Patents

Literature

34results about How to "Thick structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

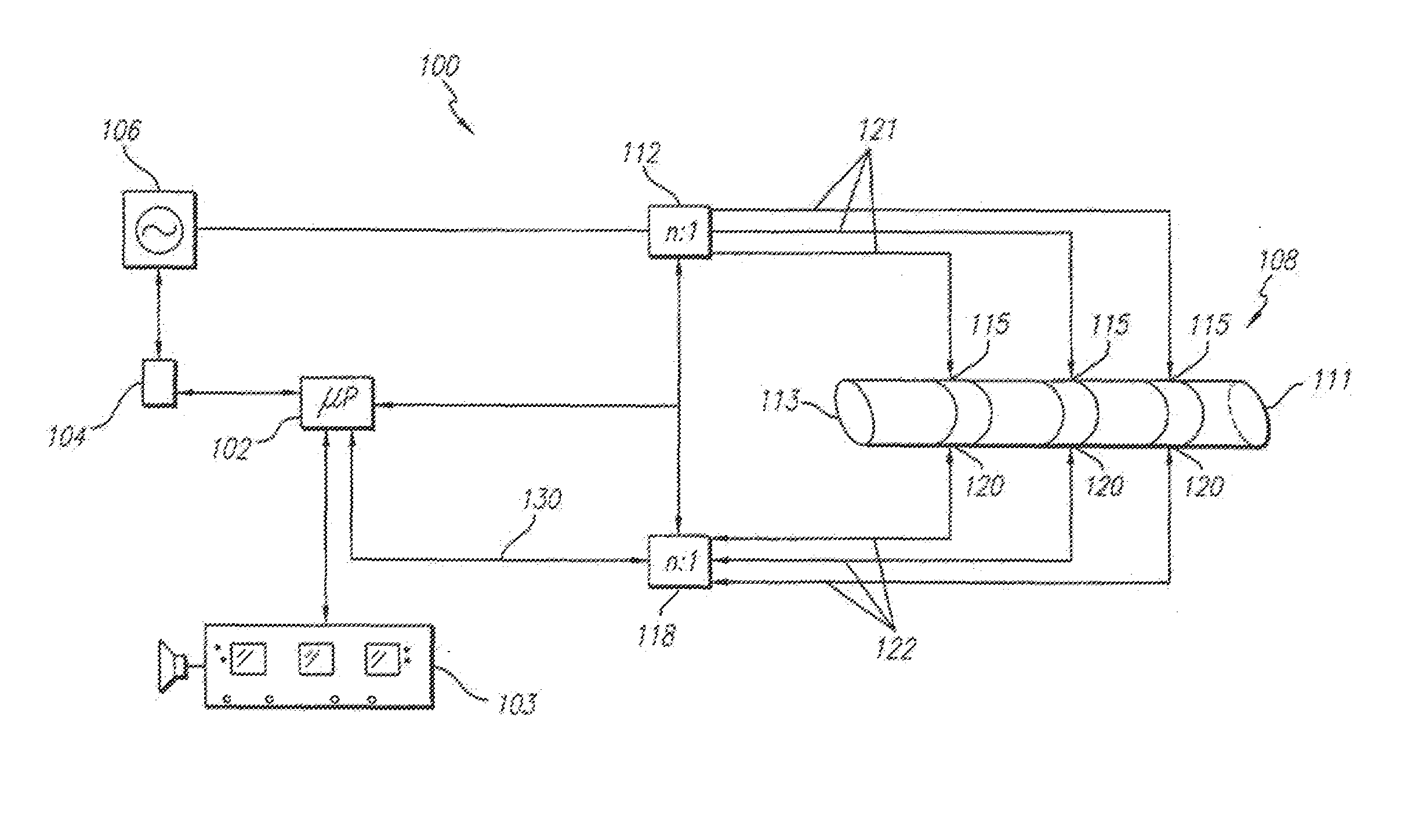

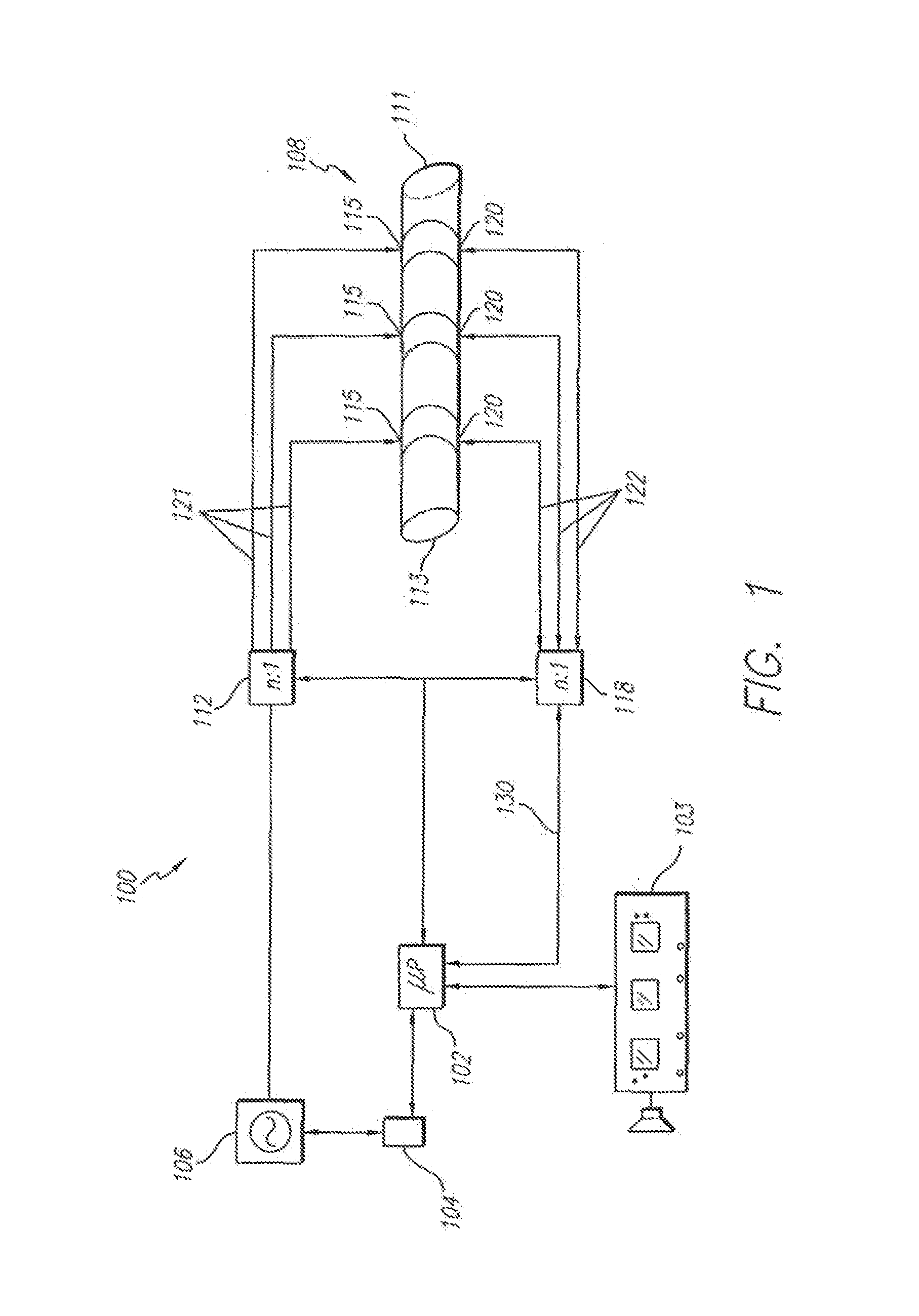

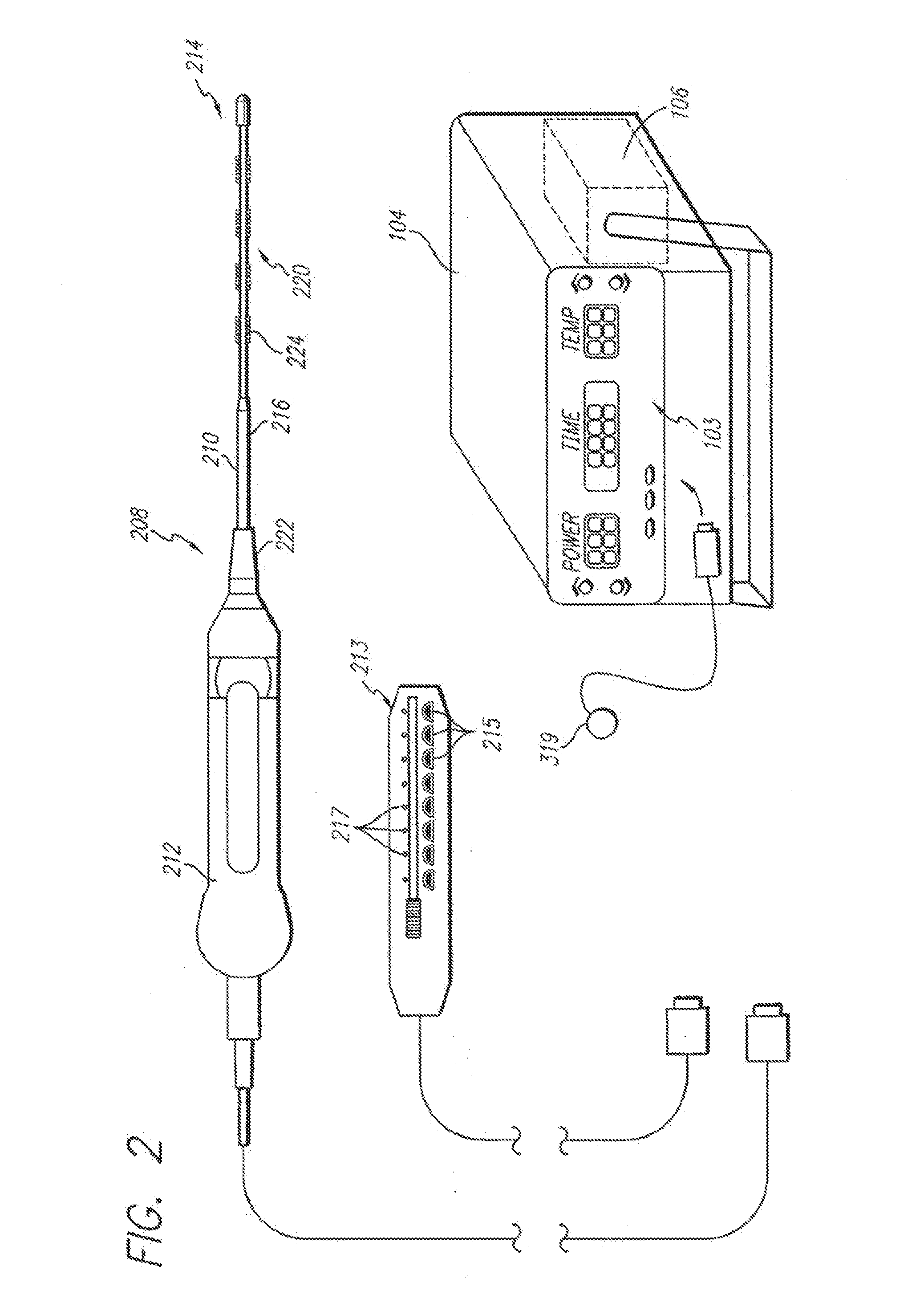

Systems and methods for controlling power in an electrosurgical probe

InactiveUS7582084B2Avoid problemsAccelerated programControlling energy of instrumentSurgical instruments for heatingControl powerCharring

Systems and methods for controlling the power supplied to an electrosurgical probe. The systems and methods may be used to monitor electrode-tissue contact, adjust power in response to a loss of contact, and apply power in such a manner that charring, coagulum formation and tissue popping are less likely to occur.

