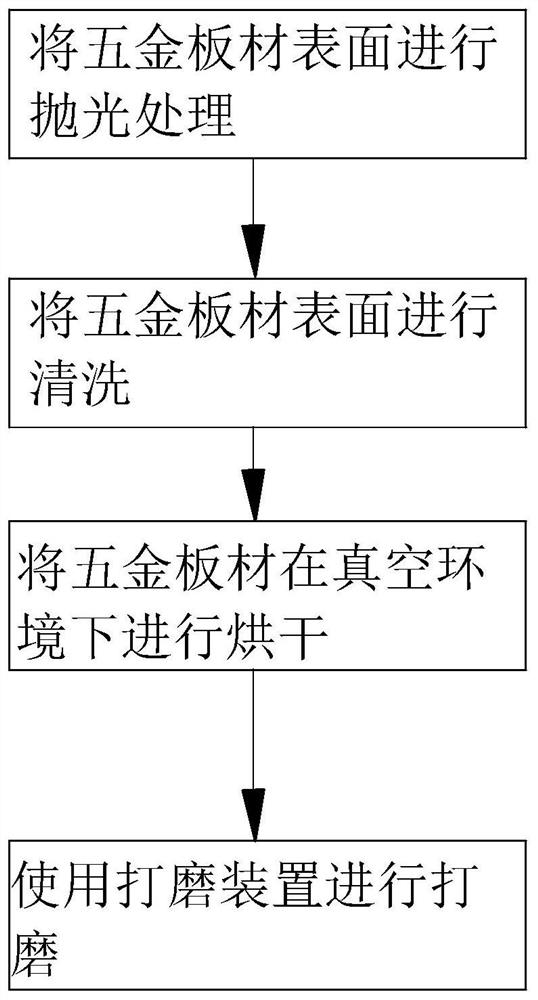

A kind of plate surface treatment process

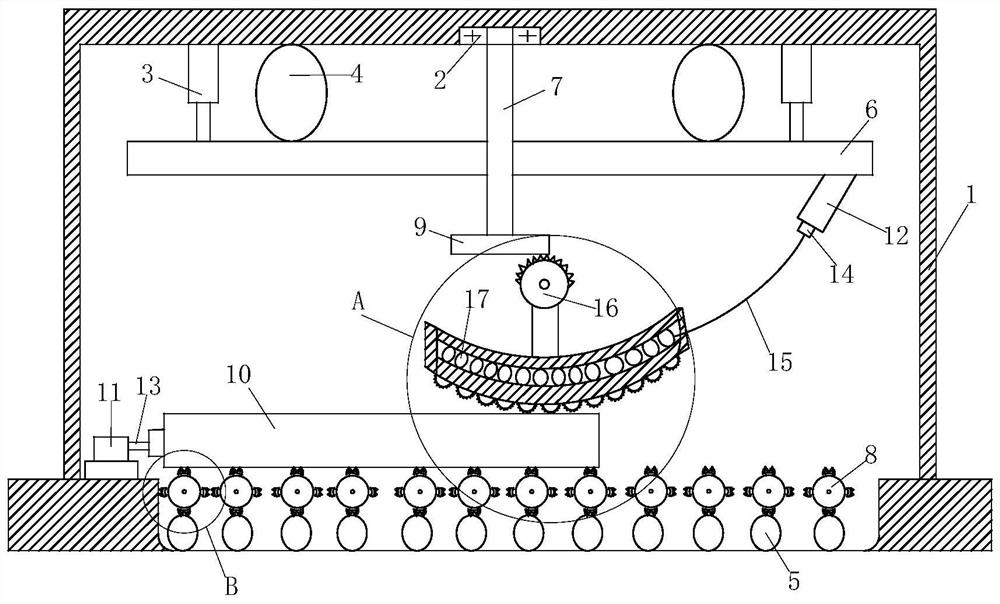

A technology of surface treatment and sheet metal, which is applied in the direction of manufacturing tools, metal processing equipment, and machine tools suitable for grinding workpiece planes, etc. It can solve the problems of machine running stuck, poor grinding quality, and low grinding efficiency, and achieve good grinding quality , High grinding efficiency, the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

