Manufacturing method of bamboo chair

A production method and technology of bamboo chairs, which are applied in the field of bamboo product manufacturing, can solve the problems of durability and poor stability of bamboo chairs, and achieve the effect of simple and convenient production, excellent stability, and maintaining texture and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

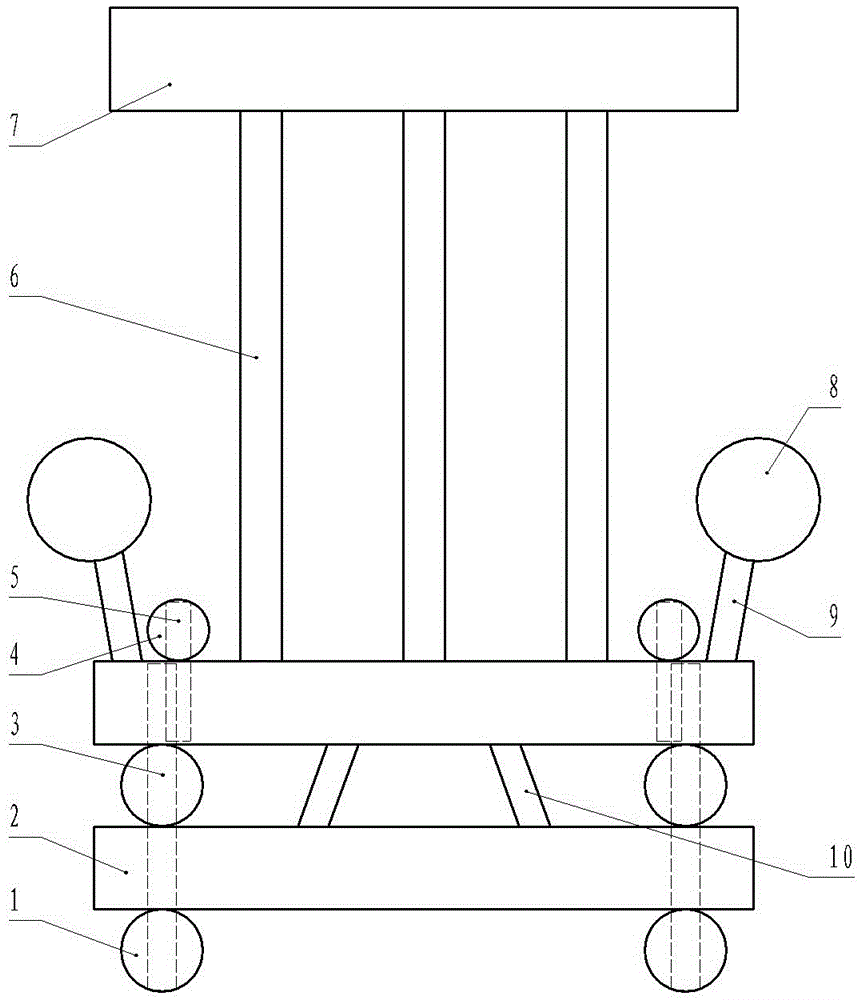

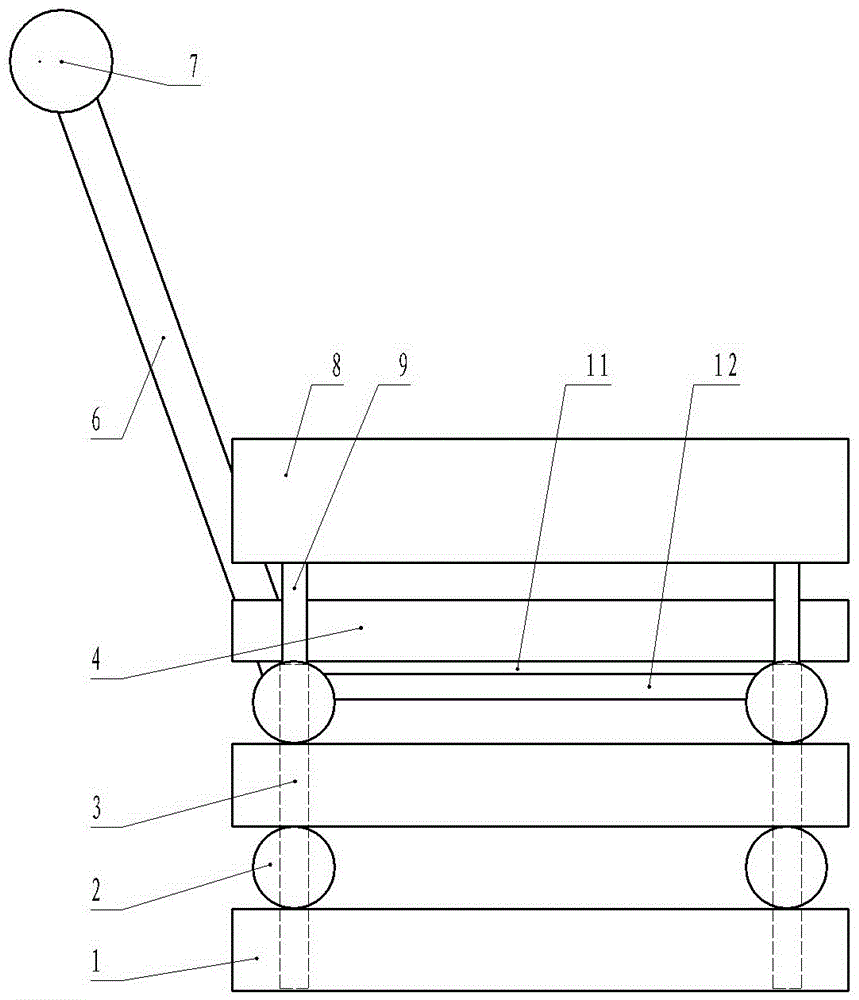

[0028] A kind of manufacture method of bamboo chair, this bamboo chair is as figure 1 , figure 2 As shown, including a seat and a chair back, the seat has two rectangular frames that are arranged up and down, the rectangular frame has two vertical bamboo tubes 1 and two horizontal bamboo tubes 2 above it, the vertical bamboo tube 1 and the horizontal bamboo tube 2 Through the fixed connection of four vertical rods 3, two support rods 10 are installed between the horizontal bamboo tubes 2 arranged up and down; a seat plate 11 is installed between the two horizontal bamboo tubes 2 on the upper part, and the seat plate 11 is spliced by several bamboo pieces Formed; on the top of the seat plate 11, two bamboo pressure cylinders 4 arranged vertically are installed, and the two bamboo pressure cylinders 4 are respectively fixed on the upper ends of the adjacent two horizontal bamboo cylinders 2 through bamboo pins 5, and the bottom of the seat plate 11 is equipped with embedded ...

Embodiment 2

[0040] The difference between the present embodiment and embodiment 1 is: the specific steps of insect control treatment are as follows:

[0041] (1) Take 1.5 kg of tobacco leaves, 1 kg of jasmine leaves, 1.2 kg of pepper leaves, 0.6 kg of alum, 1.3 kg of salt, and 0.5 kg of bleaching powder, put them into 60 kg of water and boil for 40 minutes, and obtain the filtrate after filtering;

[0042] (2) Add 120 kg of water into the soaking tank, pour the obtained filtrate into the soaking tank and stir evenly, put the parts to be assembled into the soaking tank and soak for 3 days;

[0043] (3) Take out the parts to be assembled, put them in the drying room, and dry them for 36 hours at a temperature of 70°C;

[0044] (4) Put the dried parts to be assembled into a microwave dryer, and irradiate them with microwaves for 3 minutes at a temperature of 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com