Owner:BOSTON SCI SCIMED INC

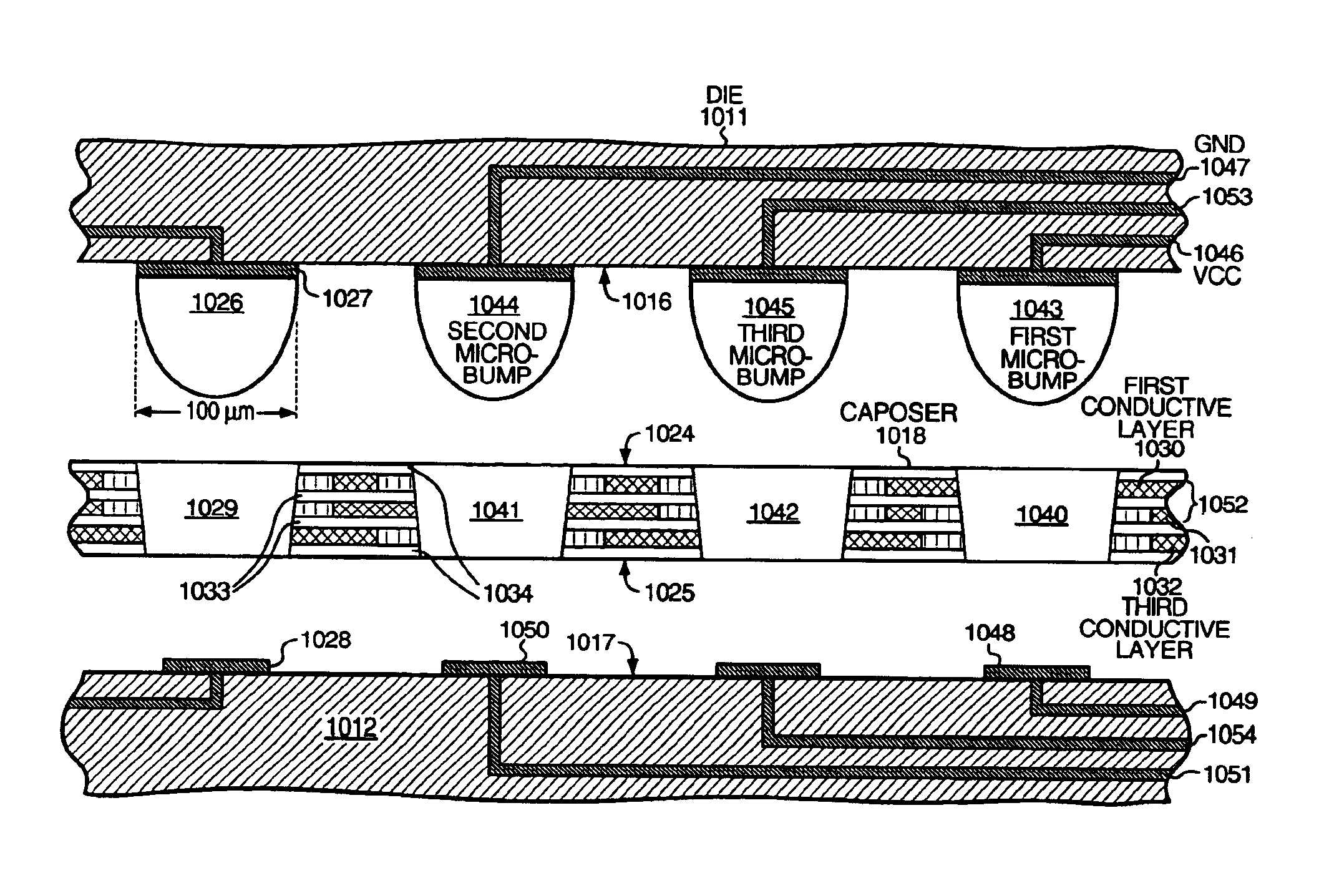

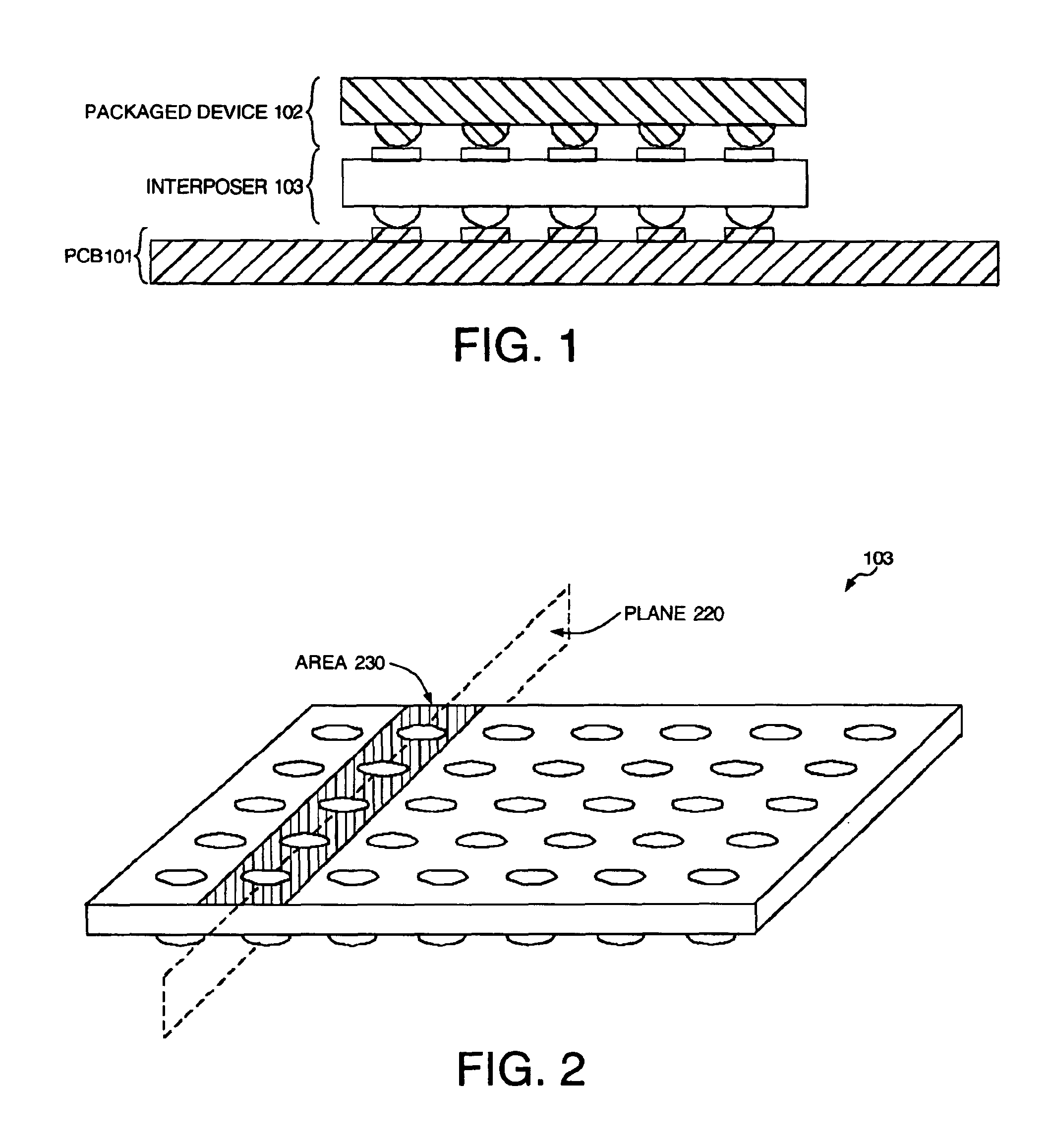

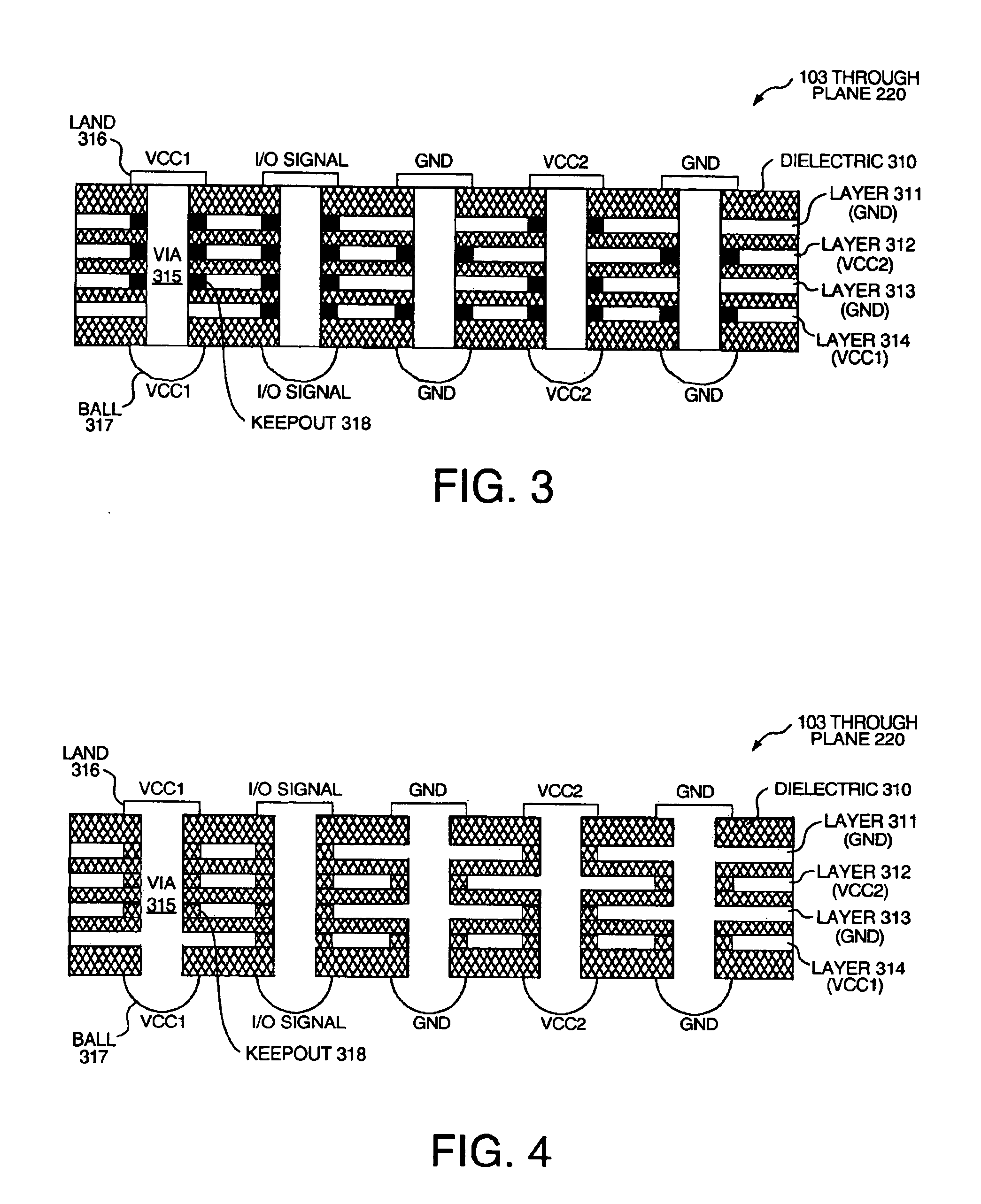

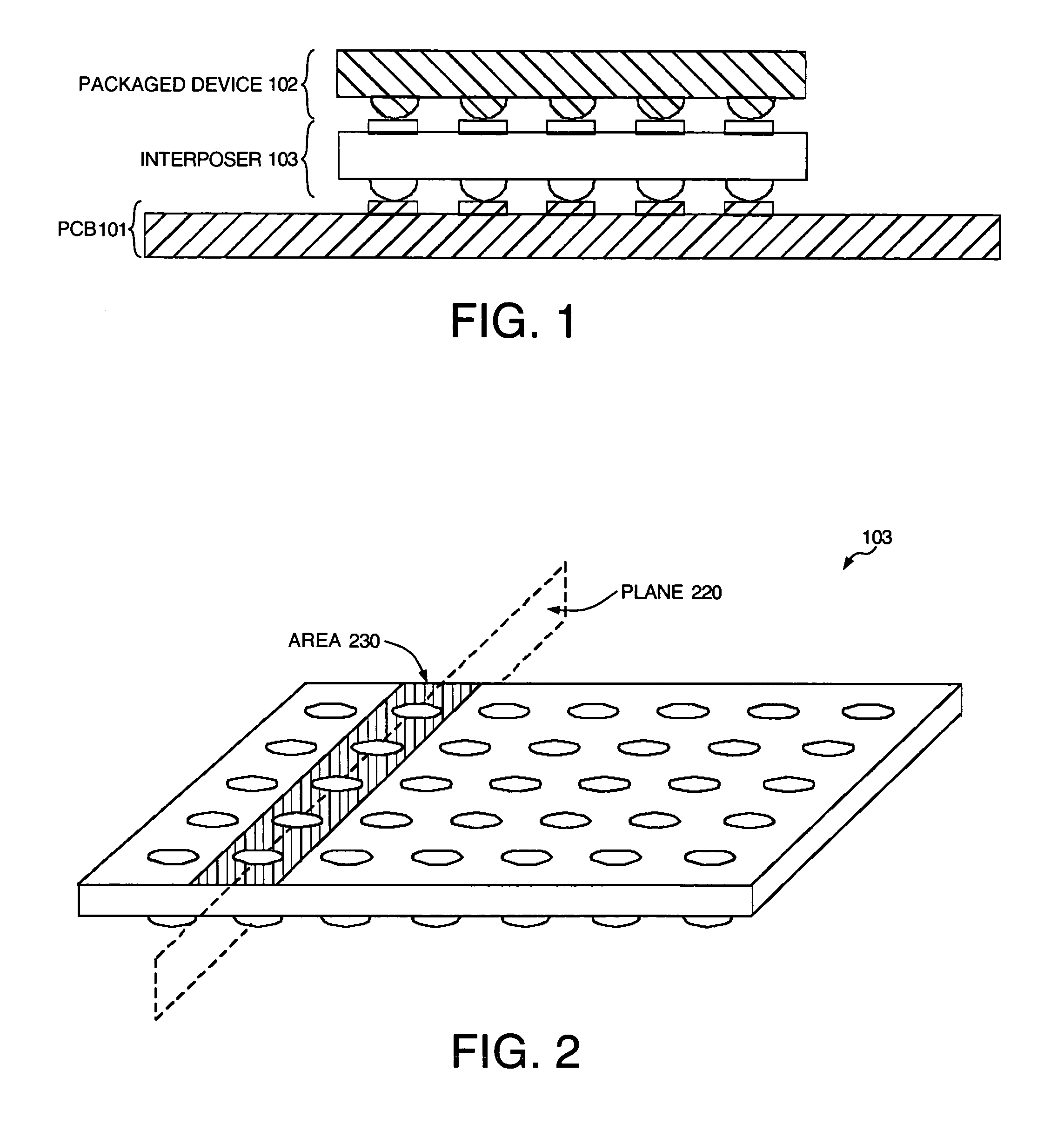

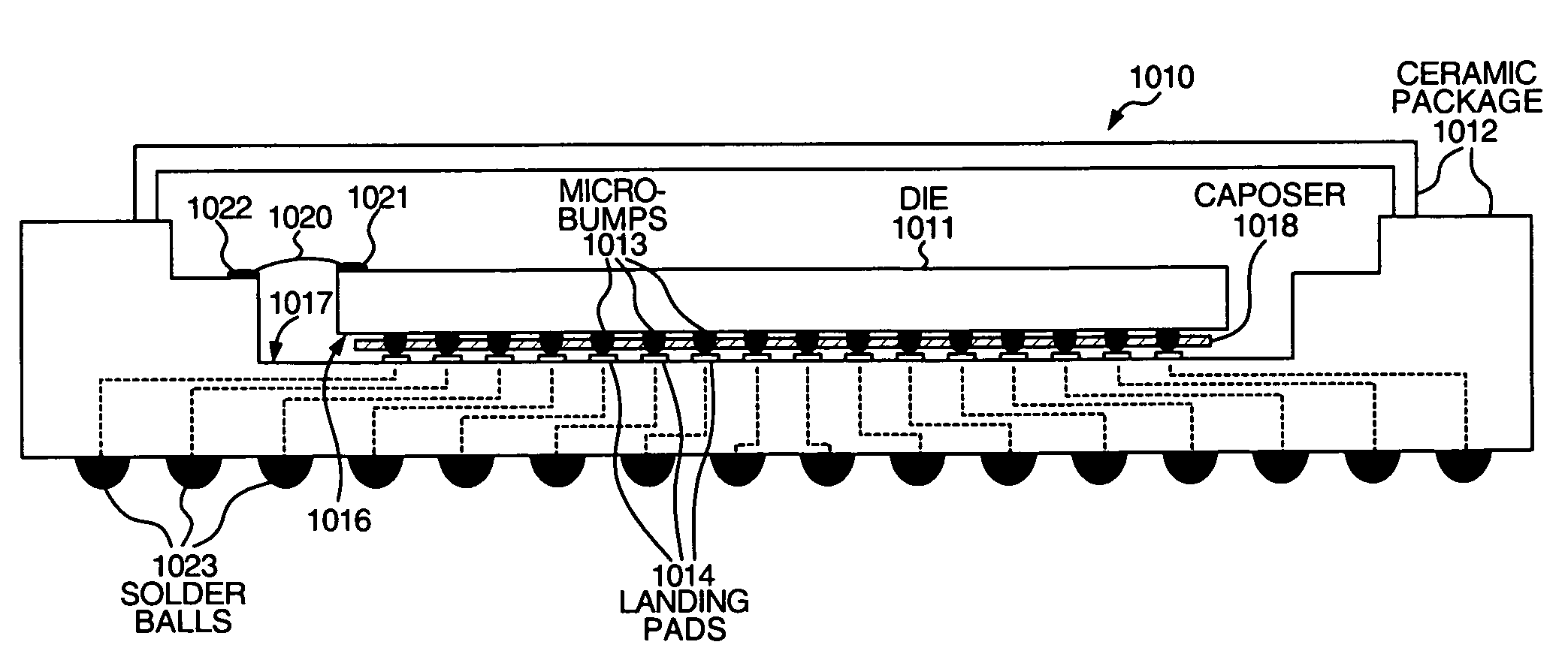

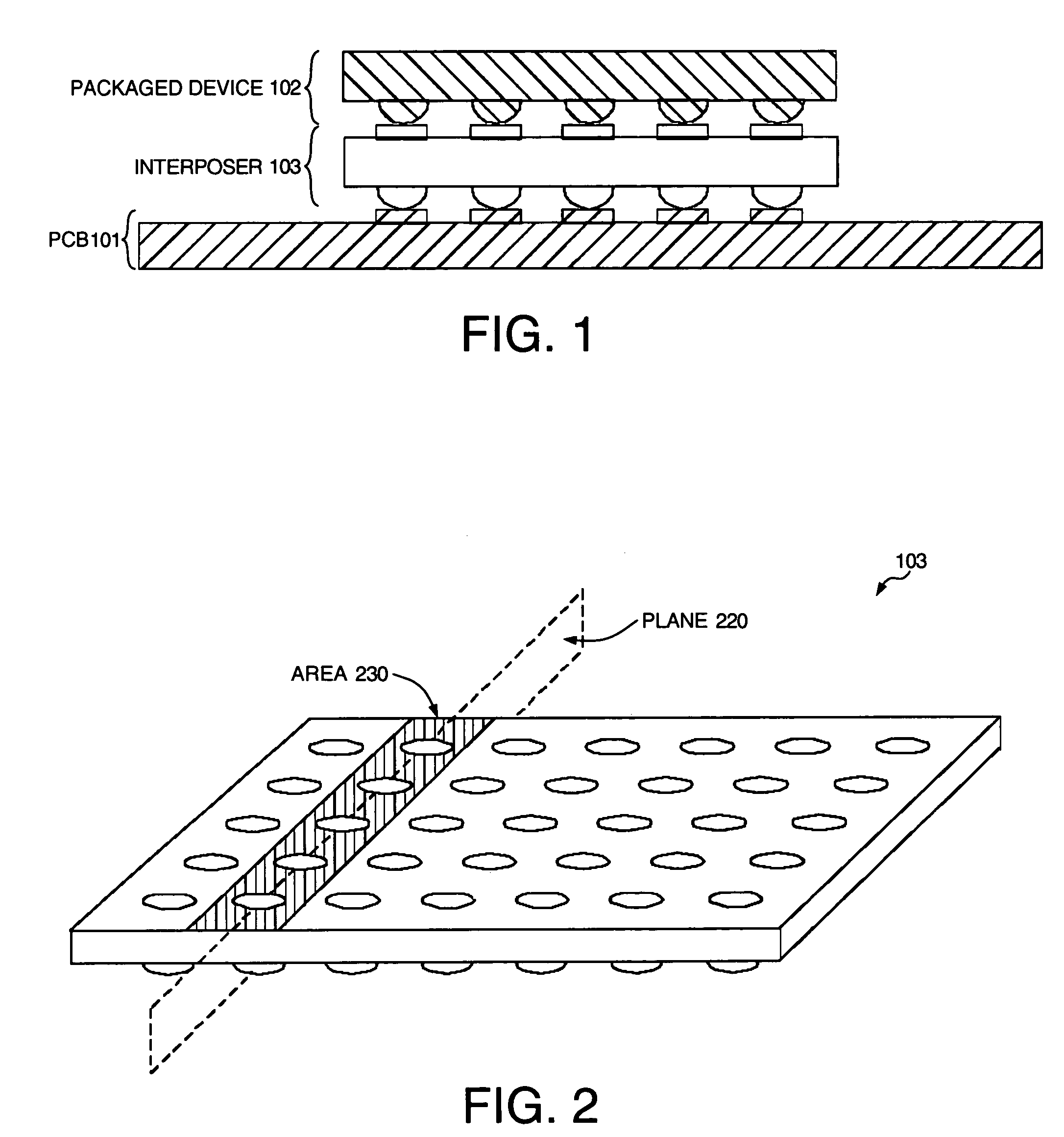

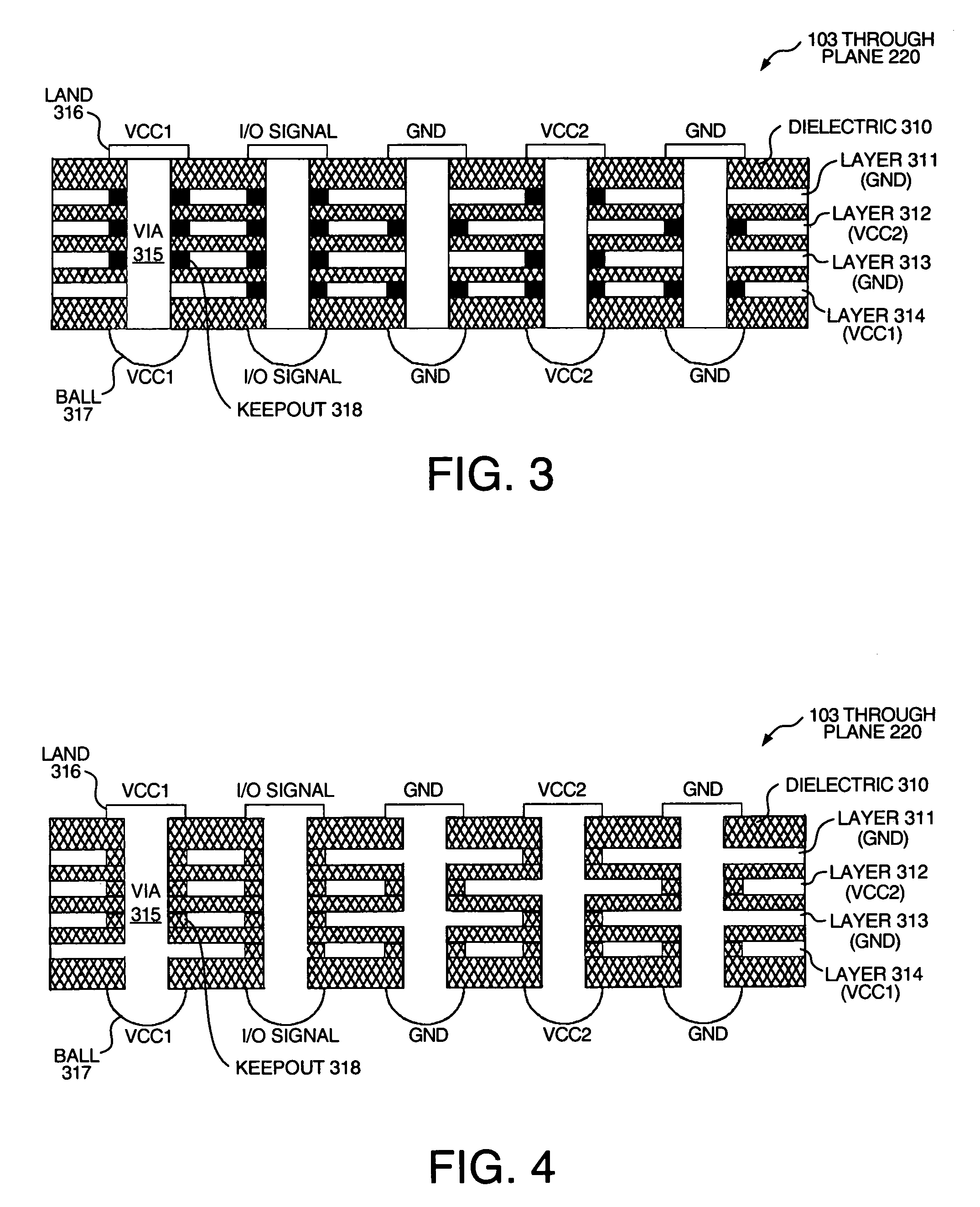

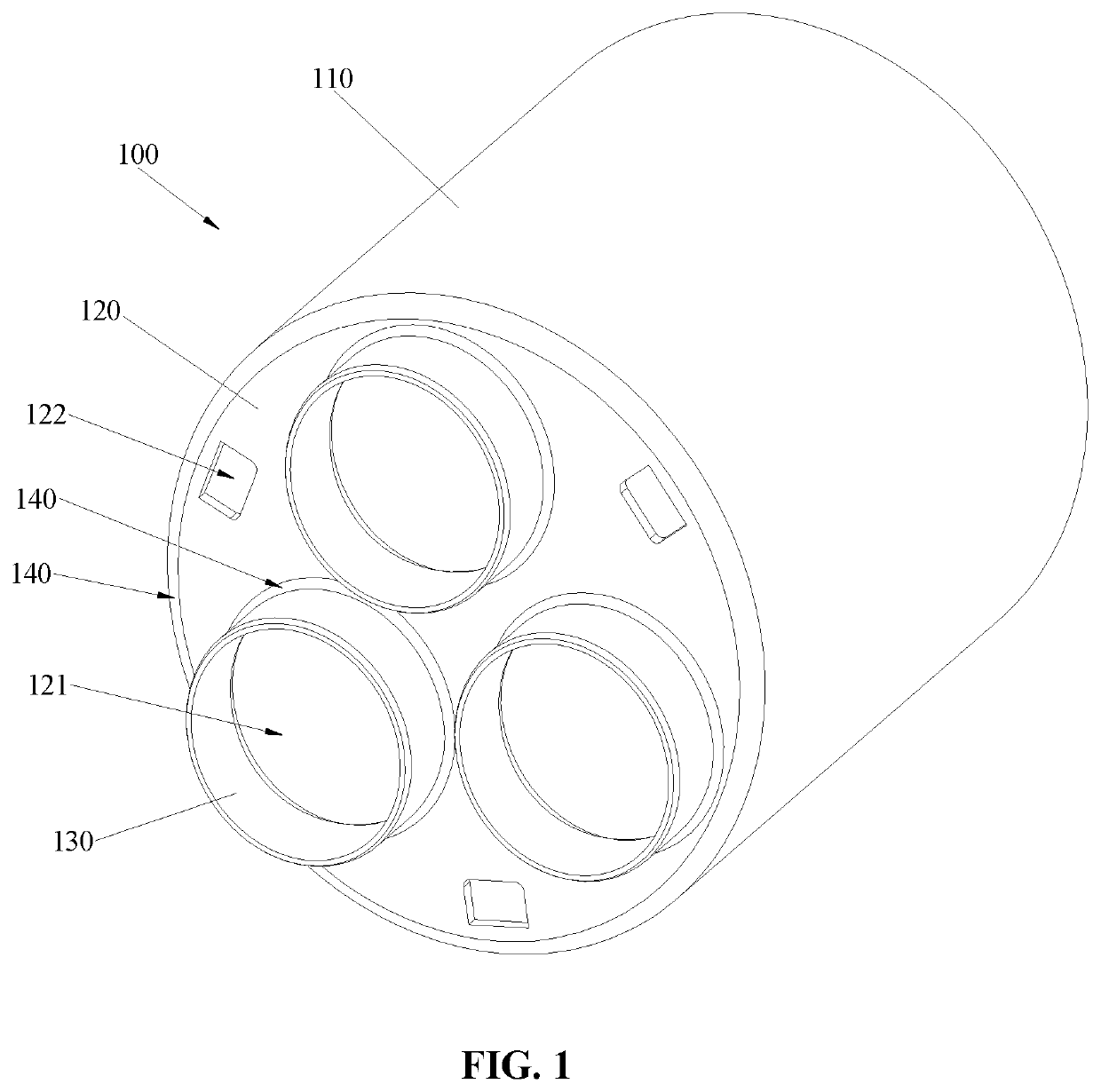

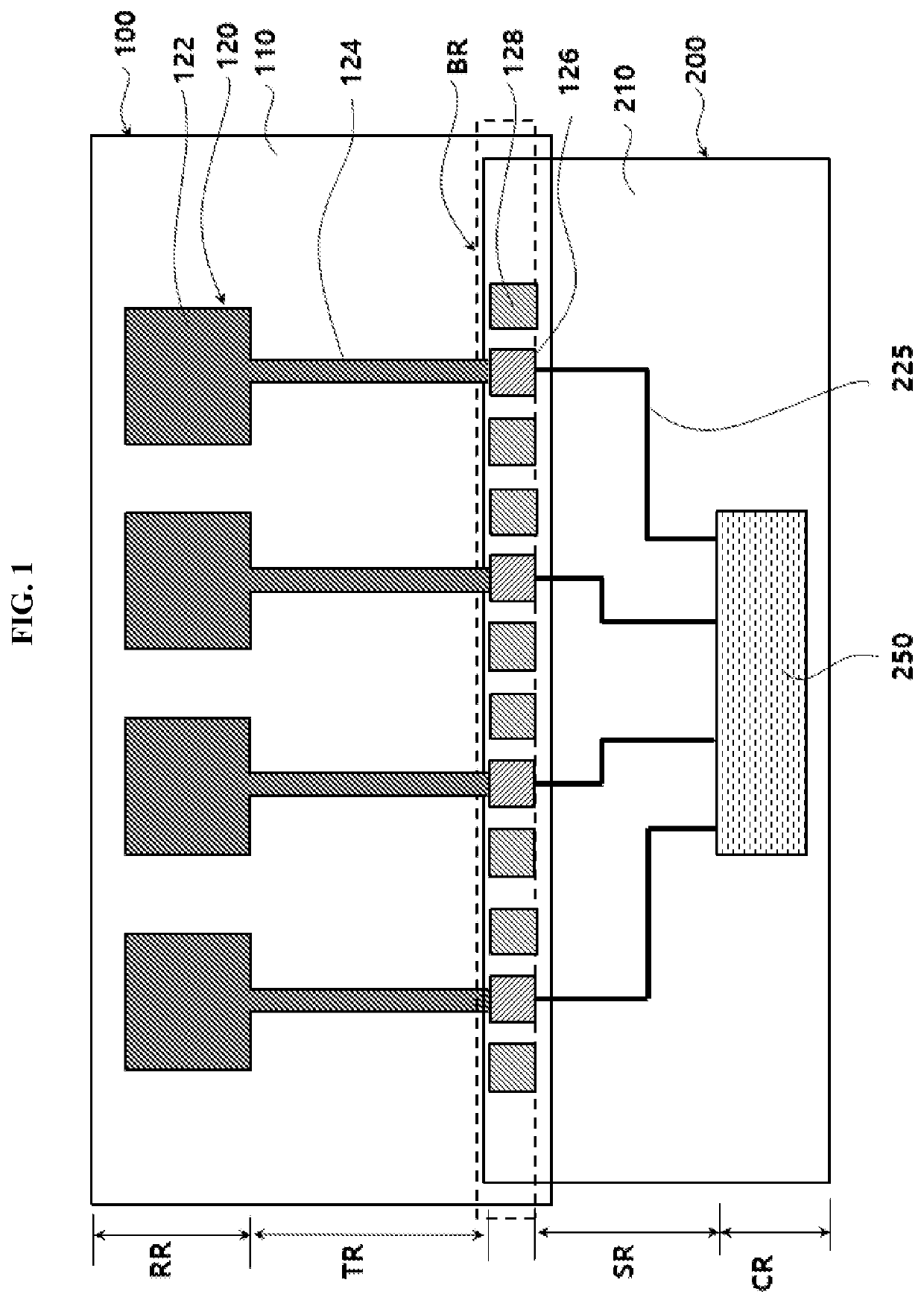

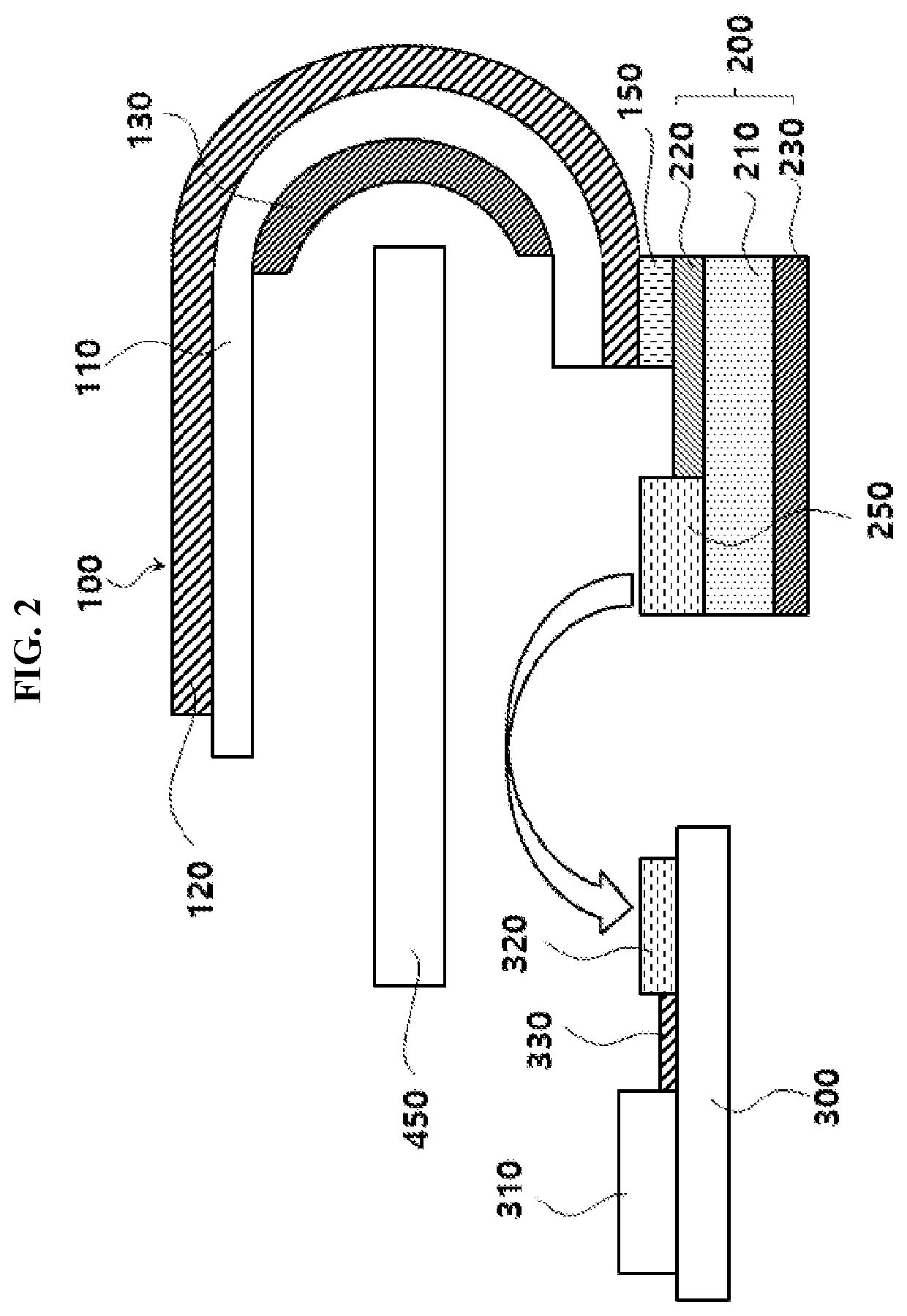

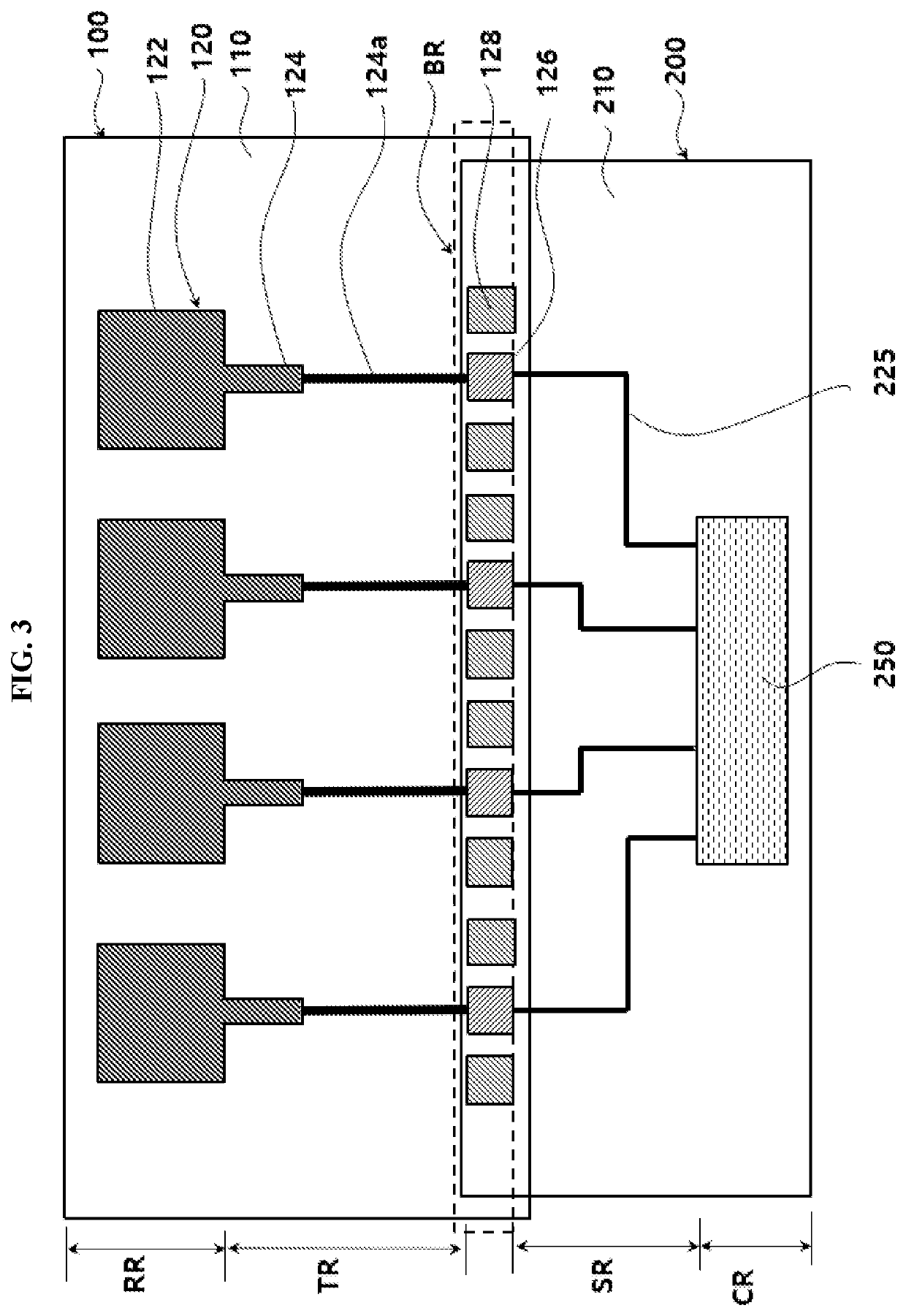

Capacitive interposer

ActiveUS6875921B1Thick structureReduce Impedance DiscontinuitiesSemiconductor/solid-state device detailsCross-talk/noise/interference reductionCapacitanceInterposer

A capacitive interposer (caposer) is disposed inside an integrated circuit package between a die and an inside surface of the package. Conductive layers within the caposer constitute a bypass capacitor. In a through-hole caposer, micro-bumps on the die pass through through-holes in the caposer and contact corresponding landing pads on the package. As they pass through the caposer, power and ground micro-bumps make contact with the plates of the bypass capacitor. In a via caposer, power and ground micro-bumps on the die are coupled to power and ground landing pads on the package as well as to the plates of the bypass capacitor by power and ground vias that extend through the caposer.

