Preparation method of corrosion resisting UV aging resistant coating modified aluminum pigment

An anti-ultraviolet and corrosion-resistant technology, which is applied in the field of pigments, can solve the problems of shedding of the coating layer and pigments, difficulty in color fixation, etc., and achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

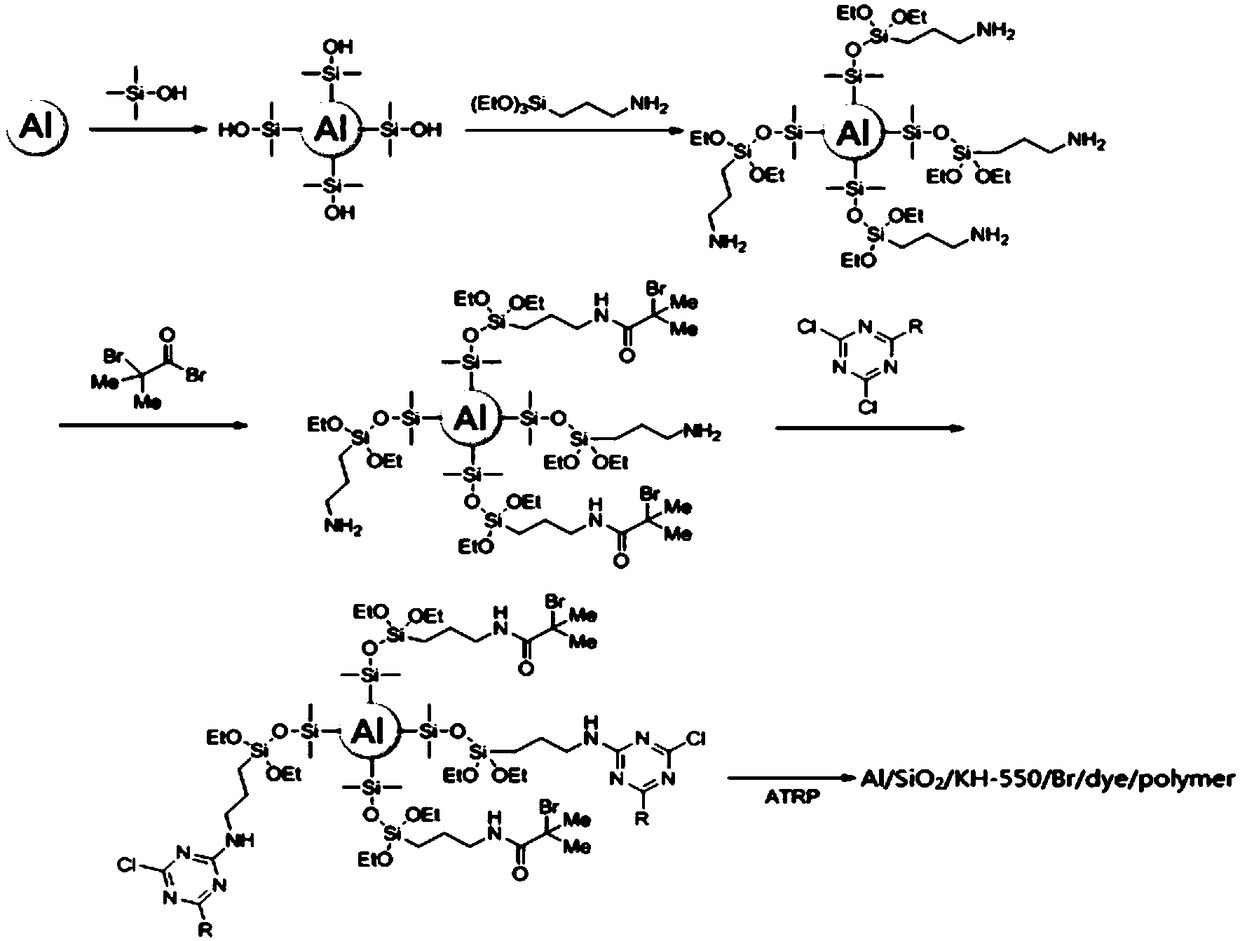

Method used

Image

Examples

Embodiment 1

[0049] (1) Mix 12 g of aluminum powder and 100 mL of absolute ethanol, and disperse ultrasonically for 20 min to obtain a dispersed phase of aluminum powder.

