Preparation method for MoSi2 coating on surfaces of metal tantalum and alloy

A coating and metal technology, which is applied in the field of preparation of MoSi2 coating on the surface of metal tantalum, can solve the problems of low deposition efficiency, harsh operating environment, and non-dense coating, and achieve the effect of tight bonding and simple control method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments.

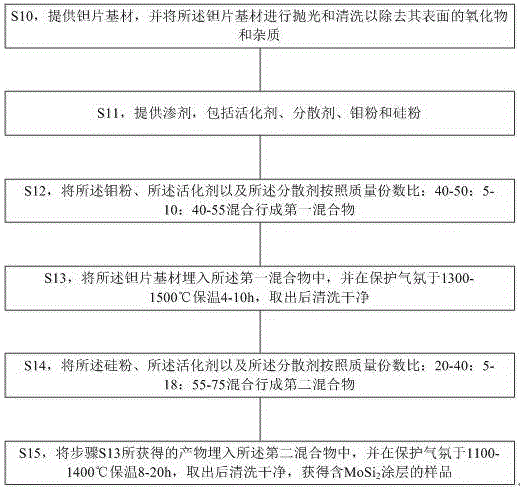

[0026] Please refer to figure 1 , the embodiment of the present invention provides a method for preparing a MoSi2 coating on a metal tantalum surface, comprising the following steps:

[0027] S10, providing a tantalum sheet substrate, and polishing and cleaning the tantalum sheet substrate to remove oxides and impurities on its surface;

[0028] S11, providing raw materials for penetrating agent, including activator, dispersant, molybdenum powder and silicon powder;

[0029] S12, mixing the molybdenum powder, the activator and the dispersant according to the ratio of parts by mass: 40-50:5-10:40-55 to form a first mixture;

[0030] S13, embedding the tantalum sheet substrate into the first mixture, keeping it warm at 1300-1500° C. for 4-10 hours in a protective atmosphere, and cleaning after taking it out;

[0031] S14, mixing the silicon powder, the activator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com