Novel manufacturing method of planar spiral inductor

The technology of a planar spiral and manufacturing method is applied in the direction of inductors, processes for producing decorative surface effects, circuits, etc., and can solve the problems of inductance, inductance coil metal layer thickness limitation, and lining that are difficult to achieve high Q value and S21 parameter. Increased bottom loss and other issues, achieving device performance consistency, easy control, avoiding conduction current and eddy current effects, and reducing substrate loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

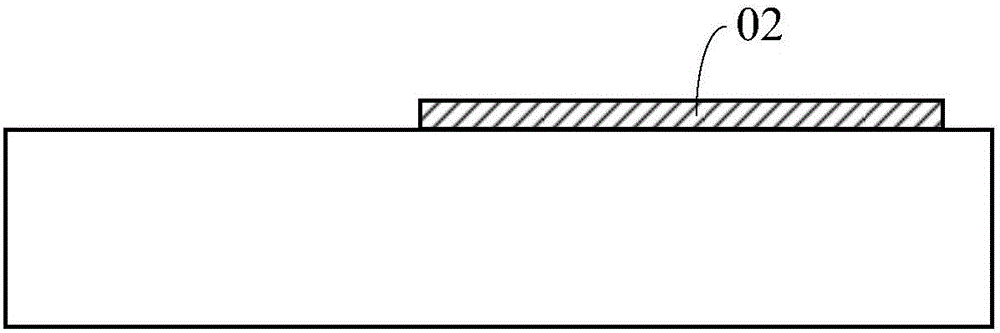

[0035] The basic idea of the invention is: the invention relates to a novel manufacturing method of a planar spiral inductor. The manufacturing method, the steps are as follows: ① use glass or quartz substrate to carry out the manufacture of planar spiral inductors; ② use MEMS technology, including metal film deposition process, dielectric layer film deposition process, thick metal layer electroplating process, thick glue light Engraving process, etching process, etc. to realize the production of planar spiral inductors; ③ There is no need for a thick insulating layer to isolate the planar spiral inductor from the substrate; ④ The planar shape and coil thickness of the planar spiral inductor are not limited. The present invention uses MEMS technology to realize the fabrication of planar spiral inductors on glass or quartz substrates, avoids the coupling and skin effect between the coil and the substrate at high frequencies, and can realize high-Q inductance, while the inducta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com