High rod power-free rotary sprayer

A technology of power rotating and spraying device, applied in spraying device, spraying device with movable outlet, dispersed particle separation and other directions, can solve the problem of large workload, can not fundamentally solve the problem of dust, virtual workload, etc., to achieve beautiful appearance and dust reduction. The effect of better performance and increased traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

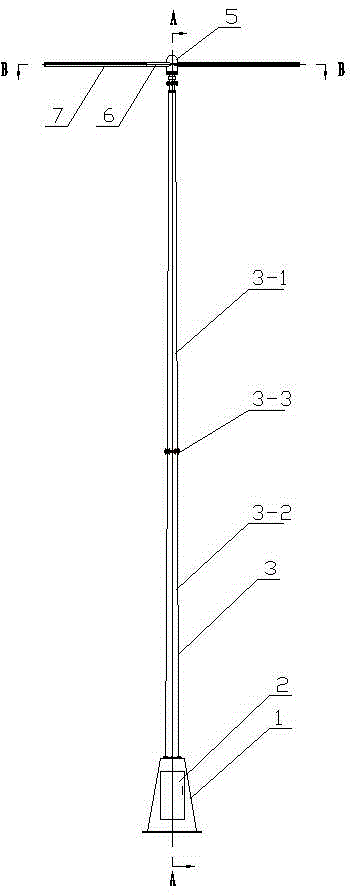

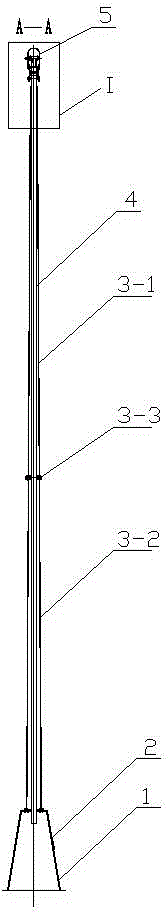

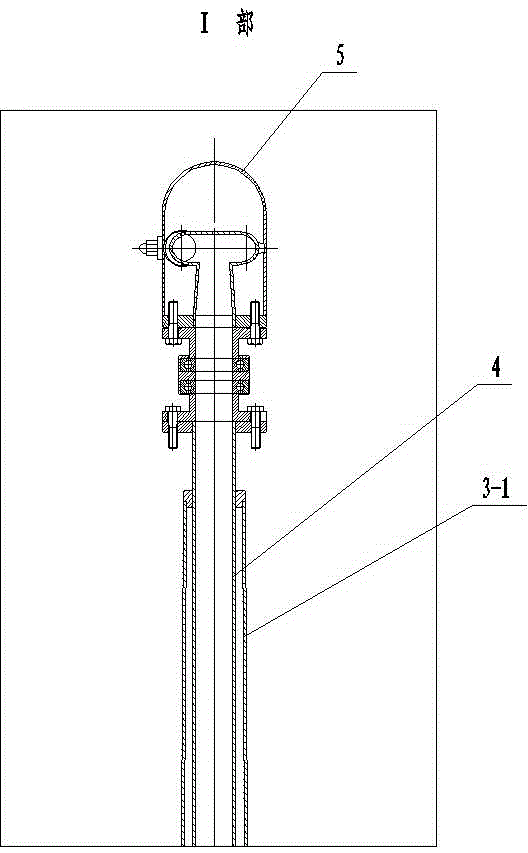

[0024] Such as figure 1 As shown in -4, it is the first type of high pole unpowered rotary spray device, which mainly includes a base 1 on which an inspection door 2 is hinged. The middle part above the base 1 is connected to a vertically arranged outer tube 3. The outer tube 3 is equipped with a vertical water pipe 4, the outer tube 3 includes an upper outer tube 3-1 and a lower outer tube 3-2, and the lower end of the upper outer tube 3-1 is connected to the lower outer tube 3-2. The upper ends are connected by the flange 3-3, the inner diameter of the flange 3-3 matches the outer diameter of the vertical water pipe 4, and the vertical water pipe 4 is fixed on the upper outer pipe 3-1 and the lower pipe 3-1 through the flange 3-3. Inside the outer tube 3-2. The upper end of the vertical water pipe 4 passes through the upper outer pipe 3-1 and then connects to the rotary joint 5, the inner chamber connected to the rotary joint 5 communicates with the vertical water pipe 4, a...

Embodiment 2

[0026] Such as Figure 5 As shown in -8, it is the second type of high pole unpowered rotary spraying device, which mainly includes a base 1', a hinged inspection door 2' on the base 1', and a vertically arranged outer pipe 3' connected to the middle part above the base 1'. The diameter of the upper end of the pipe 3' is small and the diameter of the lower end is large, and the vertical water pipe 4' is inserted in the outer pipe 3', and the outer pipe 3' includes the upper outer pipe 3-1' and the lower outer pipe 3-2', and the upper outer pipe 3-2' The lower end of -1' and the upper end of the lower outer pipe 3-2' are connected by a flange 3-3', the inner diameter of the flange 3-3' matches the outer diameter of the vertical water pipe 4', and the vertical water pipe 4 ' is fixed in the upper outer tube 3-1' and the lower outer tube 3-2' through the flange 3-3'. The upper end of the vertical water pipe 4' passes through the upper outer pipe 3-1' and then connects to the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com