Charcoal-containing plastic packing material and method for manufacturing same

A technology of plastic packaging and manufacturing method, which is applied in the field of carbon-containing plastic packaging materials and its manufacturing, can solve the problems of poor quality, insufficient compatibility of carbon and resin, and foreign body sensation, so as to reduce odor and ammonia gas, and inhibit corruption. bacteria, the effect of delaying the process of corruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0046] Manufacture of plastic packaging bags

[0047] 100kg of polyethylene resin and 0.5kg of carbon powder with an average diameter of about 10μm and a particle uniformity of 97% are put into the mixing machine, and the resin and carbon powder are mixed and extruded in a vacuum state to form a masterbatch in the form of flakes. Then, the masterbatch is blown into a film with a thickness of 0.05 mm, and then the film is cut to make a carbon-containing polyethylene zipper bag.

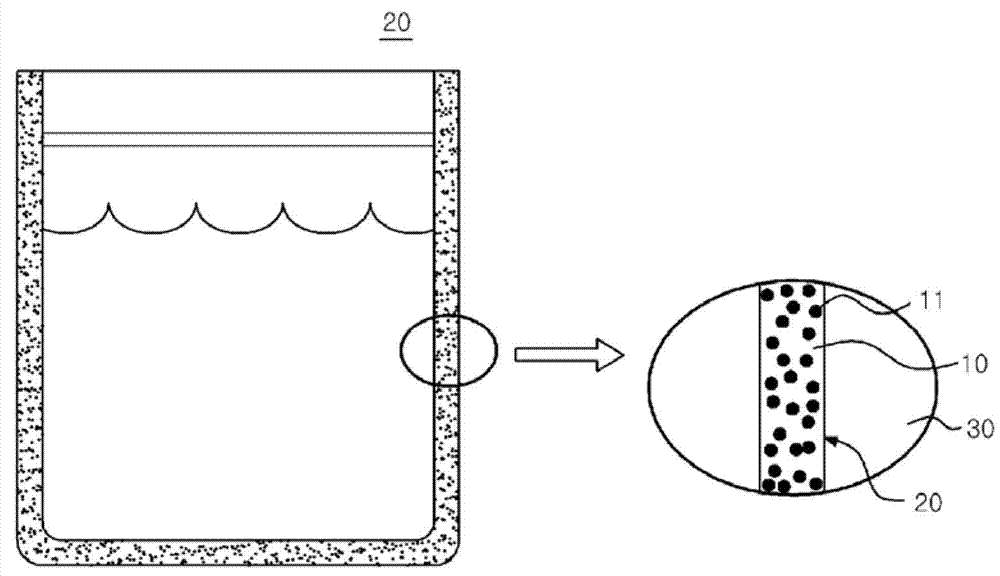

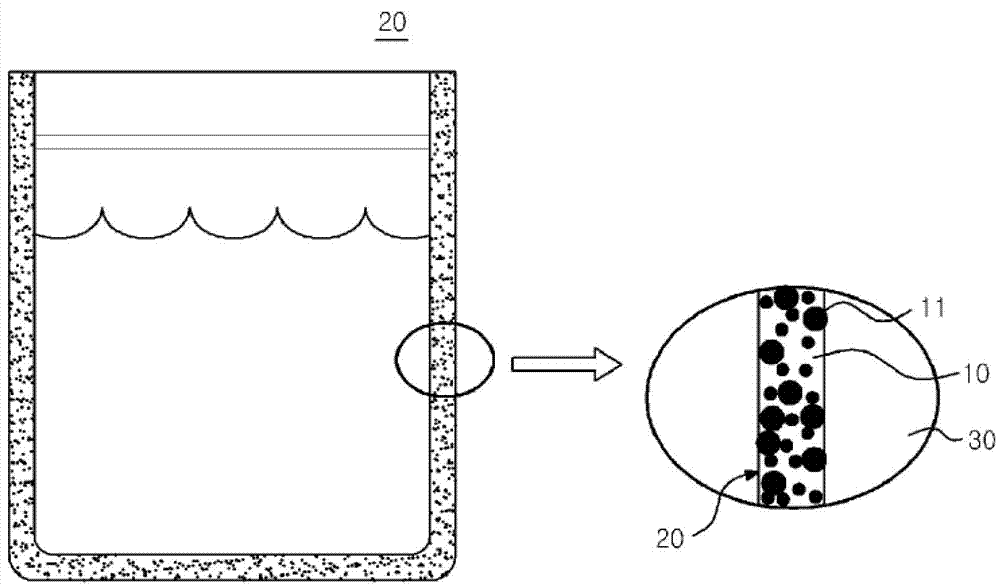

[0048] figure 1 It is a cross-sectional simulation diagram of the plastic packaging bag (zipper bag) manufactured in this way. The packaging material manufactured according to the invention can adjust the particle size and particle size distribution according to the thickness, the carbon particles will not protrude on the surface, and the surface of the packaging bag will not appear lumpy or foreign body feeling, and maintain a smooth state as a whole. on the contrary, figure 2 It is an illustra...

manufacture example 2

[0050] Manufacture of fruit trays for fruit packaging

[0051] 100kg of polyethylene resin and 2kg of charcoal powder with an average diameter of about 20μm and a particle uniformity of 92% are put into the mixing machine, and the resin and charcoal powder are mixed and extruded in a vacuum state to form a masterbatch in the form of flakes, and then extruded The masterbatch is made into thin sheets with a thickness of 0.8mm by compression molding, and then air-pressed into a fruit plate for fruit packaging.

manufacture example 3

[0053] Manufacture of airtight containers

[0054] 100kg of polyethylene resin and 7kg of charcoal powder with an average diameter of about 35μm and a particle uniformity of 85% are put into the mixing machine, and the resin and charcoal powder are mixed and extruded in a vacuum state to form a masterbatch in the form of flakes, and then injected. Forming method The masterbatch is made into a sealed container with a thickness of up to 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com