Color master batch with anti-ultraviolet function and preparation method thereof

An anti-ultraviolet and color masterbatch technology, applied in the field of color masterbatch with anti-ultraviolet function and its preparation, can solve the problems of poor ultraviolet aging resistance of the color masterbatch, and achieve extended continuous production time, short production time and long time. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

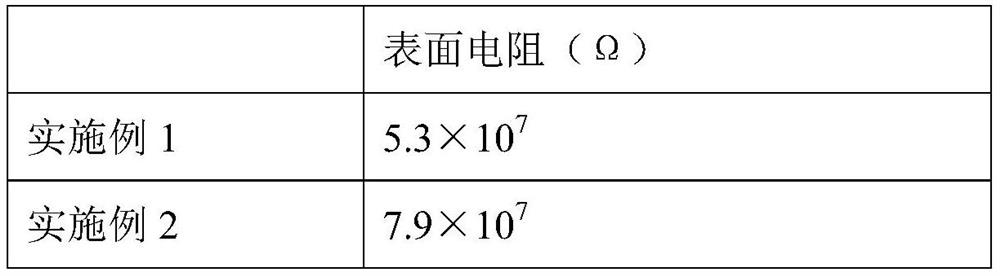

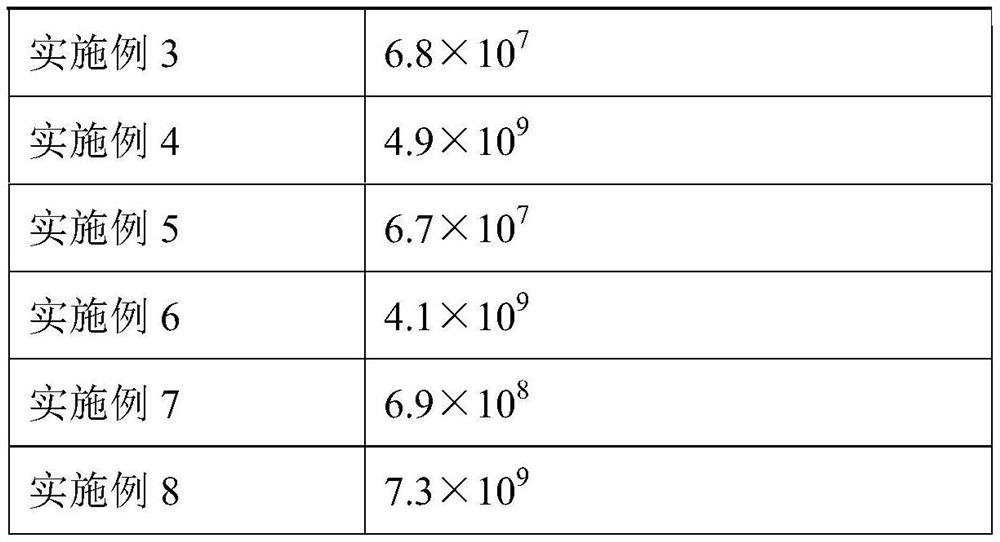

Examples

Embodiment 1

[0033] The present embodiment provides a color masterbatch with anti-ultraviolet function, comprising the following components by weight: 40 parts of linear low density polyethylene, 30 parts of titanium yellow powder, 8.5 parts of ultraviolet absorber (wherein, 2 parts of UVP327, 6 RMB and 0.5 parts of nano-titanium dioxide), 5 parts of light stabilizer GW540, 6 parts of composite antioxidant (4 parts of antioxidant 1010, 2 parts of antioxidant 168), 12 parts of magnesium stearate, ethylene bis-stearate 12 parts of amide, 8 parts of ethoxylauramide, 3 parts of PPA, and 1 part of silicon nitride whisker modified by silane coupling agent.

[0034] Wherein, the preparation method of the silicon nitride whisker modified by silane coupling agent comprises the following steps:

[0035] Place the silicon nitride whiskers in a vacuum environment at 600°C for 5 hours, disperse them evenly in absolute ethanol after cooling, and then treat them with atmospheric pressure plasma for 45 mi...

Embodiment 2

[0038] This embodiment provides a color masterbatch with anti-ultraviolet function, comprising the following components by weight: 30 parts of linear low-density polyethylene, 20 parts of phthalocyanine blue powder, 10 parts of ultraviolet absorber (wherein, 2 parts of UVP327 , 8 parts of RMB and 0.2 parts of nano titanium dioxide), 2 parts of light stabilizer GW540, 10 parts of composite antioxidant (8 parts of antioxidant 1010, 2 parts of antioxidant 168), 10 parts of polyethylene wax, pentaerythritol stearic acid 10 parts of esters, 10 parts of glycerin monostearate, 1 part of PPA, 0.25 parts of silicon nitride whiskers modified by silane coupling agent.

[0039] Wherein, the preparation method of the silicon nitride whisker modified by silane coupling agent comprises the following steps:

[0040] Place the silicon nitride whiskers in a vacuum environment at 550°C for 7 hours, disperse them evenly in absolute ethanol after cooling, and then treat them with normal pressure p...

Embodiment 3

[0043]The present embodiment provides a color masterbatch with anti-ultraviolet function, comprising the following components by weight: 50 parts of linear low density polyethylene, 40 parts of permanent red powder, 2.5 parts of ultraviolet absorber (wherein, 1 part of UVP327, 1 part of RMB and 0.5 part of nano titanium dioxide), 10 parts of light stabilizer GW540, 2 parts of composite antioxidant (1 part of antioxidant 1010, 1 part of antioxidant 168), 15 parts of calcium stearate, methyl silicone 15 parts of alkane, 2 parts of ethoxy lauramide, 5 parts of fluoropolymer processing aid PPA, 1.5 parts of silicon nitride whisker modified by silane coupling agent.

[0044] Wherein, the preparation method of the silicon nitride whisker modified by silane coupling agent comprises the following steps:

[0045] Place the silicon nitride whiskers in a vacuum environment at 650°C for 3 hours, disperse them evenly in absolute ethanol after cooling, and then treat them with atmospheric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com