General grade pitch-based carbon fiber spinning oil

A technology of pitch-based carbon fiber and spinning oil, which can be used in carbon fiber, fiber processing, textile and paper making, etc., and can solve the problems of static electricity, abrasion, and easy adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

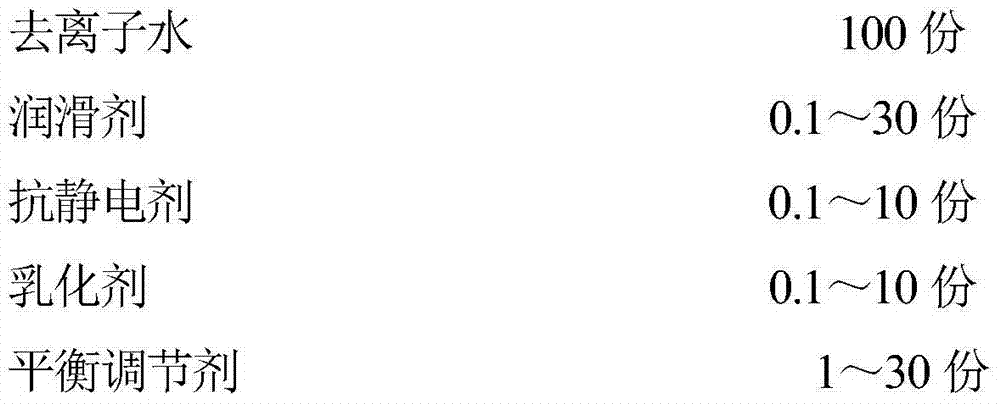

[0018] Taking 100g of deionized water used to prepare general-purpose pitch-based carbon fiber spinning oil as an example, other raw materials and their mass ratios are as follows:

[0019]

[0020] The preparation method is as follows: 100g deionized water, 2g methyl phenyl silicone oil, 5g polypropylene glycol with an average molecular weight of 200, 6g sorbitan fatty acid ester S-20 and 20g acetone are added to the beaker in turn under stirring , heated up to 50°C, stirred at constant temperature for 30 minutes, and then ultrasonicated for 15 minutes with an ultrasonic cleaner to obtain a general-grade pitch-based carbon fiber spinning oil, which has no delamination phenomenon after being placed for 3 months, and its viscosity is 8mPa.s after testing , the light transmittance is 90%, which is basically the same as the appearance, viscosity and light transmittance of the newly prepared oil agent, indicating that its stability is better.

Embodiment 2

[0022] Taking 100g of deionized water used to prepare general-purpose pitch-based carbon fiber spinning oil as an example, other raw materials and their mass ratios are as follows:

[0023]

[0024] Its preparation method is the same as that of Example 1, and the obtained oil agent has no delamination phenomenon after being placed for 3 months, its viscosity is 2 mPa.s after testing, and its light transmittance is 85%.

Embodiment 3

[0026] Taking 100g of deionized water used to prepare general-purpose pitch-based carbon fiber spinning oil as an example, other raw materials and their mass ratios are as follows:

[0027]

[0028] Its preparation method is the same as that of Example 1, and the obtained oil agent has no delamination phenomenon after being placed for 3 months, its viscosity is 10 mPa.s after testing, and its light transmittance is 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com