Wood board surface machining treatment device

A surface processing and processing device technology, which is applied in the direction of wood processing equipment, grinding drive devices, metal processing equipment, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effect of simple continuous processing, easy operation and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

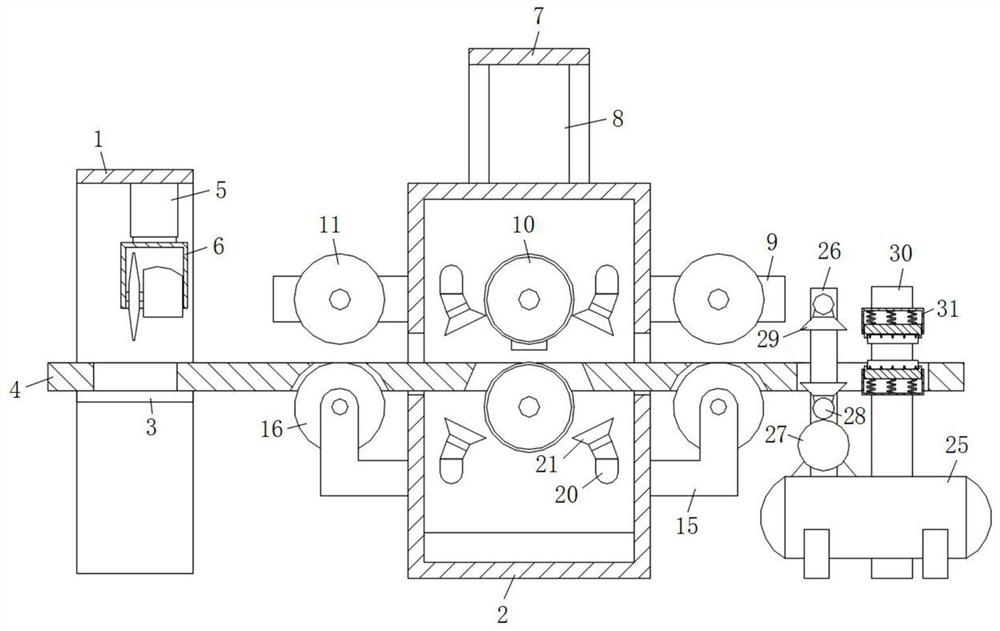

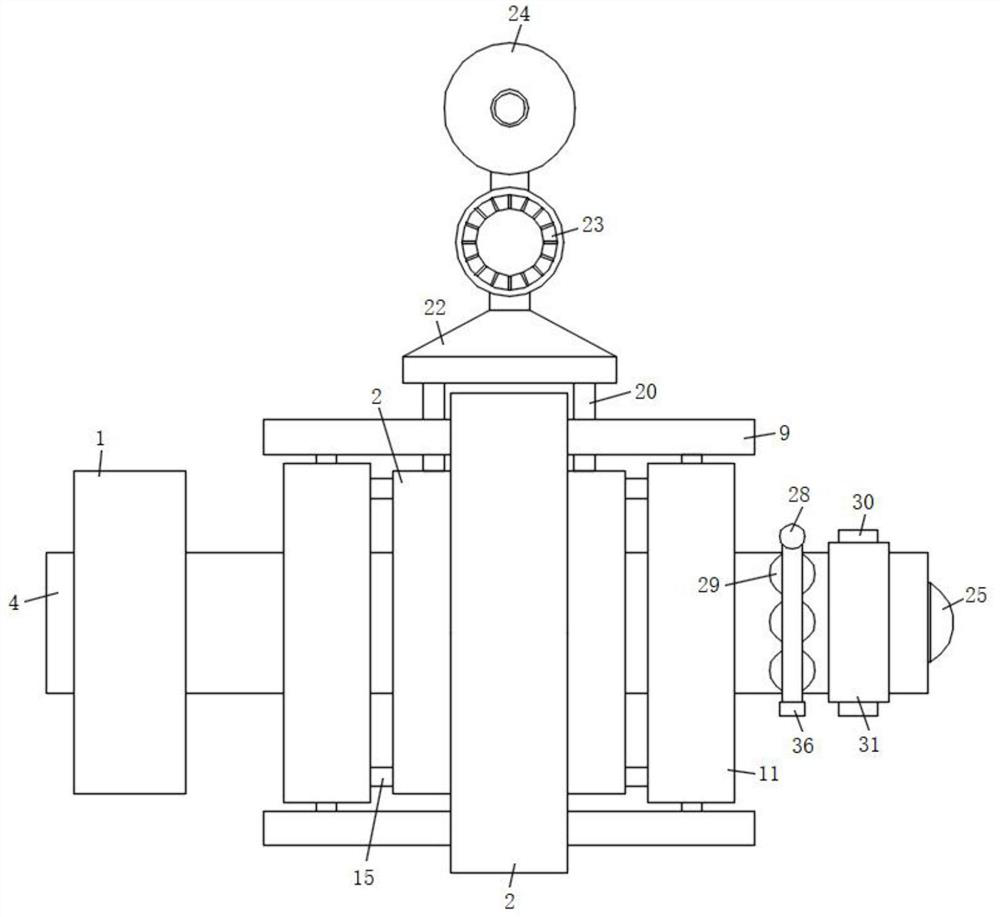

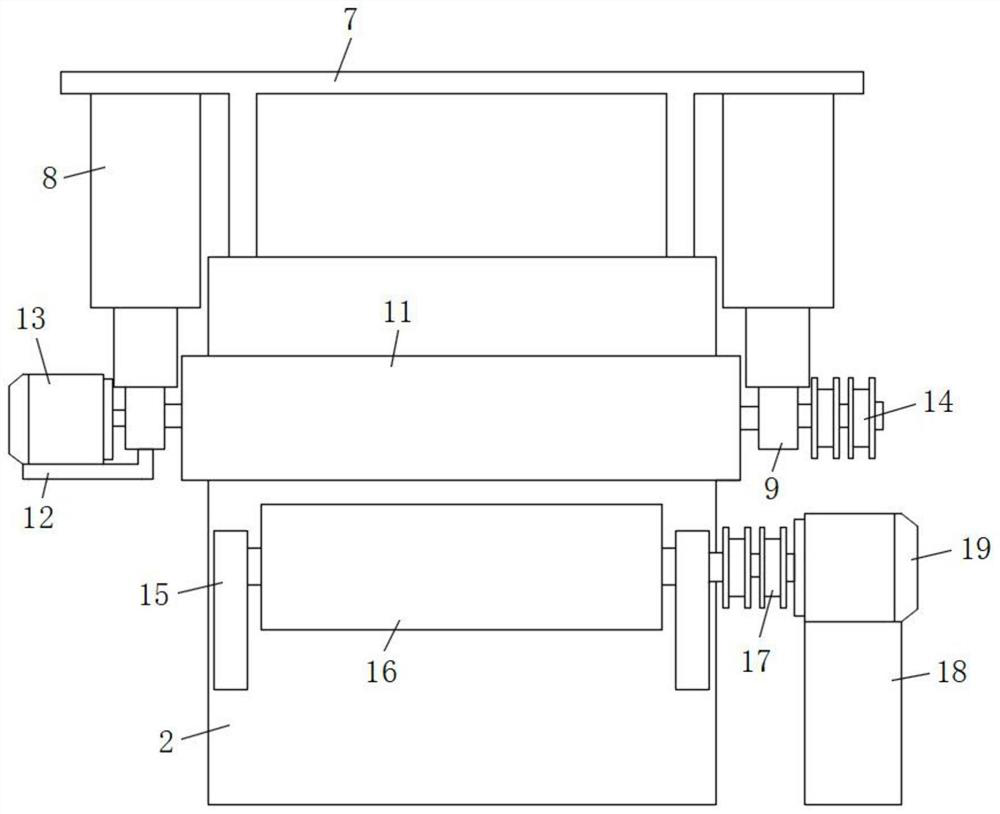

[0031] refer to Figure 1-4 , a wood surface processing device, including a cutting frame 1 and a grinding chamber 2, the middle part of the inner wall of the front and rear ends of the cutting frame 1 is also fixedly connected with a support plate 3, and both sides of the grinding chamber 2 are provided with rectangular holes, and the rectangular holes A working plate 4 is also fixedly connected between the inner bottom surface and the top surface of the support plate 3, and the inner top surface of the cutting frame 1 is also fixedly connected with a cylinder one 5 by screws, and the output end of the cylinder one 5 is fixedly connected with a cutting machine 6 by screws, and the grinding The top surface outside the room 2 is also fixedly connected with a mounting frame 7, the front and rear sides of the bottom of the mounting frame 7 are fixedly connected with a cylinder 2 8 by screws, and the output ends of the cylinder 2 8 are all connected with a mounting strip 9 by screw...

Embodiment 2

[0034] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are four dust suction pipes 20 distributed on both sides of the grinding roller 10, and the dust collecting funnels 21 are all directed from the outside of the grinding room 2 to the center of the grinding room 2. Tilt setting.

[0035] In this embodiment, dust collecting funnels 21 are arranged on both sides of the grinding roller 10, so that the dust after the plank is polished can be absorbed in time, and the working environment for plank processing is well guaranteed.

Embodiment 3

[0037] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the upper part of the front and rear end side walls of the grinding chamber 2 is provided with a strip groove, and the rotating shaft of the grinding roller 10 is slidably connected in the strip groove, and the two sides of the working plate 4 The sides extend to the positions outside the cutting frame 1 and the grinding chamber 2 respectively.

[0038] In the present embodiment, the upper part of the front and rear end side walls of the grinding chamber 2 is provided with a bar-shaped groove, and the rotating shaft of the grinding roller 10 is slidably connected in the bar-shaped groove, thereby facilitating the adjustment of the position of the grinding roller 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com