Owner:XILINX INC

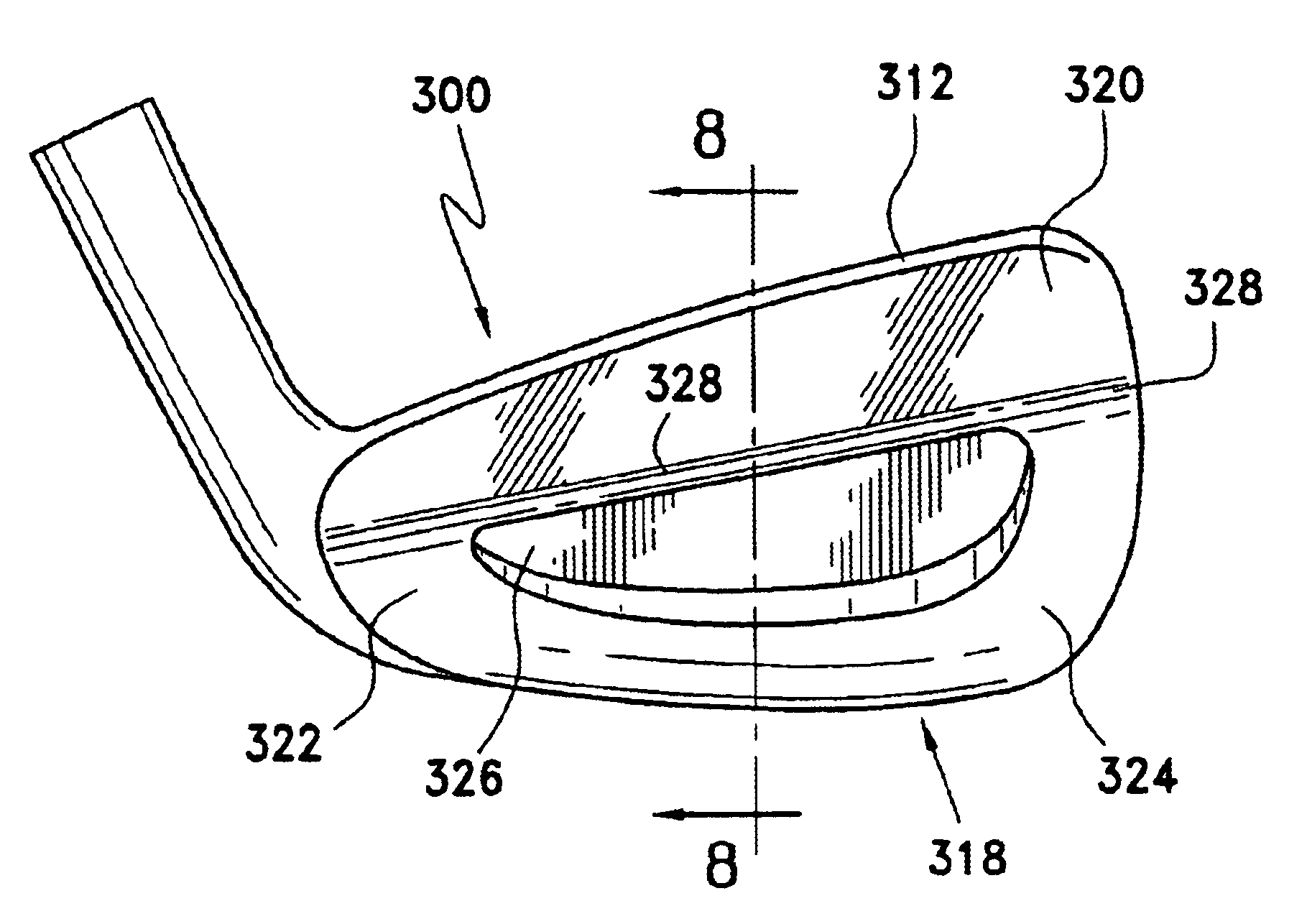

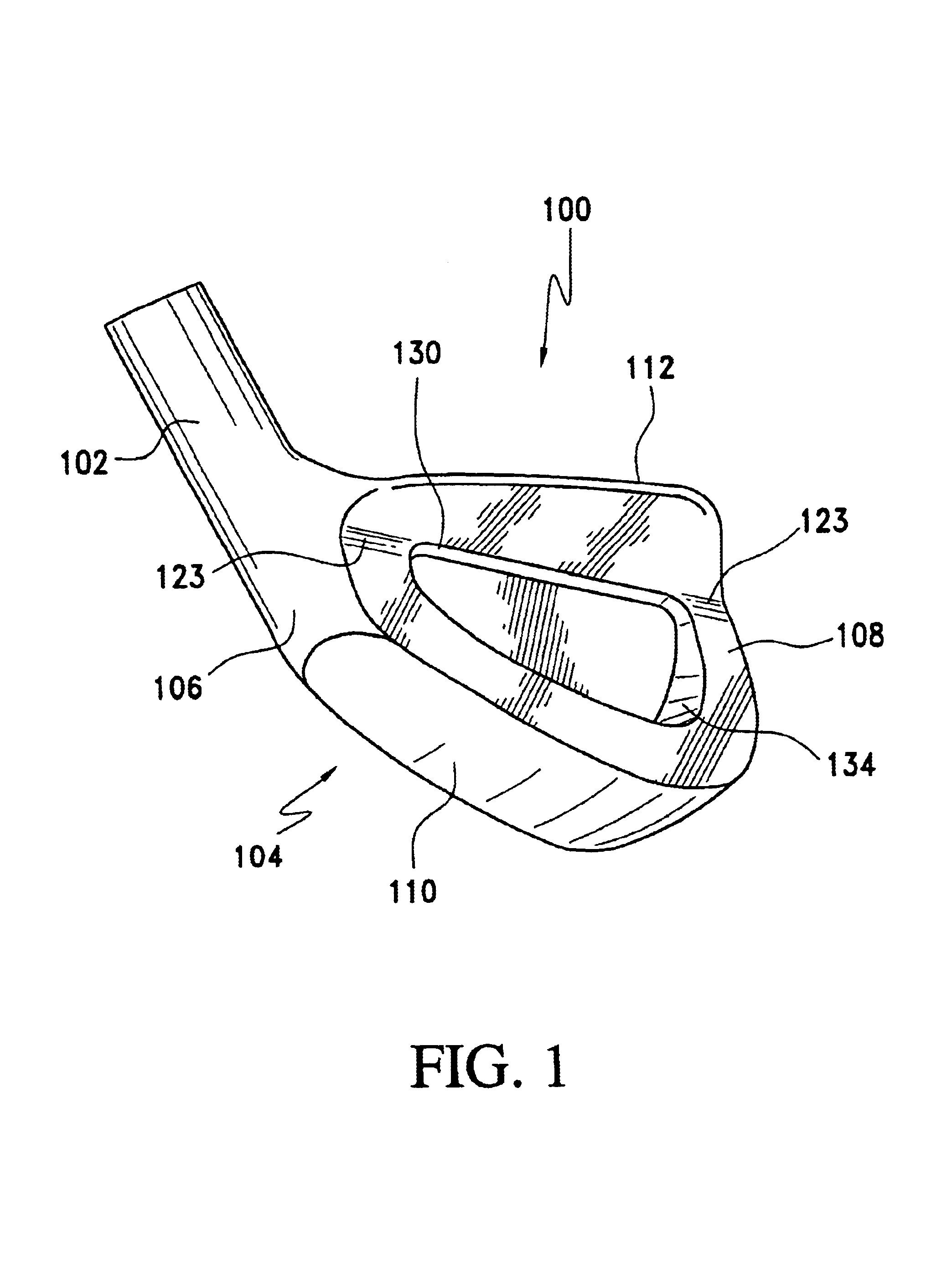

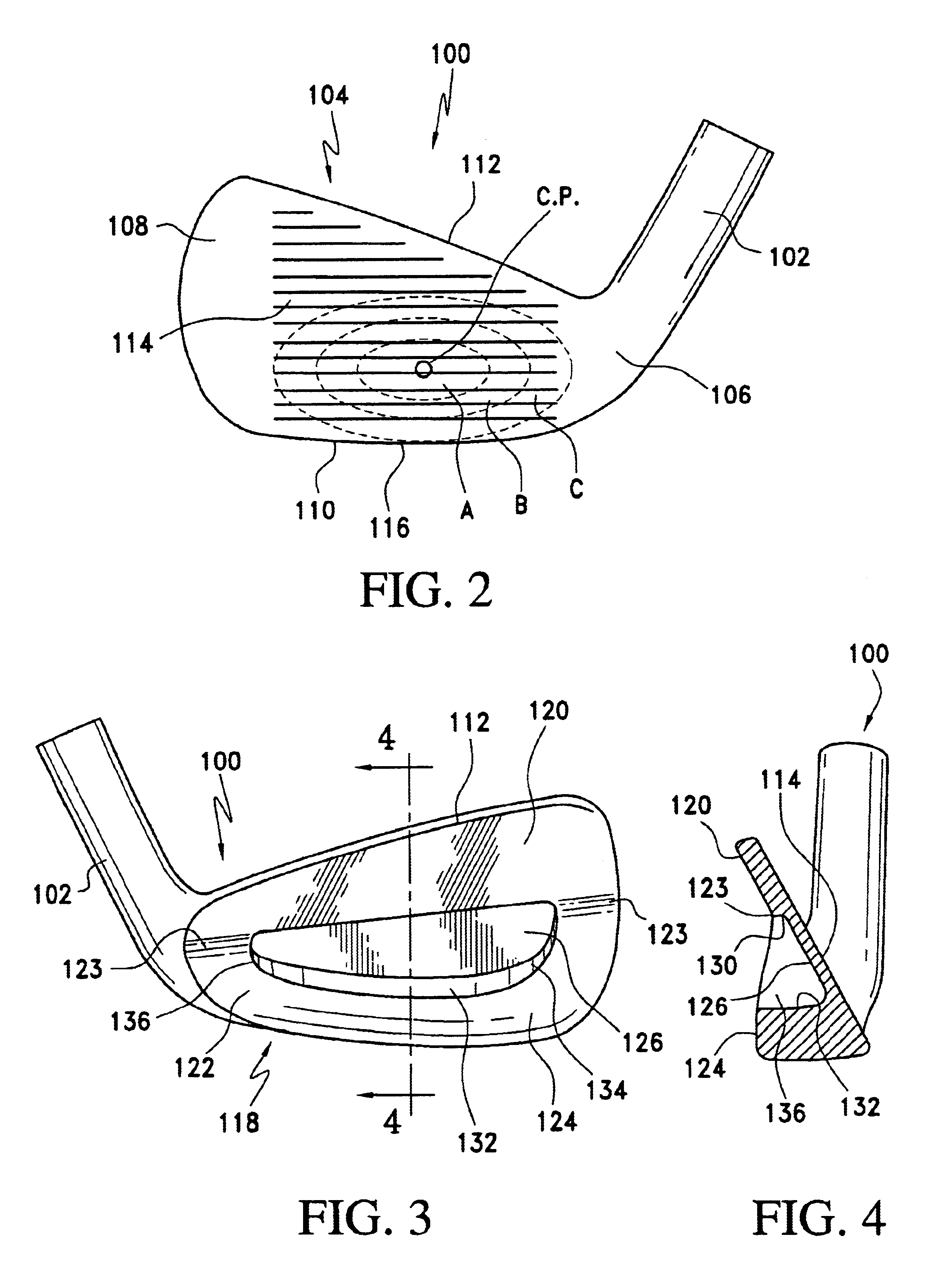

Iron type golf club

InactiveUS6849005B2Improved weight distributionImprove shot making characteristicGolf clubsRacket sportsEngineeringGolf Ball

An iron type golf club head having a rear surface having upper and lower portions; the upper portion being defined by a blade type iron structure between a top ridge surface and the lower portion; and a lower peripheral weight on the lower portion of the rear surface forming a rear cavity between the bottom sole surface the said upper portion.

Owner:RIFE GUERIN DUBOSE

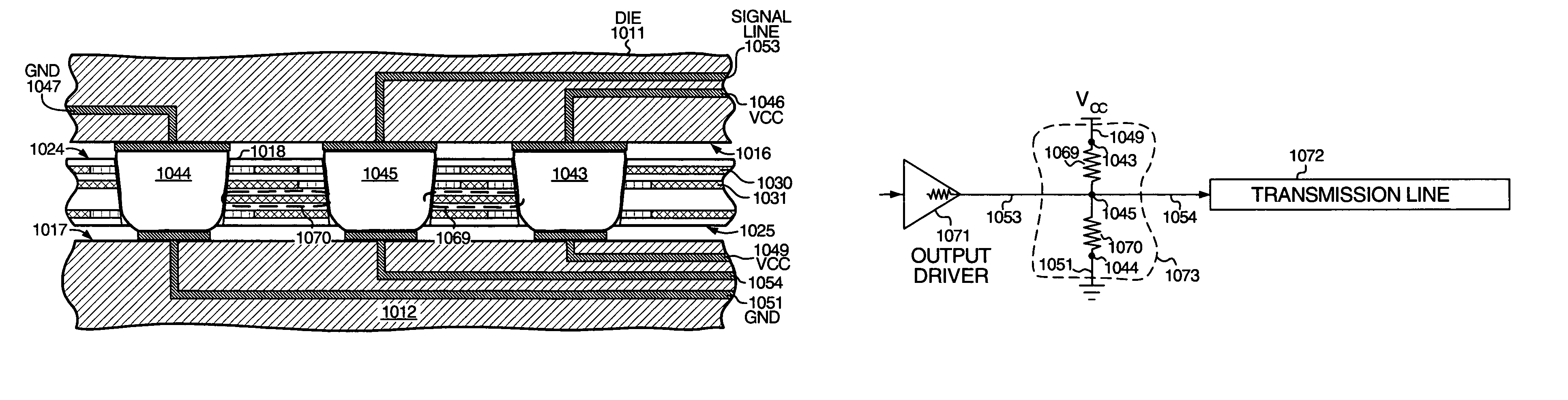

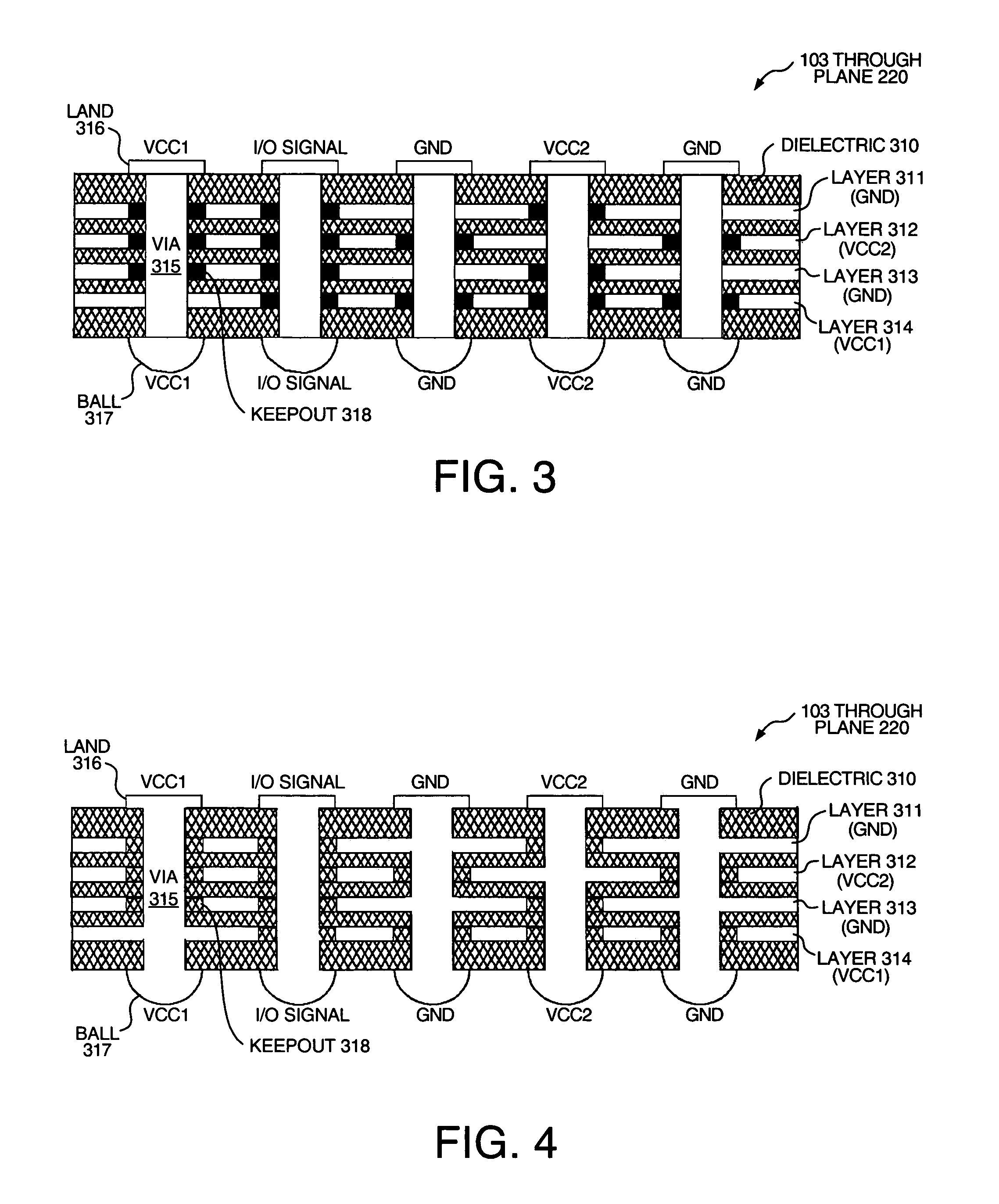

Interposer for impedance matching

ActiveUS7233061B1Thick structureReduce Impedance DiscontinuitiesSemiconductor/solid-state device detailsCross-talk/noise/interference reductionCapacitancePrinted circuit board

A capacitive interposer (caposer) is disposed inside an integrated circuit package between a die and an inside surface of the package. Conductive layers within the caposer constitute a bypass capacitor. In a through-hole caposer, micro-bumps on the die pass through through-holes in the caposer and contact corresponding landing pads on the package. As they pass through the caposer, power and ground micro-bumps make contact with the plates of the bypass capacitor. In a via caposer, power and ground micro-bumps on the die are coupled to power and ground landing pads on the package as well as to the plates of the bypass capacitor by power and ground vias that extend through the caposer. In signal redistribution caposer, conductors within the caposer redistribute signals between die micro-bumps and package landing pads. In an impedance matching caposer, termination structures within the caposer provide impedance matching to a printed circuit board trace.

Owner:XILINX INC

Interposing structure

InactiveUS7566960B1Thick structureReduce Impedance DiscontinuitiesSemiconductor/solid-state device detailsSolid-state devicesCapacitanceElectrical conductor

A capacitive interposer (caposer) is disposed inside an integrated circuit package between a die and an inside surface of the package. Conductive layers within the caposer constitute a bypass capacitor. In a through-hole caposer, micro-bumps on the die pass through through-holes in the caposer and contact corresponding landing pads on the package. As they pass through the caposer, power and ground micro-bumps make contact with the plates of the bypass capacitor. In a via caposer, power and ground micro-bumps on the die are coupled to power and ground landing pads on the package as well as to the plates of the bypass capacitor by power and ground vias that extend through the caposer. In signal redistribution caposer, conductors within the caposer redistribute signals between die micro-bumps and package landing pads. In an impedance matching caposer, termination structures within the caposer provide impedance matching to a printed circuit board trace.

Owner:XILINX INC

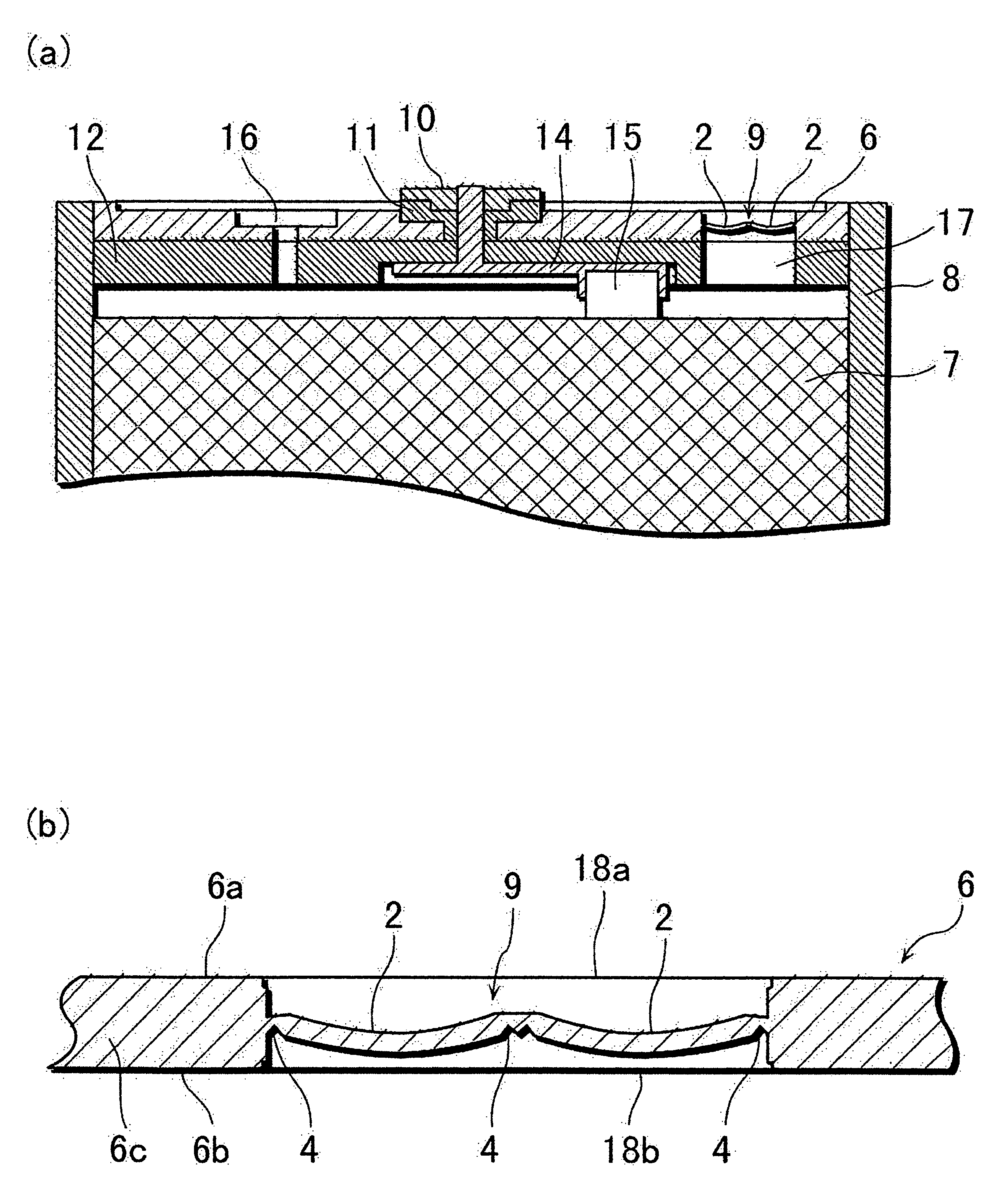

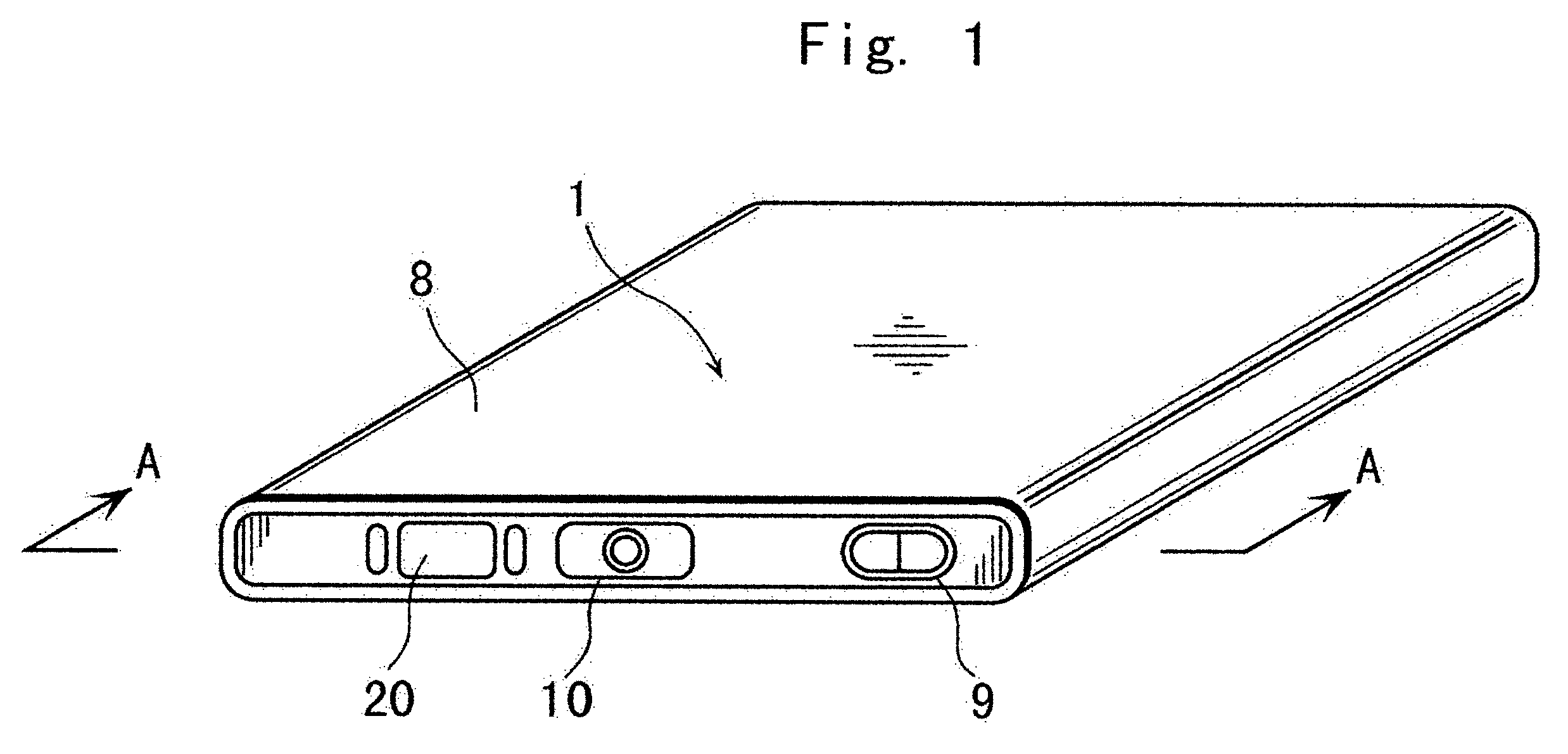

Sealed cell having non-resealable safety valve

ActiveUS20050112455A1Thicker valve structureReduce decreaseNon-aqueous electrolyte accumulatorsNon-aqueous electrolyte cellsInternal pressureEngineering

A sealed cell having a safety mechanism is provided. The safety mechanism has a non-resealable valve structure formed in a sealing plate that seals the cell. The valve structure is broken as soon as the internal pressure reaches or exceeds a predetermined value so as to permit the internal gas to be released outside. The valve structure has at least one dome protruding toward the interior of the cell, which in turn has at the periphery thereof a break groove for facilitating the breakage of the valve structure. This makes the valve structure highly responsive to the internal pressure and causes to form a break-opened orifice of a sufficient area at the time of operation in response to the increased internal pressure. The valve structure is not unnecessarily broken by the impacts of, for example, dropping. As a result, the safety of the sealed cell is significantly improved.

Owner:SANYO ELECTRIC CO LTD

Novel manufacturing method of planar spiral inductor

ActiveCN106129047AReduce lossImprove insulation performanceDecorative surface effectsSemiconductor/solid-state device detailsPlanar spiral inductorsQuartz substrate

The invention relates to a novel manufacturing method of a planar spiral inductor. Manufacturing of the planar spiral inductor is carried out through a glass or quartz substrate; manufacturing of the planar spiral inductor is achieved by an MEMS technology which comprises a metal thin film deposition process, a dielectric layer thin film deposition technology, a thick metal layer plating process, a thick resist lithography process, an etching process and the like; the planar spiral inductor and the substrate do not need to be isolated by a thick insulating layer; and the plane shape of the planar spiral inductor and the thickness of a coil are not limited. Manufacturing of the planar spiral inductor is achieved by the MEMS technology on the glass or quartz substrate; the coupling effect and the skin effect between the coil and the substrate at a high frequency are avoided; a high Q-value inductor can be achieved; meanwhile, the thickness of a metal layer of an inductance coil is not limited; and the loss of the coil is low. The technology is simple; the requirements of multiple fields of a signal isolator, a planar antenna, a microwave baseband line, a planar spiral inductor resonator and the like can be met; and the process difficulty is reduced.

