Nanometer self-cleaning film, preparation method thereof and lamp

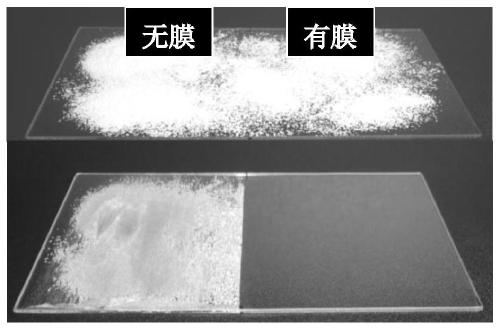

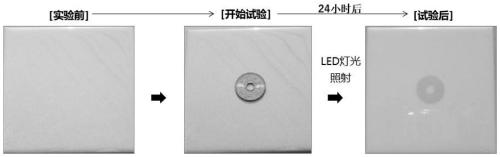

A nano-self-cleaning, thin-film technology, used in biocide-containing paints, antifouling/underwater coatings, conductive coatings, etc., can solve problems such as large thickness of protective film, waste of material coating process, and complexity, and reduce maintenance. Time, improved luminosity and service life, small film thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of nanometer self-cleaning film in the present embodiment, this nanometer self-cleaning film is made up of A, B two-layer film, and described A, B two-layer film are made of containing nanoscale TiO 2 and SiO 2 Made of photocatalyst material. The A-layer film is a bottom layer film for bonding, and the B-layer film is a surface film for photocatalytic self-cleaning.

[0033] A kind of preparation method of nanometer self-cleaning film as above, its preparation method comprises the following steps:

[0034] 1) Preparation of layer A film

[0035] a. Measure 0.5mol / L of TiCl 4 The solution 90mL was magnetically stirred at a temperature of 70°C for 30min, and slowly added dropwise 0.3mol / L Na 2 SiO 3 Solution 10mL, after dropwise addition, continue to stir for 20min, and add 0.5mL cationic surfactant cetyltrimethylammonium bromide to it;

[0036] b. Add NaOH solution dropwise to adjust the pH value to 8, so that the solution obtained in step a precipitates. Afte...

Embodiment 2

[0049] A kind of nanometer self-cleaning film in the present embodiment, this nanometer self-cleaning film is made up of A, B two-layer film, and described A, B two-layer film are made of containing nanoscale TiO 2 and SiO 2 Made of photocatalyst material. The A-layer film is a bottom layer film for bonding, and the B-layer film is a surface film for photocatalytic self-cleaning.

[0050] A kind of preparation method of nanometer self-cleaning film as above, its preparation method comprises the following steps:

[0051] 1) Preparation of layer A film

[0052] a. Measure 0.5mol / L of TiCl 4 The solution 90mL was magnetically stirred at a temperature of 70°C for 30min, and slowly added dropwise 0.3mol / L Na 2 SiO 3 Solution 20mL, after dropwise addition, continue to stir for 20min, and add 0.5mL cationic surfactant cetyltrimethylammonium bromide to it;

[0053] b. Add NaOH solution dropwise to adjust the pH value to 8, so that the solution obtained in step a precipitates. Af...

Embodiment 3

[0066] A kind of nanometer self-cleaning film in the present embodiment, this nanometer self-cleaning film is made up of A, B two-layer film, and described A, B two-layer film are made of containing nanoscale TiO 2 and SiO 2 Made of photocatalyst material. The A-layer film is a bottom layer film for bonding, and the B-layer film is a surface film for photocatalytic self-cleaning.

[0067] A kind of preparation method of nanometer self-cleaning film as above, its preparation method comprises the following steps:

[0068] 1) Preparation of layer A film

[0069] a. Measure 0.5mol / L of TiCl 4 The solution 90mL was magnetically stirred at a temperature of 70°C for 30min, and slowly added dropwise 0.3mol / L Na 2 SiO 3 Solution 30mL, after dropwise addition, continue to stir for 20min, and add 0.5mL of cationic surfactant cetyltrimethylammonium bromide to it;

[0070] b. Add NaOH solution dropwise to adjust the pH value to 8, so that the solution obtained in step a precipitates,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com