Vacuum bag convenient for exhausting and manufacturing process

A technology of vacuum bags and air extraction nozzles, which is applied to container manufacturing machinery, packaging under vacuum/special atmosphere, bags, etc., can solve the problems of incomplete air extraction, low strength of PE materials, easy vacuum bags, etc., and achieve the cost of processing equipment Low cost, simple valve structure and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

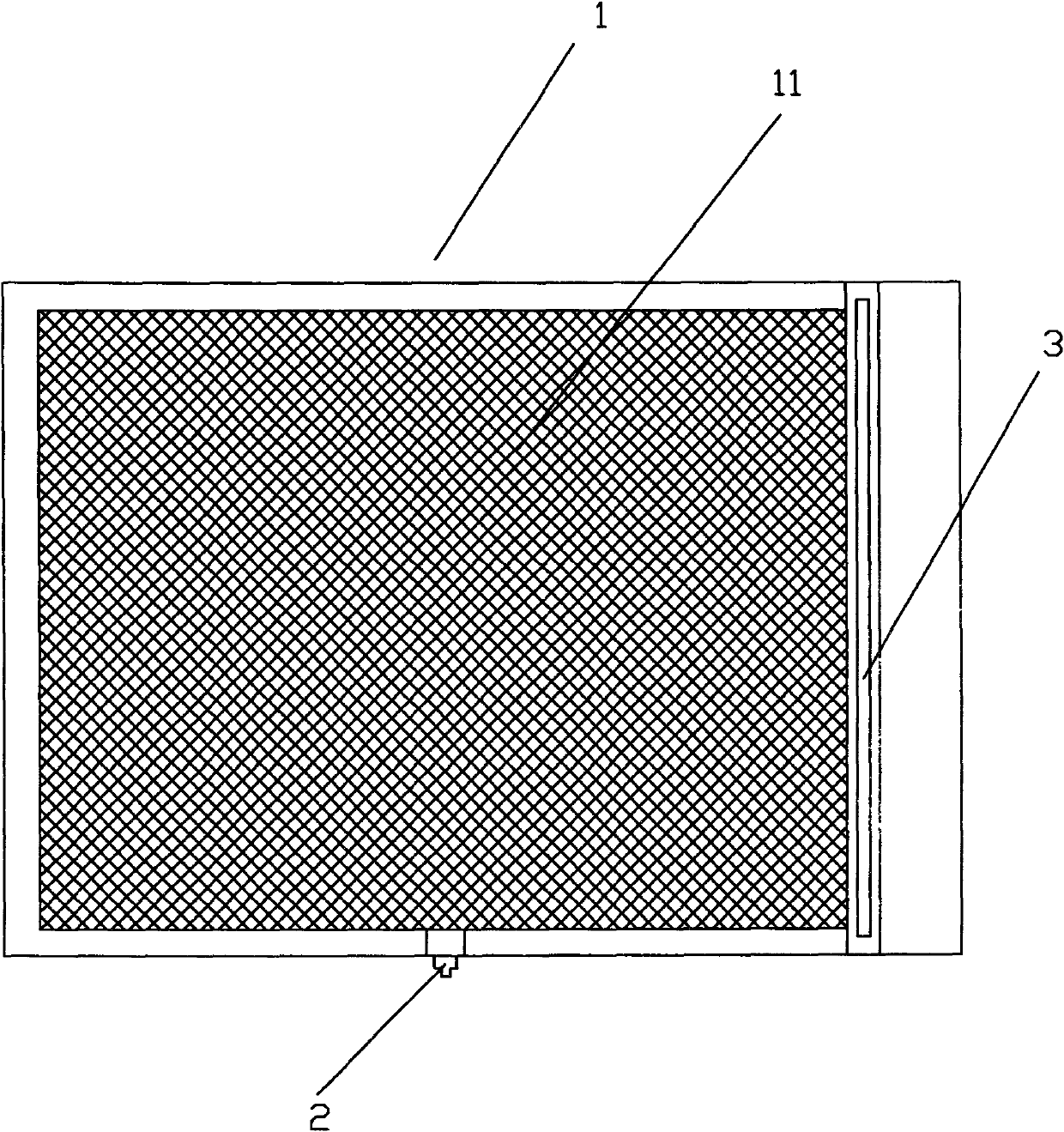

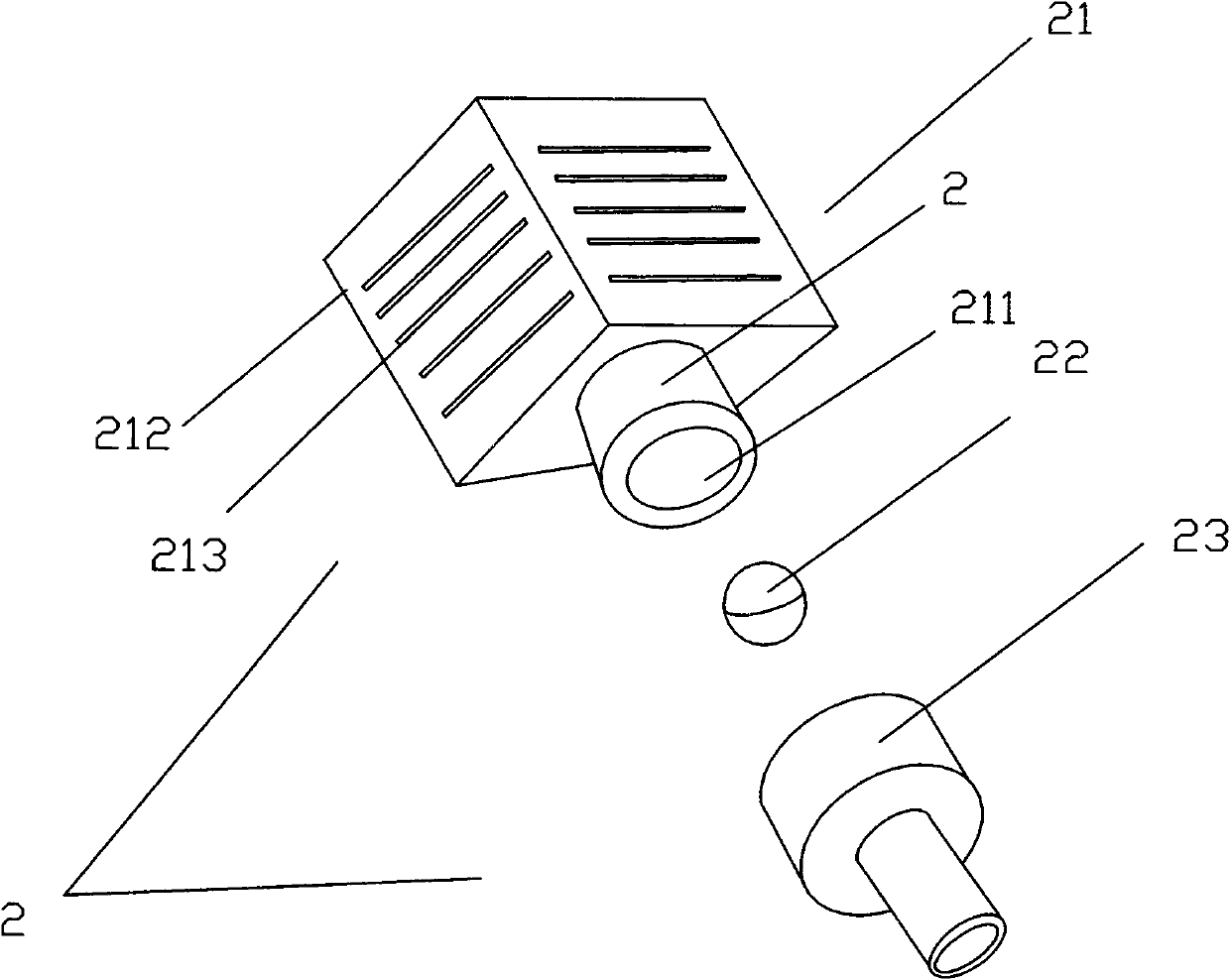

[0020] See figure 1 As shown, the disclosed vacuum bag of the present invention includes a bag body 1, an air valve 2 and a seal 3, the air valve 2 is sealed on the side of the