Owner:BEIJING MXTRONICS CORP +1

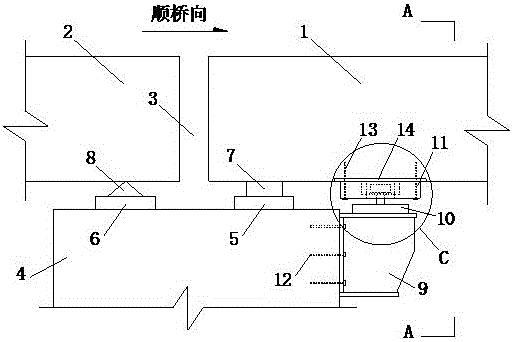

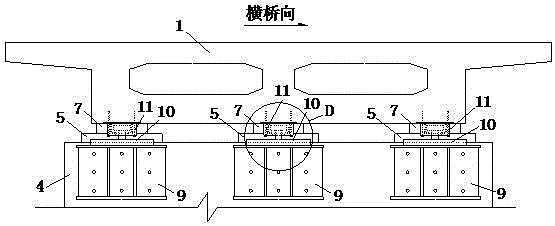

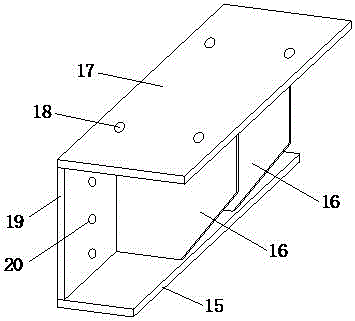

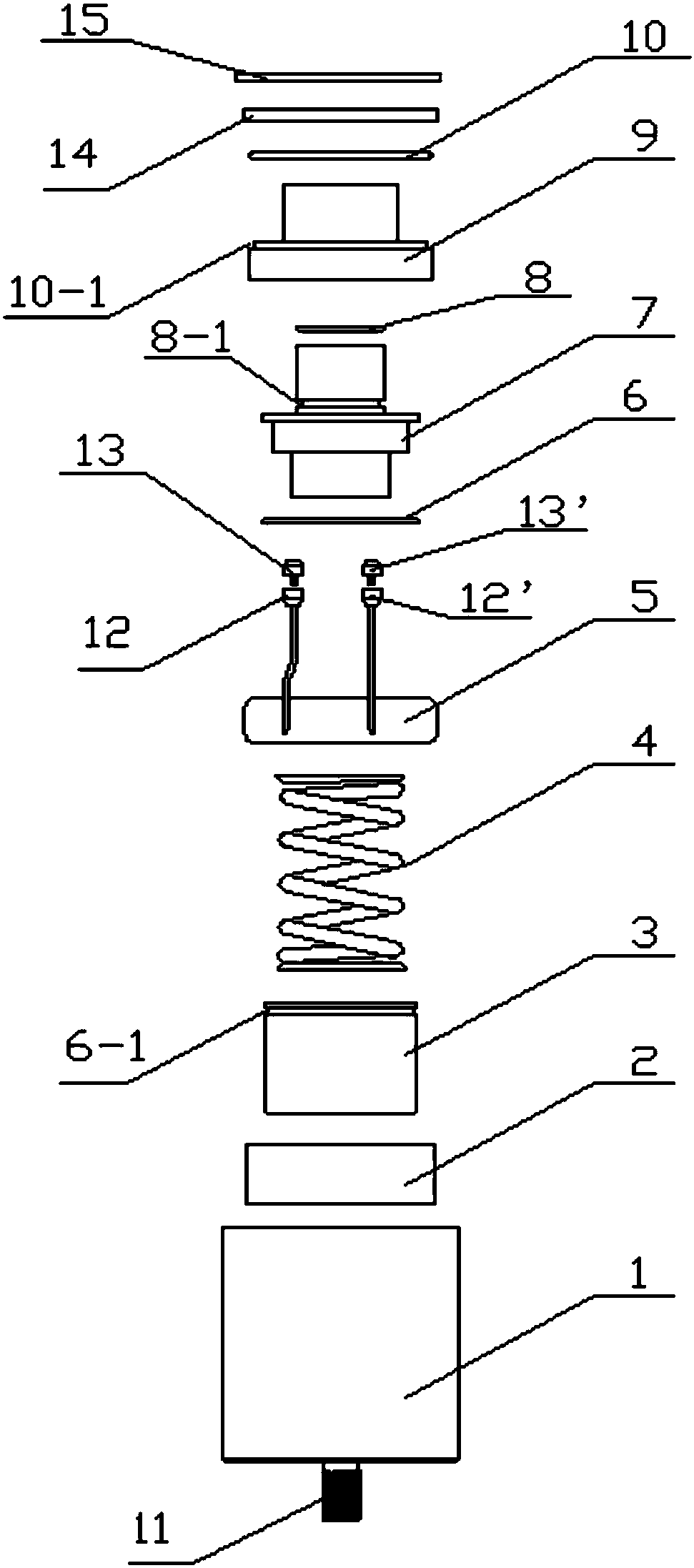

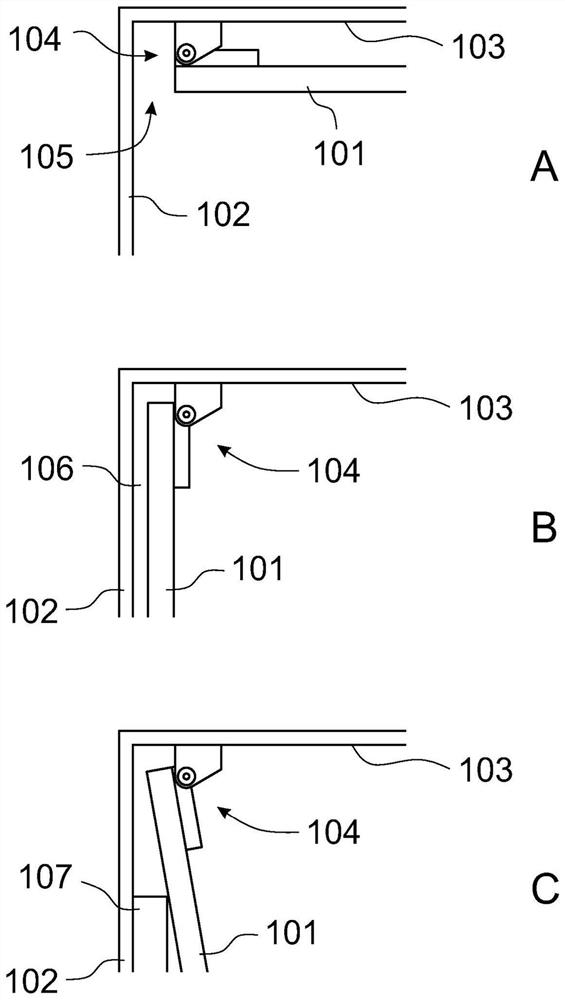

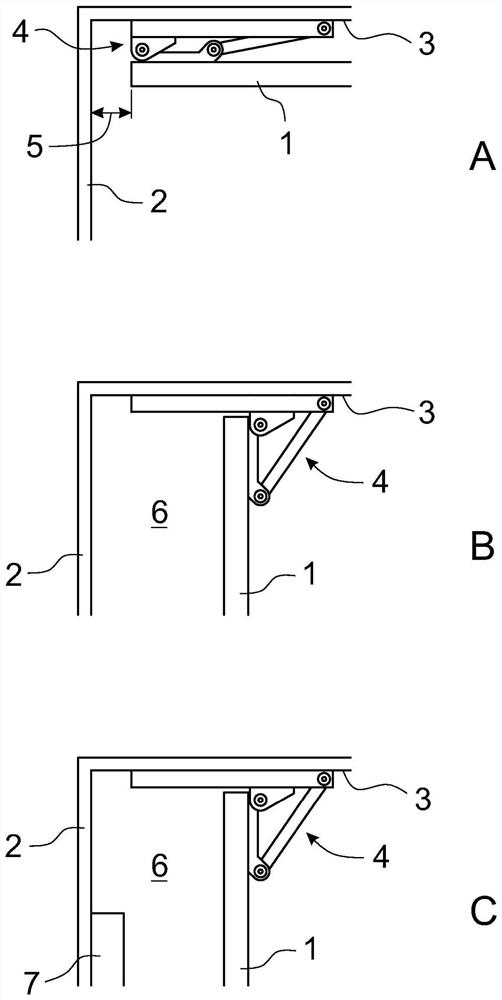

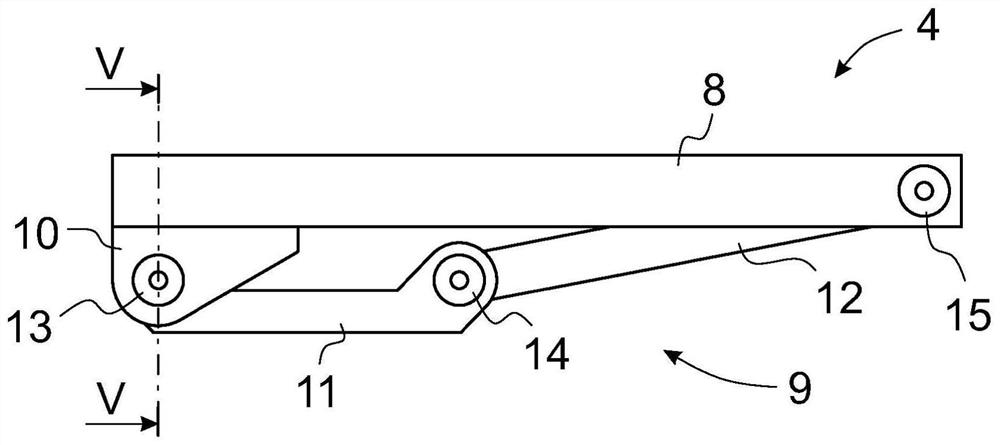

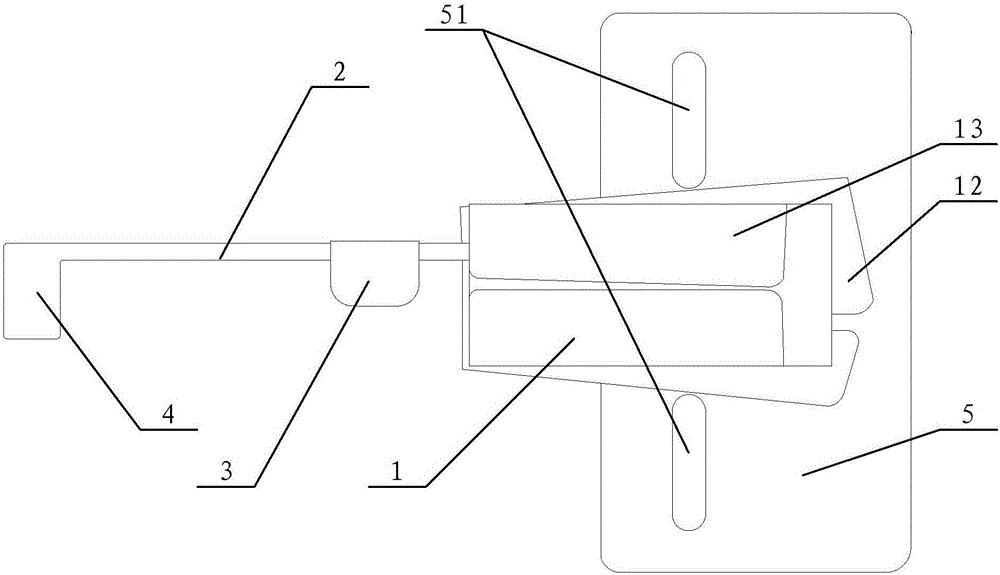

Three-way limiting buffering bridge anti-seismic stop dog structure and arranging and installing method

InactiveCN106436558AFree from damageAvoid damageBridge structural detailsExpansion jointCanis lupus familiaris

The invention discloses a three-way limiting buffering bridge anti-seismic stop dog structure and an arranging and installing method. The bridge anti-seismic stop dog structure comprises a steel corbel, a stop dog lower structure and a stop dog upper structure; the steel corbel is fixed to the side face, in the bridge axial direction, of the top of a pier close to a bridge movable supporting base, the stop dog lower structure is fixed to the top of the steel corbel through bolts, a groove is formed in the lower portion of the stop dog upper structure, the stop dog upper structure is fixed to the bottom of a main beam of the bridge through bolts, and an impact block is arranged on the upper portion of the stop dog lower structure. Relative large displacement between a beam body and the pier in the bridge axial direction, bridge transverse direction and vertical direction can be effectively limited, damage to the movable supporting base and expansion joints is reduced, and the beam body is prevented from falling in the bridge axial direction and bridge transverse direction and prevented from vertically getting away from the supporting base to cause damage on the supporting base, beam cocking damage and vertical impact damage between the beam body and the supporting base. The three-way limiting buffering bridge anti-seismic stop dog structure is simple in structure, convenient to construct, easy to repair and replace and suitable for new and old bridges.

Owner:NANCHANG UNIV

Sealed cell having non-resealable safety valve

ActiveUS7687188B2Reduce decreaseThick structureNon-aqueous electrolyte accumulatorsNon-aqueous electrolyte cellsInternal pressureEngineering

A sealed cell having a safety mechanism is provided. The safety mechanism has a non-resealable valve structure formed in a sealing plate that seals the cell. The valve structure is broken as soon as the internal pressure reaches or exceeds a predetermined value so as to permit the internal gas to be released outside. The valve structure has at least one dome protruding toward the interior of the cell, which in turn has at the periphery thereof a break groove for facilitating the breakage of the valve structure. This makes the valve structure highly responsive to the internal pressure and causes to form a break-opened orifice of a sufficient area at the time of operation in response to the increased internal pressure. The valve structure is not unnecessarily broken by the impacts of, for example, dropping. As a result, the safety of the sealed cell is significantly improved.

