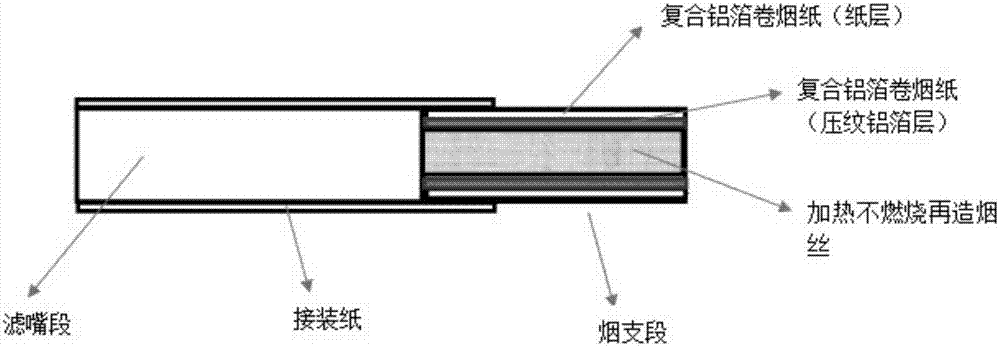

Method for preparing heating but incombustible cigarettes and application thereof

A heat-not-burn and cigarette technology, which is applied in the application, preparation of tobacco, smoker’s supplies, etc. It can solve the problems of affecting production efficiency, frequent equipment parking, and short tobacco section of cigarettes, so as to enhance the atomization effect and reduce the drop of tobacco , Improve the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

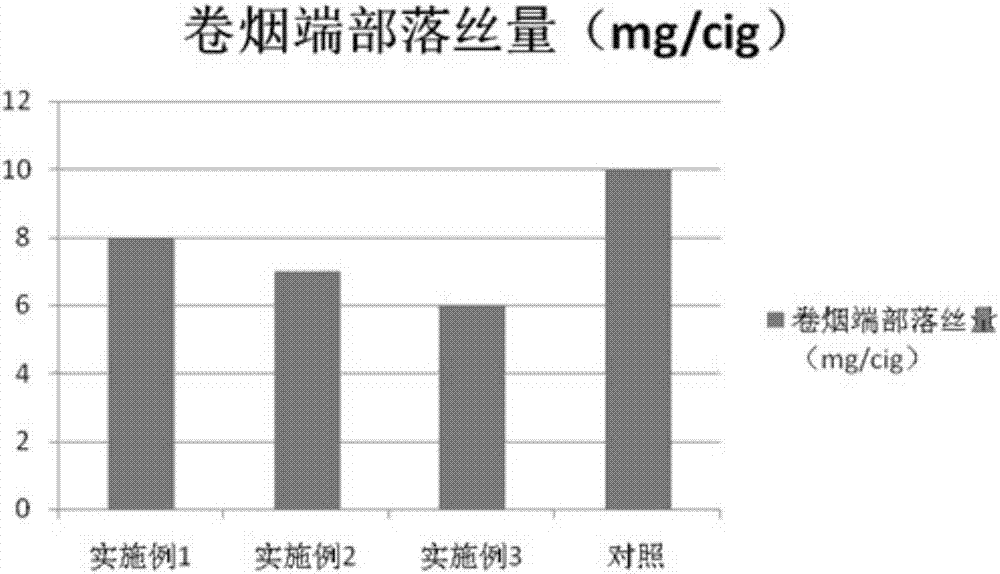

Embodiment 1

[0038]A method for preparing heat-not-burn cigarettes, comprising the following technical steps:

[0039] (1) Raw material preparation: Prepare raw materials according to mass percentage ratio: 50% of tobacco raw material, 25% of atomizing agent glycerin, 5% of solid adhesive (sodium alginate, potassium alginate, CMC, PAC), 5% of tobacco additives ( Solid calcium salt 3%, tobacco flavoring 2%), fiber (wood fiber and coconut fiber, by mass ratio 4:1) 2%, 45 ℃ warm water 18%;

[0040] (2) Mixing and crushing of dry materials: put tobacco raw materials, solid adhesive and solid tobacco additives (calcium carbonate, calcium lactate, 2% and 1% by mass percentage) in a low-temperature pulverizer in proportion, and pulverize to 200 °C at 2 ° C. Mesh, mix evenly;

[0041] (3) Mix and disperse the wet material evenly: Pour the fiber and 45°C warm water into the material bucket in proportion, stir at a high speed of 400r / min, and use 50KHz ultrasonic cavitation to assist in dissolving ...

Embodiment 2

[0046] A method for preparing heat-not-burn cigarettes, comprising the following technical steps:

[0047] (1) Raw material preparation: Prepare raw materials according to mass percentage ratio: tobacco raw material 65%, atomizer 11% (glycerin, propylene glycol, ethylene glycol are respectively 6%, 3%, 2% by mass percentage), solid adhesive 4 %, tobacco additives 3.5% (solid calcium salt 3%, tobacco spice mint 0.5%), fiber 1.5% (tobacco rod fiber, bagasse pulp are respectively 1% and 0.5% by mass percentage), 55 ℃ warm water 15%;

[0048] (2) Mixing and crushing of dry materials: put tobacco raw materials, solid adhesive and solid tobacco additives (calcium carbonate, calcium citrate, calcium tartrate are 1% by mass percentage respectively) in liquid nitrogen low temperature pulverizer in proportion, 3 ℃ Grinding to 240 mesh, at this time, it is pulverized at low temperature and high speed to mix evenly;

[0049] (3) Mix and disperse the wet material evenly: Pour the fiber an...

Embodiment 3

[0054] A method for preparing heat-not-burn cigarettes, comprising the following technical steps:

[0055] (1) Raw material preparation: Raw materials are prepared according to mass percentage ratio: 70% of tobacco raw material, 10% of atomizing agent (8% and 2% of glycerin and propylene glycol respectively by mass percentage), 3% of solid adhesive (rosin, chitosan , sodium glycerophosphate is equal mass ratio), tobacco additive 1% (calcium carbonate 0.5%, tobacco extract 0.5%), fiber 1% (wood pulp, bamboo pulp, etc. mass ratio), 60 ℃ warm water 15%;

[0056] (2) Mixing and crushing of dry materials: put tobacco raw materials, solid adhesive and solid tobacco additive calcium salt in proportion to a liquid nitrogen low-temperature pulverizer, pulverize to 300 mesh at 4°C, and then pulverize at low temperature and high speed to mix evenly;

[0057] (3) Mix and disperse the wet material evenly: Pour the fiber and warm water into the material bucket in proportion, stir at a high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com