Patents

Literature

84results about How to "Avoid breakdown phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

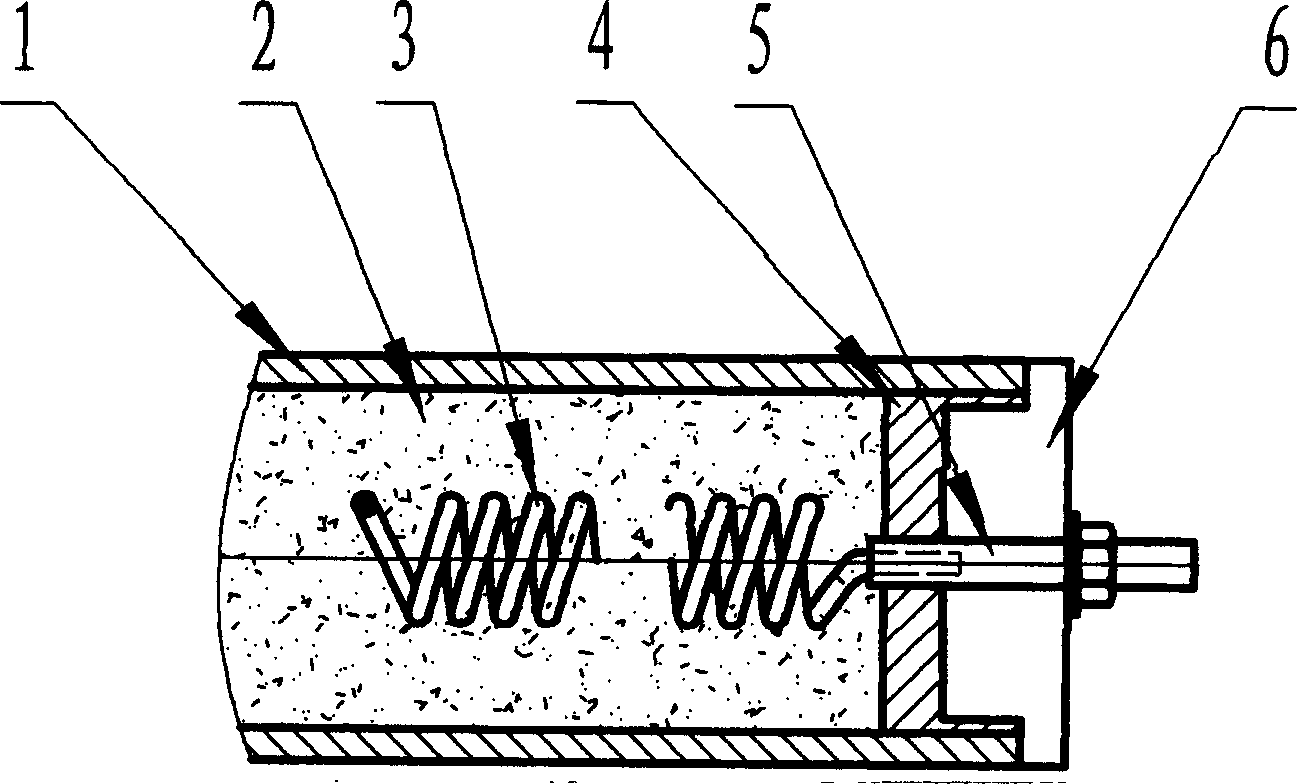

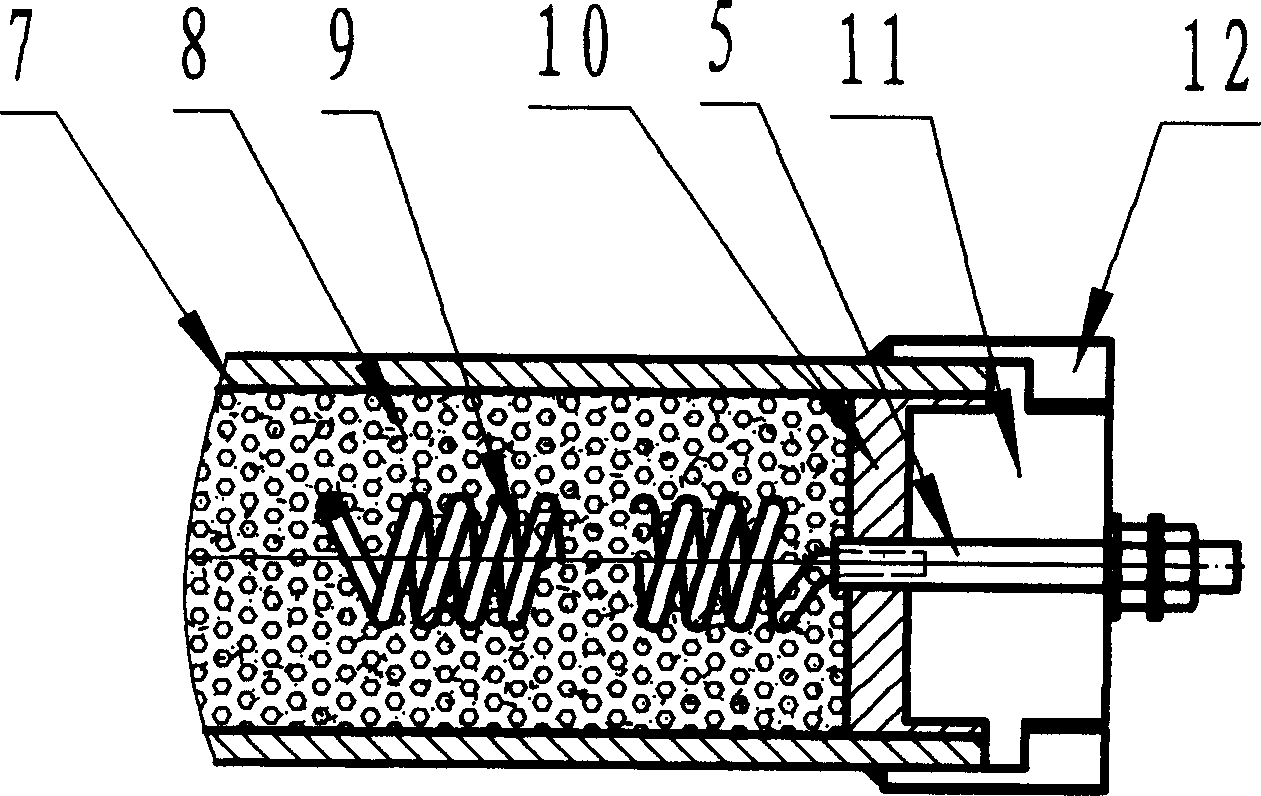

Vacuum high temp. electric heating pipe and product tech. thereof

InactiveCN1787699ANot easily oxidizedSolution to short lifeOhmic-resistance waterproof/air-tight sealsHeating element shapesHydrogenCarbon fibers

A vacuum high temperature heater tube includes a refractory steel outer guard tube and a hot wire, in which, a mixed filling layer is set between the surrounding of the hot wire and the guard tube, a seal casing cap is set at the line end, an insulation porcelain base is set out of the seal casing cap, a screw cutting sleeve is set at the outer end of the insulation porcelain base and the back of the cutting sleeve is fixed to the outer wall of the guard tube. The production technology includes: cleaning the guard tube, drying, removing hydrogen, winding the carbon hot wire on a stainless steel rod in twist and putting it at the center of the guard tube, filling a matched MgO compound material uniformly and vibrating it to draw out the stainless steel rod steadily to be filled, shrinking the tube, heating it to 150deg.C for 1 hour to be vacuumed and removing moisture till 500Kohm insulation resistance, filling a seal casing cap, pressing tightly the insulation porcelain base with the screw cutting sleeve to be welded with the outer wall of the guard tube, shaping, testing and verifying and packing the product.