Owner:PANASONIC ENERGY CO LTD

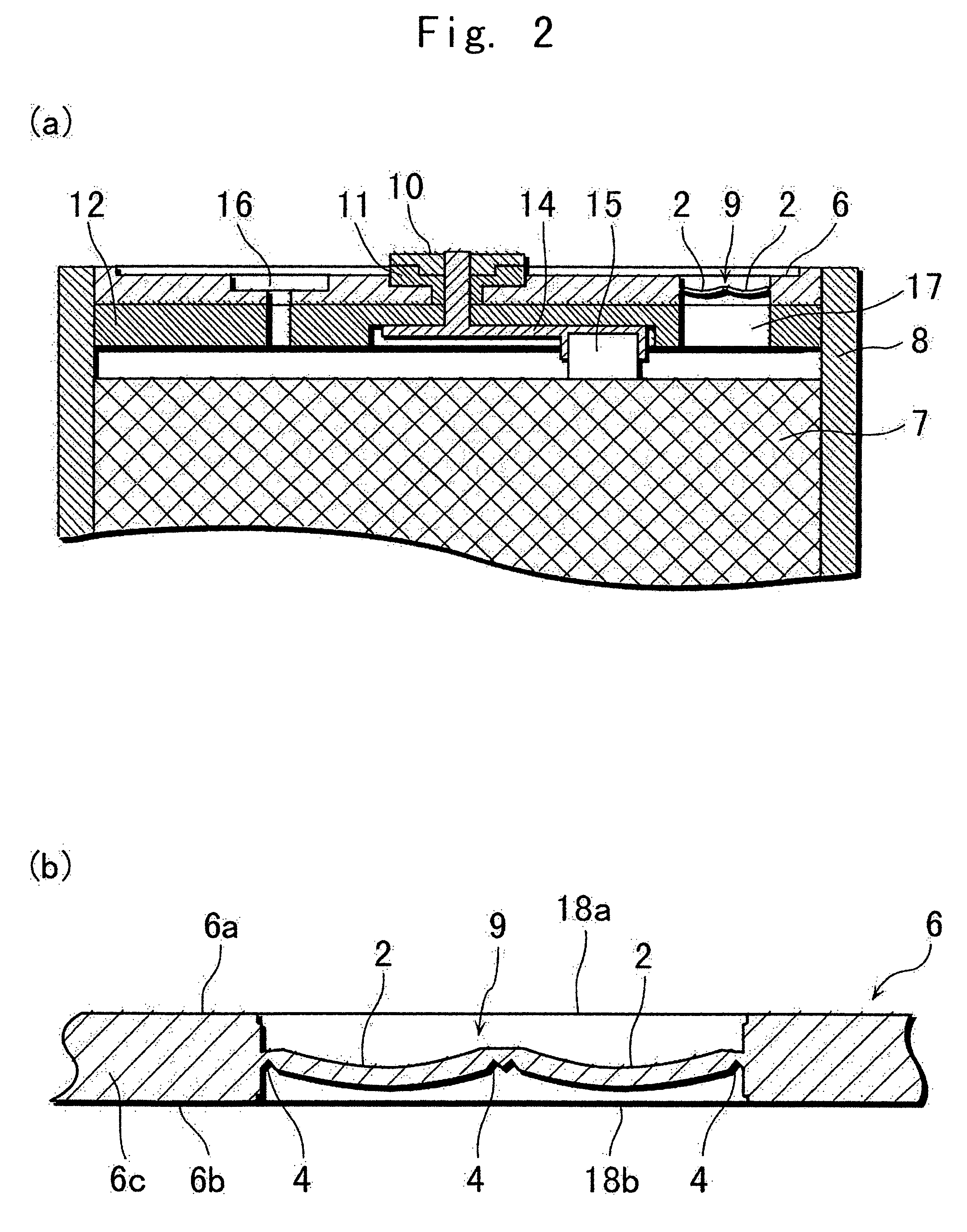

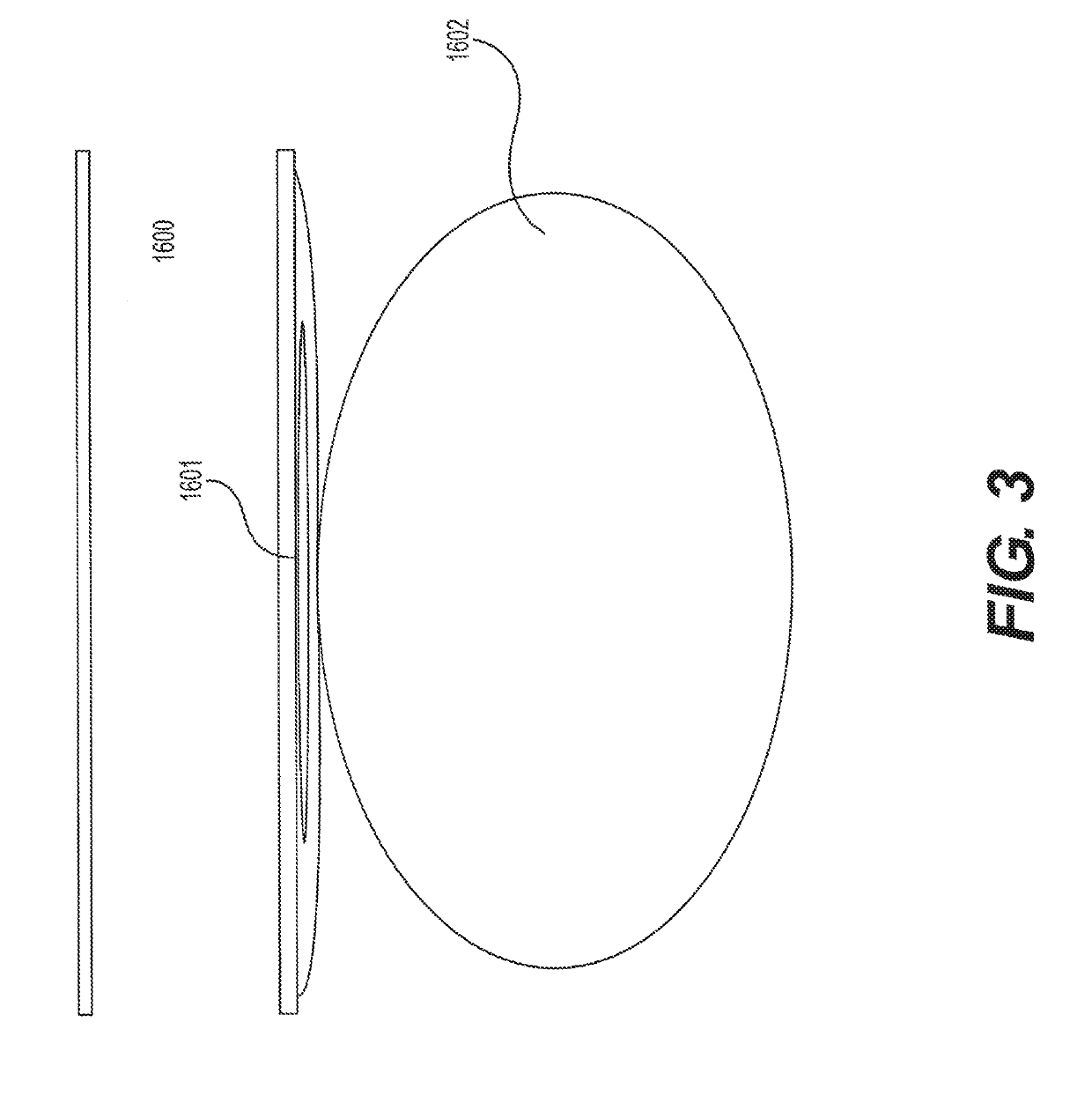

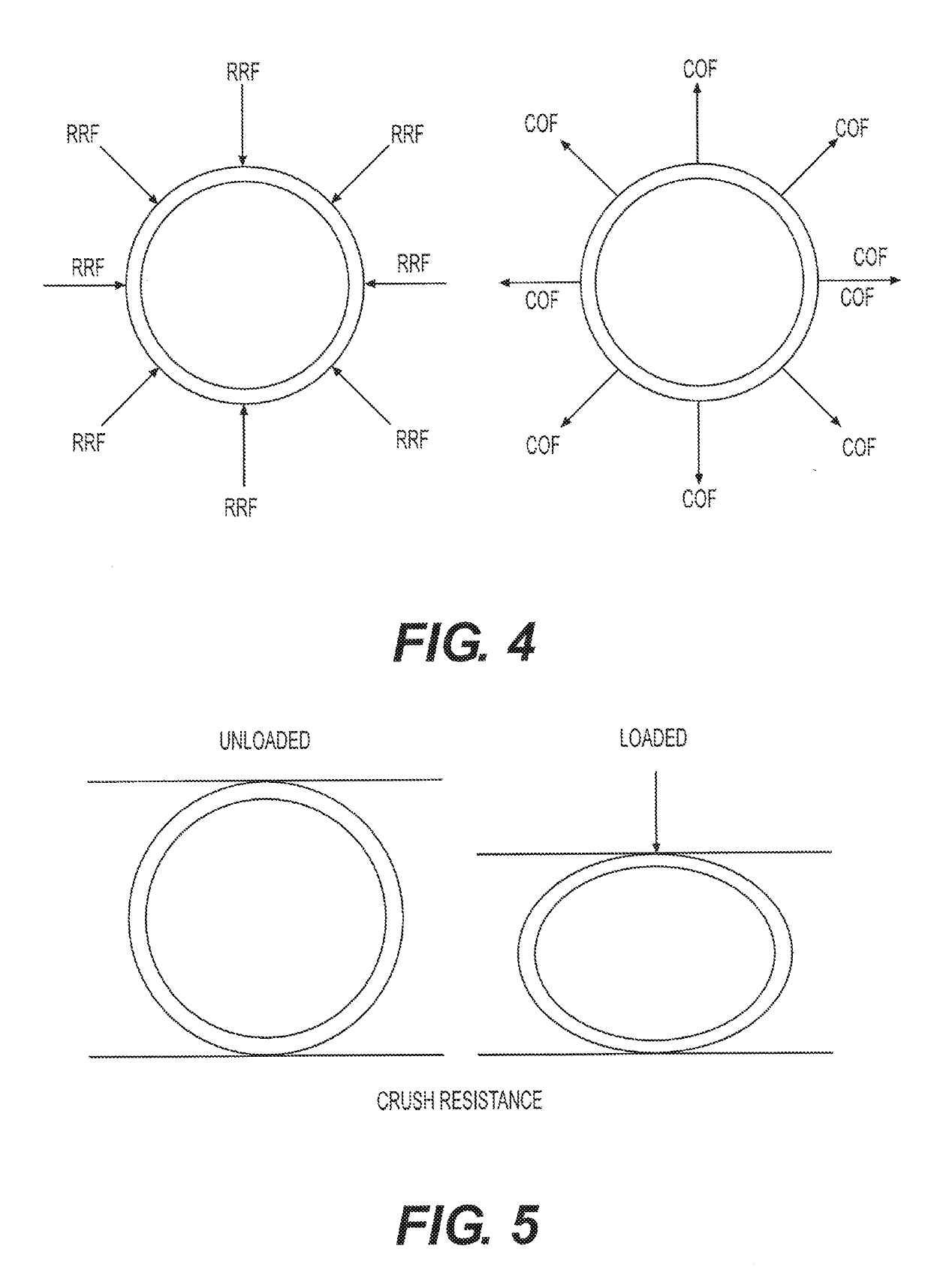

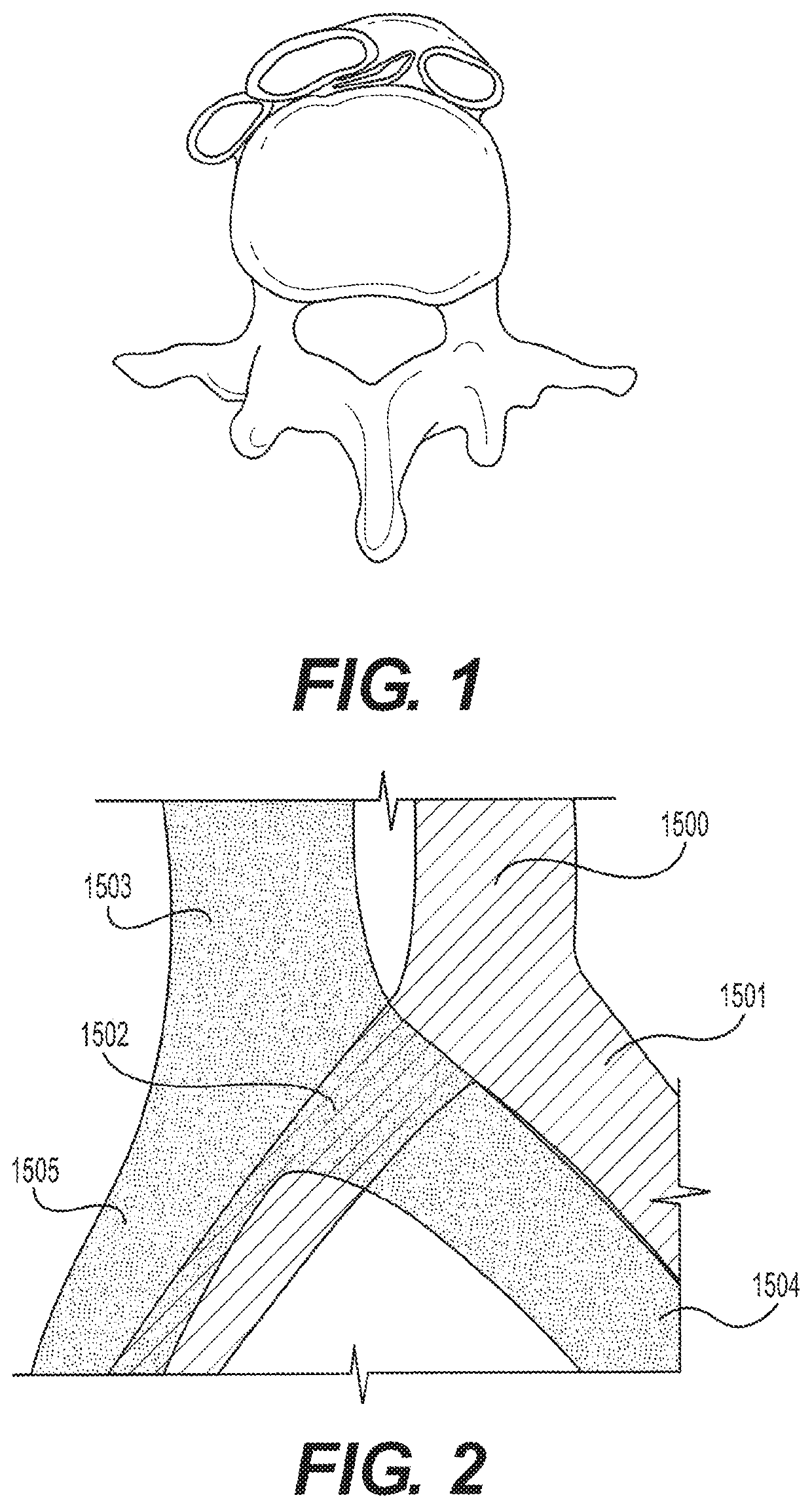

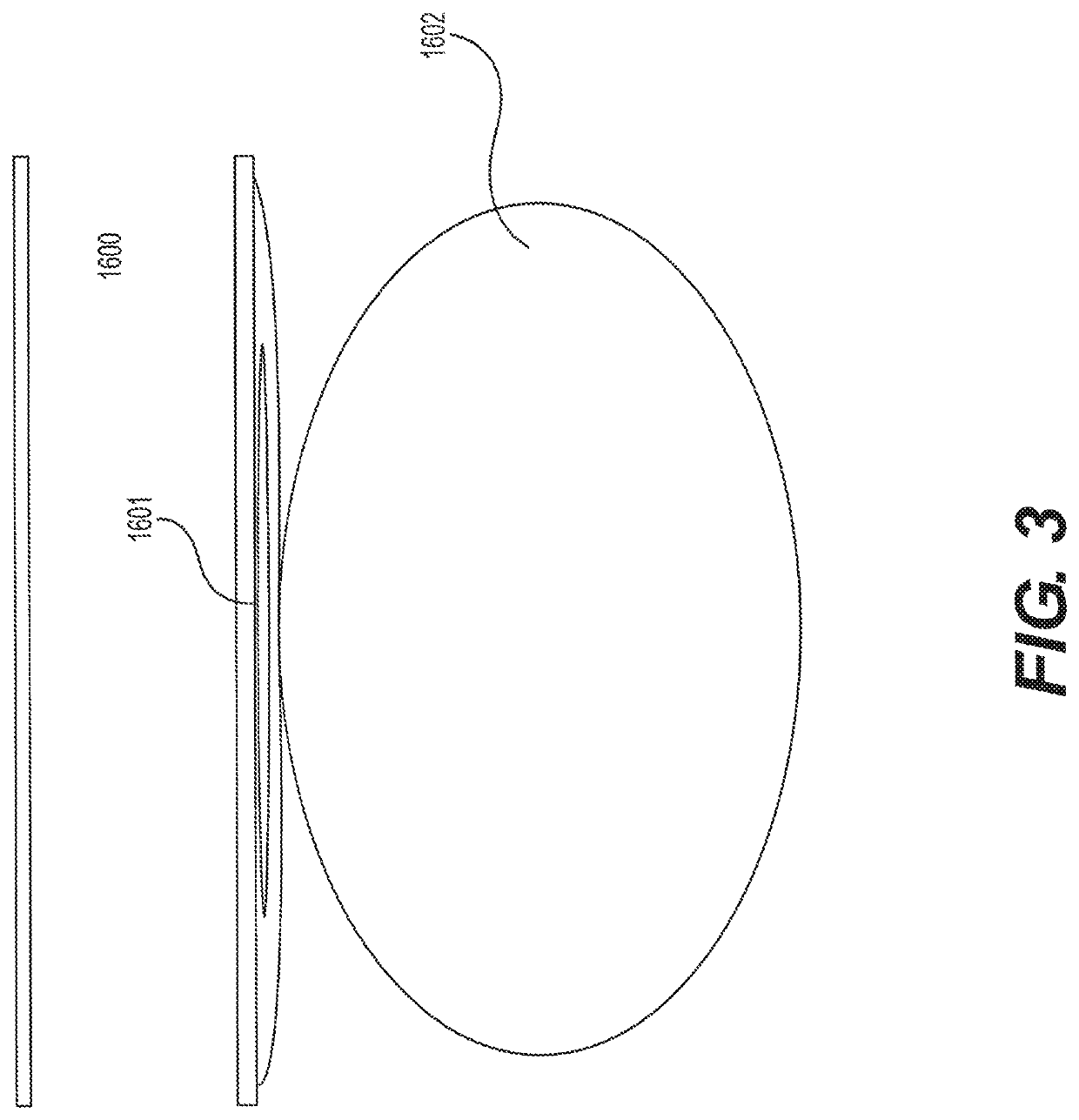

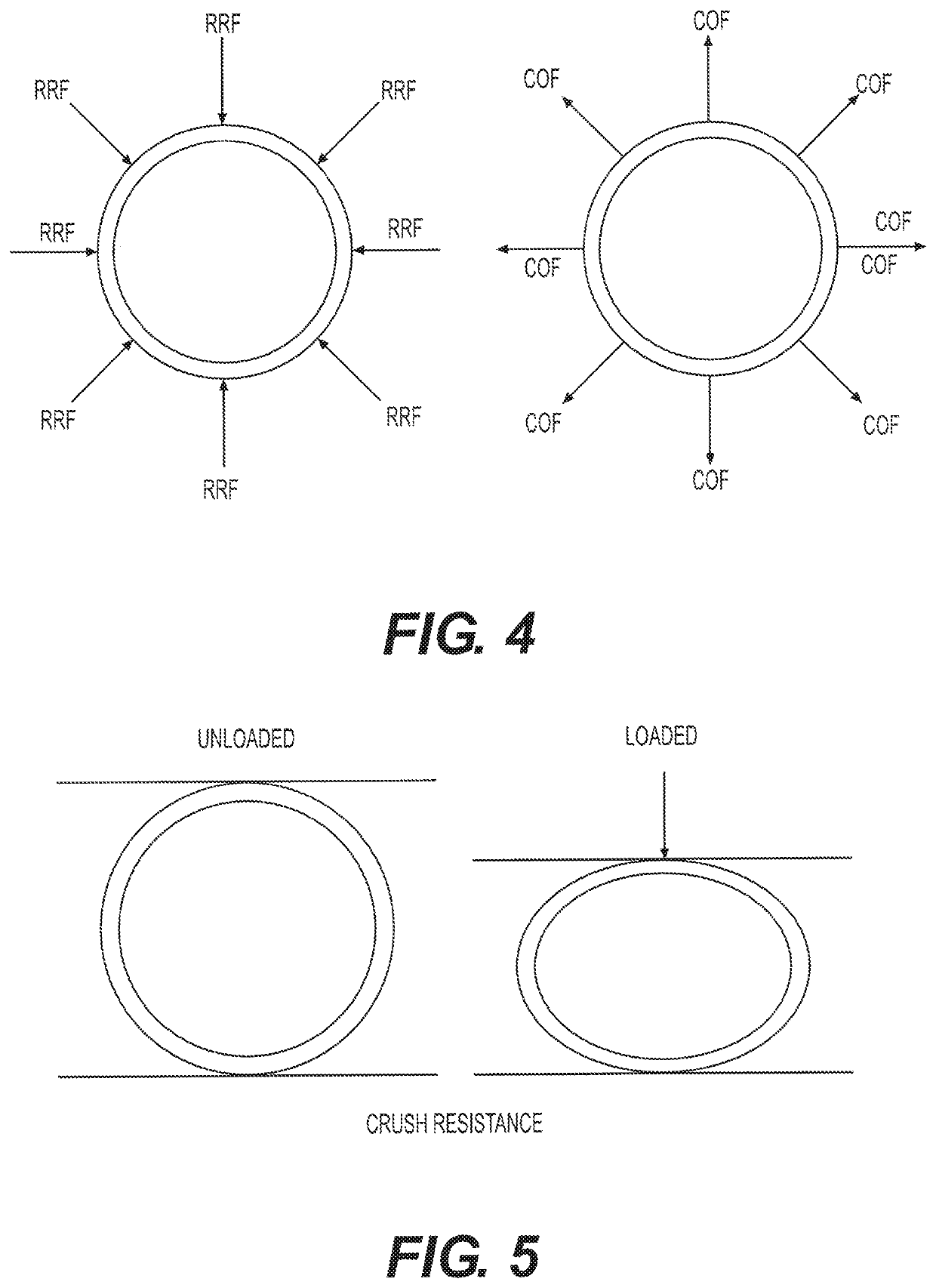

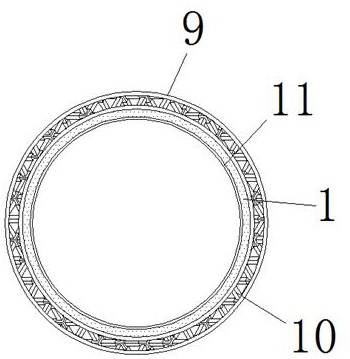

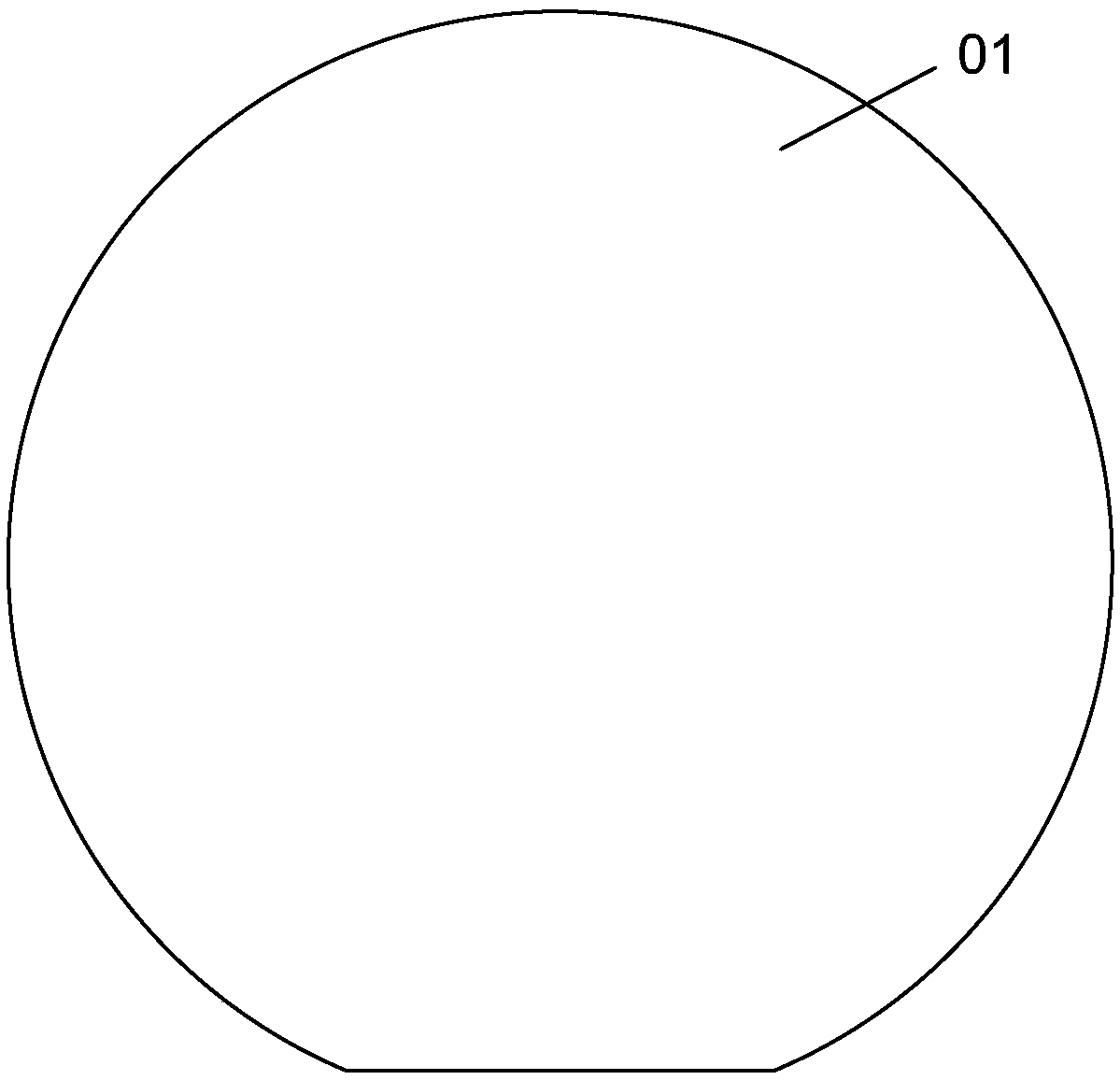

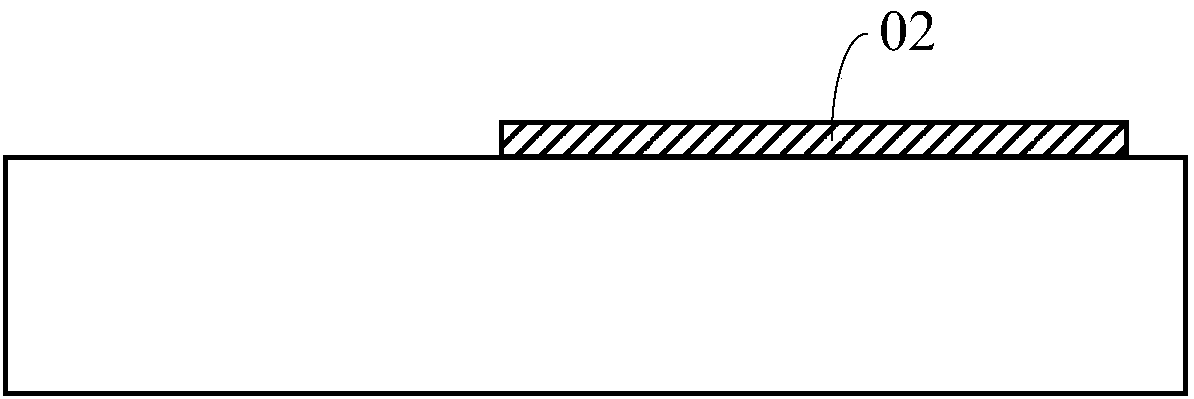

Tapering stent

ActiveUS20190247209A1Radial stiffness be greatThick structureStentsRevolution surface grinding machinesPliabilityInsertion stent

A stent includes a high radial force segment and a highly flexible segment, where the diameters of the high radial force segment and the highly flexible segment are different. For example, the stent may be formed from a tube having varying diameters as it extends distally combined with increased strut density to achieve increased flexibility distally while reducing loss of radial stiffness. The stent may further be placed with an additional stent segment, where the additional stent segment has a radial force similar to the radial force of the highly flexible force segment.

