Medical scalpel cutting edge grinding device

A grinding and cutting edge technology, applied in the field of medical scalpel edge grinding devices, can solve problems such as low efficiency and difficulty in ensuring product quality stability, and achieve the effects of reducing energy consumption, product quality stability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

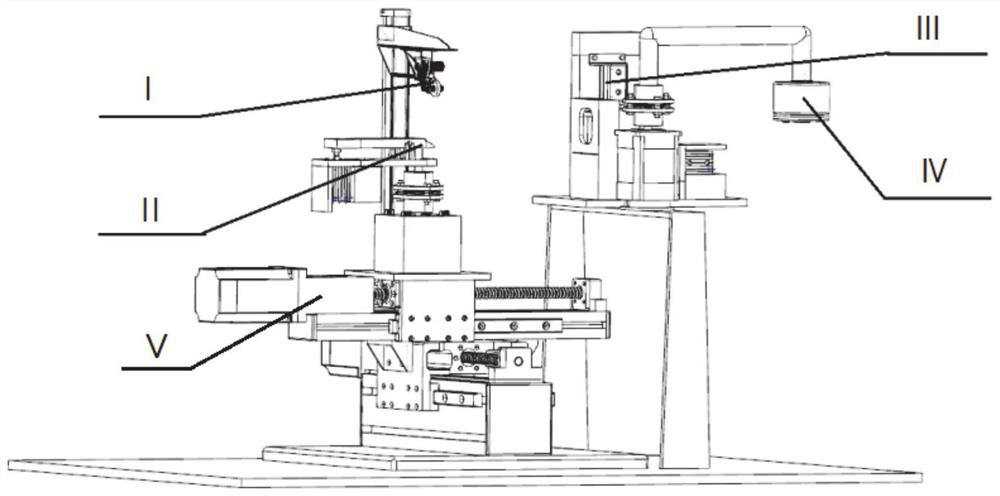

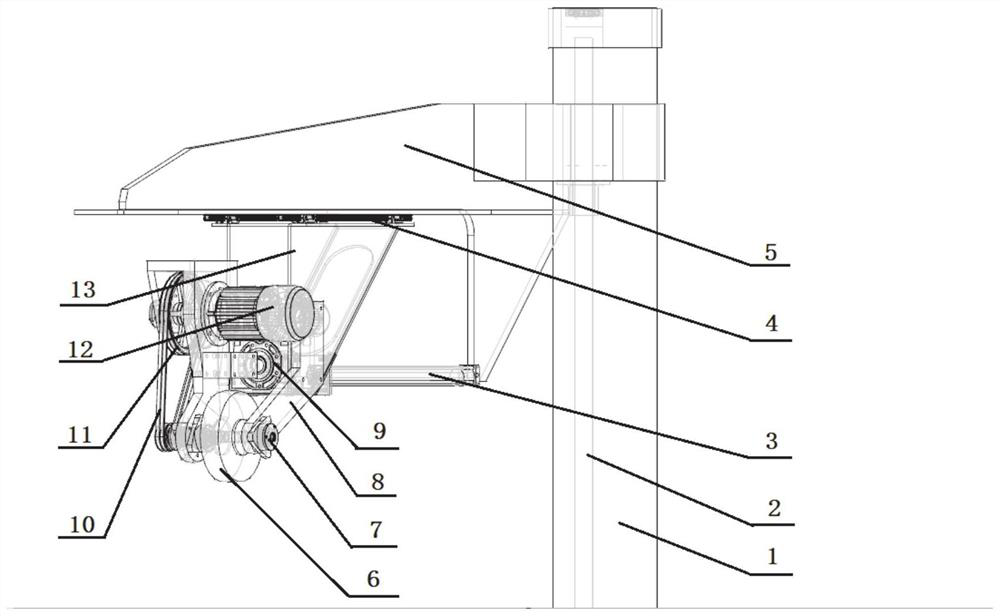

[0037] In a typical embodiment of the present invention, such as Figure 1-Figure 5 As shown, a medical scalpel edge grinding device is proposed, including grinding mechanism I, clamping mechanism II, loading mechanism III, and unloading mechanism IV; wherein, the bottom of the clamping mechanism is set on the two-dimensional mobile platform V, The grinding mechanism I is correspondingly arranged above the clamping mechanism II, and the loading mechanism III and the unloading mechanism IV are arranged at the relative positions of the clamping mechanism II, and the loading mechanism, the unloading mechanism and the clamping mechanism are separated by a certain distance.

