Multi-degree-of-freedom high-precision motion platform based on few-branch-chain mechanism

A technology of motion platform and degree of freedom, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, installation, etc., which can solve the problems of short service life, large volume, low sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

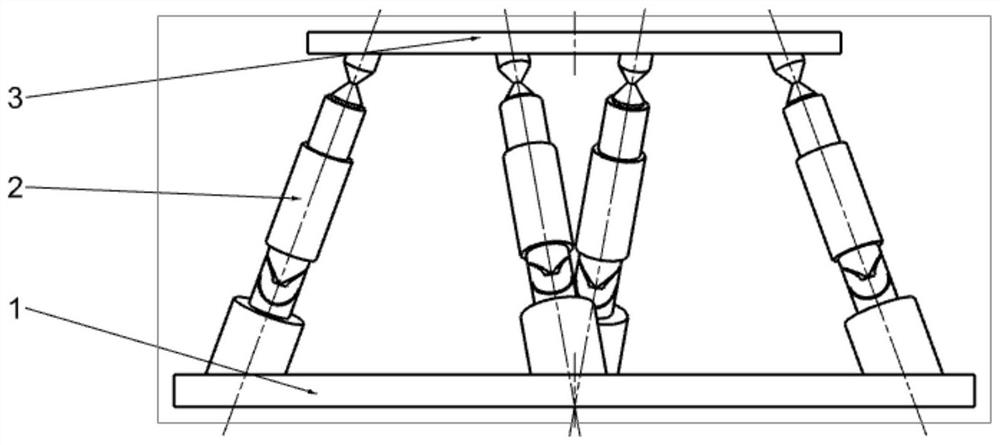

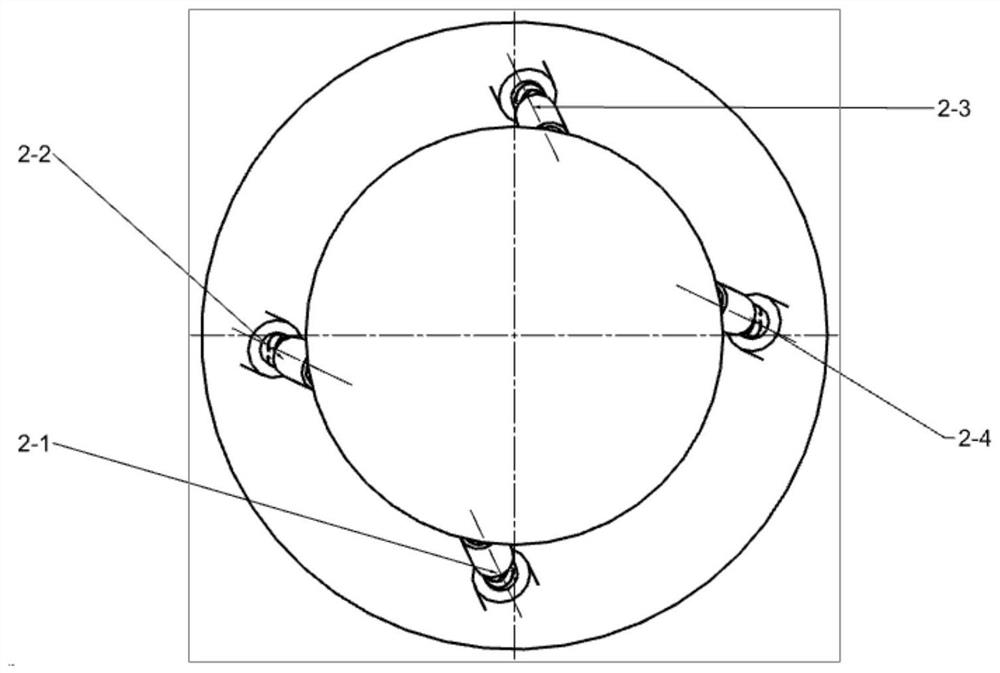

[0029] A multi-degree-of-freedom parallel motion platform driven by a flexible hinge and a piezoelectric inertial actuator includes a static platform 1, four telescopic branch chains 2 corresponding to two pairs, and a dynamic platform 3.

