A polyethylene composition with excellent puncture resistance and weather resistance

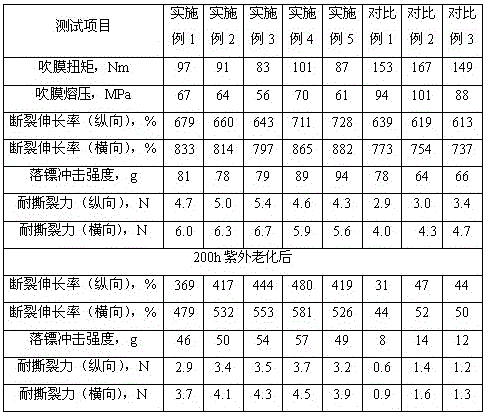

A technology with weather resistance and puncture resistance, which is applied in the field of polyethylene resin composition and polyethylene composition, can solve the problems of agricultural shed film processing performance, dart impact strength and anti-ultraviolet aging ability, and achieve good anti-ultraviolet aging Excellent performance, excellent weather resistance, and high puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

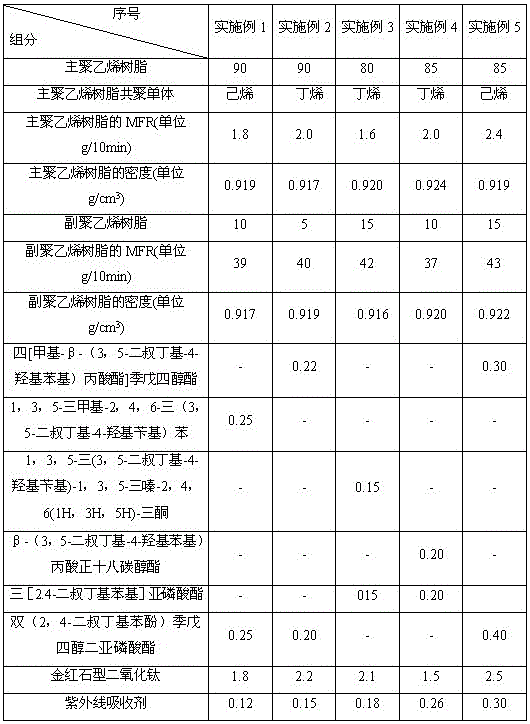

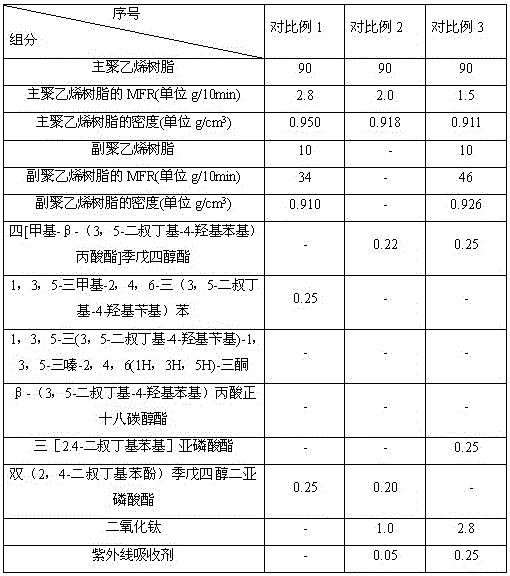

[0020] The proportioning components of the polyethylene resin composition for film are shown in Table 1 and Table 2.

[0021] Density is tested according to GB / T 1033.2-2010, using method D, tested after boiling for 30 minutes; melt mass flow rate (MFR) is tested according to GB / T 3682-2000, with a load of 2.16kg.

[0022] Table 1 Example 1 ~ 5 polyethylene resin composition (by weight)

[0023]

[0024] Preparation method: a) polyethylene resin, antioxidant, titanium dioxide, and ultraviolet absorber are put into a high-speed mixer and stirred at a stirring speed of 1300 rpm, stirring time is 12 minutes, and stirring temperature is 38°C; b) the uniformly mixed materials are added to Melt, plasticize, extrude, and pelletize in a twin-screw extruder. The screw aspect ratio is 33, and the processing temperature is 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com