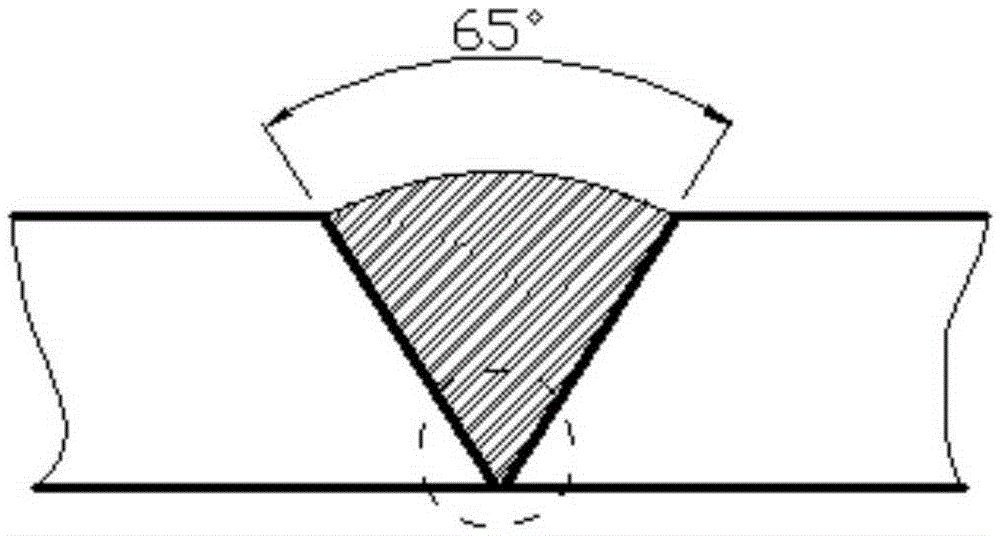

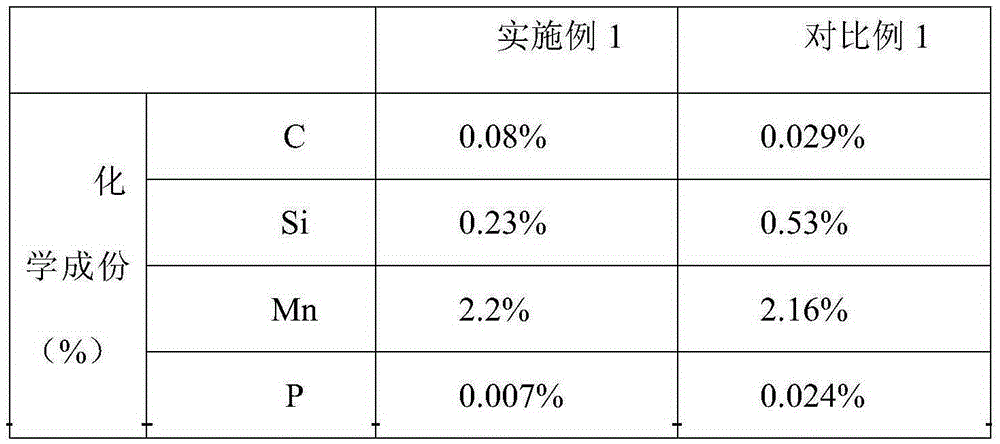

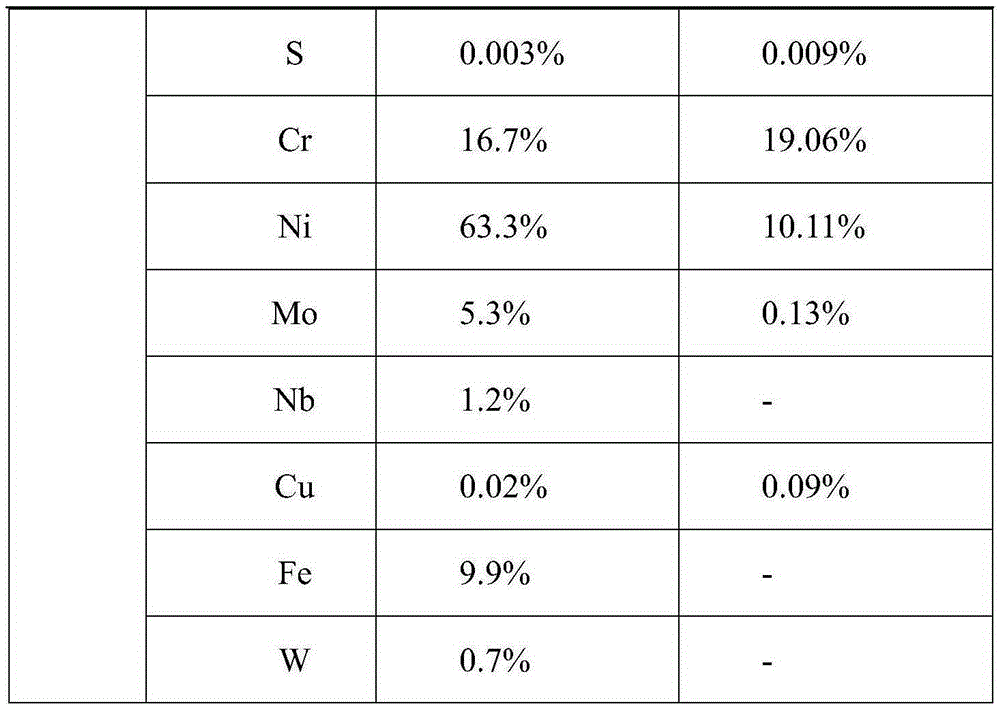

[0030] 1) The electrode arc welding groove adopts a unilateral V-shaped groove, the front groove angle is 65°, and the groove gap is 1mm; the electrode type used is ENiCrFe-9, and its composition is as follows: C: 0.08%, Si: 0.23%, Mn: 2.2%, P: 0.007%, S: 0.003%, Cr: 16.7%, Ni: 63.3%, Mo: 5.3%, Nb: 1.2%, Cu: 0.02%, Fe: 9.9%, W: 0.7%.

[0031] 2) Dry the moisture on the surface of the X7Ni9 and S30408 steel plates with a flame, and the temperature of the steel plates before welding is 28°C;

[0032] 3) Welding process parameters: the first backing welding current is 90A, the arc voltage is 20V, the welding heat input of the backing welding is 6KJ / cm; the subsequent filling welding welding current is 135A, the arc voltage is 25, the welding speed is 8cm / min, and 25.3KJ / cm, the electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com