[0030] refer to figure 1 , the static platform 1 and the dynamic platform 3 are connected by a flexible ball pair and a flexible Hooke hinge, and the telescopic branch chain 2 is changed in displacement by a piezoelectric inertial driver.

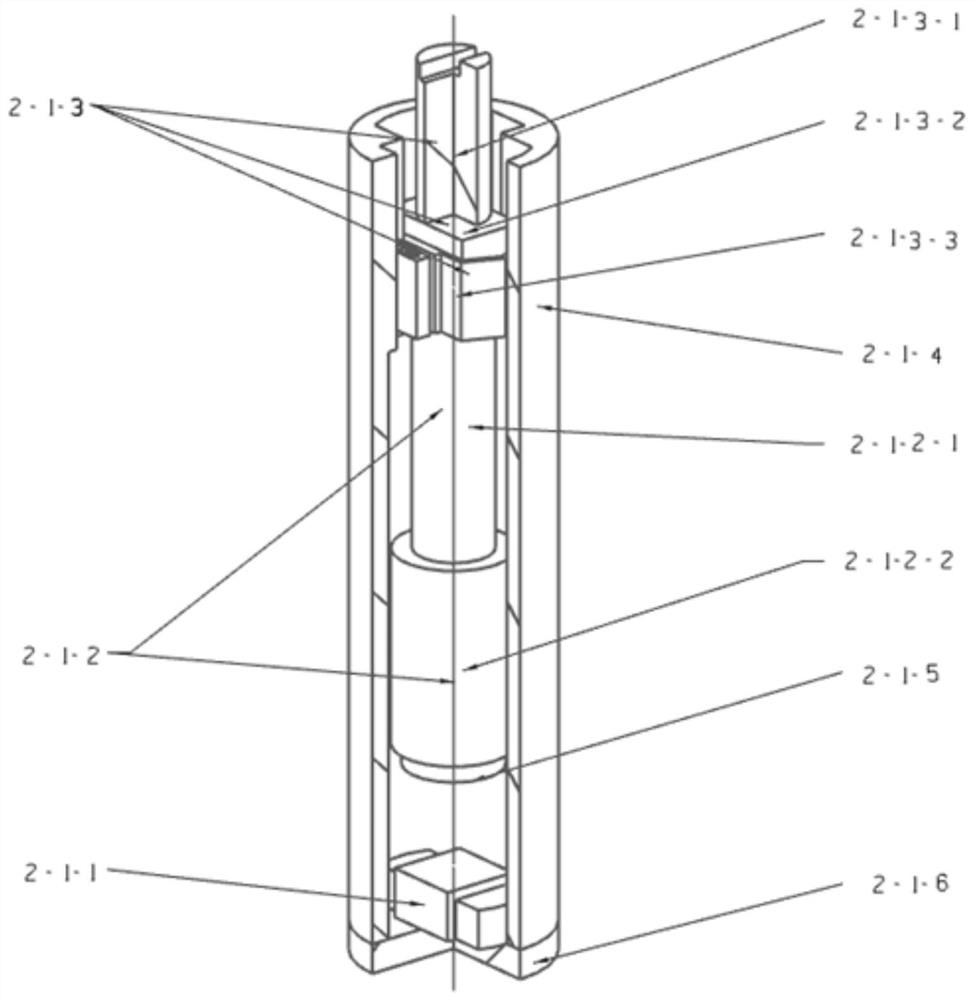

[0031] refer to image 3, the scalable branch chain 2 of the multi-degree-of-freedom motion platform is driven by a linear inertial piezoelectric actuator with a displacement sensing function, and the actuator includes a proportional linear Hall sensor 2-1-1, an actuating body 2- 1-2. Motion unit 2-1-3, cylindrical shell 2-1-4, permanent magnet 2-1-5, base 2-1-6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com