Owner:萧鲲

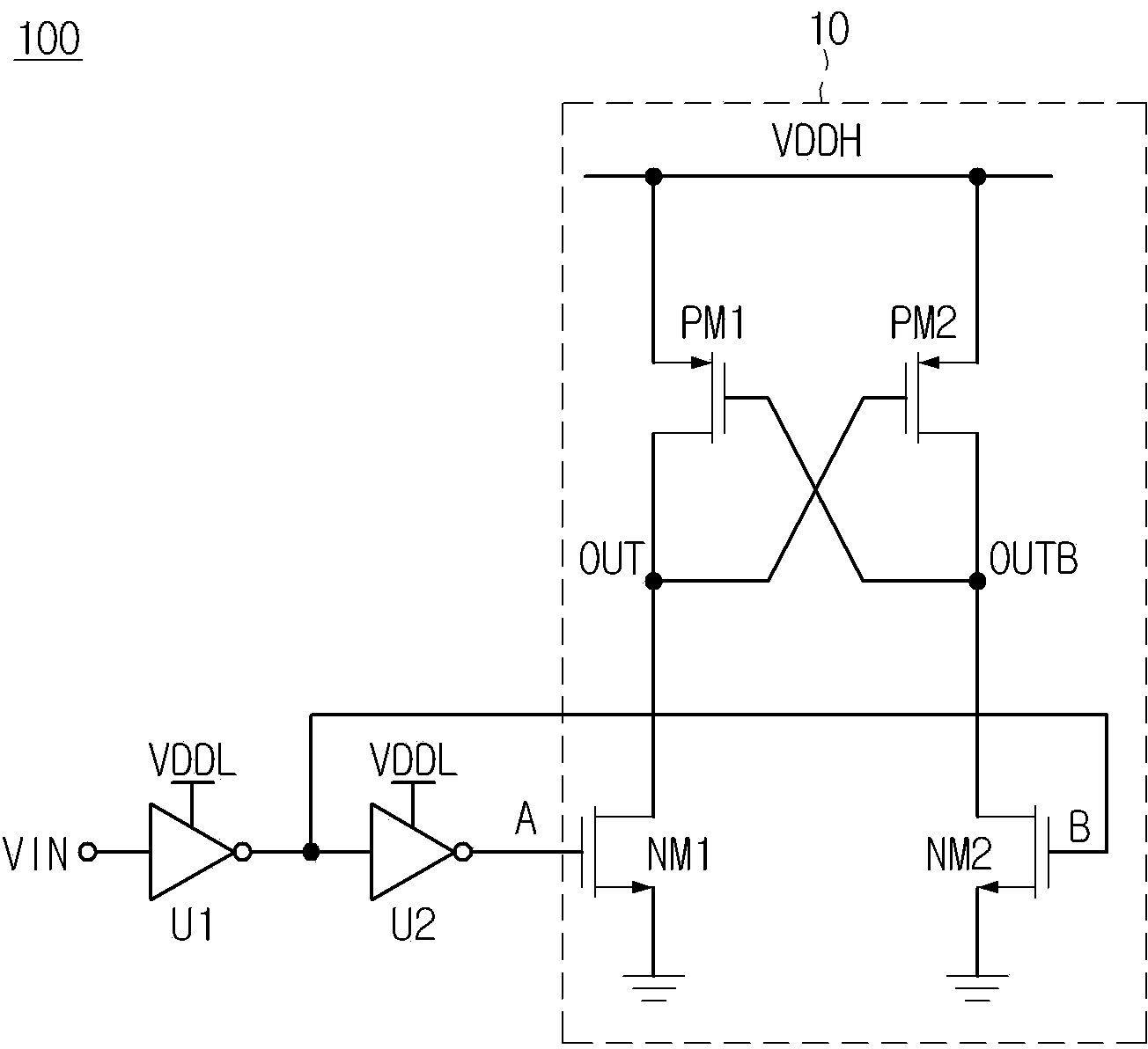

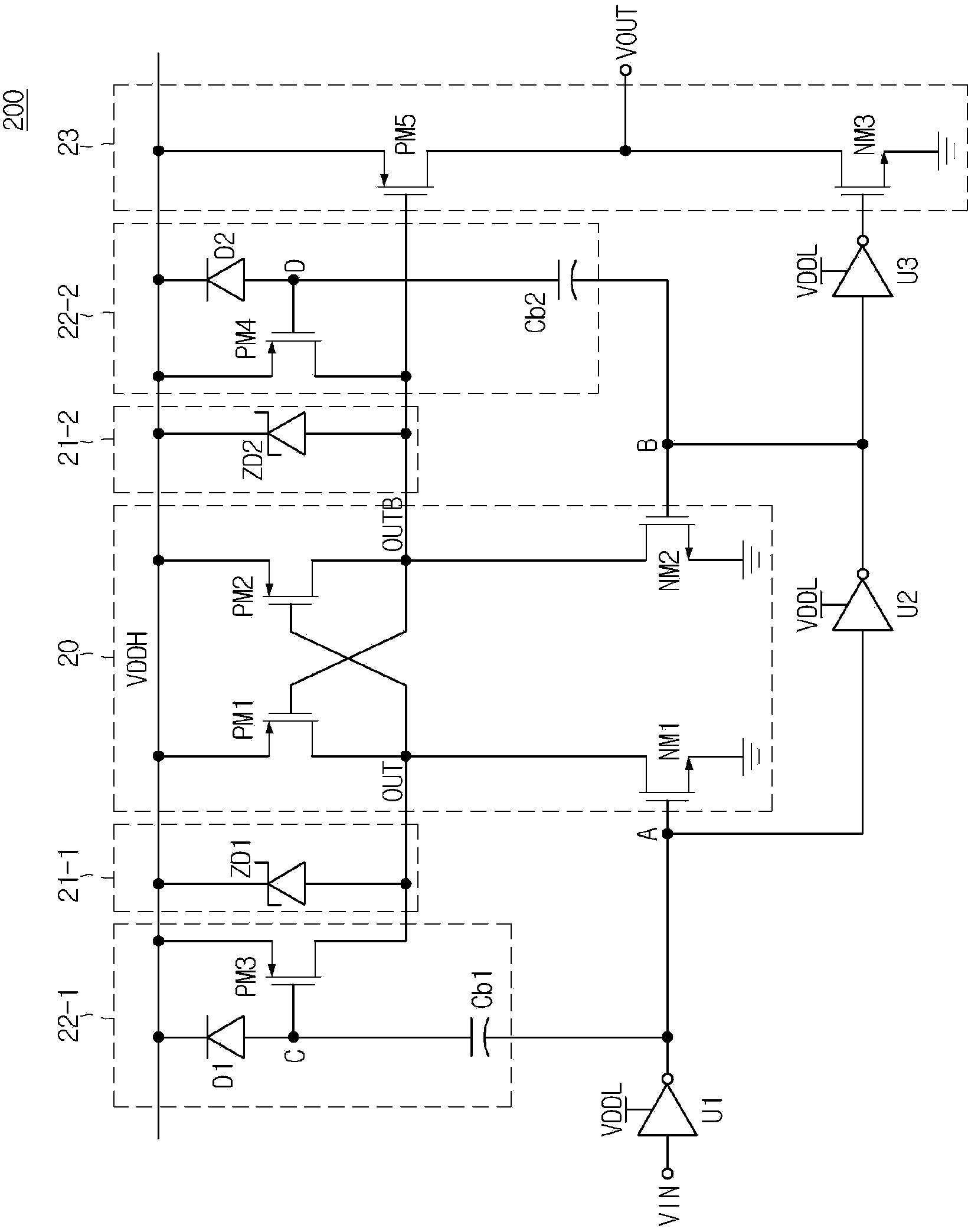

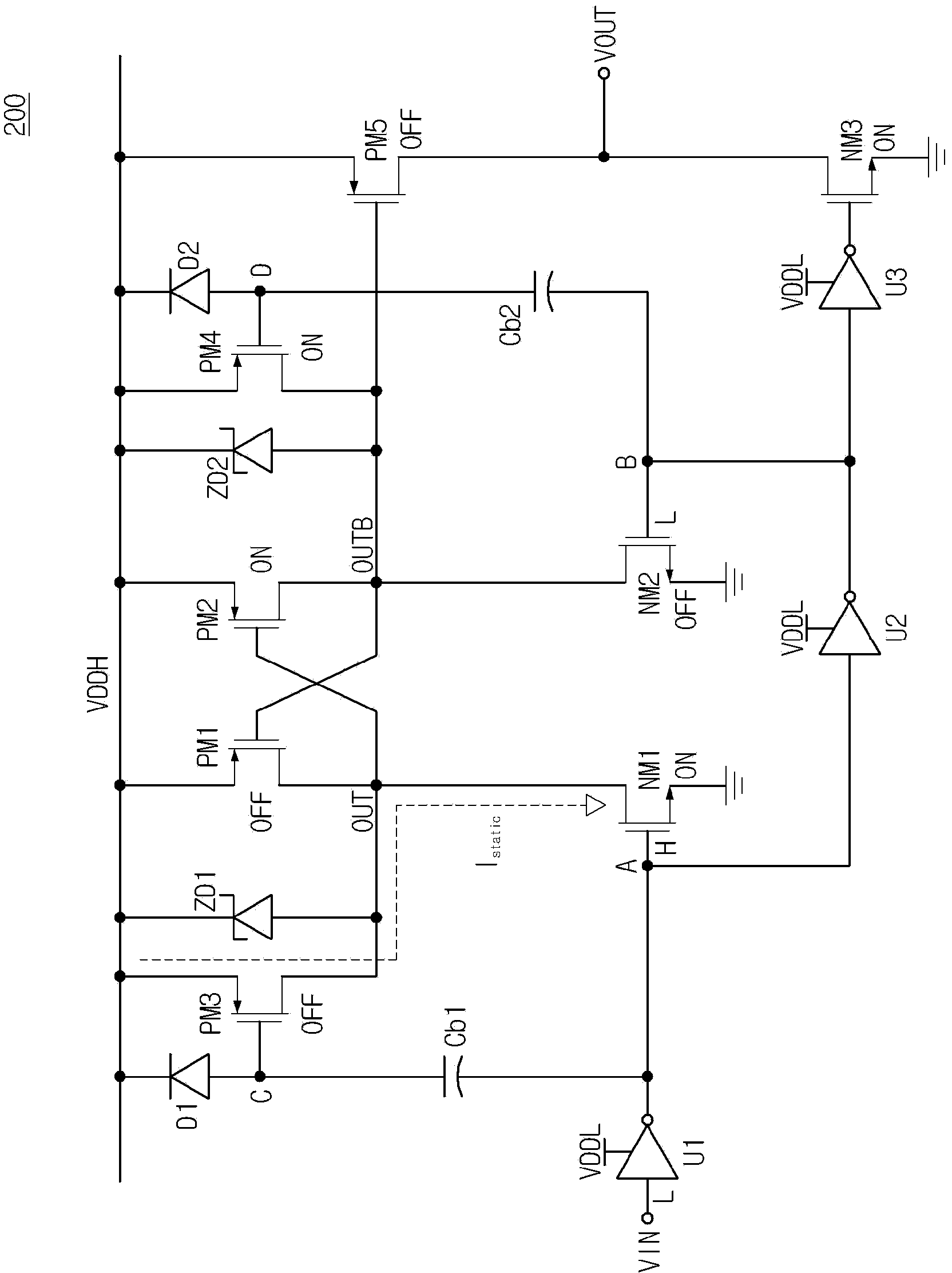

Level shift device

InactiveCN103684412APrevent Vgs breakdown phenomenonReduce power consumptionStatic indicating devicesLogic circuits coupling/interface using field-effect transistorsVoltage generatorLow voltage

Disclosed is a level shift device. The level shift device to convert an input signal having a low-voltage level into an output signal having a high-voltage level includes a latch-type level shifter and a voltage generator. The latch-type level shifter includes two upper pull-up P channel transistors and two lower P channel transistors to prevent the gate-source voltage breakdown of the two upper pull-up P channel transistors. The two upper pull-up P channel transistors and the two lower P channel transistors form a latch structure. The voltage generator generates a voltage to prevent the gate-source voltage brake down of the two upper pull-up P channel transistors and provides the voltage to the gate electrodes of the two lower P channel transistors.

