Antistatic biaxially-oriented polylactic acid film and preparation method thereof

A biaxially stretched, polylactic acid technology is applied in the field of antistatic biaxially stretched polylactic acid film and its preparation to achieve the effects of improving elongation at break, improving optical properties and reducing haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

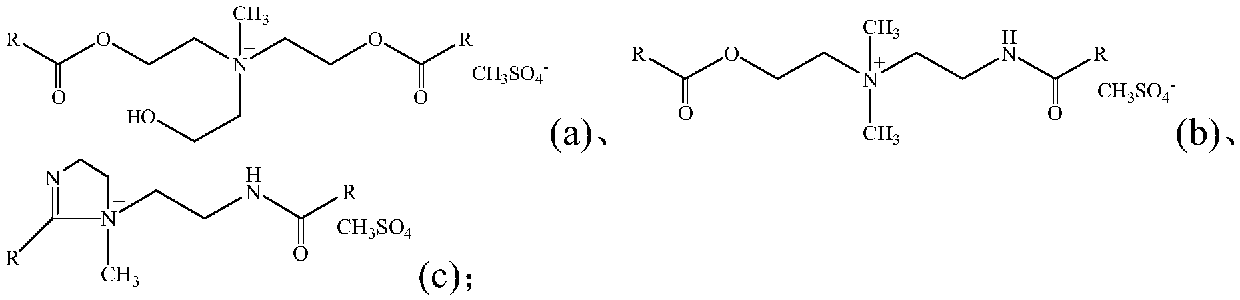

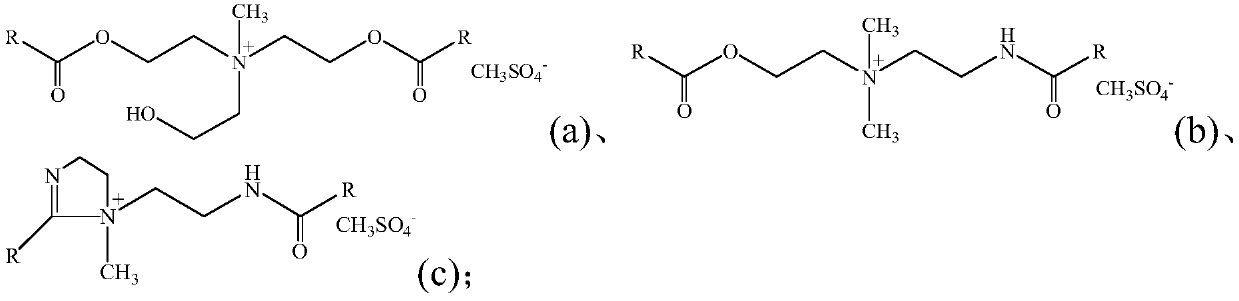

[0024] Get polylactic acid and bis(palmyl carboxyethyl) hydroxyethyl methyl sulfate methyl ester salt (that is, the quaternary ammonium salt of the structure shown in formula (a), wherein R represents palmitic acid) and mix uniformly in a weight ratio of 9:1 Finally, use a twin-screw extruder to extrude and granulate at 250°C to obtain an antistatic masterbatch with an ester-based quaternary ammonium salt content of 10%; take 1kg of antistatic masterbatch and 9kg of polylactic acid and mix them evenly and send them through the twin-screw Extruded by extruder (extruder temperature is 150°C, die head temperature is 220°C), cooled cast sheet (35°C), and then stretched vertically and horizontally asynchronously 3.5×3.5 times (100°C) to obtain ester group A BOPLA film with a quaternary ammonium content of 1% and a thickness of 25 μm.

Embodiment 2

[0026] Get polylactic acid and bis(palmyl carboxyethyl) hydroxyethyl methyl sulfate methyl ester salt (that is, the quaternary ammonium salt of the structure shown in formula (a), wherein R represents palmitic acid) and mix uniformly in a weight ratio of 4:1 Finally, use a twin-screw extruder to extrude and granulate at 230°C to obtain an antistatic masterbatch with an ester-based quaternary ammonium salt content of 20%; take 1kg of antistatic masterbatch and 9kg of polylactic acid and mix them evenly and send them through the twin-screw Extruded by extruder (extruder temperature is 150°C, die head temperature is 220°C), cooled cast sheet (35°C), and then stretched vertically and horizontally asynchronously 3.5×3.5 times (100°C) to obtain ester group BOPLA film with 2% quaternary ammonium salt content and 25 μm thickness.

Embodiment 3

[0036] Get polylactic acid and stearamidomethyl sulfate (quaternary ammonium salt of structure shown in formula (b), wherein R represents stearic acid) after mixing uniformly by the weight ratio of 3:1, use twin-screw extruder Extrude and granulate at 200°C to obtain an antistatic masterbatch with an ester quaternary ammonium salt content of 25%; get 1.2kg antistatic masterbatch and 8.8kg polylactic acid and mix them uniformly and send them to extrude through a twin-screw extruder ( The extruder temperature is 150°C, the die head temperature is 220°C), the cast sheet is cooled (35°C), and then stretched vertically and horizontally asynchronously 3.5×3.5 times (100°C) to obtain an ester quaternary ammonium salt content of 3 %, a BOPLA film with a thickness of 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com