Special polyethylene flour bag packaging film

A bag packaging and polyethylene technology, which is applied in the field of special film for polyethylene flour bag packaging, can solve the problems of not being able to store too long, complex production process, difficult promotion, etc., achieve ideal heat sealing effect, facilitate transportation and storage, Excellent puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

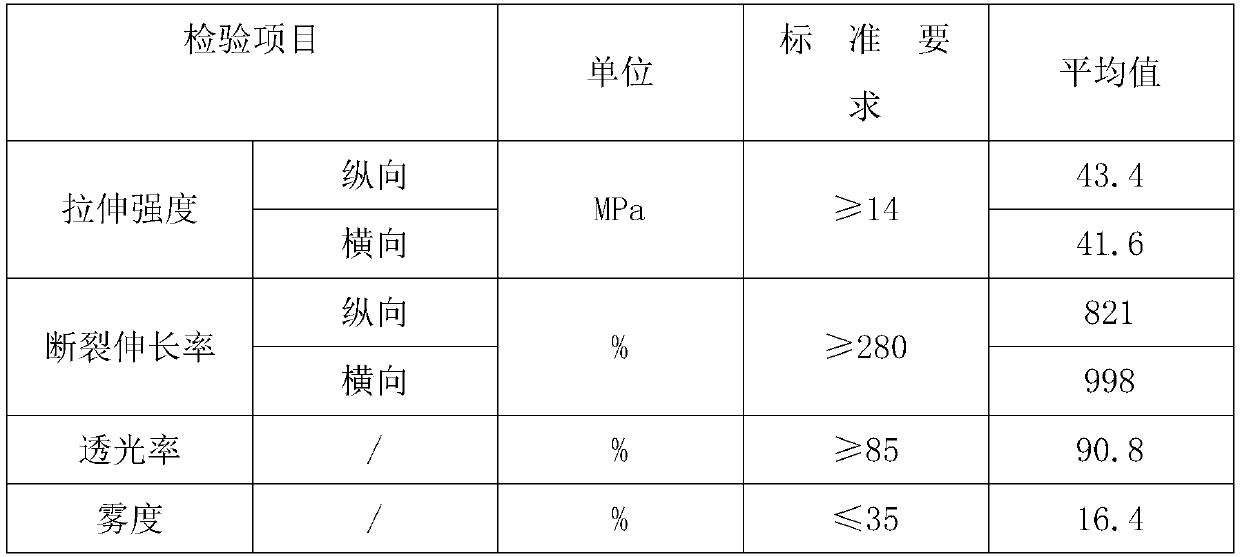

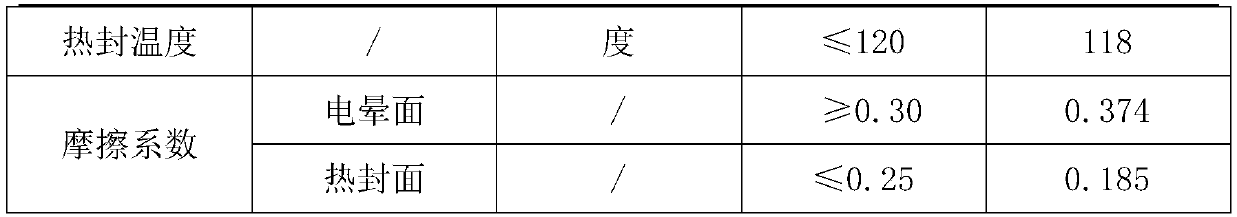

Embodiment 1

[0034] inner layer:

[0035] Domestic linear polyethylene material A: 51%, metallocene linear material A imported from Japan: 25%, low-density polyethylene material imported from the United States 15%, opening smooth agent: 2%, antistatic agent: 4%, PPA parent Material 3%.

[0036] Middle:

[0037] Metallocene linear material B imported from Japan: 35%, low-density polyethylene material imported from the United States 25%, domestic linear polyethylene material A: 38%, and PPA masterbatch 2%.

[0038] Outer layer:

[0039] Domestic linear polyethylene material B: 44%, 36% metallocene linear material imported from the United States, 18% low-density polyethylene material imported from the United States, and 2% PPA masterbatch.

