Composite carbon source for sewage denitrification as well as preparation and using methods of composite carbon source

A composite carbon source, denitrification technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

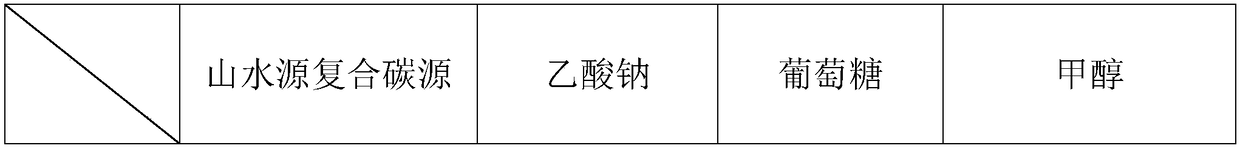

[0069] A composite carbon source for sewage denitrification may also include the following raw materials in parts by weight:

[0070] 5 parts of 25% sodium acetate solution,

[0071] 3 parts of 40% glucose solution,

[0072] Concentration is 4 parts of xylitol solution of 60%,

[0073] 22 parts of glycerol,

[0074] 15 parts of methanol with a purity of 99%,

[0075] 1 part ethanol,

[0076] 10 parts of ethylene glycol,

[0077] 3 parts of glacial acetic acid,

[0078] Active peptide 1 part,

[0079] The concentration is 10 parts of 42% compound amino acid solution.

[0080] Said composite carbon source for sewage denitrification, said composite amino acid is a mixture of glycine Gly, serine Ser, tyrosine Tyr, glutamine Gln, and alanine Ala.

[0081] The preparation method of the composite carbon source for denitrification of sewage comprises the following process:

[0082] S1. Prepare raw materials: take 5 parts of sodium acetate solution with a concentration of 25%,...

Embodiment 2

[0085] A composite carbon source for sewage denitrification may also include the following raw materials in parts by weight:

[0086] Concentration is 15 parts of sodium acetate solution of 35%,

[0087] Concentration is 8 parts of dextrose solution of 45%,

[0088] Concentration is 6 parts of xylitol solution of 65%,

[0089] 28 parts of glycerol,

[0090] 25 parts of methanol with a purity of 99%,

[0091] 4 parts ethanol,

[0092] 15 parts of ethylene glycol,

[0093] 6 parts of glacial acetic acid,

[0094] Active peptide 5 parts,

[0095] The concentration is 14 parts of 48% compound amino acid solution.

[0096] Said composite carbon source for sewage denitrification, said composite amino acid is a mixture of glycine Gly, serine Ser, tyrosine Tyr, glutamine Gln, and alanine Ala.

[0097] The preparation method of the composite carbon source for denitrification of sewage comprises the following process:

[0098] S1. Prepare raw materials: take 15 parts of sodium ...

Embodiment 3

[0101] A composite carbon source for sewage denitrification may also include the following raw materials in parts by weight:

[0102] Concentration is 30% sodium acetate solution 10 parts,

[0103] 5 parts of 45% glucose solution,

[0104] Concentration is 5 parts of xylitol solution of 65%,

[0105] 25 parts of glycerol,

[0106] 20 parts of methanol with a purity of 99%,

[0107] 3 parts ethanol,

[0108] 12 parts of ethylene glycol,

[0109] 5 parts of glacial acetic acid,

[0110] 3 active peptides,

[0111] The concentration is 12 parts of 45% compound amino acid solution.

[0112] Said composite carbon source for sewage denitrification, said composite amino acid is a mixture of glycine Gly, serine Ser, tyrosine Tyr, glutamine Gln, and alanine Ala.

[0113] The preparation method of the composite carbon source for denitrification of sewage comprises the following process:

[0114] S1. Prepare raw materials: take 10 parts of sodium acetate solution with a concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com