Owner:VESPER MEDICAL INC

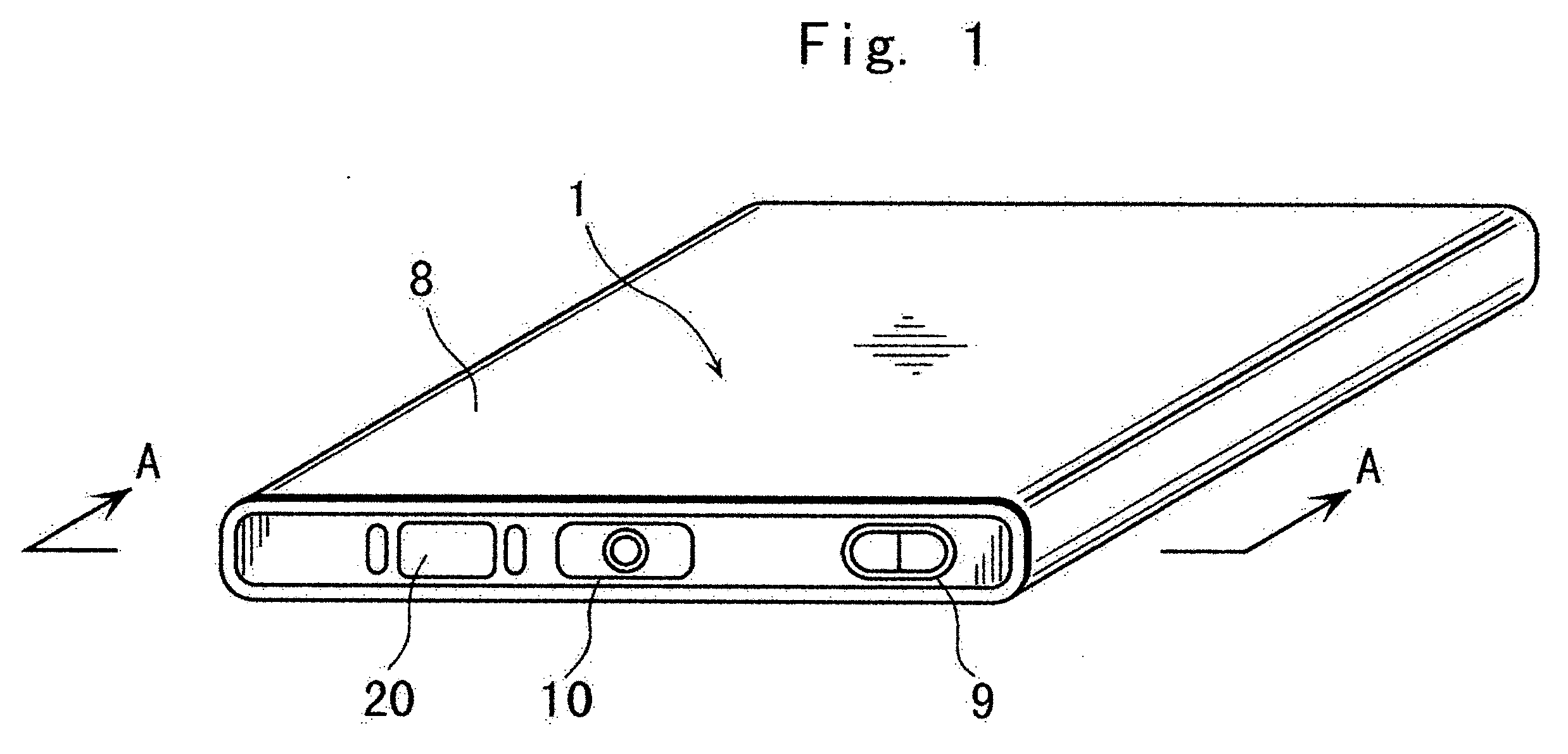

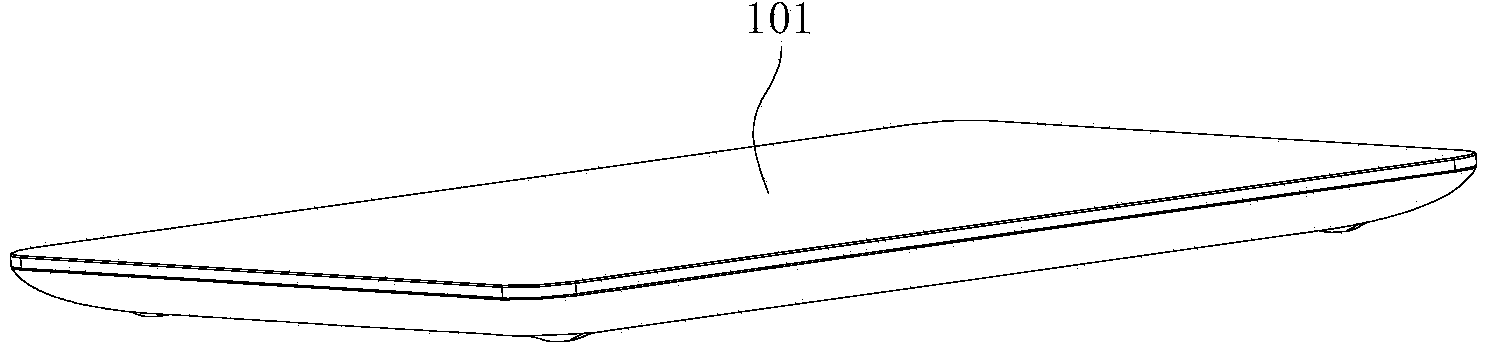

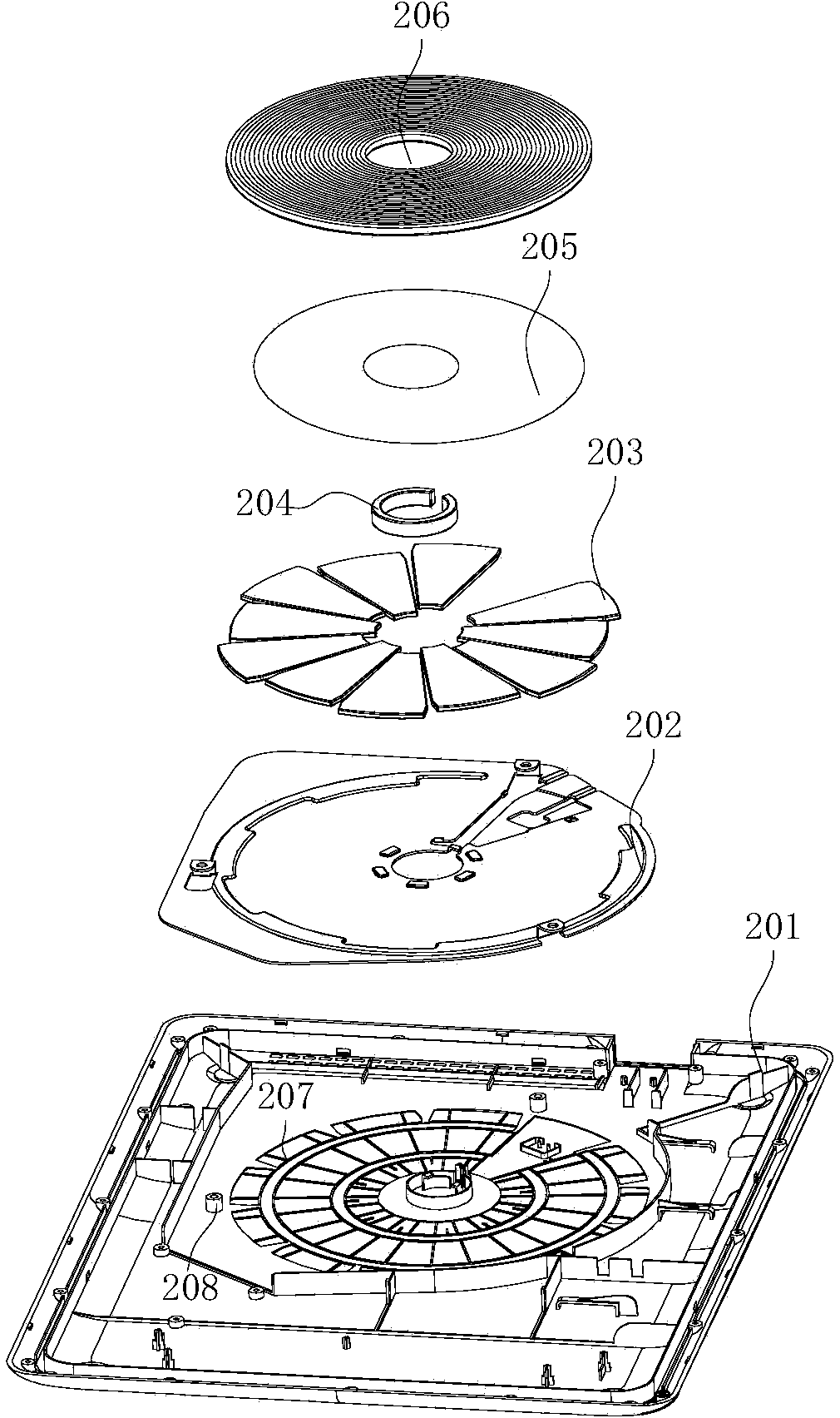

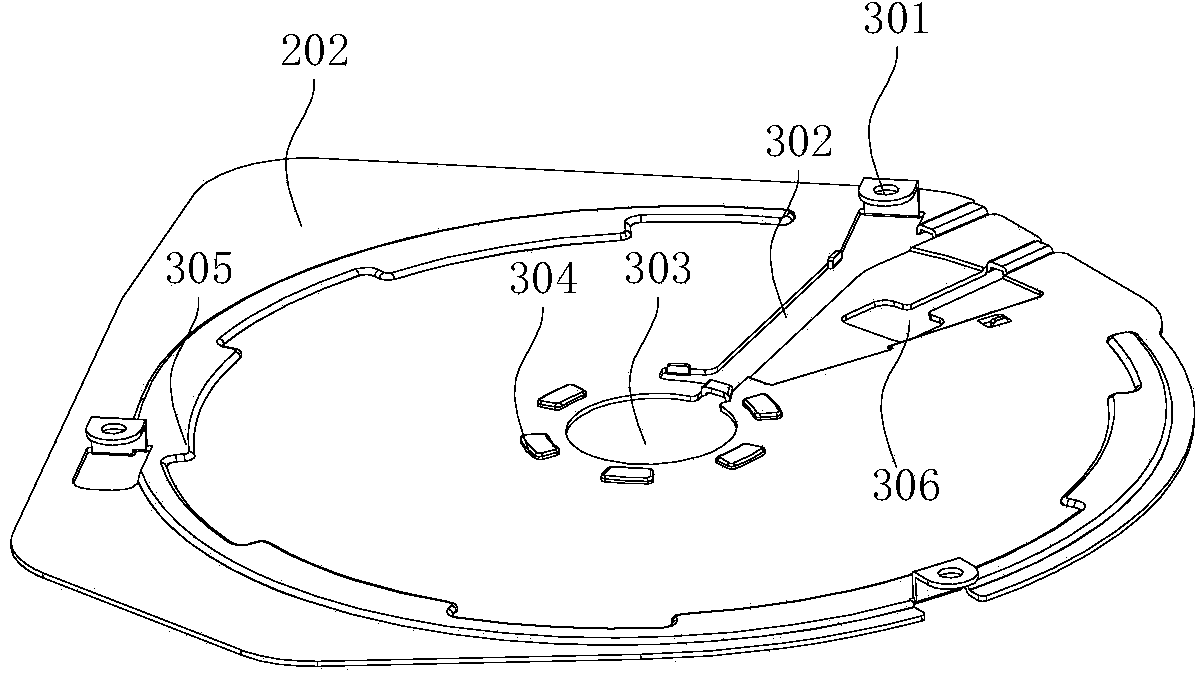

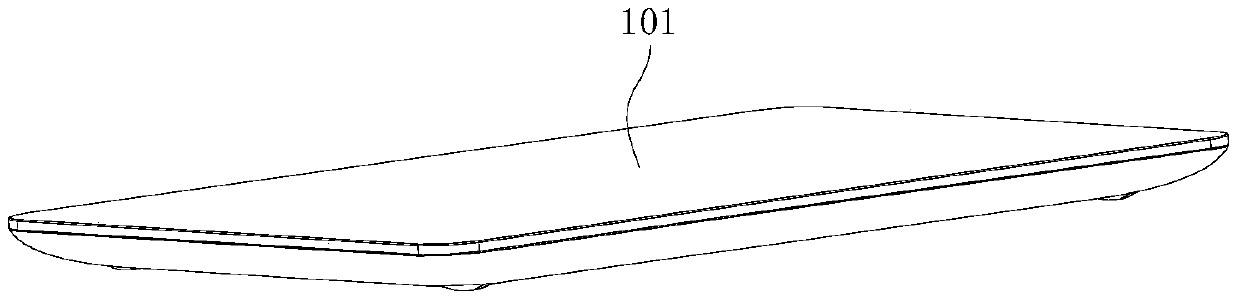

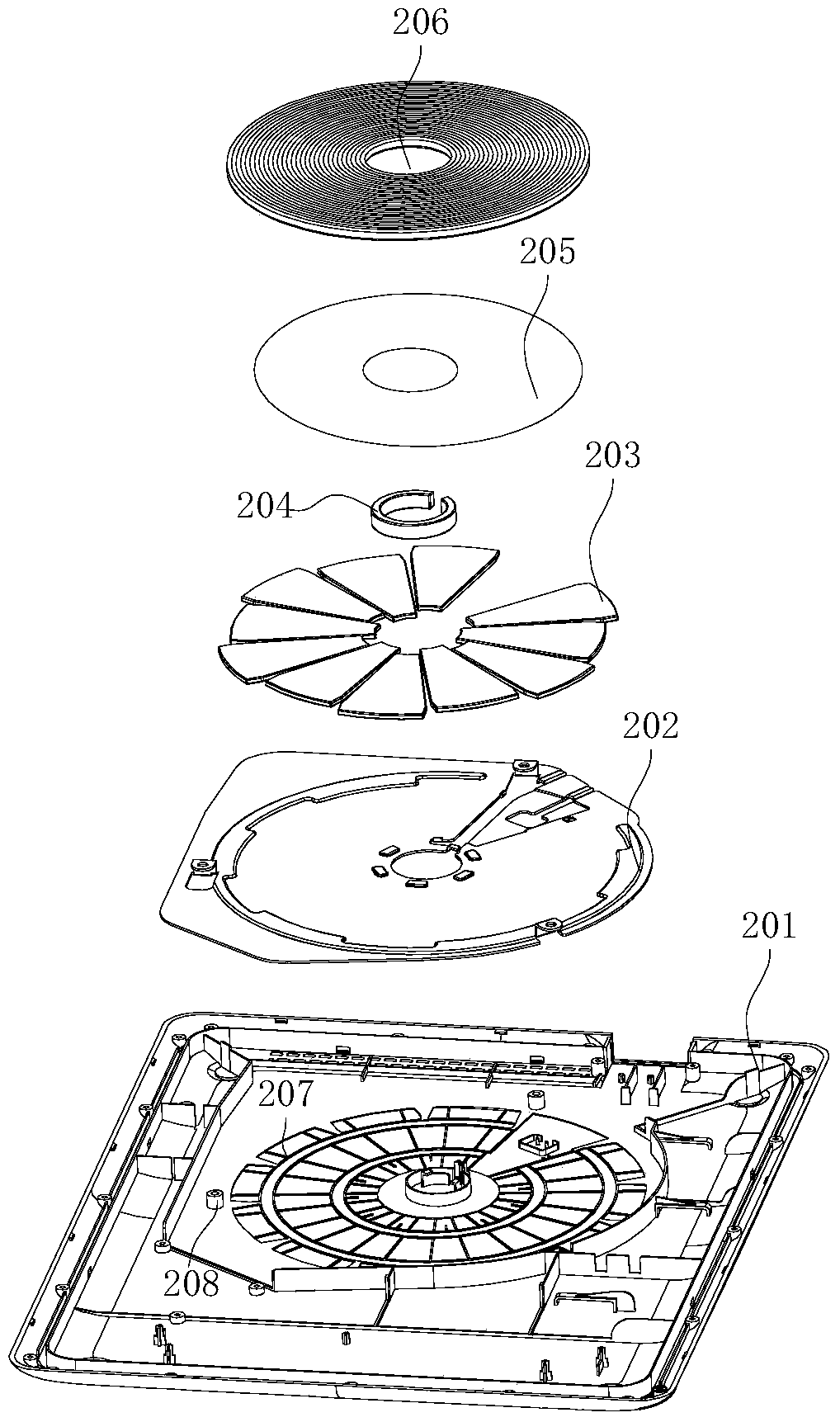

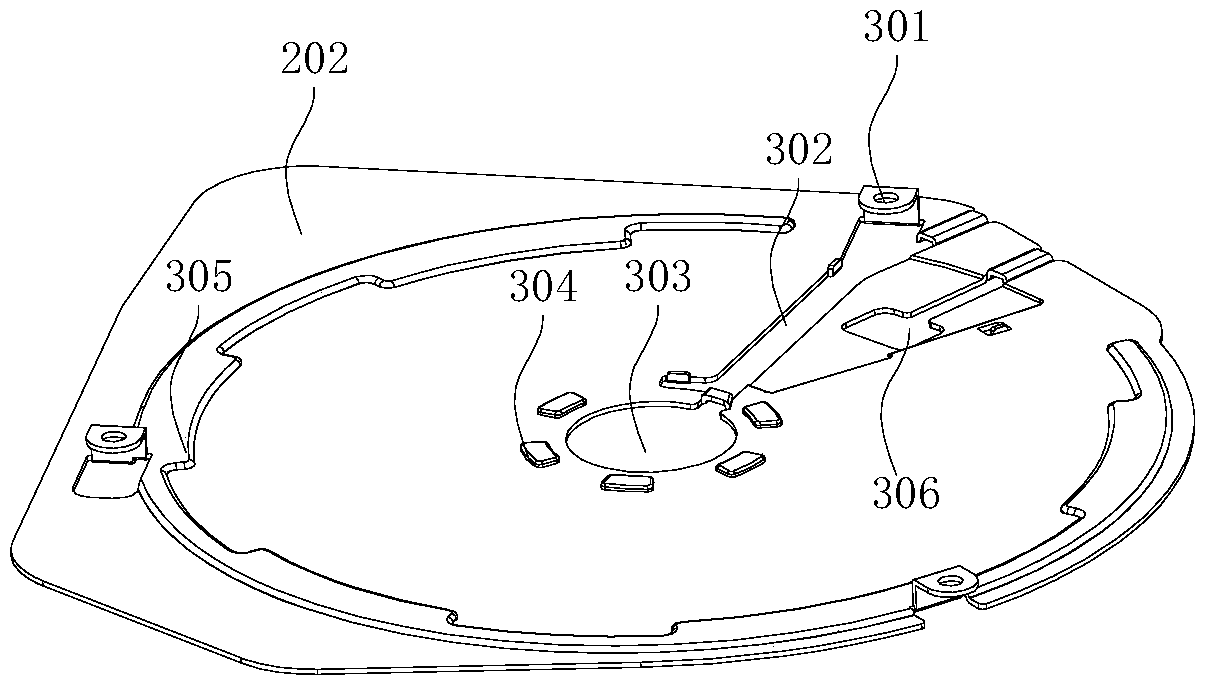

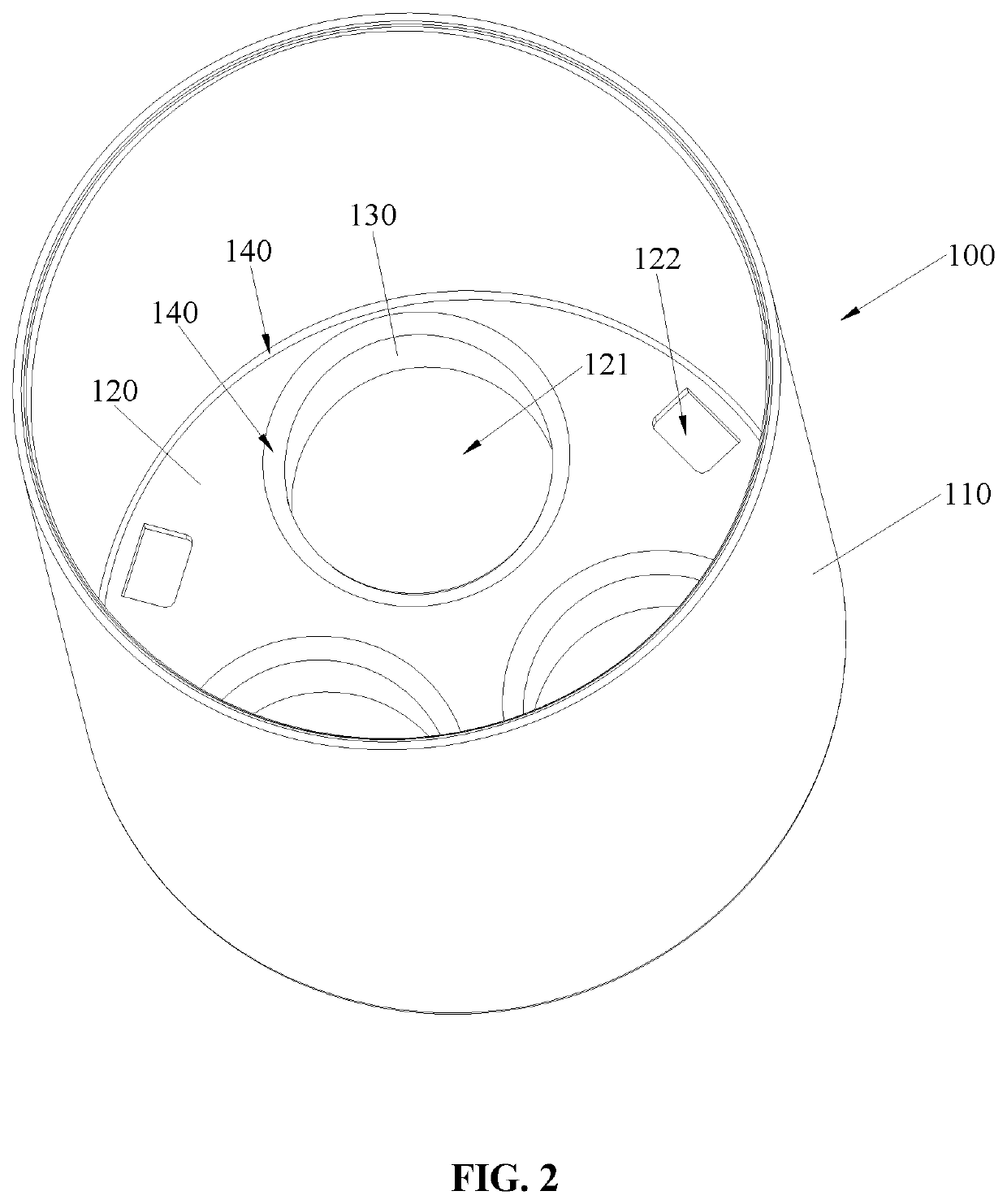

Induction cooker with magnetic stripe arranged at upper side of support

ActiveCN104110708AImprove cooling effectImprove ductilityDomestic stoves or rangesLighting and heating apparatusClamp connectionInduction motor

The invention relates to the field of household electrical appliance and especially relates to an induction cooker (101) with a magnetic stripe arranged at the upper side of a support. The induction cooker comprises a panel and a bottom casing (201), the panel and the bottom casing (201) form a cavity, a support (202), the magnetic stripe and a coil (206) are arranged in the cavity, and the support (202) is prepared from Al, is in a shape of a plate and is directly and fixedly arranged on the bottom casing (201). The coil (206), the magnetic stripe, an insulation sheet (205) and the support (202) are fixed to form a heating module by bonding connection or clamp connection. The induction cooker has an ultrathin structure having the thickness less than 20mm, has unaffected thermal diffusivity and avoids reverse direction heating problems.

Owner:JOYOUNG CO LTD

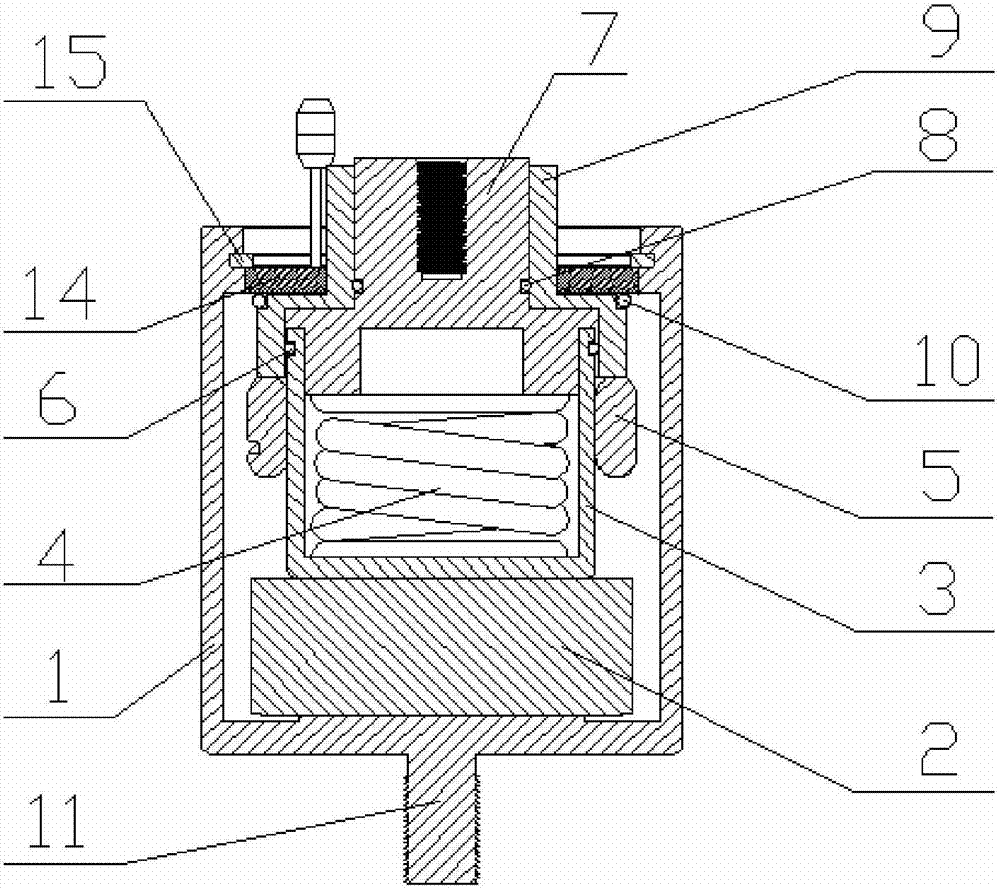

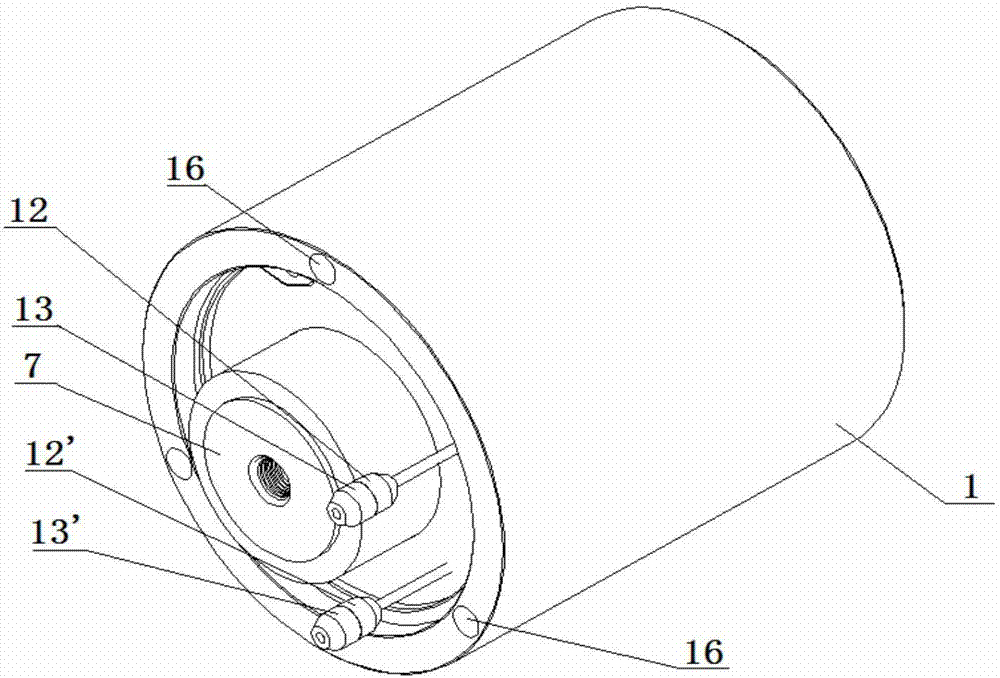

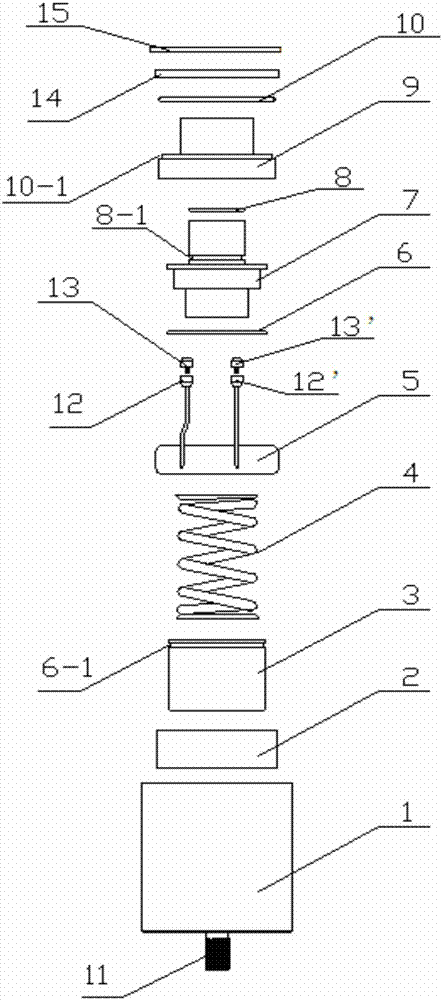

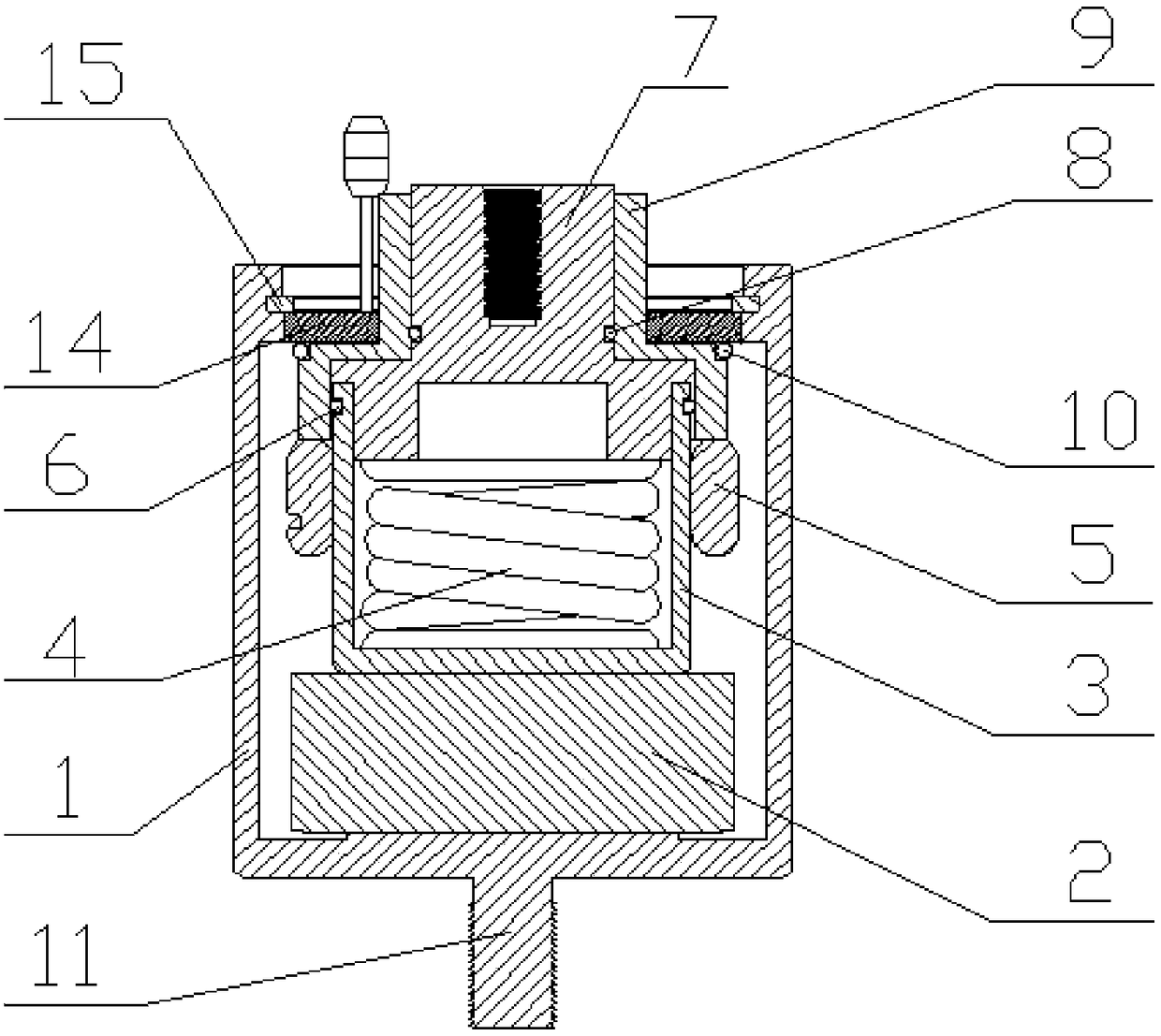

Surge protector with long service lifetime and high protection

ActiveCN106960709AImprove insulation performanceImprove corrosion resistanceResistor housing/enclosing/embeddingOvervoltage protection resistorsElectrical resistance and conductancePower flow

The invention relates to a surge protector with long service lifetime and high protection. The surge protector comprises a current output outer cylinder, wherein a zinc oxide piezoresistor substrate is arranged at an internal bottom part of the current output outer cylinder, a pressure bearing ring, a polarity cross cap and a T-shaped isolation sleeve are sequentially arranged on the piezoresistor substrate, an induction coil is wound around the pressure bearing ring in a matching way, a current transmission end of an induction coil is connected with a passive current comparison module by two groups of wiring caps, and the piezoresistor substrate, the polarity cross cap and the induction coil are pressed in the current output outer cylinder by a hole elastic baffle ring to form a whole current discharge passage. The surge protector has the advantages of reasonable structure, reliable working performance, good protection effect, long service lifetime and the like, and is convenient to operate, and the development trend for effect improvement of a current surge protector and the increasingly market demand can be satisfied very well.

Owner:西安市西无二电子信息集团有限公司

Manufacturing method of bamboo chair

InactiveCN105965655AThick structureGood stabilityRadiation/waves wood treatmentWood treatment detailsHandrailCushion

The invention discloses a manufacturing method of a bamboo chair, and relates to the technical field of manufacturing of bamboo products. The bamboo chair comprises a chair seat and a chair back, wherein the chair seat is provided with two rectangular frames which are arranged up and down; each rectangular frame is provided with two longitudinal bamboo tubes and two transverse bamboo tubes; the longitudinal bamboo tubes and the transverse bamboo tubes are fixedly connected through four vertical rods; a seat plate is mounted between the two transverse bamboo tubes at the upper part; two longitudinally arranged bamboo pressing tubes are mounted above the seat plate; a plurality of reinforcing rods embedded in the two adjacent transverse bamboo tubes are mounted below the seat plate; bamboo tube handrails are mounted at the two ends of the two transverse bamboo tubes at the upper part through support rods; the chair back comprises a plurality of obliquely arranged back rods; one ends of the plurality of back rods are mounted in one transverse bamboo tube at the upper part in an interpenetrating manner; and a bamboo tube back cushion is mounted at the other ends of the plurality of back rods in a sleeving manner. The manufacturing method comprises the steps of A, material selection and blanking; B, moth proofing, and C, bamboo chair assembly. The bamboo chair manufactured through the method is thick and solid in structure, firm in use, excellent in performance, durable in use, easy and convenient to manufacture, and mothproof, safe and nontoxic to use.

Owner:三江县善茶轩工艺品有限公司

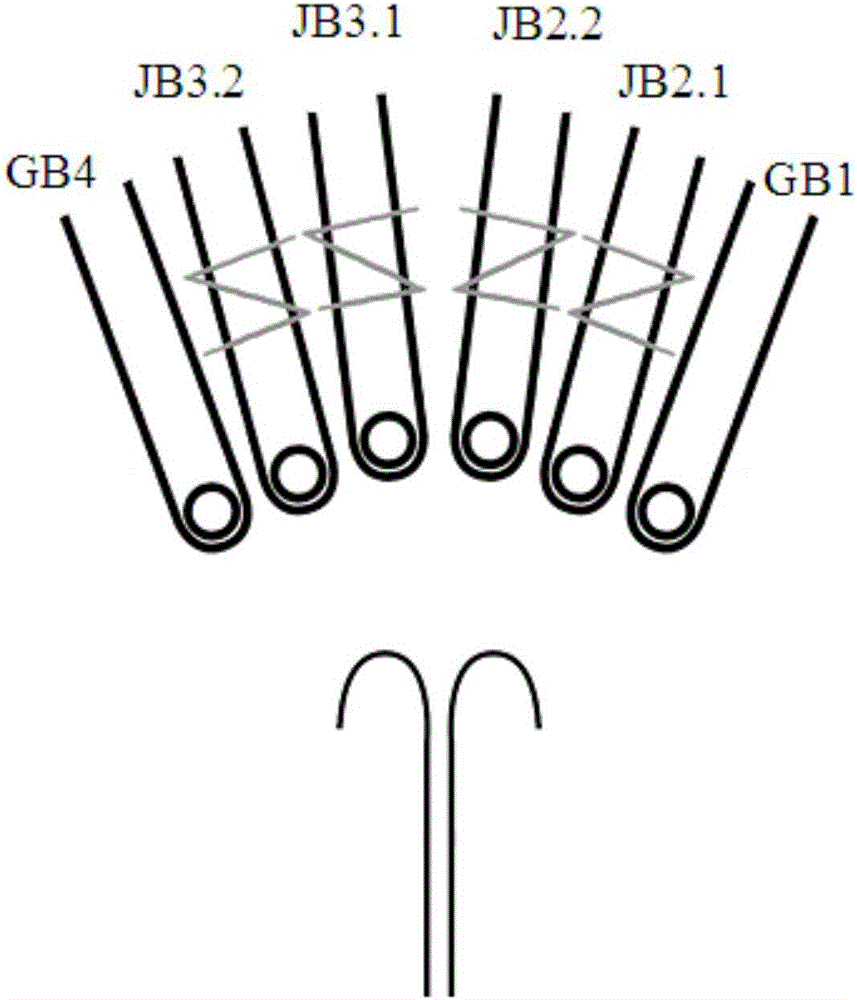

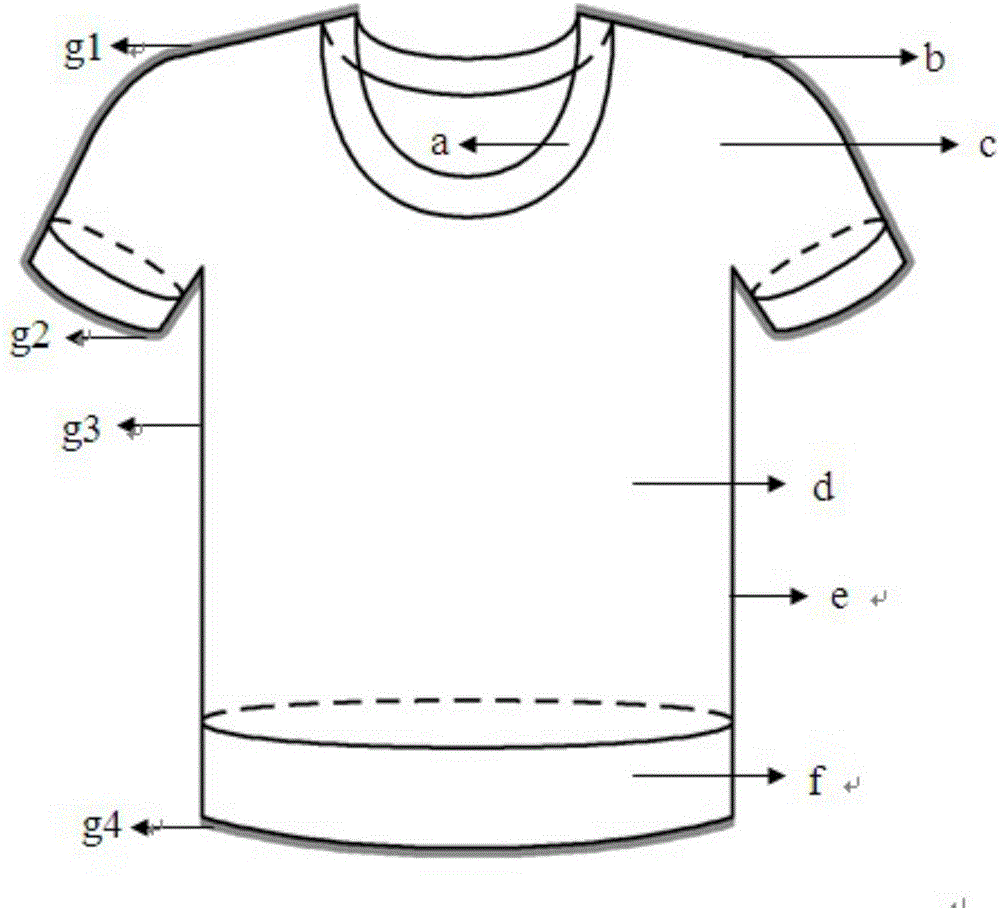

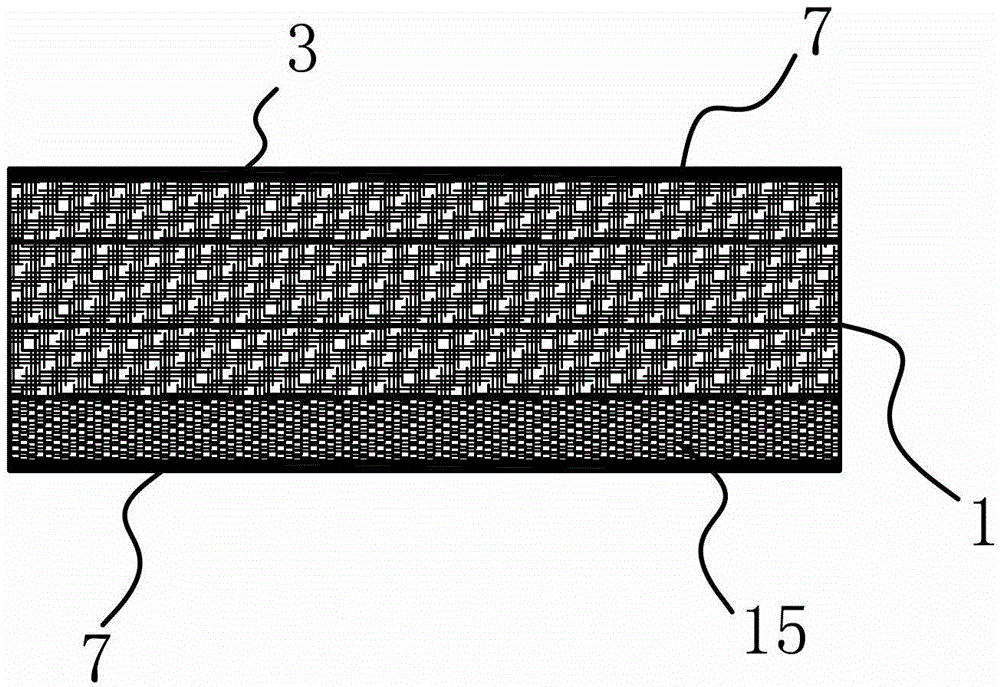

Warp-knitted fully-shaped side-seam-free T-shirt and weaving method thereof

The invention relates to a warp-knitted fully-shaped side-seam-free T-shirt and a weaving method thereof. The warp-knitted fully-shaped side-seam-free T-shirt comprises a collar part, shoulder part, shoulder-connecting sleeve parts, a main body part, side seam part and a lower hem part and consists of a front piece and a back piece. The warp-knitted fully-shaped side-seam-free T-shirt is characterized in that the front piece and the back piece on two sides of the collar part form shoulder connection through thick sewing contextures of the shoulder parts, the cuff zones of the shoulder-connecting sleeve parts are of thickness contextures, and the front piece and the back piece on the cuff edges of the shoulder-connecting sleeve parts and the lower edges of sleeves form sleeve part connection through thick sewing contextures. The front piece and the back piece of the large body part form side seams through edge connecting contextures, and the side beam parts are of thickness contextures of crossed square continuous contextures. A main body of the lower hem part is of a thickness contexture, and the lower edge of the lower hem part form a lower hem sewing part by adopting a separated structure and a thick sewing contexture. The collar part adopts a thick contexture. The main body contextures of the shoulder-connecting sleeve parts and the contexture of the large body part are mainly of thickness contextures to intersperse a mesh contexture. The warp-knitted fully-shaped side-seam-free T-shirt adopts a one-piece type shoulder-connecting sleeve style cylindrical structure, and no cutting or sewing process is needed.