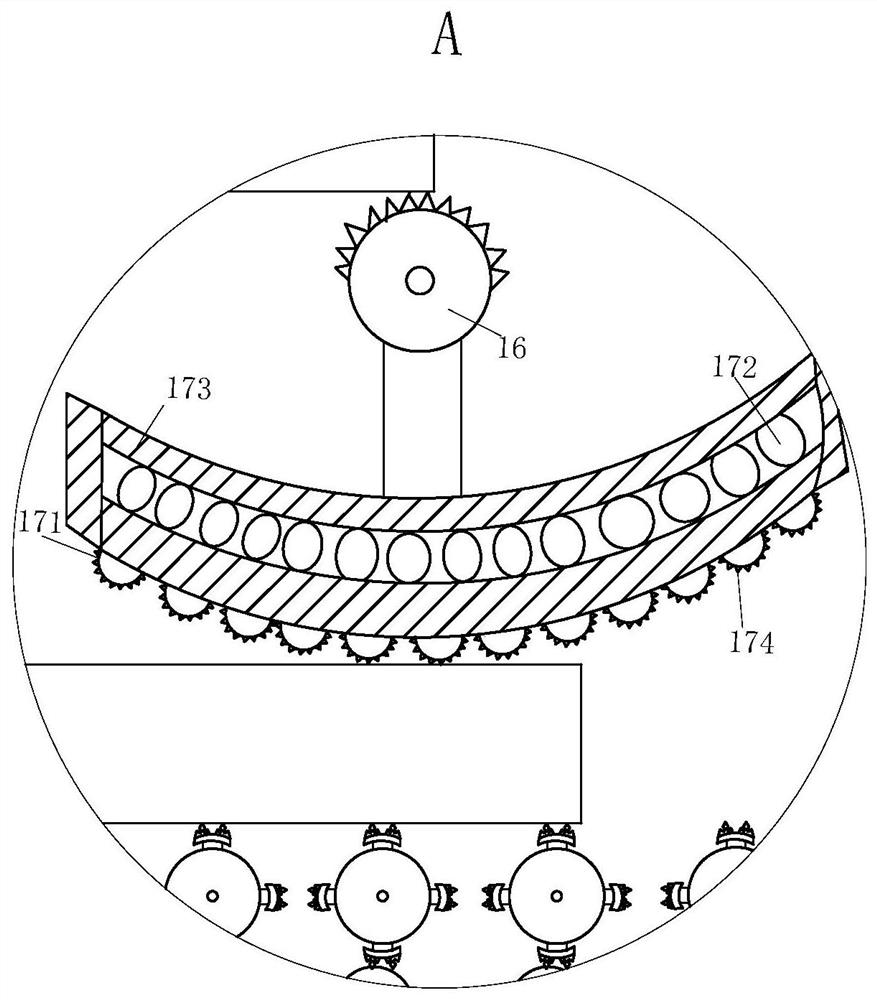

[0038] As an embodiment of the present invention, the arc grinding plate 17 includes a grinding surface 171, air holes, a third air bag 172 and a fixed plate 173; the third air bag 172 is arranged in the middle of the arc grinding plate 17, and the third air bag 172 Sandwiched between two fixed plates 173; the grinding surface 171 is located on the lower surface of the fixed plate 173 to improve the grinding effect; the air hole is located in the middle of the two grinding surfaces 171, and the air hole communicates with the third airbag 172, which can increase the heat dissipation rate and improve the grinding effect. Effect. During work, the arc grinding plate 17 grinds the metal plate 10, and the No. 3 air bag 172 shrinks, which can prevent the hardware plate 10 and the arc grinding plate 17 from being stuck. This structure improves the grinding efficiency and increases the service life of the machine.

[0039] As an embodiment of the present invention, the grinding surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com