[0038] The bottom of the loading mechanism and the unloading mechanism can be arranged on the bracket, so that the height of the loading mechanism, the unloading mechanism and the clamping mechanism correspond; the bracket and the bottom of the two-dimensional mobile platform can be fixed on the workbench.

[...

Embodiment 2

[0064] Propose a kind of working method of medical scalpel edge grinding device in the present embodiment, comprise the following steps:

[0065] Step 1: put the blade to be ground into the tool holder 23, and press it under the action of the blade pressing plate 25, and push the blade out from the tool holder 23 under the combined action of the pusher cylinder 22 and the pusher plate 21;

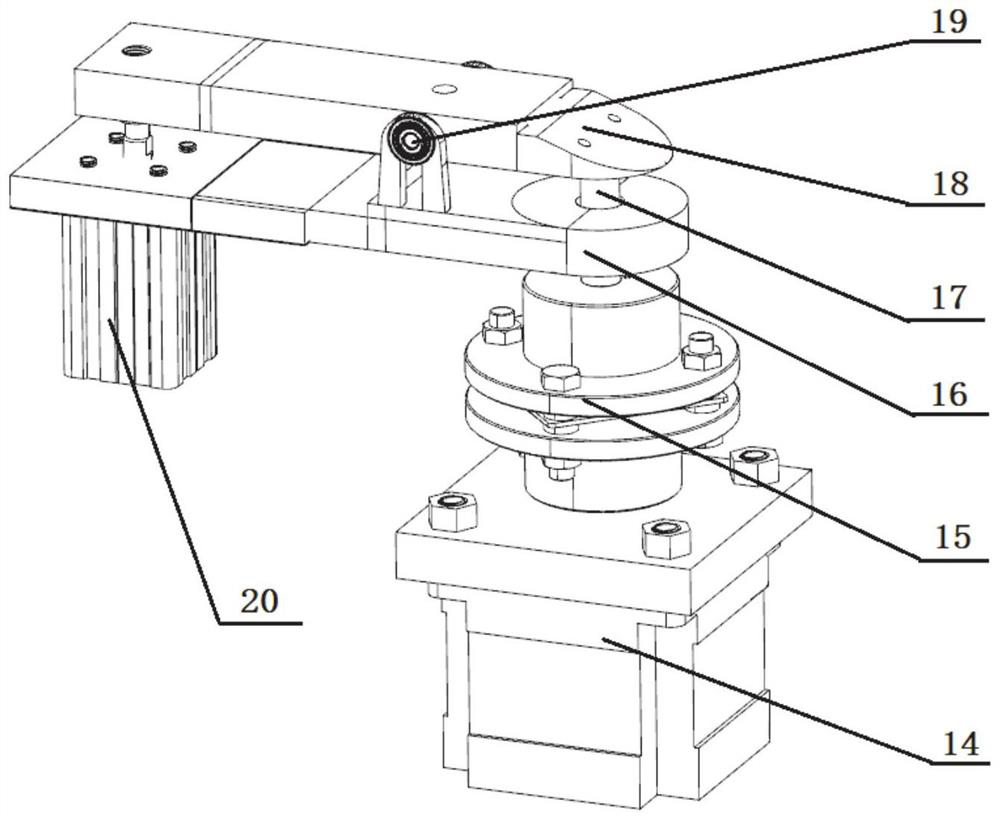

[0066] Step 2: The two-dimensional mobile platform carries the duckbill-shaped clamping end 18 and moves to the knife-out position, when the right end of the duckbill-shaped clamping end 18 moves downward with the help of the clamp booster cylinder 20 to combine with the clamp base and When locked, the clamping of the blade is completed. At this time, the gas spring 17 located under the clamping end is compressed, and the elastic force of the gas spring 17 is given by the clamp power cylinder 20 through the upper end of the clamp. The clamp power cylinder is locked and clamped. The end clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com