[0040] The domestic linear polyethylene material B is Daqing Petrochemical 7042, the metallocene linear material A imported from Japan is Japanese KF360T, the metallocene linear material B imported from Japan is Japanese SP150H, and the low-density pol...

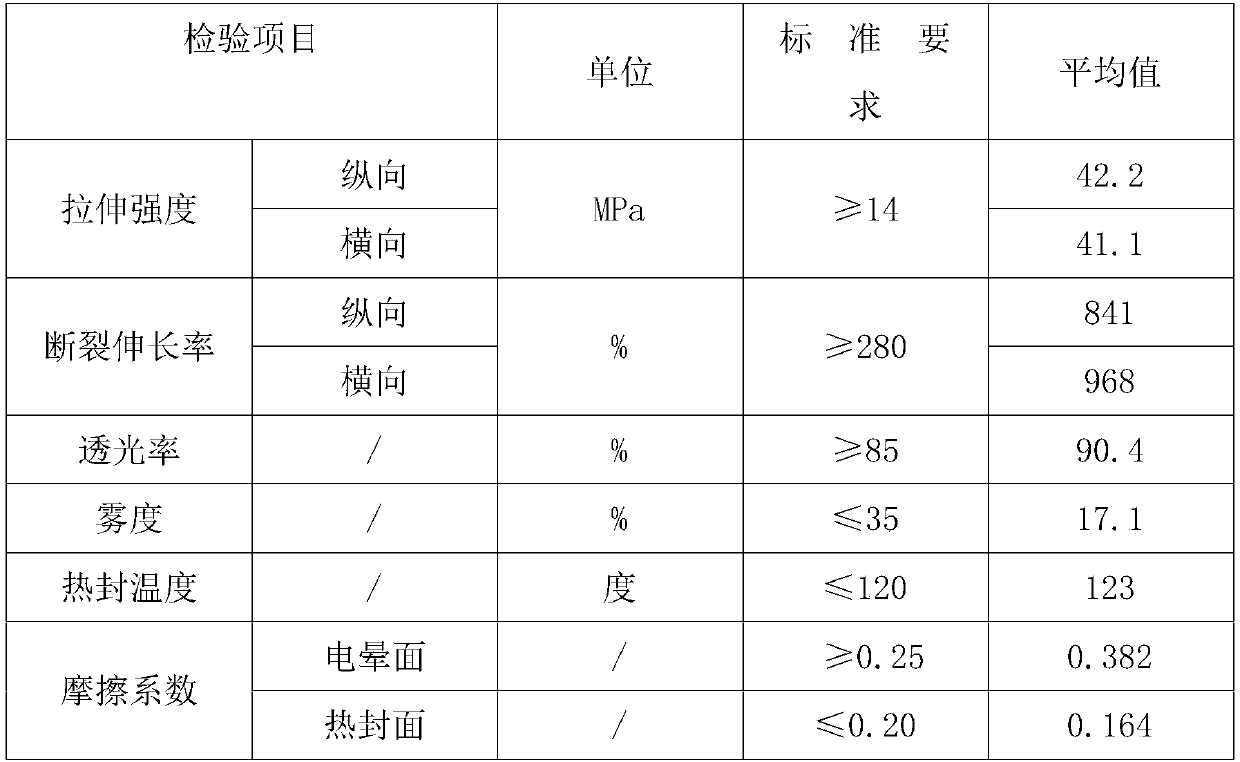

Embodiment 2

[0043] inner layer:

[0044] Domestic linear polyethylene material A: 55%, metallocene linear material A imported from Japan: 22%, low-density polyethylene material imported from the United States 14.5%, opening smooth agent: 2.5%, antistatic agent: 3%, PPA parent Material 3%.

[0045] Middle:

[0046] Metallocene linear material B imported from Japan: 34%, low-density polyethylene material imported from the United States 34%, domestic linear polyethylene material A: 30%, and PPA masterbatch 2%.

[0047] Outer layer:

[0048]Domestic linear polyethylene material B: 42%, metallocene linear material imported from the United States 43%, low-density polyethylene material imported from the United States 13%, and PPA masterbatch 2%.

[0049] The domestic linear polyethylene material B is Daqing Petrochemical 7042, the metallocene linear material A imported from Japan is Japanese KF360T, the metallocene linear material B imported from Japan is Japanese SP150H, and the low-density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com