A kind of anti-fingerprint environmental protection water-based paint and preparation method thereof

A water-based paint, fingerprint-resistant technology, used in biocide-containing paints, antifouling/underwater coatings, polyether coatings, etc., can solve the problems of high cost, low adhesion and stability, and poor fingerprint resistance. Achieve the effect of fast drying, good passivation and good fingerprint resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

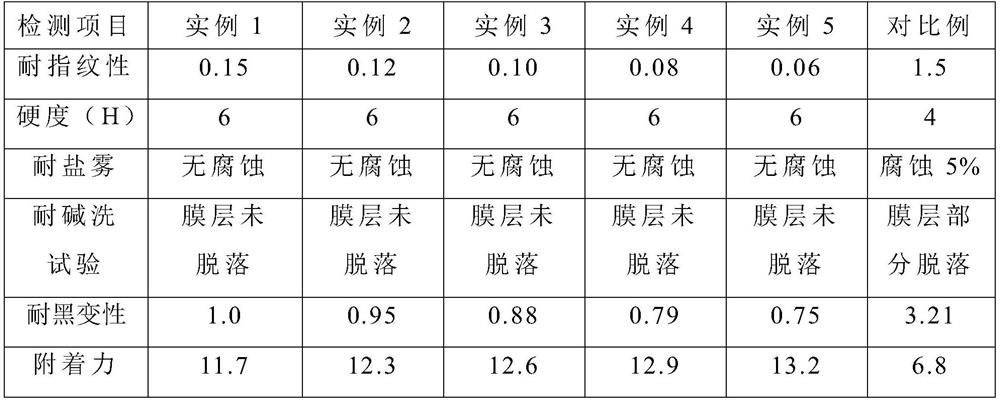

Examples

Embodiment 1

[0036] A fingerprint-resistant environmental protection water-based paint, which is made of the following components in parts by weight: 50 parts of modified sulfone-based polyphenylene ether polymer film-forming, 10 parts of epoxy resin, 10 parts of surface-modified nano-silica, azodicarbonate 1 part of isobutyronitrile, 10 parts of water, 1 part of hydroxyethyl cellulose, 1 part of polyoxyethylene polyoxypropanolamine ether.

[0037] The preparation method of the modified sulfone-based polyphenylene ether polymer film-forming liquid comprises the following steps:

[0038] ⅠAdd 10g of bis(3-amino-4-hydroxyphenyl)sulfone and 70g of sodium hydroxide into 700g of water, stir and react at room temperature for 4 hours, and then remove the water by rotary evaporation to obtain bis(3-amino-4-hydroxy Phenyl) sulfone sodium salt;

[0039] ⅡAdd 24g of bis(3-amino-4-hydroxyphenyl)sulfone sodium salt and 10g of single-end epoxy silicone oil prepared in step I into 100g of tetrahydrofuran,...

Embodiment 2

[0046] A fingerprint-resistant environmental protection water-based paint, which is made of the following components in parts by weight: 53 parts of modified sulfone-based polyphenylene ether polymer film-forming, 13 parts of epoxy resin, 13 parts of surface-modified nano-silica, azodicarbonate 2 parts of isoheptanonitrile, 13 parts of water, 2 parts of acrylic thickener TT-9352, 2 parts of polydimethylsiloxane.

[0047] The preparation method of the modified sulfone-based polyphenylene ether polymer film-forming liquid comprises the following steps:

[0048] ⅠAdd 10g of bis(3-amino-4-hydroxyphenyl)sulfone and 70g of sodium hydroxide to 750g of water, stir and react at room temperature for 4.5 hours, and then remove the water by rotary evaporation to obtain bis(3-amino-4-hydroxyl) Phenyl) sulfone sodium salt;

[0049] ⅡAdd 24g of bis(3-amino-4-hydroxyphenyl)sulfone sodium salt and 10g of single-end epoxy silicone oil prepared in step Ⅰ to 115g of hexamethylphosphoramide, and ...

Embodiment 3

[0056] A fingerprint-resistant environmental protection water-based paint, which is made of the following components in parts by weight: 56 parts of modified sulfone-based polyphenylene ether polymer film-forming, 15 parts of epoxy resin, 16 parts of surface-modified nano-silica, azodicarbonate 2 parts of isoheptanonitrile, 15 parts of water, 2 parts of polyvinylpyrrolidone thickener, 1 part of polyoxypropylene glyceryl ether.

[0057] The preparation method of the modified sulfone-based polyphenylene ether polymer film-forming liquid comprises the following steps:

[0058] ⅠAdd 10g of bis(3-amino-4-hydroxyphenyl)sulfone and 70g of sodium hydroxide into 800g of water, stir and react at room temperature for 5 hours, and then remove the water by rotary evaporation to obtain bis(3-amino-4-hydroxy Phenyl) sulfone sodium salt;

[0059] Ⅱ Add 24 g of bis(3-amino-4-hydroxyphenyl) sulfone sodium salt and 10 g of single-end epoxy silicone oil prepared in step I into 135 g of dichlorom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com