bag body, and the inner side of the bag body 1 is provided with a guide The air groove 11 and the air guide groove 11 are die grooves of the bag body 1 . The grooves of the compression mold are in the shape of a net, and the grooves of the compression mold are distributed on at least one bag surface of the vacuum bag. In order to achieve a better air extraction effect, the inner surface of the entire vacuum bag can also be provided with die grooves.

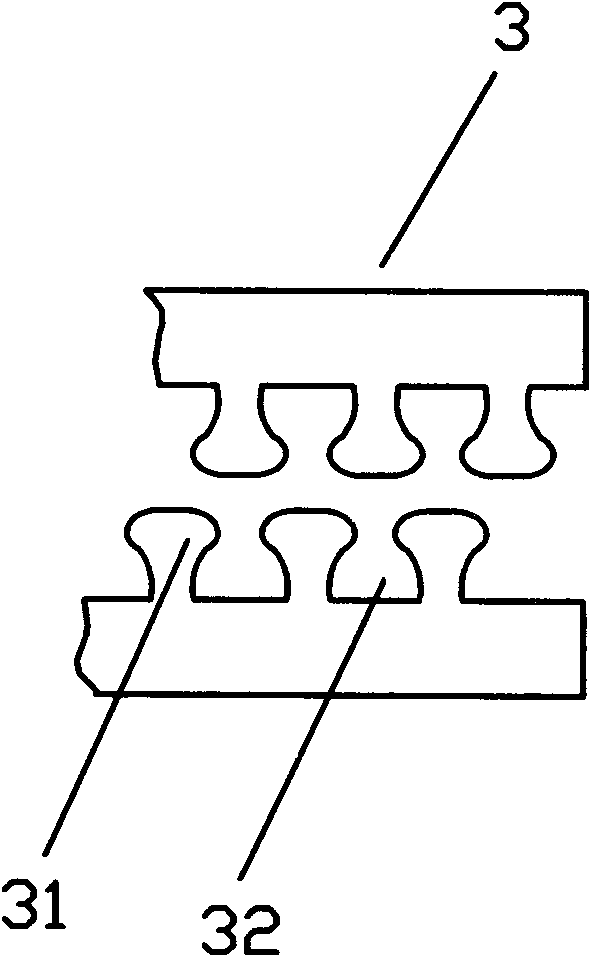

[0021] See figure 2 As shown, the described storage seal 3 is a sealing groove 31 and a sealing strip 32 stuck on the sealing groove, and there are at least two sealing grooves 31 and sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com