A kind of conductive plastic material and preparation method thereof

A conductive plastic, carbazole-based technology, applied in the field of conductive plastic materials and their preparation, can solve the problems of low requirements for equipment and reaction conditions, unstable quality of conductive plastic materials, weak anti-electromagnetic interference ability, etc. The effect of electromagnetic drying ability, excellent anti-ultraviolet aging ability and strong anti-electromagnetic interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

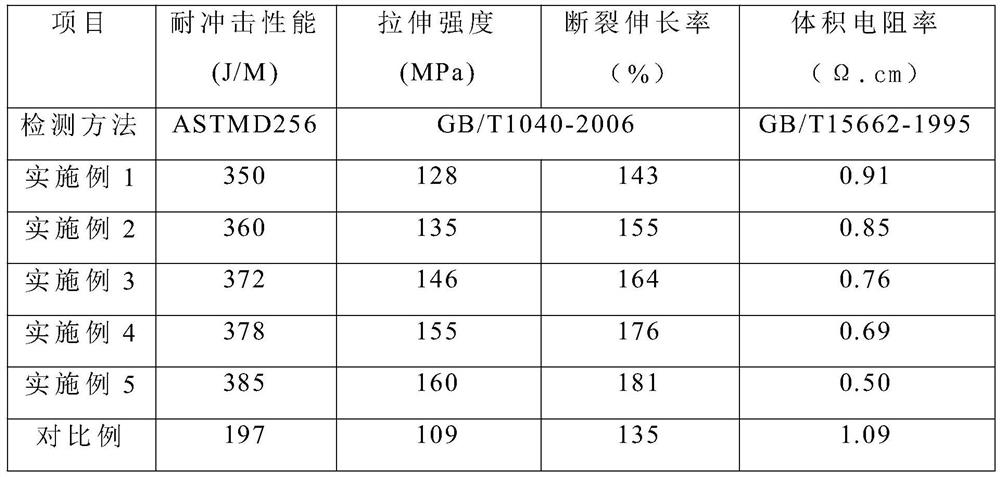

Examples

Embodiment 1

[0031] A conductive plastic material, made of the following components by weight: 60 parts of polysulfide grafted carbonate-based carbazole-type ionomer, 5 parts of carboxylated fullerene, 1 part of silane coupling agent KH5601, K- 2 parts resin.

[0032] The preparation method of the polythioether grafted carbonate-based carbazole type ionomer comprises the steps:

[0033] 1) Dissolve 310g of 4,4'-bis(9-ethyl-3-carbazolevinyl)-1,1'-biphenyl and 100g of ethanol-2-chlorocarbonate in 1000g of dimethyl sulfoxide to form a solution , then add 30g of sodium hydroxide therein, stir and react at 40°C for 10 hours in a nitrogen atmosphere, then add 1-[2-(trimethylsilyl)ethoxycarbonyloxy]benzotri 30 g of azole, continued to stir for 1 hour, then precipitated in water, washed the product 5 times with ethanol, and then placed it in a vacuum drying oven at 65 ° C for 10 hours to obtain a carbonate-based carbazole-type ionomer;

[0034] 2) Dissolve 30 g of the carbonate-based carbazole-t...

Embodiment 2

[0039] A conductive plastic material, made of the following components by weight: 63 parts of polysulfide grafted carbonate-based carbazole ionomer, 7 parts of amino-modified fullerene, 2 parts of silane coupling agent KH5702, thermoplastic Elastomer POE 3 parts.

[0040] The preparation method of the polythioether grafted carbonate-based carbazole type ionomer comprises the steps:

[0041]1) Dissolve 313g of 4,4'-bis(9-ethyl-3-carbazolevinyl)-1,1'-biphenyl and 100g of ethanol-2-chlorocarbonate in N,N-dimethylformaldehyde A solution was formed in 1150 g of amide, and 45 g of potassium hydroxide was added thereto, and stirred and reacted at 45°C for 12 hours in a helium atmosphere, and then 1-[2-(trimethylsilyl)ethoxycarbonyl was added to the reaction system Oxygen] benzotriazole 35g, continue to stir for 1.2 hours, then precipitate in water, and wash the product 6 times with ethanol, and then place it in a vacuum drying oven at 67°C for 12 hours to obtain a carbonate-based ca...

Embodiment 3

[0047] A conductive plastic material, made of the following components by weight: 65 parts of polysulfide grafted carbonate-based carbazole-type ionomer, 8 parts of carboxylated fullerene, 3 parts of silane coupling agent KH5503, ethylene- 3 parts of vinyl acetate copolymer.

[0048] The preparation method of the polythioether grafted carbonate-based carbazole type ionomer comprises the steps:

[0049] 1) Dissolve 316g of 4,4'-bis(9-ethyl-3-carbazolevinyl)-1,1'-biphenyl and 100g of ethanol-2-chlorocarbonate in 1350g of N-methylpyrrolidone to form Solution, then add potassium carbonate 55g therein, in neon gas atmosphere, stir reaction at 50 ℃ for 13 hours, then add 1-[2-(trimethylsilyl)ethoxycarbonyloxy]benzo 40g of triazole, continued to stir for 1.5 hours, then precipitated in water, washed the product 7 times with ethanol, and then placed it in a vacuum drying oven at 70°C for 13 hours to obtain a carbonate-based carbazole-type ionomer;

[0050] 2) Dissolve 40 g of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com