Waterborne polyurethane fabric coated gloves and production process thereof

A water-based polyurethane, production process technology, used in coatings, gloves, clothing, etc., to achieve the effect of low requirements, saving raw materials, and excellent puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

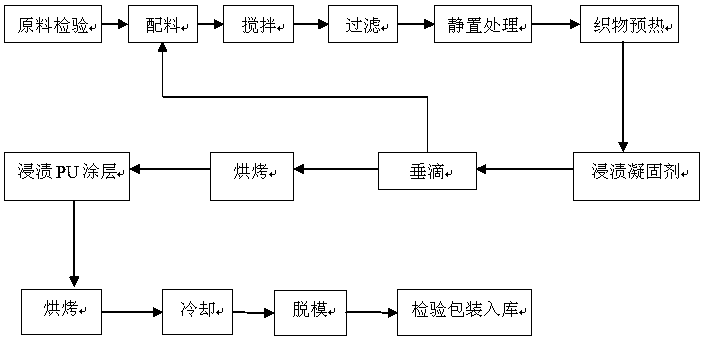

[0034] Such as figure 1 As shown, according to an embodiment of the present invention, the present embodiment discloses a production process of water-based polyurethane fabric coated gloves, specifically, the production process of the water-based polyurethane fabric coated gloves is as follows:

[0035] The first step is to prepare the experimental substrate

[0036] Blend according to coagulant: pure water = 6:100 mass percent, and stir for 20 minutes to prepare coagulant aqueous solution.

[0037] Waterborne polyurethane coating agent was prepared according to waterborne polyurethane resin: inorganic filler: defoamer: thickener = 100:10:0.5:1.

[0038] The second step is to put the inner liner of the knitted glove on the hand mold, preheat it to 50°C and keep it warm for 2 minutes, then immerse the palm of the glove in the coagulant for 5 seconds and take it out, and then control the temperature in the oven to 80°C on the hand mold The gloves were dried for about 4 minutes...

Embodiment 2

[0044] Such as figure 2 As shown, according to another embodiment of the present invention, this embodiment discloses a water-based polyurethane fabric coated glove prepared by the production process of the water-based polyurethane fabric coated glove of the above-mentioned embodiment, the water-based polyurethane fabric coated The layered glove includes: a knitted glove 1 and a water-based polyurethane coating 2 arranged on the knitted glove. Specifically, the water-based polyurethane coating described in this embodiment is provided on the palm and fingers of the knitted glove. Anhydrous polyurethane coating on the wrist of knitted gloves. The gloves prepared in this example have excellent properties such as puncture resistance, cutting resistance, abrasion resistance, and high strength by coating the knitted glove liner with water-based polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com