Preventive maintenance material for asphalt pavement

A technology of preventive maintenance and asphalt pavement, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of reducing the anti-skid ability of the surface layer of asphalt pavement, weak anti-skid ability, complex process, etc. Achieve the effect of reducing UV aging, improving anti-skid ability, and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

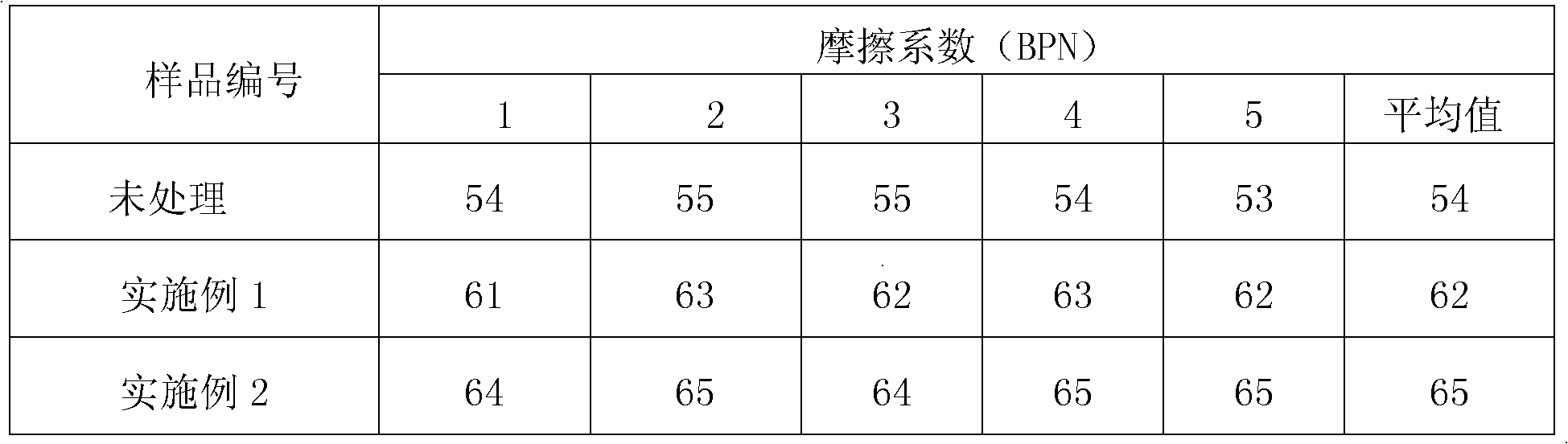

Embodiment 1

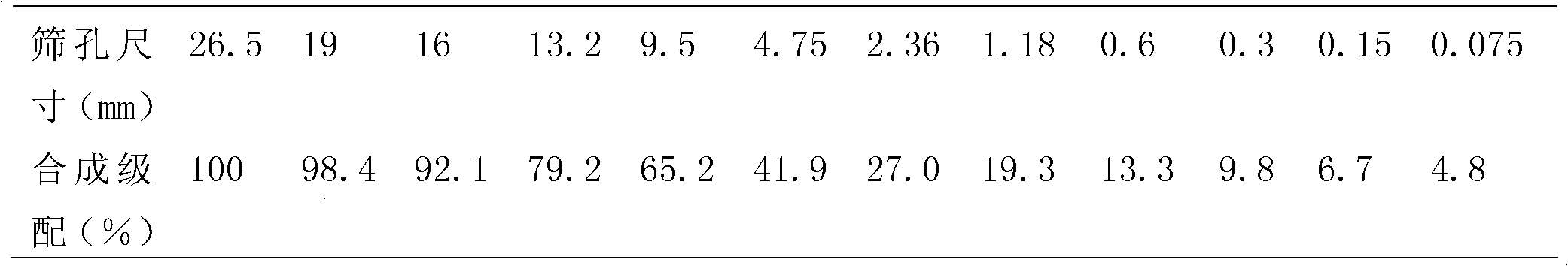

[0024] A preventive maintenance material for asphalt pavement, which is composed of organosilicon resin solution, silane coupling agent, fine stone chips, and waste rubber powder raw materials. The weight percentage of each raw material is: organosilicon resin solution 40%, silane coupling agent 5%, fine stone chips 50%, waste rubber powder 5% (without adding UV absorbers).

[0025] The organosilicon resin solution is an MQ organosilicon resin solution, the synthesis method of the organosilicon resin is a silicate method, and the concentration of the MQ organosilicon resin solution is 20-50 wt%. The silane coupling agent is γ-aminopropyltriethoxysilane. The fine stone chips are basalt, and the size range of basalt is 0.3mm to 1.18mm. The size range of waste rubber powder is 0.3mm~1.18mm.

[0026] The construction (preparation) of a preventive maintenance material for asphalt pavement: 1) Stir the above-mentioned organosilicon resin solution, ultraviolet absorber, and silane ...

Embodiment 2

[0028] A preventive maintenance material for asphalt pavement, which is composed of organic silicon resin solution, ultraviolet absorber, silane coupling agent, fine stone chips, and waste rubber powder raw materials. The weight percentage of each raw material is: organic silicon resin solution 40%, UV absorber 1%, silane coupling agent 5%, fine stone chips 50%, waste rubber powder 4%.

[0029] The organic silicon resin solution is an MQ organic silicon resin solution, the synthetic method of the organic silicon resin is a silicate method, and the concentration of the MQ organic silicon resin solution is 20-50 wt%. The ultraviolet absorber is benzophenones (UV-531). The silane coupling agent is γ-aminopropyltriethoxysilane. The fine stone chips are basalt, and the size range of basalt is 0.3mm to 1.18mm. The size range of waste rubber powder is 0.3mm~1.18mm.

[0030] The construction (preparation) of a preventive maintenance material for asphalt pavement: 1) Stir the above-...

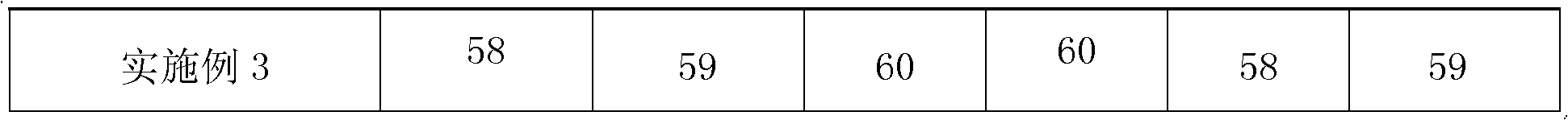

Embodiment 3

[0032] A preventive maintenance material for asphalt pavement, which is composed of organic silicon resin solution, ultraviolet absorber, silane coupling agent, fine stone chips, and waste rubber powder raw materials. The weight percentage of each raw material is: organic silicon resin solution 50%, UV absorber 2%, silane coupling agent 5%, fine stone chips 39%, waste rubber powder 4%.

[0033] The organic silicon resin solution is an MQ organic silicon resin solution, the synthetic method of the organic silicon resin is a silicate method, and the concentration of the MQ organic silicon resin solution is 20-50 wt%. The UV absorber is benzotriazoles (UV-326). The silane coupling agent is γ-glycidyl etheroxypropyltrimethoxysilane. The fine stone chips are steel slag, and the size range of steel slag is 0.3mm~1.18mm. The size range of waste rubber powder is 0.3mm~1.18mm.

[0034]The construction (preparation) of a preventive maintenance material for asphalt pavement: 1) Stir t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com