High-temperature-resistant self-adhesive waterproofing coiled material and preparation method thereof

A self-adhesive waterproof membrane, self-adhesive waterproof technology, applied in the direction of non-polymer adhesive additives, adhesives, adhesive types, etc., can solve the problem of poor viscosity, elongation at break and high temperature resistance. Self-healing function, poor tensile strength and other problems, to achieve the effect of enhancing toughness and mechanical properties, improving anti-ultraviolet aging performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

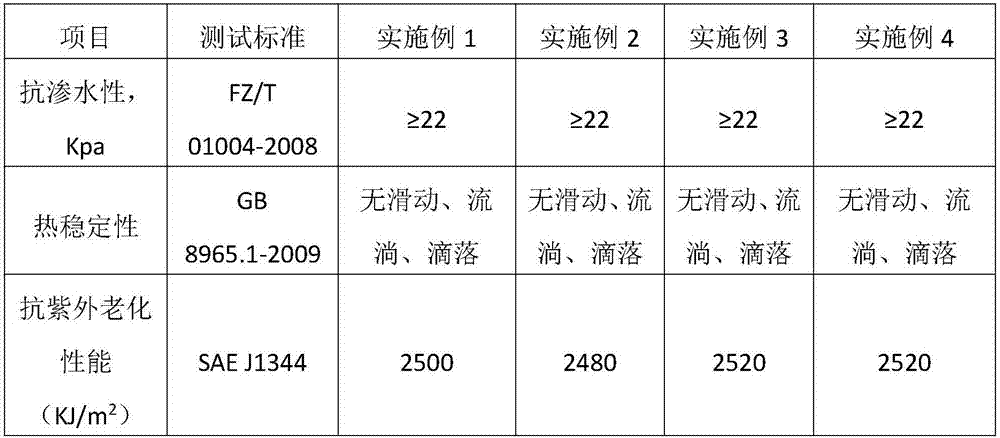

Examples

Embodiment 1

[0029] A high-temperature-resistant self-adhesive waterproof coiled material, the waterproof coiled material comprises a five-layer structure, which are respectively from top to bottom: a polyethylene terephthalate (PET) isolation film layer (1), a high-temperature-resistant self-adhesive waterproof Rubber material layer (2), polyester tire base material layer (3), high temperature resistant self-adhesive waterproof rubber material layer (4), polyethylene terephthalate (PET) film isolation film layer (5).

[0030] Wherein, the high temperature-resistant self-adhesive waterproof rubber compound is prepared from the following raw materials in parts by weight: 10 parts of chloroether rubber, 2 parts of dioctyl sebacate, 5 parts of benzotriazole-modified zinc oxide, and 5 parts of polyoxymethylene , 3 parts of daily chemical silicone elastomer, 40 parts of petroleum asphalt, 20 parts of natural asphalt.

[0031] Wherein, petroleum asphalt is naphthenic straight-run petroleum aspha...

Embodiment 2

[0037] A high-temperature-resistant self-adhesive waterproof coiled material, the waterproof coiled material comprises a five-layer structure, from top to bottom: a polyethylene (PE) isolation film layer (1), a high-temperature-resistant self-adhesive waterproof rubber layer (2) , glass fiber tire base material layer (3), high temperature resistant self-adhesive waterproof rubber material layer (4), polyethylene (PE) isolation film layer (5).

[0038] Wherein, the high-temperature-resistant self-adhesive waterproof rubber compound is prepared from the following raw materials in parts by weight: 12 parts of chloroether rubber, 3 parts of naphthenic oil, 6 parts of benzotriazole-modified zinc oxide, 6 parts of polyoxymethylene, daily chemical 4 parts of silicone elastomer, 45 parts of petroleum asphalt, 25 parts of natural asphalt.

[0039]Wherein, the petroleum asphalt is naphthenic straight-run petroleum asphalt, and the penetration is 200 (in 0.1mm); the natural asphalt is na...

Embodiment 3

[0045] A high-temperature-resistant waterproof coiled material, the waterproof coiled material comprises a five-layer structure, from top to bottom: a polyethylene terephthalate isolation film layer (1), a high-temperature-resistant self-adhesive waterproof rubber layer (2 ), a glass fiber reinforced polyester felt base material layer (3), a high temperature resistant self-adhesive waterproof rubber layer (4), and a polyethylene terephthalate isolation film layer (5).

[0046] Wherein, the high temperature-resistant self-adhesive waterproof rubber compound is prepared from the following raw materials in parts by weight: 14 parts of chloroether rubber, 3 parts of maleic acid, 7 parts of benzotriazole-modified zinc oxide, 6 parts of polyoxymethylene, Daily chemical silicone elastomer 5 parts, petroleum asphalt 47 parts, natural asphalt 26 parts.

[0047] Wherein, petroleum asphalt is naphthenic straight-run petroleum asphalt, and penetration is 250 (in 0.1mm); Natural asphalt is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com