Warp-knitted fully-shaped side-seam-free T-shirt and weaving method thereof

A fully forming, side seam technology, applied in the direction of warp knitting, textiles, papermaking, knitting, etc., can solve the problems of single structure of warp knitted seamless fabrics, adverse effects on product appearance, and inability to meet fabrics, etc., to achieve rich changes and sizes. Stable, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings.

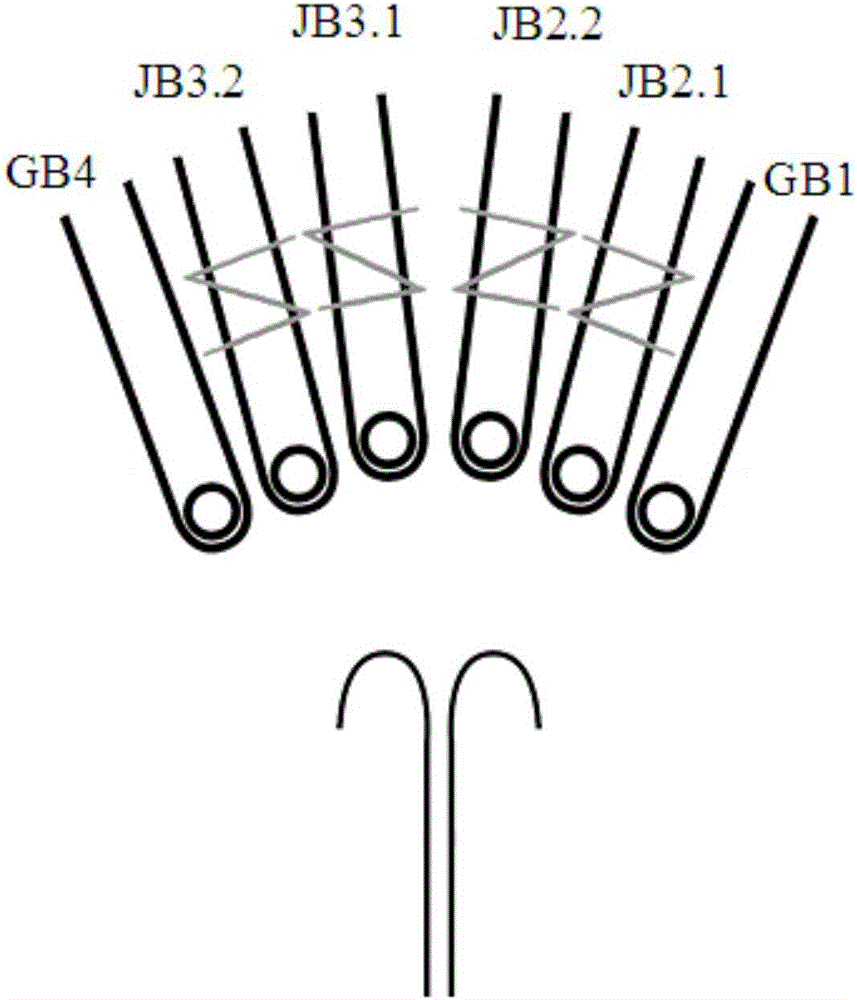

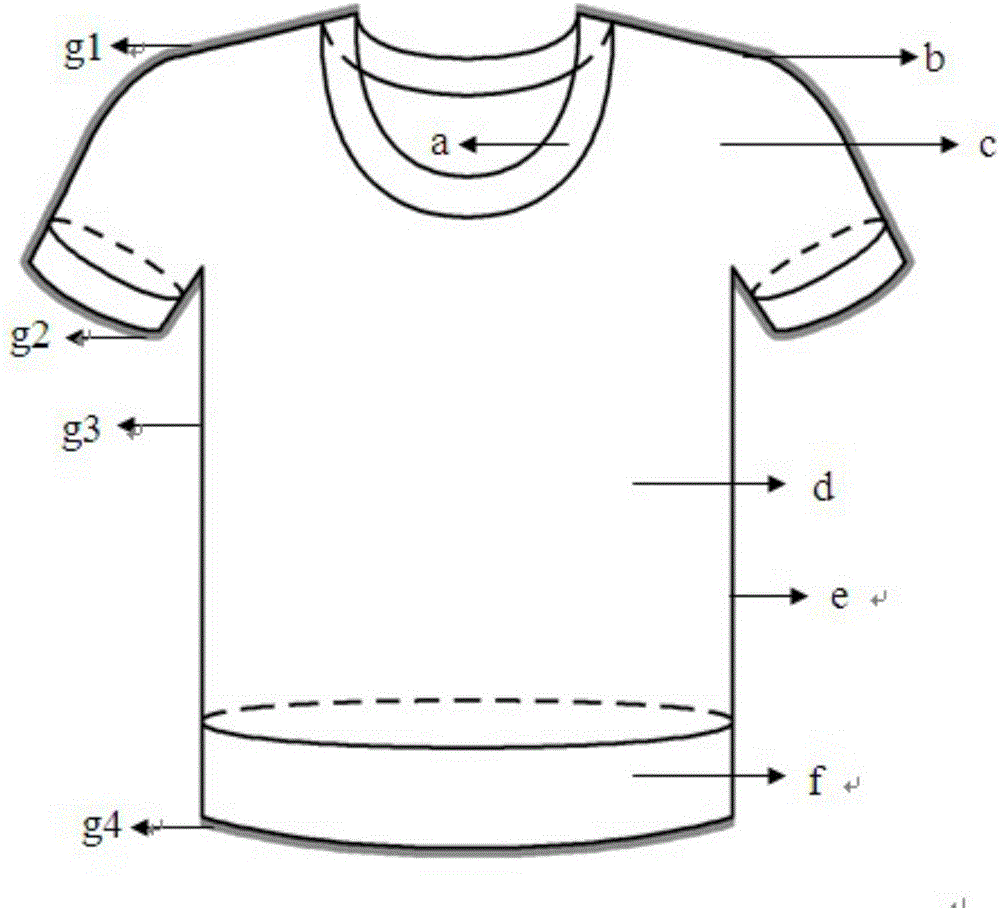

[0039] like figure 2As shown, the warp-knitted fully formed non-side seam T-shirt of the present invention has a short-sleeved one-piece raglan sleeve structure, and the main body and sleeves of the T-shirt are a one-piece cylindrical structure without any cutting and sewing dividing lines. The inclination is consistent with the shoulder of the human body, and the inclination of the sleeve is consistent with the regular movement needs of the human arm.

[0040] like figure 2 As shown, the warp knitted fully formed short-sleeved T-shirt without side seams of the present invention comprises a collar a, a shoulder b, a raglan sleeve c, a body d, a side seam e and a hem f, and the T-shirt consists of Composed of two front and rear pieces; the shoulder connection g1 is formed by the thick stitched tissue of the shoulder b between the front and rear pieces on both sides of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com