Owner:YIXING HUAYI KNITTING

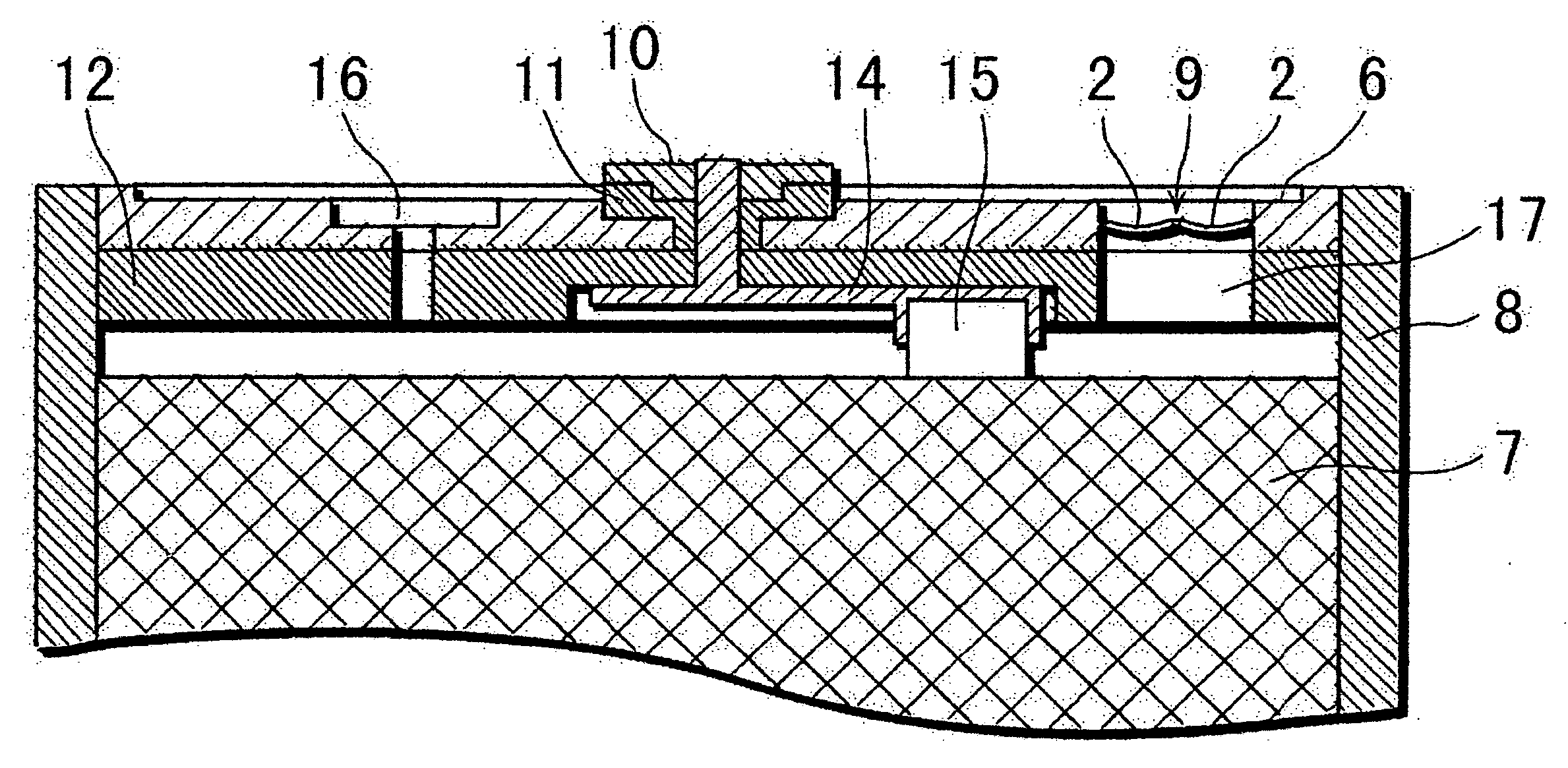

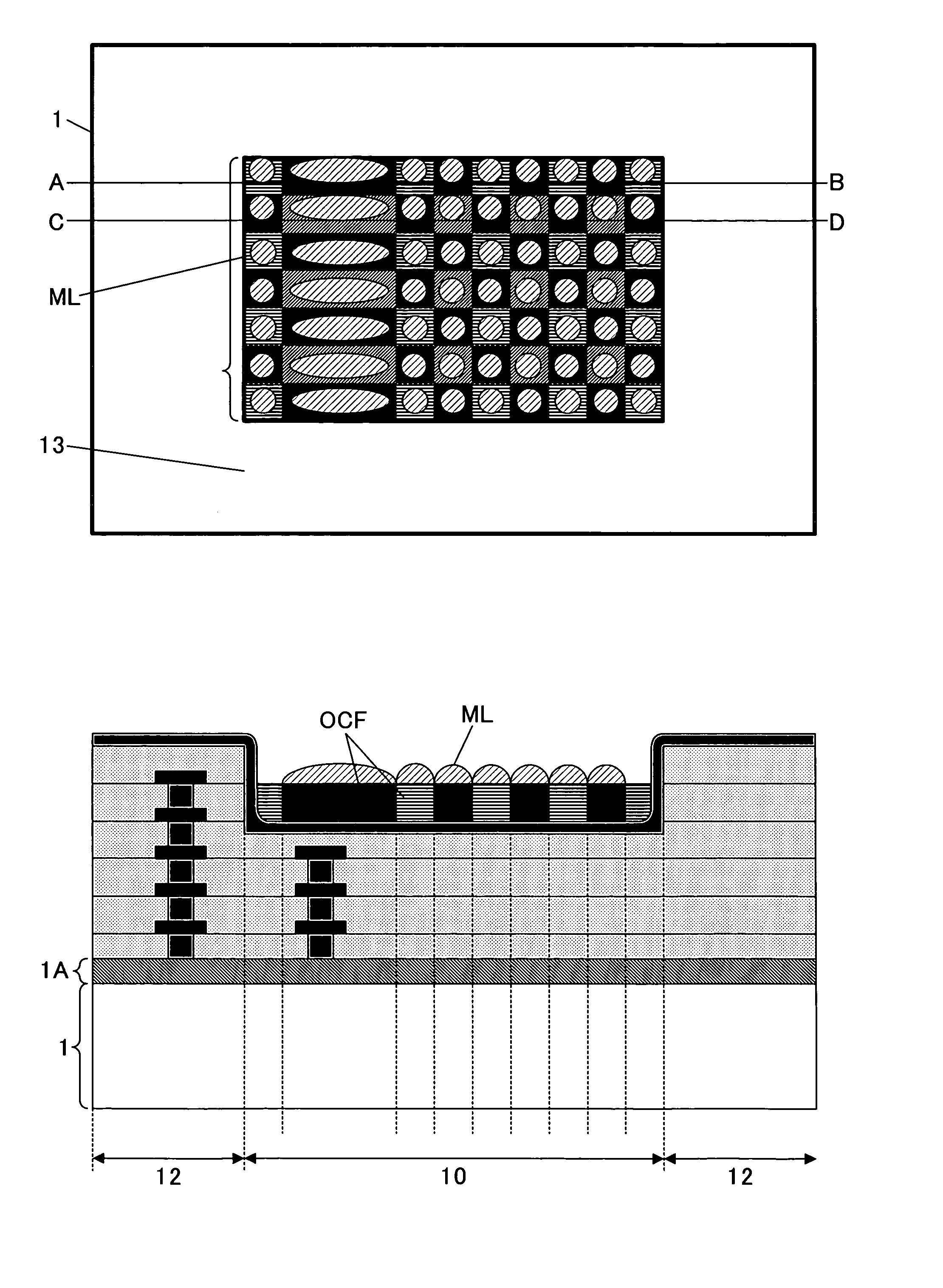

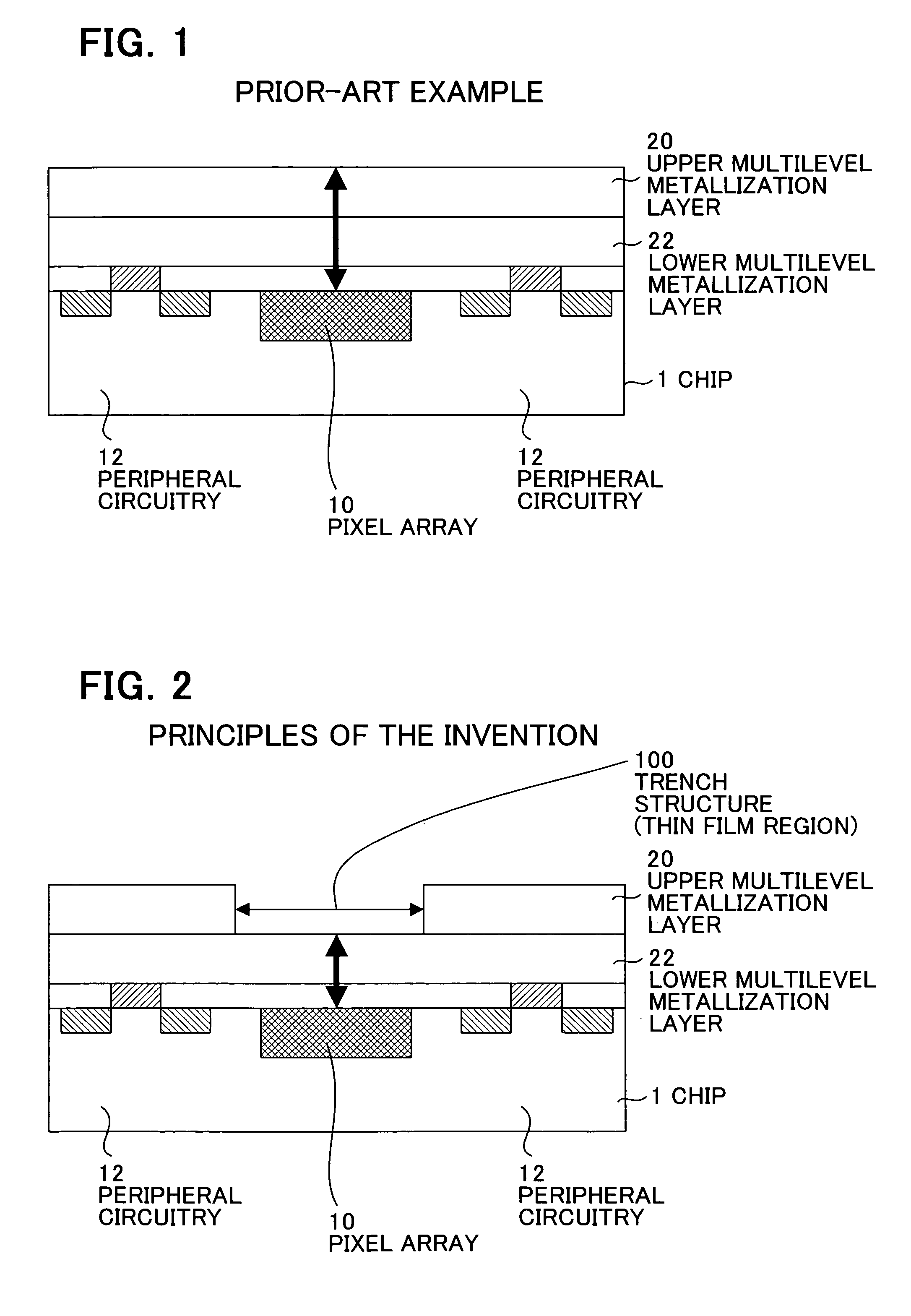

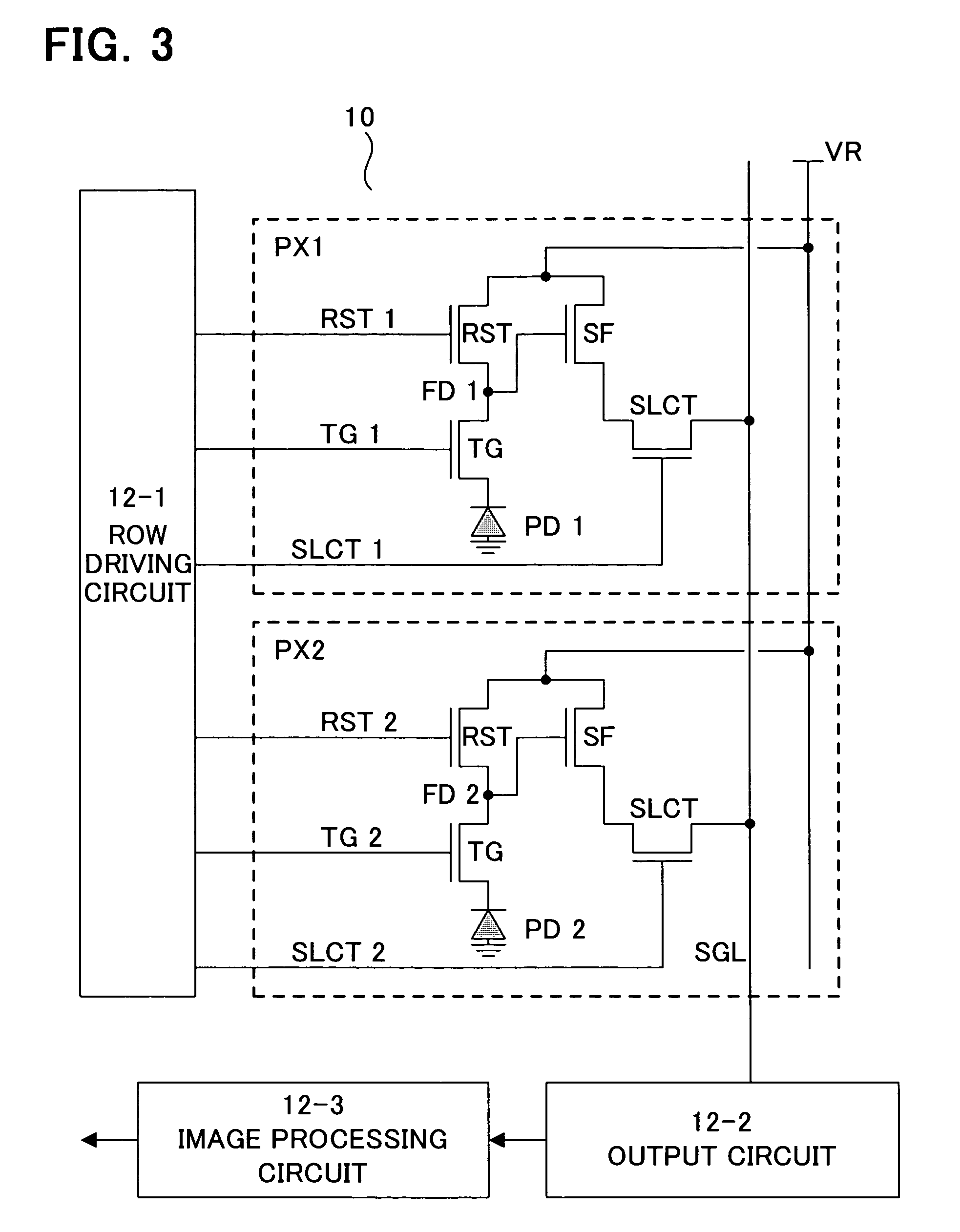

Solid-state imaging device

ActiveUS8013370B2Minimizing scattering and attenuationSuppress scatterTelevision system detailsSolid-state devicesComputer sciencePixel array

A solid-state imaging device has a substrate in which are formed a pixel array portion having a plurality of pixels, and a peripheral circuitry portion. The device is characterized in that a first multilevel metallization structure is formed over the peripheral circuitry portion, and a second multilevel metallization structure thinner than the first multilevel metallization structure is formed over the pixel array portion.

Owner:SOCIONEXT INC

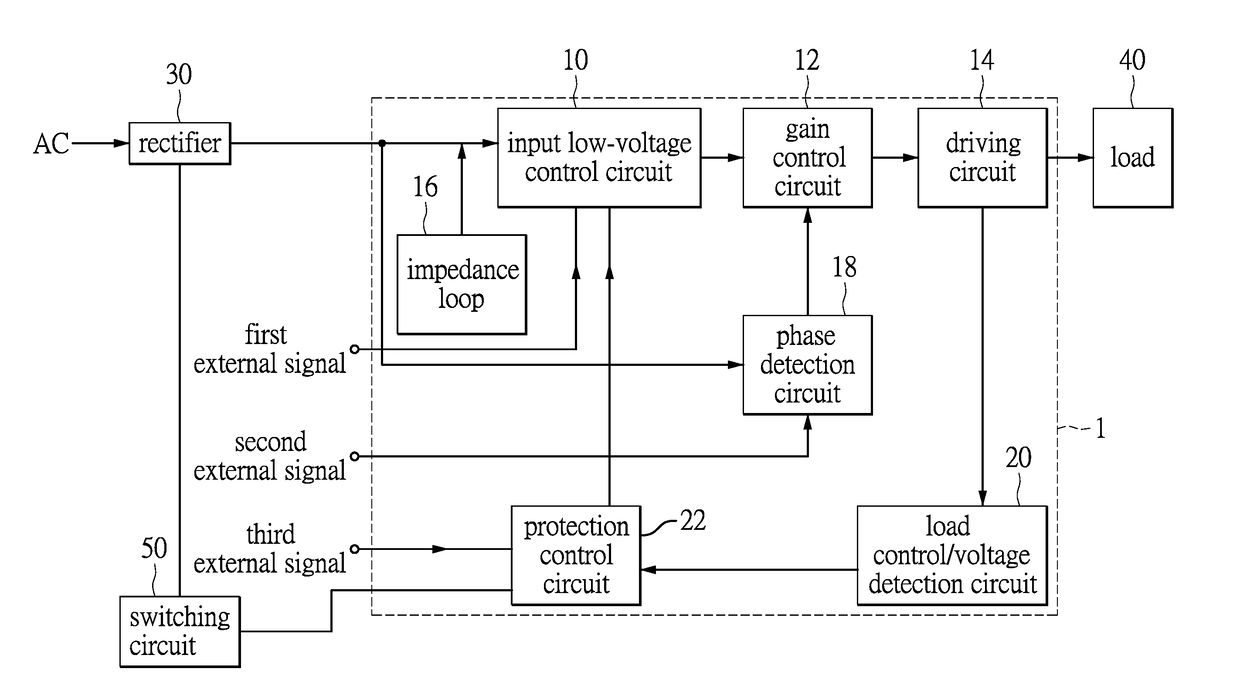

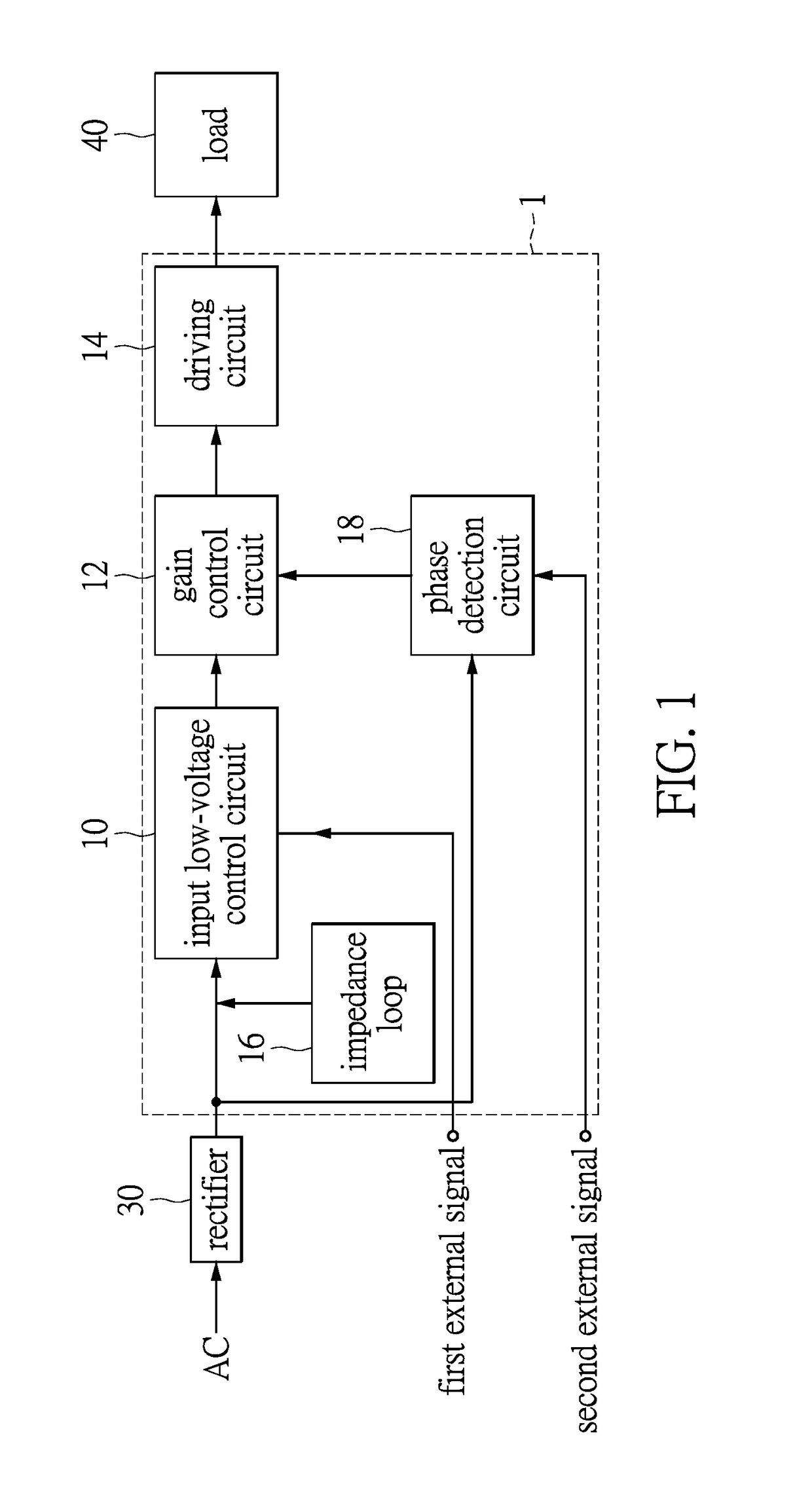

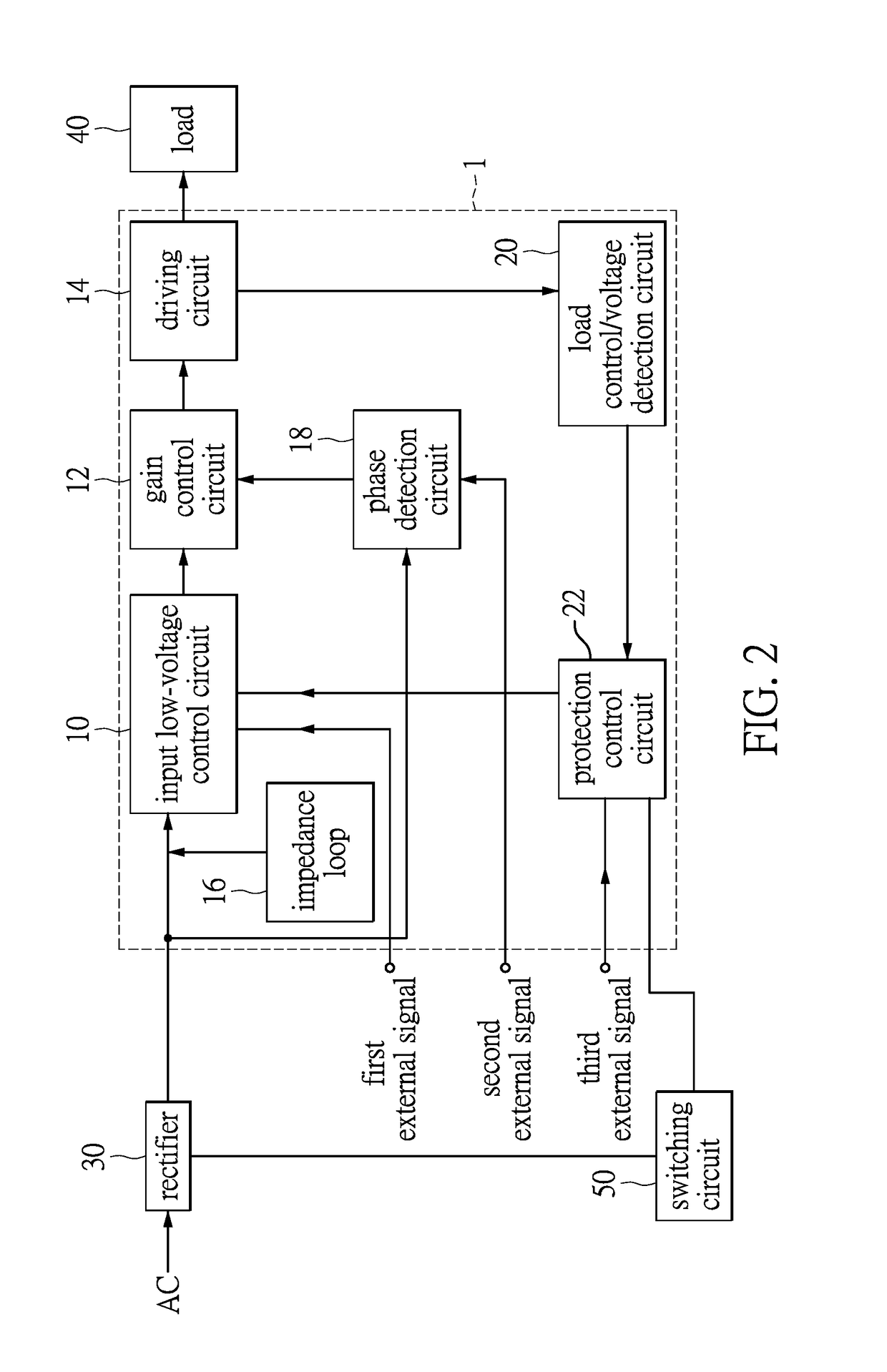

Traffic light driving control circuit

ActiveUS20170094747A1Avoid prolonged useLower component costsElectrical apparatusRoad vehicles traffic controlTraffic signalPhase difference

Disclosed is a drive integrated circuit for controlling a traffic light. The drive IC comprises an input end and an output end, an input low-voltage control circuit, a gain control circuit, a driving circuit, an impedance loop and a phase detection circuit. The input low-voltage control circuit connects to the input end of the drive IC, and receives a first external signal. The gain control circuit connects to the input low-voltage control circuit. The driving circuit connects to the gain control circuit. The impedance loop connects to the input end to detect whether the traffic light is damaged. The phase detection circuit connects to the input end to detect a phase difference of the driving signal. By integrating circuits having different detection and control functions in one single chip, the cost of the drive IC decreases and the traffic light can have a less thick structure.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Manufacturing method of bamboo chair

InactiveCN108656297AEasy to makeThick structureCane mechanical workingWood charring/burningHandrailHeating time

The invention discloses a manufacturing method of a bamboo chair. The manufacturing method comprises the following steps of (A) selecting and cutting materials: selecting phyllostachys pubescens whichgrows for more than four years, cutting into to-be-assembled parts according to the specification and size of each part required by assembling the bamboo chair, and scraping the green husk, wherein the to-be-assembled parts include longitudinal bamboo pipes, transverse bamboo pipes, vertical rods, bamboo pressing pipes, bamboo bolts, back rods, bamboo pipe backing blocks, bamboo pipe handrails, support rods, reinforcing rods and bamboo sheets; (B) separating colors, disinfecting and carbonizing: sending a finished product of the bamboo chair into a drying and disinfecting carbon dryer, specifically, the heating temperature of the drying and disinfecting carbon dryer is 160 to 190 DEG C, the heating time is 2 to 4 hours, the bamboo chair is carbonized till the carbonizing degree is 5% to 30%, and then taking out; and (C) assembling the bamboo chair.

Owner:施文杰

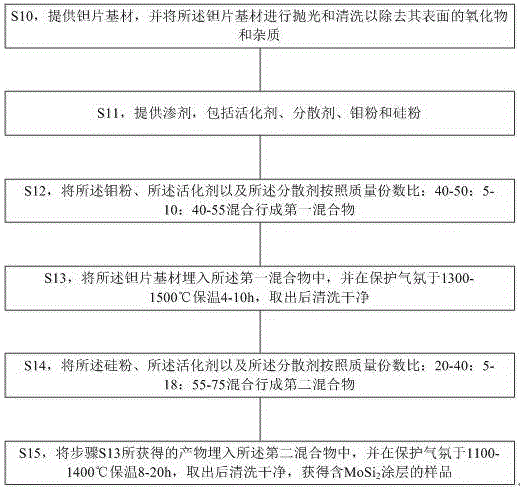

Preparation method for MoSi2 coating on surfaces of metal tantalum and alloy

The invention discloses a preparation method for a MoSi2 coating on surfaces of metal tantalum and an alloy. The preparation method comprises the steps that S10, a tantalum substrate is provided, and the tantalum substrate is polished and cleaned to remove oxides and impurities on the surface of the tantalum substrate; S11, an osmotic agent raw material, which comprises an activator, a dispersant, molybdenum powder and silicon powder, is provided; S12, the molybdenum powder, the activator and the dispersant are mixed according to a mass part ratio of (40-50):(5-10):(40-55) to form a first mixture; S13, the tantalum substrate is buried in the first mixture, is subjected to heat preservation for 4-10 h at 1300-1500 DEG C in a protection atmosphere, and is taken out and cleaned; S14, the silicon powder, the activator and the dispersant are mixed according to a mass part ratio of (20-40):(5-18):(55-75) to form a second mixture; and S15, the product obtained in the step S13 is buried into the second mixture, is subjected to heat preservation for 8-20 h at 1100-1400 DEG C in the protection atmosphere, and is taken out and cleaned, so that a sample with the MoSi2 coating is obtained.

