Coalcutter coal rock distribution recognition device and method adopting terahertz imaging technology

A technology of terahertz imaging and coal mining machines, applied in mining equipment, testing machinery, mining equipment, etc., can solve unsatisfactory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

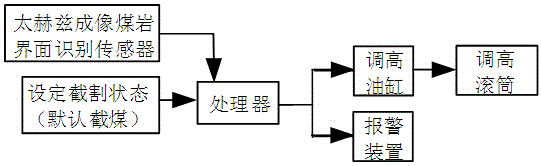

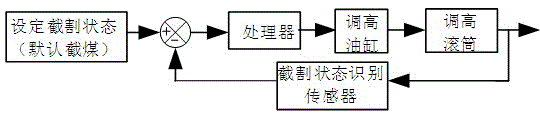

[0015] Such as figure 1 As shown, the coal shearer coal-rock distribution recognition device using terahertz imaging technology includes a terahertz imaging coal-rock interface recognition sensor, a processor, a height-adjusting oil cylinder, a height-adjusting roller, and an alarm device. The output signal of the terahertz imaging coal-rock interface recognition sensor is sent to the processor, the processor outputs the signal to the height adjustment cylinder, the height adjustment oil cylinder outputs the signal to the height adjustment roller, or the processor outputs the signal to the alarm device. The processor memory has the parameters of the set cutting state (default coal cutting) of the drum at each cutting position. The terahertz imaging coal and rock distribution recognition sensor identifies the coal and rock distribution at each cutting position of the next cutting cycle of the shearer, and outputs the recognition result to the processor. Rock distribution reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com