Manufacturing technology for composite elastic textiles and manufacturing equipment thereof

A technology for textile fabrics and manufacturing processes, applied in textiles and papermaking, cutting of textile materials, non-woven fabrics, etc., can solve the problems of inability to limit the elastic stretching range, unreasonable equipment manufacturing design, poor water absorption and wear resistance, etc. To achieve the effect of easy implementation, simple structure and thick structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

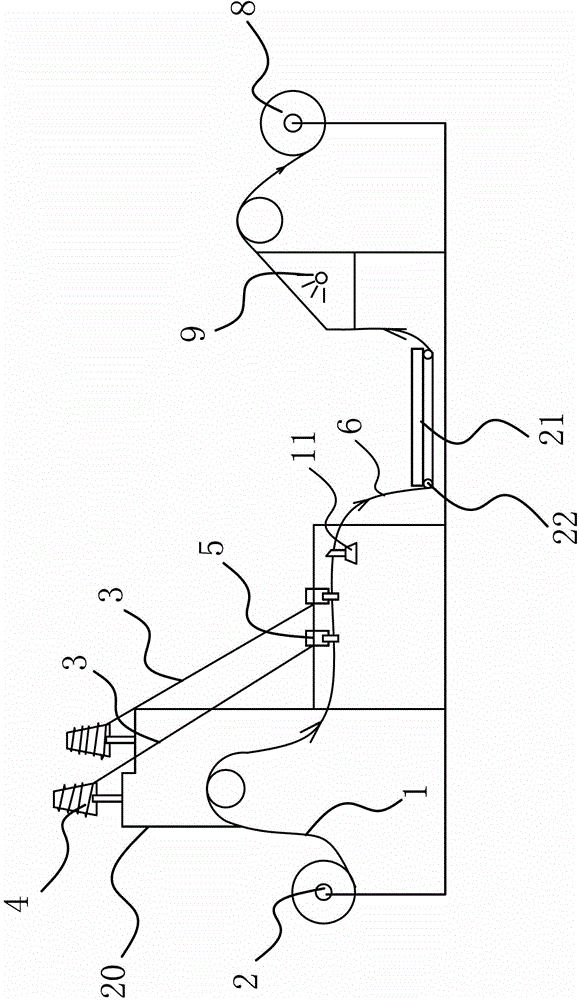

[0029] Such as Figure 1-2 Shown, this composite elastic textile fabric manufacturing process comprises the following steps:

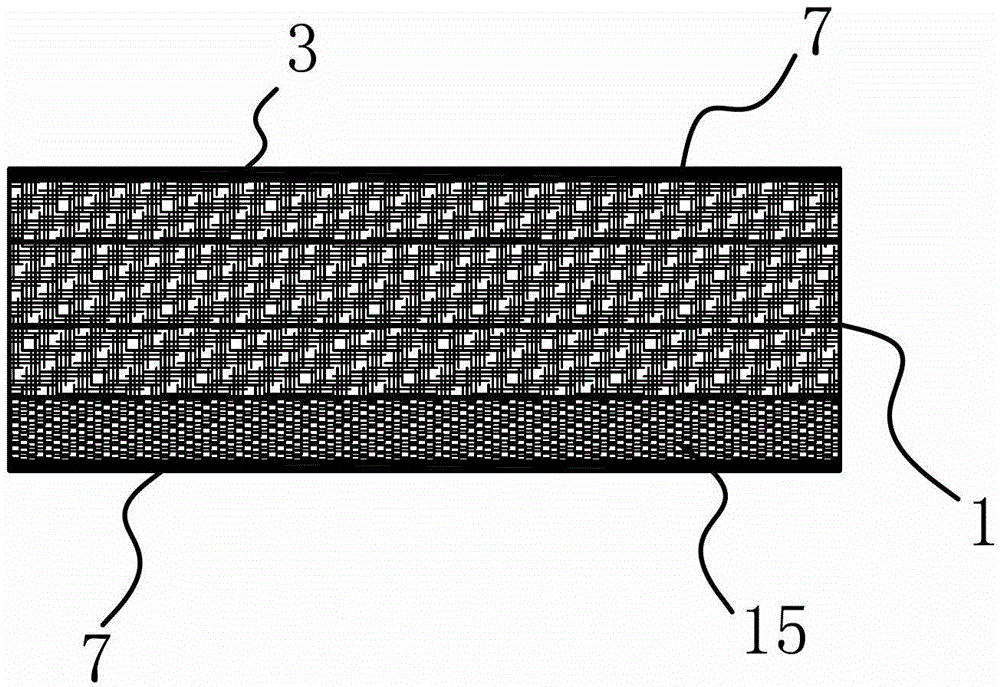

[0030] A. Feeding: Place the base cloth 1 on the feeding mechanism 2 of the manufacturing equipment, select at least two elastic yarns 3 and have at least two elastic yarns 3 with different elasticity, and place the yarns 3 on the manufacturing equipment. On the pay-off mechanism 4 of the equipment. In this embodiment, the selected yarns 3 include two types, one of which is a low-elasticity yarn 16 and the other is a high-elasticity yarn 17 . This structure allows the composite elastic textile fabric to have both good elasticity and a limited range of stretch.

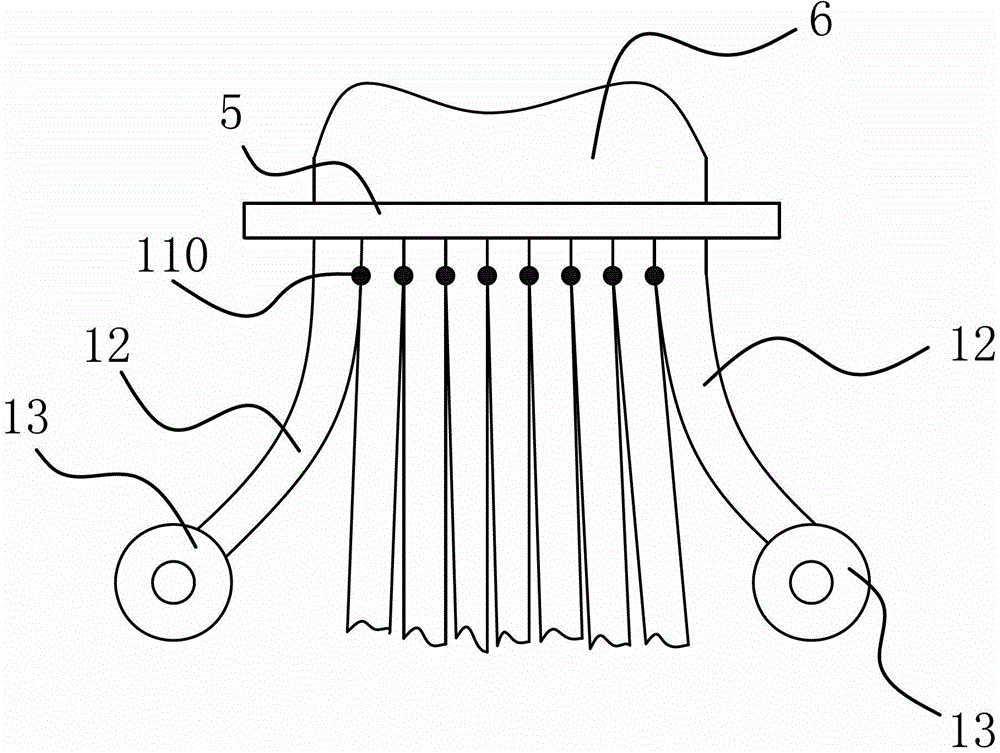

[0031] B. Weaving: use the weaving mechanism 5 of the manufacturing equipment to weave independently on the base cloth 1 to make a wide-width composite elastic textile fabric 6; According to the feeding direction of the base fabric 1 and the side strips 15 whose weaving density is greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com