An integrated processing device for NdFeB magnets

A processing device, NdFeB technology, applied in metal processing, feeding device, metal processing equipment and other directions, can solve the problems of difficult processing, low processing efficiency, simultaneous processing, etc., to achieve simple operation, high grinding efficiency, and high integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

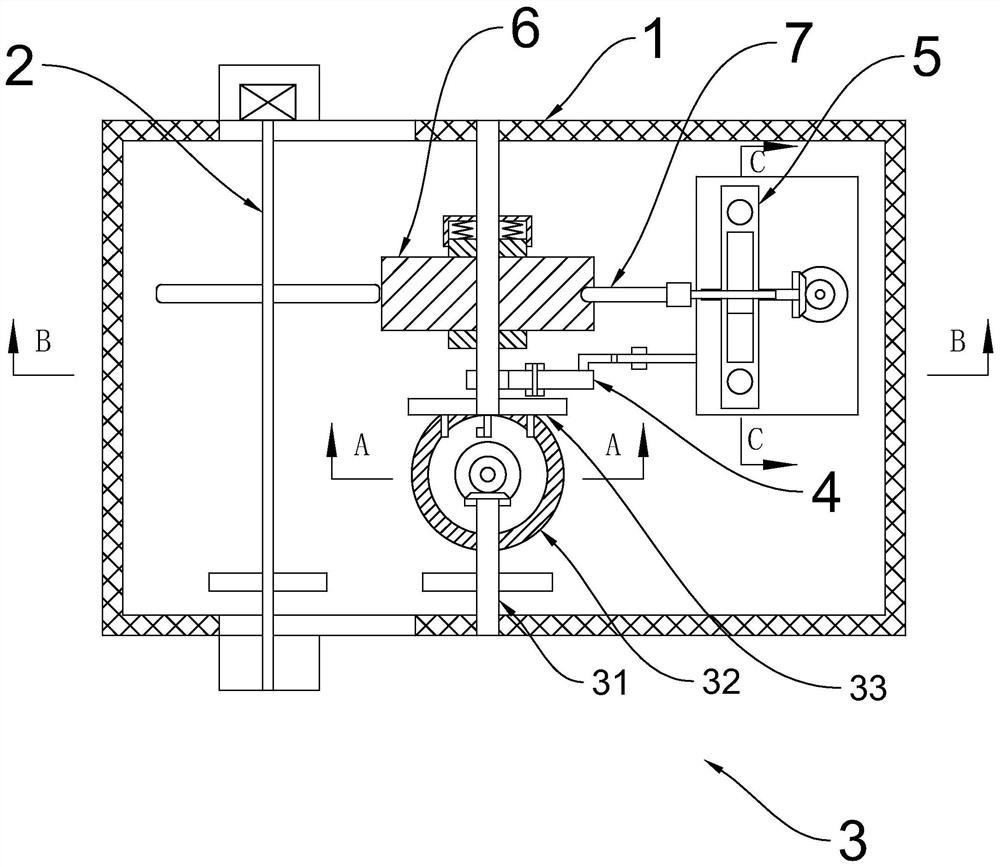

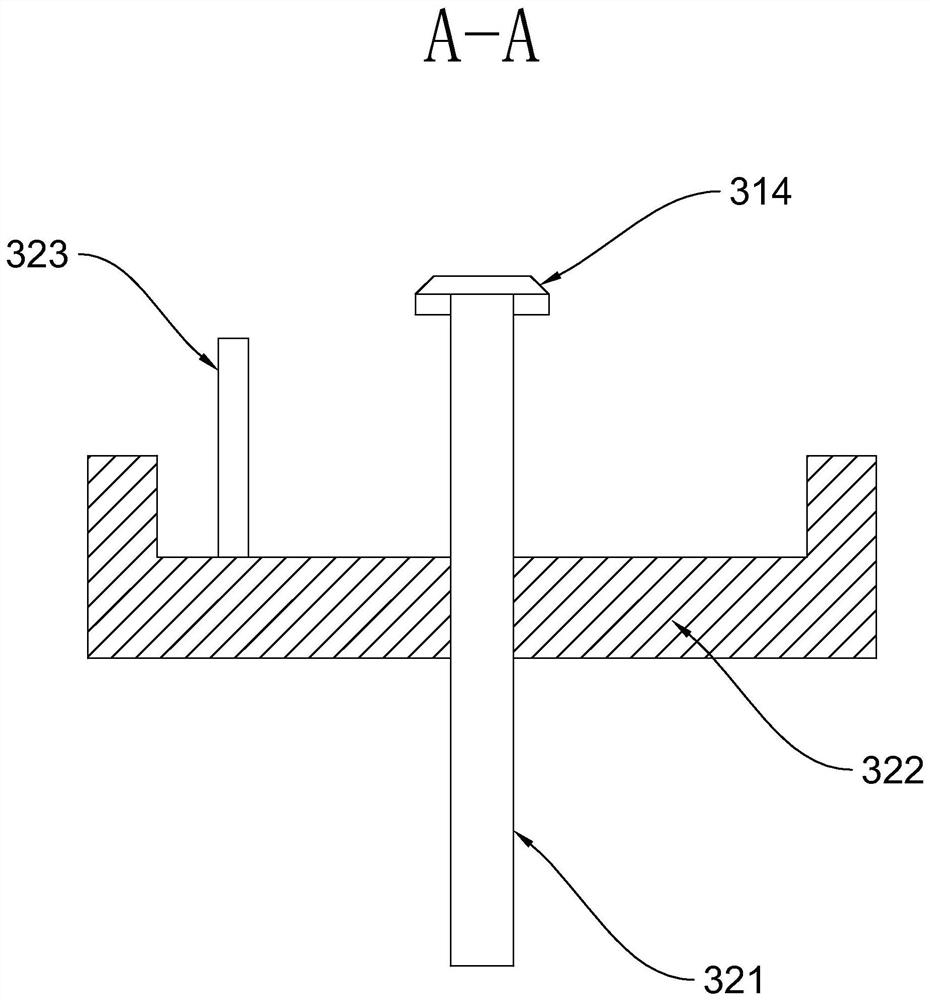

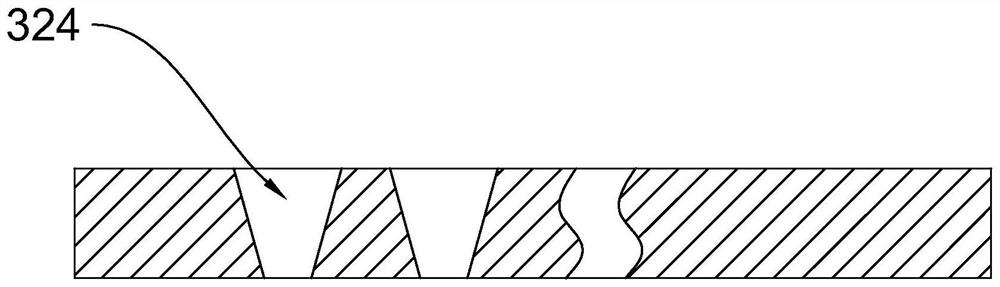

[0030] Such as Figure 1 to Figure 9As shown, an integrated processing device for NdFeB magnets, the integrated processing device includes a stand 1, a cutting assembly 2, a steering mechanism 3, a lifting mechanism 5, a traction mechanism 4 and a grinding assembly 7; the steering mechanism 3 It includes a steering drive mechanism 31, a runner 32 and a special-shaped steering wheel 33, and the special-shaped steering wheel 33 is installed side by side with the workpiece 6 on the seventh rotating shaft 601 arranged in the horizontal direction; the steering drive mechanism 31 and the cutting assembly 2 The first gear 205 is meshed and driven, and the steering drive mechanism 31 drives the special-shaped steering wheel 33 to rotate through the runner 32; the cutting assembly 2 and the grinding assembly 7 are respectively provided on both sides of the workpiece 6; The cutting assembly 2 moves horizontally along the chute 101 on both sides of the platform 1, the grinding assembly 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com