Owner:LSIS CO LTD

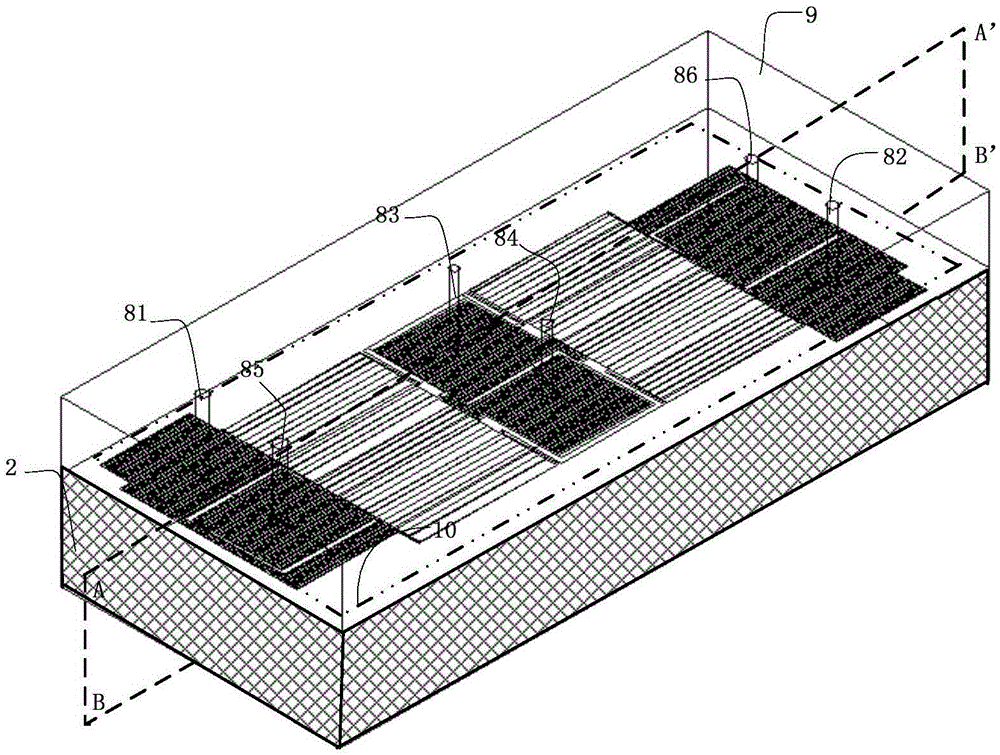

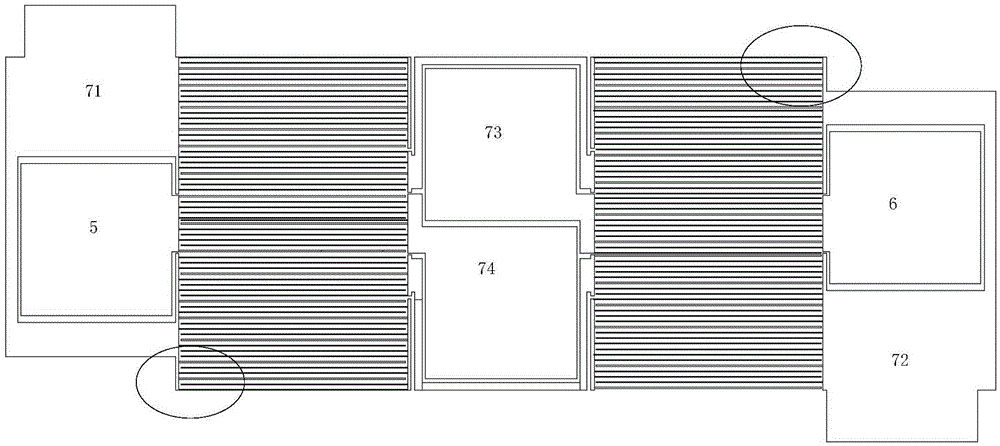

