Belt conveyor dust suppression device

A belt conveyor, water pump motor technology, applied in conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of high powder content, dust at the blanking point, material drop, etc., and achieve good applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

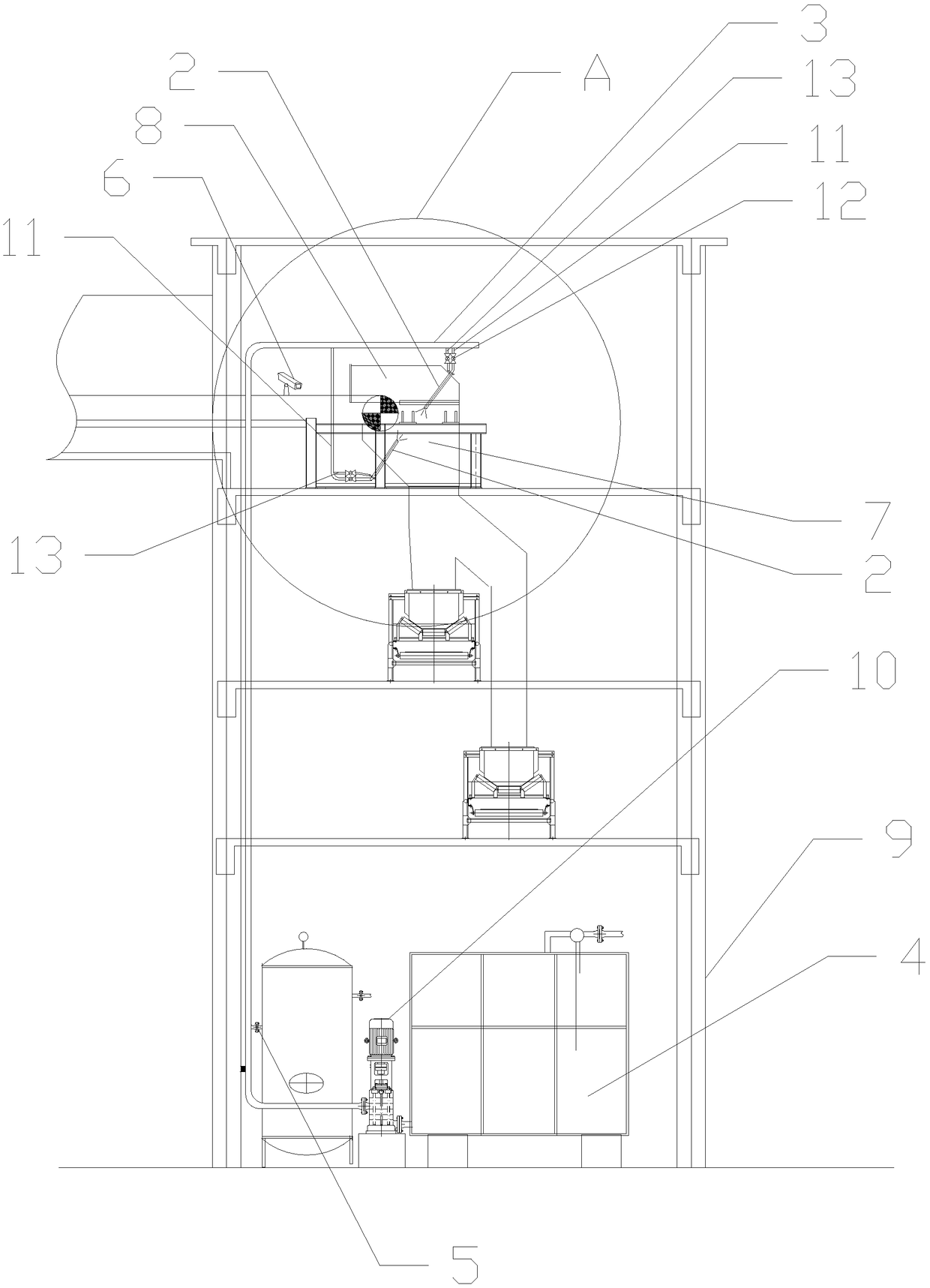

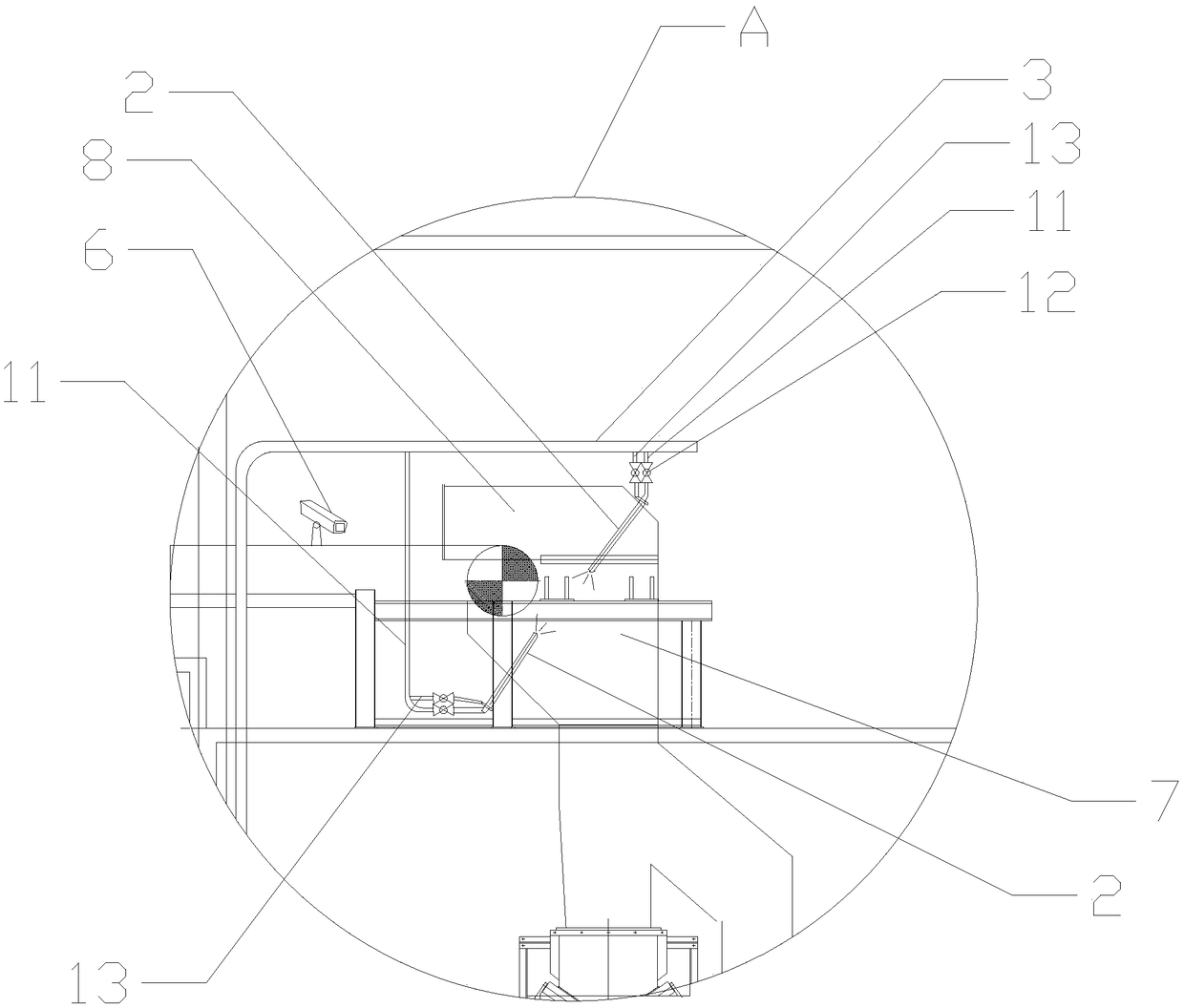

[0014] The present invention is described in further detail now in conjunction with accompanying drawing.

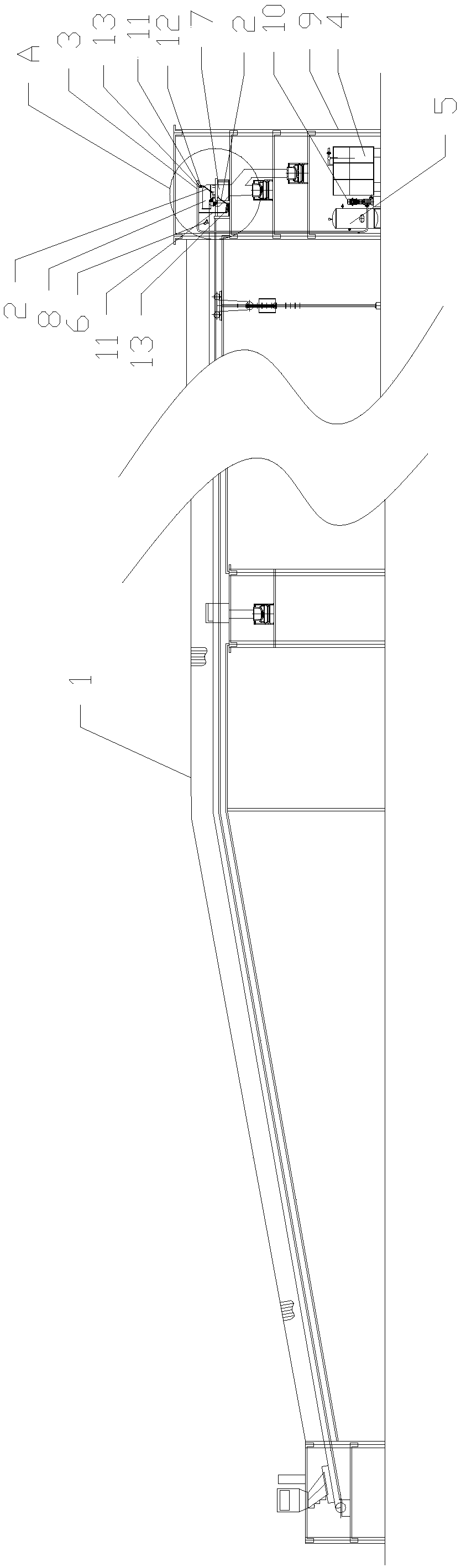

[0015] Such as figure 1 As shown, a belt conveyor dust suppression device includes a belt conveyor 1, a high-pressure water mist nozzle 2, a threading pipe 3, a water tank 4, an air storage tank 5 and a camera 6, and is characterized in that: the right end of the belt conveyor 1 There is a high-pressure water mist spray gun 2 symmetrically installed on both sides of the lower hopper 7 through flange bolts, and two high-pressure water mist spray guns 2 are symmetrically installed on both sides of the belt conveyor head cover 8 on the belt conveyor 1 through flange bolts. The right end of the belt conveyor 1 is provided with a transfer frame 9, and the bottom of the transfer frame 9 is provided with a water tank 4, an air storage tank 5 and a multi-stage pressurized water pump motor 10, the water tank 4 is connected with the multi-stage pressurized water pump motor 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com