Distributed feedback injection amplification semiconductor laser

A distributed feedback and semiconductor technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems affecting the stability of amplified lasers, and achieve the effects of ensuring power stability, beam quality, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

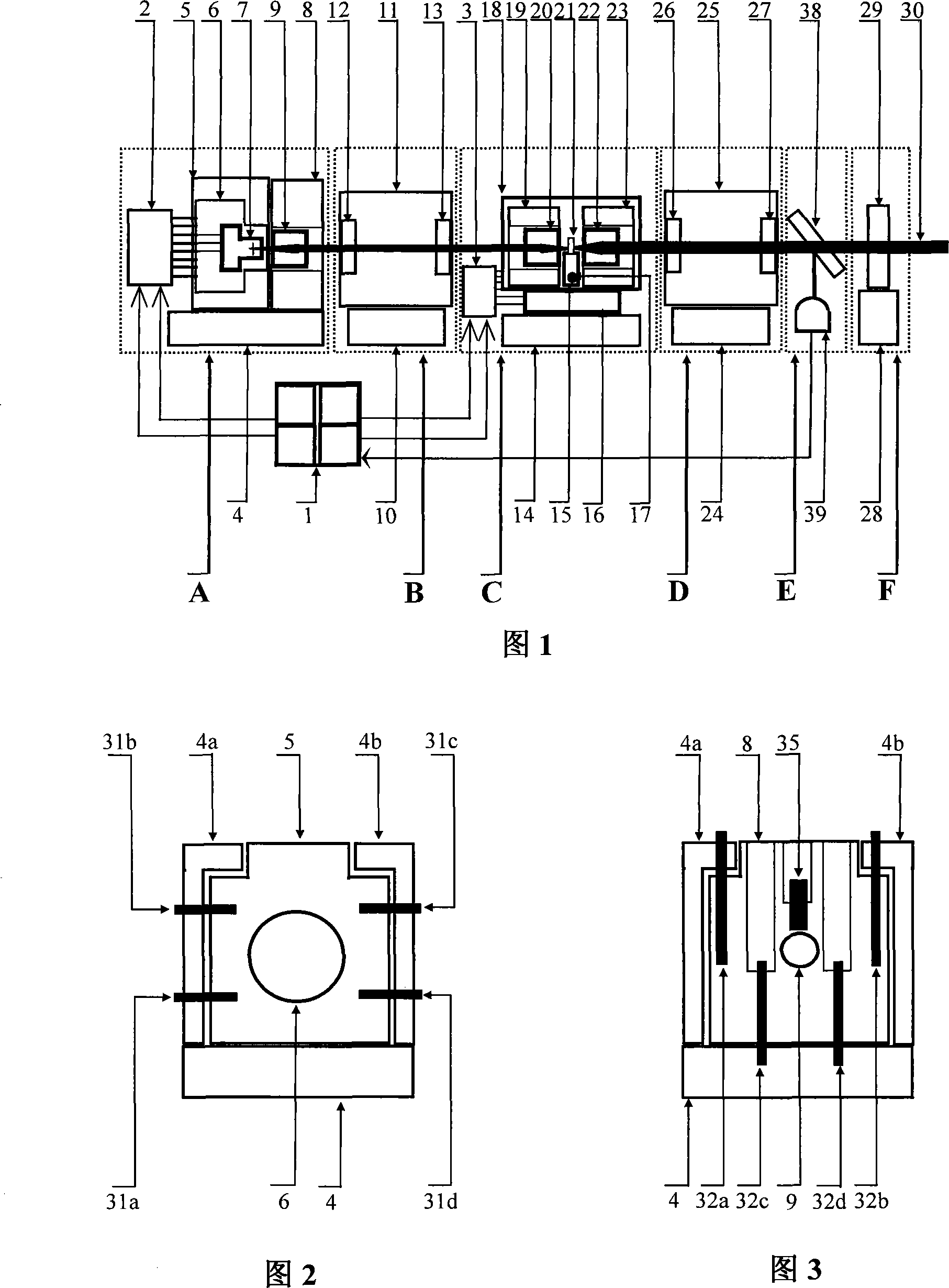

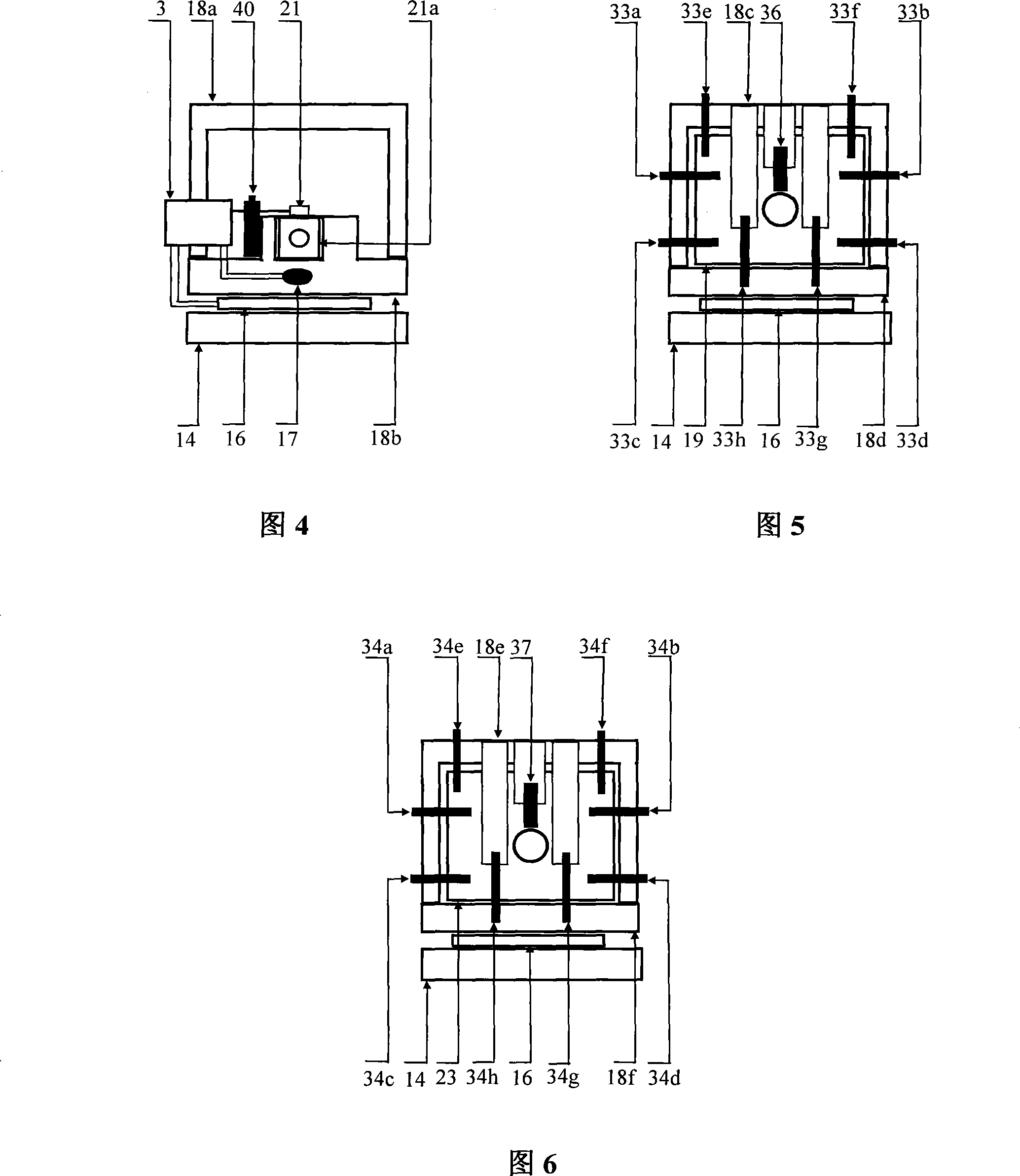

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] According to Figure 1, it can be seen that the tapered amplified semiconductor laser consists of six main lasers A, the first optical isolator B, the tapered laser amplifier C, the second optical isolator D, the weak light detection laser power stabilization system E and the laser shaping system F Partial composition. The main laser A includes the current temperature control interface 2, the main laser base 4, the main laser adjustment seat 5, the thermoelectric cooling package module 6, the distributed feedback semiconductor laser tube 7, the main laser collimation lens adjustment seat 8, and the main laser collimation lens 9 . The first optical isolator B includes an optical isolator base 10 , a Glan Taylor prism 12 , an optical rotator 11 and a Glan Taylor prism 13 . The conical laser amplifier C includes a conical laser amplifier base 14, a conical laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com