[0050] (2) Mix 2mL of hydrochloric acid, 10mL of distilled water, 5mL of ether, 10mL of tetraethyl orthosilicate and 60mL of absolute ethanol, and stir at 40°C for 1 hour to reach a sol state.

[0051] (3) Slowly add the dispersed phase of aluminum powder into the sol, continue stirring at 40°C, add 12 mL of ammonia water drop by drop while stirring, and continue stirring for 3 hours to obtain Al / SiO 2 Mutually.

[0052] (4) Mix 15mL of aminopropyltriethoxysilane (KH-550) and 20mL of absolute ethanol, and add Al / SiO 2 phase, kept stirring for 2h, ended the reaction, poured it out, centrifuged, washed with absolute ethanol 3 times, and dried the product in a 50°C drying oven to obtain Al / SiO 2 / KH-550.

[0053] (5) Take 3g Al / SiO 2 / KH-550, slowly add 134mL of anhydrous toluene and 22.4mL of anhydrous triethylamine, ...

Embodiment 2

[0058] (1) Mix 12 g of aluminum powder and 100 mL of absolute ethanol, and disperse ultrasonically for 20 min to obtain a dispersed phase of aluminum powder.

[0059] (2) Mix 2mL of hydrochloric acid, 10mL of distilled water, 5mL of ether, 10mL of tetraethyl orthosilicate and 60mL of absolute ethanol, and stir at 40°C for 1 hour to reach a sol state.

[0060] (3) Slowly add the dispersed phase of aluminum powder into the sol, continue stirring at 40°C, add 12 mL of ammonia water drop by drop while stirring, and continue stirring for 3 hours to obtain Al / SiO2 Mutually.

[0061] (4) Mix 15mL of aminopropyltriethoxysilane (KH-550) and 20mL of absolute ethanol, and add Al / SiO 2 phase, kept stirring for 2h, ended the reaction, poured it out, centrifuged, washed with absolute ethanol 3 times, and dried the product in a 50°C drying oven to obtain Al / SiO 2 / KH-550.

[0062] (5) Take 3g Al / SiO 2 / KH-550, slowly add 134mL of anhydrous toluene and 22.4mL of anhydrous triethylamine, ul...

Embodiment 3

[0067] (1) Mix 12 g of aluminum powder and 100 mL of absolute ethanol, and disperse ultrasonically for 20 min to obtain a dispersed phase of aluminum powder.

[0068] (2) Mix 3mL of hydrochloric acid, 15mL of distilled water, 5mL of diethyl ether, 20mL of tetraethyl orthosilicate and 60mL of absolute ethanol, and stir at 40°C for 1 hour to reach a sol state.

[0069] (3) Slowly add the dispersed phase of aluminum powder into the sol, continue stirring at 40°C, add 15 mL of ammonia water drop by drop while stirring, and continue stirring for 3 hours to obtain Al / SiO 2 .

[0070] (4) Mix 25mL of aminopropyltriethoxysilane (KH-550) and 10mL of absolute ethanol, and add Al / SiO 2 phase, kept stirring for 2h, ended the reaction, poured it out, centrifuged, washed with absolute ethanol 3 times, and dried the product in a 50°C drying oven to obtain Al / SiO 2 / KH-550.

[0071] (5) Take 3g Al / SiO 2 / KH-550, slowly add 134mL of anhydrous toluene and 22.4mL of anhydrous triethylamine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com