Owner:XIAMEN UNIV OF TECH

The induction cooker with the magnetic strip on the upper side of the bracket

ActiveCN104110708BImprove cooling effectImprove ductilityDomestic stoves or rangesLighting and heating apparatusClamp connectionInduction motor

The invention relates to the field of household electrical appliance and especially relates to an induction cooker (101) with a magnetic stripe arranged at the upper side of a support. The induction cooker comprises a panel and a bottom casing (201), the panel and the bottom casing (201) form a cavity, a support (202), the magnetic stripe and a coil (206) are arranged in the cavity, and the support (202) is prepared from Al, is in a shape of a plate and is directly and fixedly arranged on the bottom casing (201). The coil (206), the magnetic stripe, an insulation sheet (205) and the support (202) are fixed to form a heating module by bonding connection or clamp connection. The induction cooker has an ultrathin structure having the thickness less than 20mm, has unaffected thermal diffusivity and avoids reverse direction heating problems.

Owner:JOYOUNG CO LTD

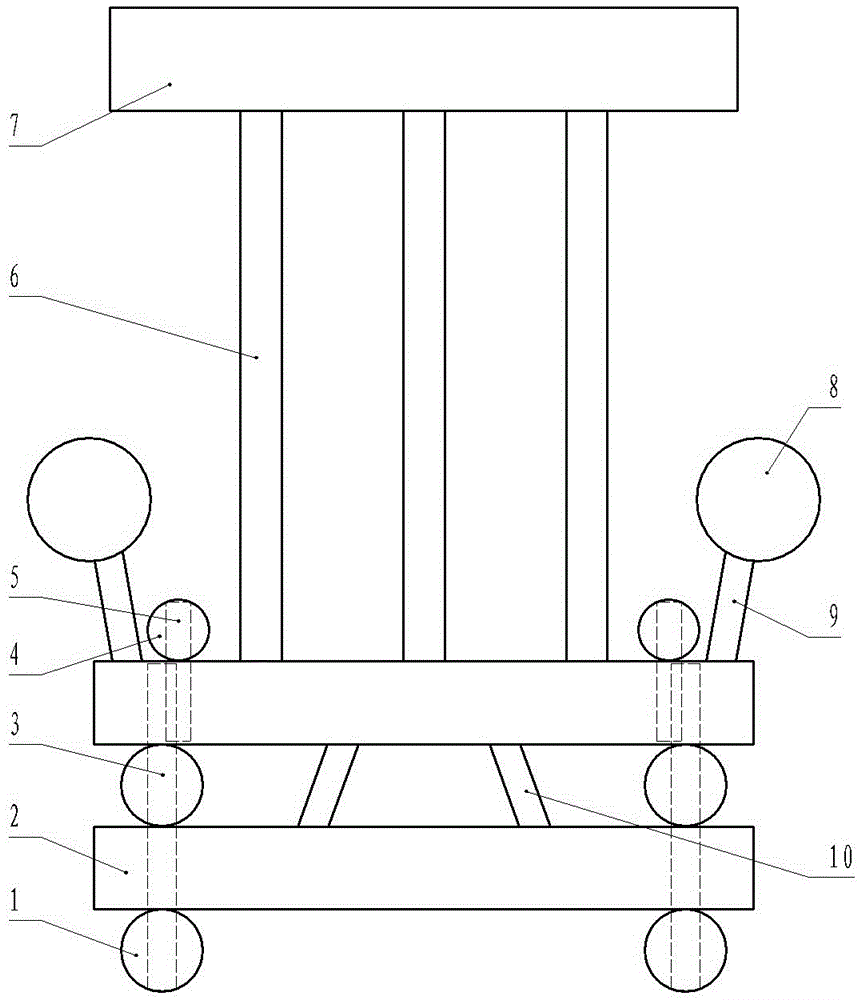

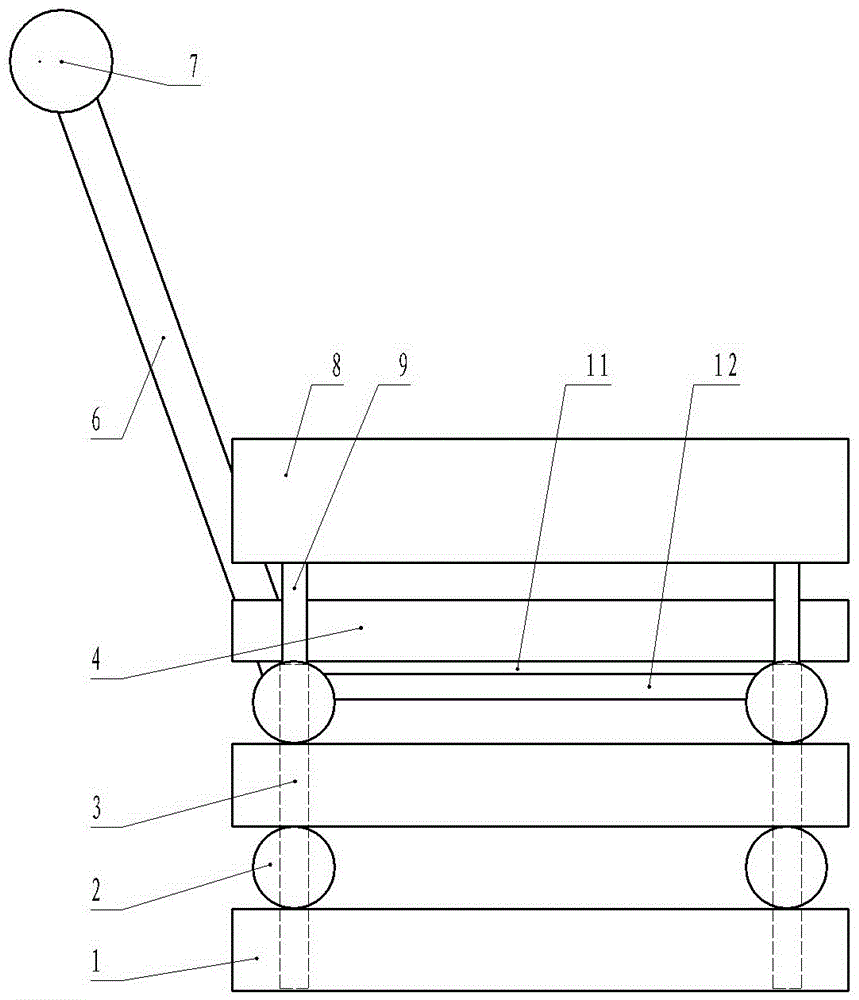

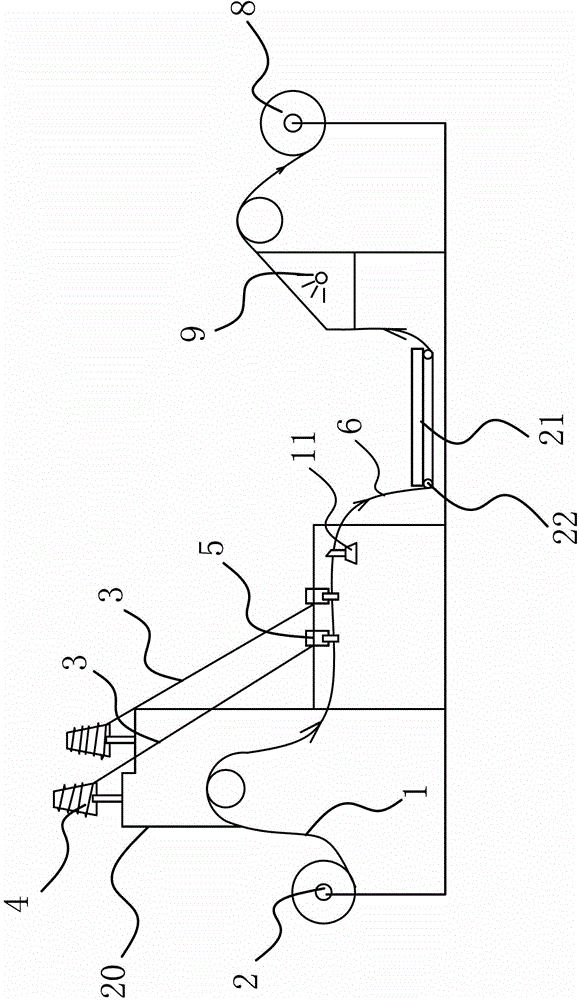

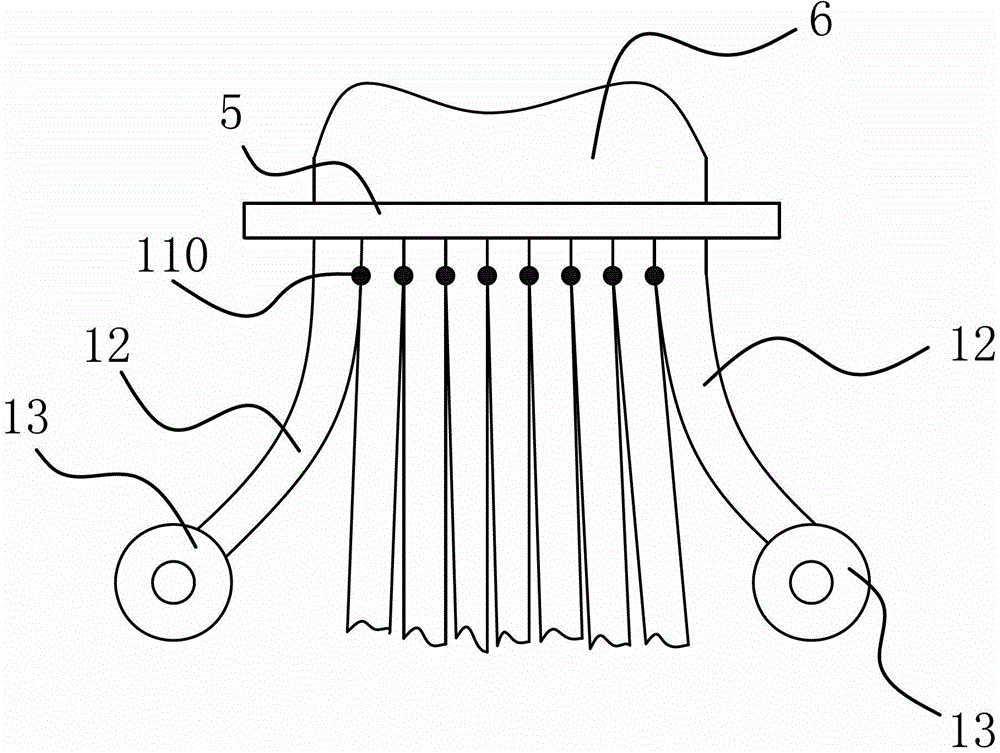

Manufacturing technology for composite elastic textiles and manufacturing equipment thereof

InactiveCN102787451BIncrease elasticitySimple structureSevering textilesNon-woven fabricsManufacturing technologyWear resistance

The invention belongs to the technical field of weaving, and particularly relates to manufacturing technology for composite elastic textiles and manufacturing equipment thereof. The manufacturing technology for composite elastic textiles and manufacturing equipment thereof solve the technical problems of low product quality and high processing difficulty in the prior art and the like. A first idea of the invention is to provide the manufacturing technology for composite elastic textiles, which comprises the following steps: A, loading material; B, weaving; C, segmenting; and D, rolling. The second idea is to provide the manufacturing equipment for composite elastic textiles, which comprises a rack, wherein a material feeding mechanism, a line paying off mechanism and a weaving mechanism are arranged on the rack; and a hot segmenting mechanism is arranged on one side of the weaving mechanism and includes a plurality of hot segmenting heads. The manufacturing technology for composite elastic textiles and manufacturing equipment thereof have the advantages of simplicity of implementing, operation and use, high processing efficiency, low manufacturing cost, reasonable design, simple structure, and good working stability; and the processed composite elastic textiles have a thick structure, good water absorbability and wear resistance, and can not only have good elasticity, but also limit the stretching range.

Owner:浙江采绒供应链管理有限公司

A surge protector with long service life and high protection

ActiveCN106960709BFacilitated releaseExtended service lifeResistor housing/enclosing/embeddingOvervoltage protection resistorsElectrical resistance and conductanceZinc

The invention relates to a surge protector with long service lifetime and high protection. The surge protector comprises a current output outer cylinder, wherein a zinc oxide piezoresistor substrate is arranged at an internal bottom part of the current output outer cylinder, a pressure bearing ring, a polarity cross cap and a T-shaped isolation sleeve are sequentially arranged on the piezoresistor substrate, an induction coil is wound around the pressure bearing ring in a matching way, a current transmission end of an induction coil is connected with a passive current comparison module by two groups of wiring caps, and the piezoresistor substrate, the polarity cross cap and the induction coil are pressed in the current output outer cylinder by a hole elastic baffle ring to form a whole current discharge passage. The surge protector has the advantages of reasonable structure, reliable working performance, good protection effect, long service lifetime and the like, and is convenient to operate, and the development trend for effect improvement of a current surge protector and the increasingly market demand can be satisfied very well.

Owner:西安市西无二电子信息集团有限公司

Manufacturing method of bamboo bed

InactiveCN114131722AAvoid breakingDoes not change colorCane mechanical workingReed/straw treatmentEngineeringProcess engineering

The invention provides a manufacturing method of a bamboo bed. The manufacturing method comprises the following steps: selecting a bamboo material; removing moisture; soaking in tung oil; cooling and shaping; manufacturing a bed board; preparing the bamboo bed; performing baking; and polishing, coating and forming. Compared with the prior art, the manufacturing method of the bamboo bed has the advantages that the bamboo bed is excellent in stability and durable in use.

Owner:SHAOYANG BAILONG BAMBOO & WOOD

Elevator car roof device

Owner:KONE CORP

Tapering stent

ActiveUS11364134B2Thick structureImprove radial stiffnessStentsRevolution surface grinding machinesSurgeryBiomedical engineering

A stent includes a high radial force segment and a highly flexible segment, where the diameters of the high radial force segment and the highly flexible segment are different. For example, the stent may be formed from a tube having varying diameters as it extends distally combined with increased strut density to achieve increased flexibility distally while reducing loss of radial stiffness. The stent may further be placed with an additional stent segment, where the additional stent segment has a radial force similar to the radial force of the highly flexible force segment.

Owner:VESPER MEDICAL INC

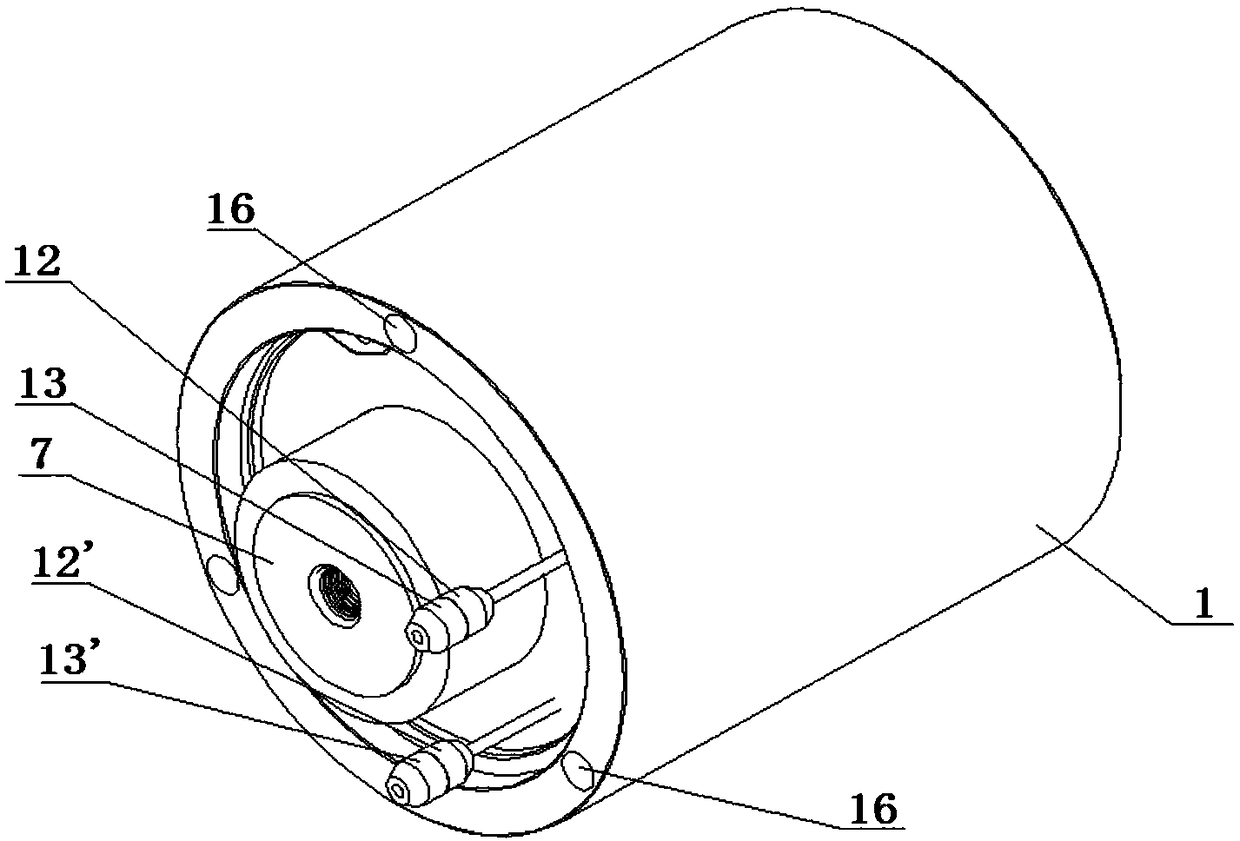

High-voltage connector and electromagnetic shielding shell for high-voltage connector

PendingUS20220140542A1Increasing thicknessGood uniformityCouplings bases/casesEngineeringDeep drawing

The present application provides a high-voltage connector and an electromagnetic shielding shell for the high-voltage connector, the electromagnetic shielding shell has an integrated barrel-shaped structure formed by a deep drawing process, and integrated barrel-shaped structure includes a barrel wall and a barrel bottom that are connected to each other. By providing an integrated barrel-shaped structure formed by the deep drawing process, the entire electromagnetic shielding shell does not have structural slits, thereby improving the current passing capacity and electromagnetic shielding performance, and there is no overlap of multiple sheet metal materials in the structure of the electromagnetic shielding shell, and can increase the thickness of the electromagnetic shielding shell under the same conditions, and it can also make the structure thickness of the electromagnetic shielding shell have better uniformity, avoid the situation of thick local structure, and the space occupied by the electromagnetic shielding shell in the high-voltage connector is reduced and materials are saved, which can reduce the material cost and manufacturing cost of the product.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

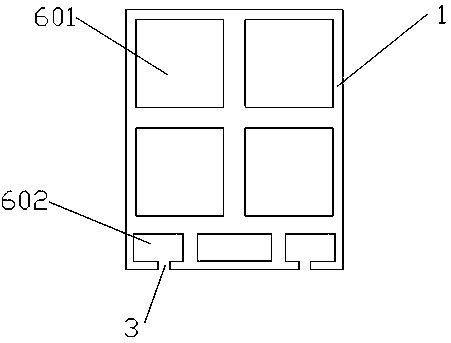

Combined plastic-wood co-extruded wall plate

The invention discloses a combined plastic-wood co-extruded wall plate, which comprises a board plate body and a connecting piece, wherein the plate body is provided with a plurality of cavities; twocavities on one side of the plate body are provided with passages; the connecting piece is a flat plate with 2 T-shaped bulges; the outer sides of all the bulges on the flat plate are provided with fixing holes; the widths of the longitudinal edges of the bulges are less than those of the passages; the lengths of the transverse edges of the bulges are more than the widths of the passages; the plate body is connected with the connecting piece through clamping the bulges into the passages. The plate body in the combined plastic-wood co-extruded wall plate can be fixedly arranged on the peripheryof a wall body in a riveting manner through the connecting piece; the use of a binder is avoided; the environment is protected, and the pollution is reduced.

Owner:江苏福瑞森塑木科技股份有限公司

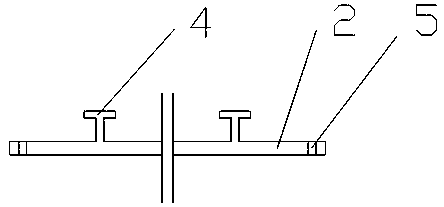

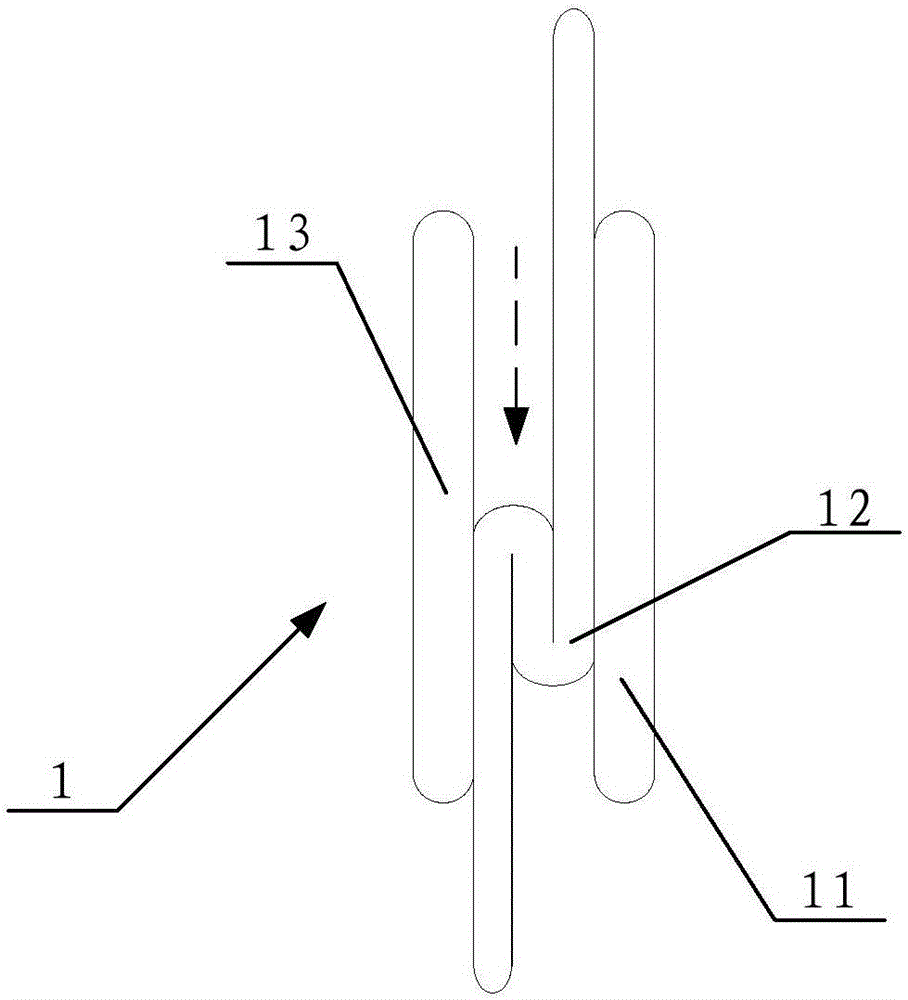

Double needle multilayer automatic return-intestine pulling cylinder and hair band sewing method using the same

InactiveCN106757835AFull Coverage GuaranteedGuaranteed packageWork-feeding meansMechanical engineeringPoor quality

The invention discloses a double needle multilayer automatic return-intestine pulling cylinder and a hair band sewing method using the same and relates to the technical field of sewing. The invention is aimed at solving the problems of poor quality, short service life and low sewing efficiency of hair bands and single matching of cloth and accessories. The double needle multilayer automatic return-intestine pulling cylinder comprises a multilayer clipping seam member, a guide support rod and a ring; one end of the guide support rod is connected to an outlet end of the multilayer clipping seam member; the guide support rod is installed corresponding to the vacant layer between a top layer and a middle layer of the multilayer clipping seam member; a guide sheet is installed on the guide support rod; the guide sheet is installed close to an outlet end of the multilayer clipping seam member; the ring is connected to the other end of the guide support rod; the multilayer clipping seam member is used for the passing through of elastic threads and multilayer cloth; the guide support rod is used for guiding the outlet direction of the elastic threads and discharging direction of cloth; the guide sheet is used for passing through the elastic threads and basically guaranteeing that elastic threads are wrapped with the cloth at the outside; the ring is used for passing through the elastic threads and cloth and further guaranteeing that the elastic threads are wrapped with the cloth at the outside.

Owner:王方根

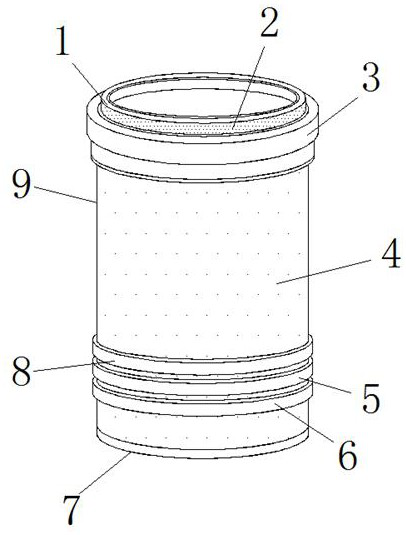

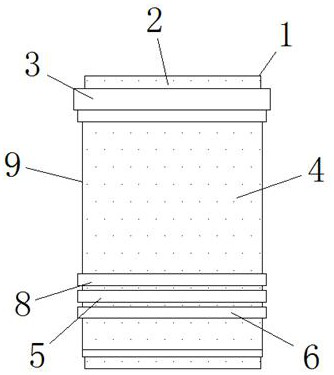

Cylinder sleeve with good sealing performance for gasoline engine

InactiveCN112196687AReasonable structureImprove sealingCylinder headsSealing arrangements for enginesGasolineRebar

The invention discloses a cylinder sleeve with good sealing performance for a gasoline engine. The cylinder sleeve comprises a cylinder sleeve top reinforcing ring, a first outer convex ring, a cylinder sleeve bottom ring opening and a cylinder sleeve body, wherein the cylinder sleeve top reinforcing ring is installed at the top end of the cylinder sleeve body, and a reinforcing structure is installed in the cylinder sleeve body; and the reinforcing structure comprises an inner partition cavity, first reinforcing steel bars, second reinforcing steel bars and reinforcing steel bar blocks. The reinforcing structure is installed in the cylinder sleeve body, the inner partition cavity is formed in the cylinder sleeve body in the using process, the reinforcing steel bar blocks are installed inthe inner partition cavity, the first reinforcing steel bars and the second reinforcing steel bars are connected to the outer walls of the reinforcing steel bar blocks, and the first reinforcing steelbars, the second reinforcing steel bars and the reinforcing steel bar blocks are distributed in a shape like a Chinese character 'mi'. The interior of the inner partition cavity is structurally filled and reinforced, so that the structural strength of the interior of the inner partition cavity is higher, supporting and wrapping are more stable, the quality of the interior in use is better, a bearing is effectively protected, and the service life of the cylinder sleeve is prolonged.

Owner:YANCHENG JIANGDONG GASOLINE ENGINE MFG +1

A New Manufacturing Method of Planar Spiral Inductor

ActiveCN106129047BReduce lossImprove insulation performanceDecorative surface effectsSemiconductor/solid-state device detailsPlanar spiral inductorsQuartz substrate

The invention relates to a novel manufacturing method of a planar spiral inductor. Manufacturing of the planar spiral inductor is carried out through a glass or quartz substrate; manufacturing of the planar spiral inductor is achieved by an MEMS technology which comprises a metal thin film deposition process, a dielectric layer thin film deposition technology, a thick metal layer plating process, a thick resist lithography process, an etching process and the like; the planar spiral inductor and the substrate do not need to be isolated by a thick insulating layer; and the plane shape of the planar spiral inductor and the thickness of a coil are not limited. Manufacturing of the planar spiral inductor is achieved by the MEMS technology on the glass or quartz substrate; the coupling effect and the skin effect between the coil and the substrate at a high frequency are avoided; a high Q-value inductor can be achieved; meanwhile, the thickness of a metal layer of an inductance coil is not limited; and the loss of the coil is low. The technology is simple; the requirements of multiple fields of a signal isolator, a planar antenna, a microwave baseband line, a planar spiral inductor resonator and the like can be met; and the process difficulty is reduced.

Owner:BEIJING MXTRONICS CORP +1

Antenna package and image display device including the same

ActiveUS20220190467A1Improve productivityExtended transmission lengthLoop antennas with ferromagnetic coreAntenna supports/mountingsElectrical connectionEngineering

An antenna package according to an embodiment of the present disclosure includes an antenna device including a dielectric layer and an antenna unit disposed on the dielectric layer, and a circuit board. The antenna unit includes a radiator and a transmission line extending from the radiator. The circuit board includes a core layer and a signal wiring disposed on the core layer and electrically connected to the antenna unit. The circuit board has a bonding region adhered to the antenna device, a signal transmission region including the signal wiring and a connect region including a connector connected to a terminal end portion of the signal wiring. A length of the transmission line of the antenna unit is greater than or equal to a length of the signal transmission region of the circuit board.

Owner:DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com