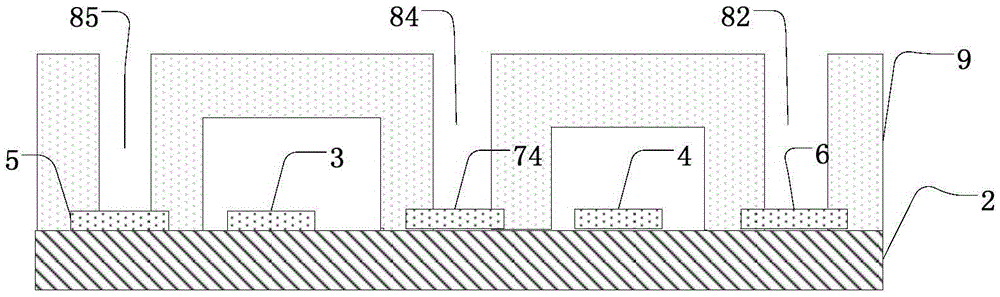

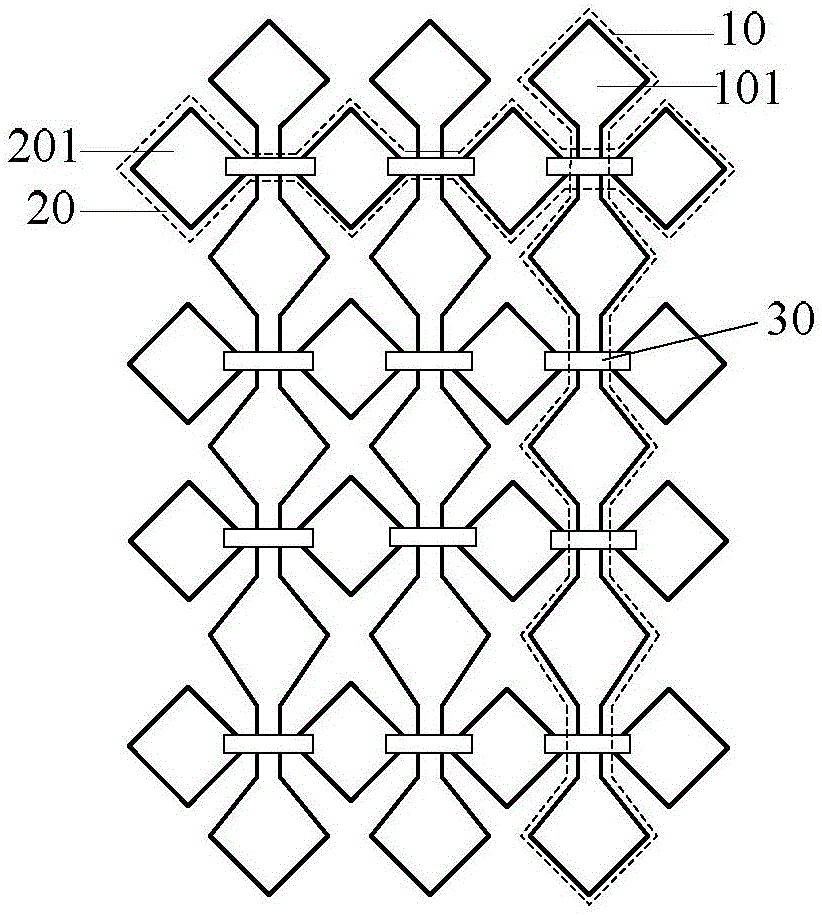

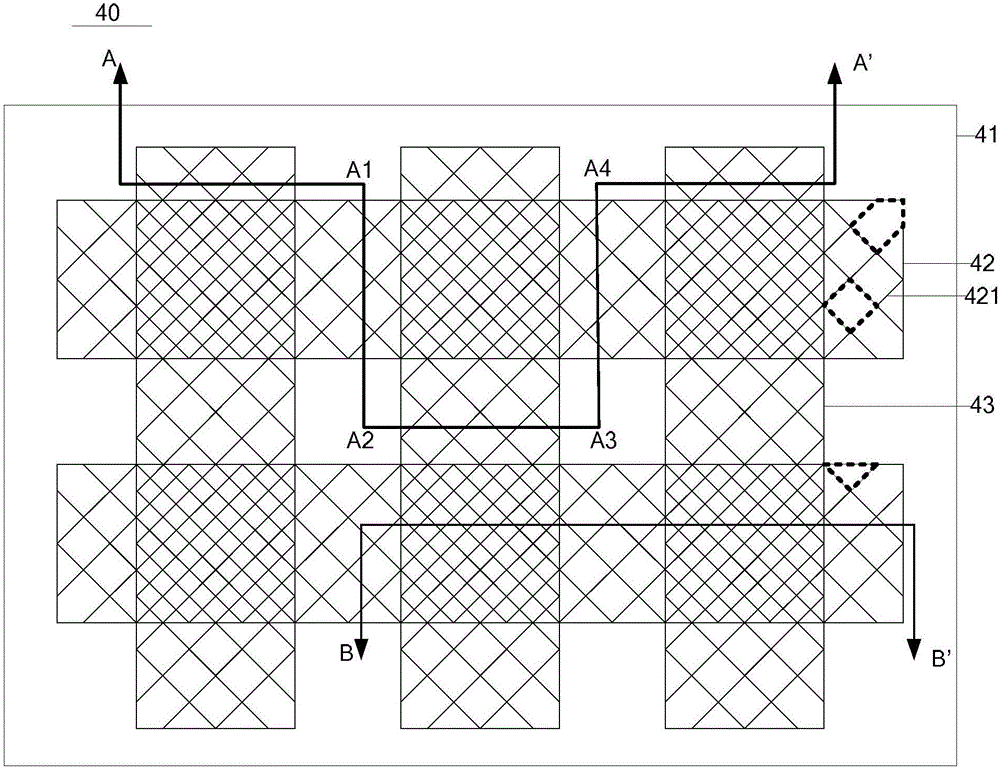

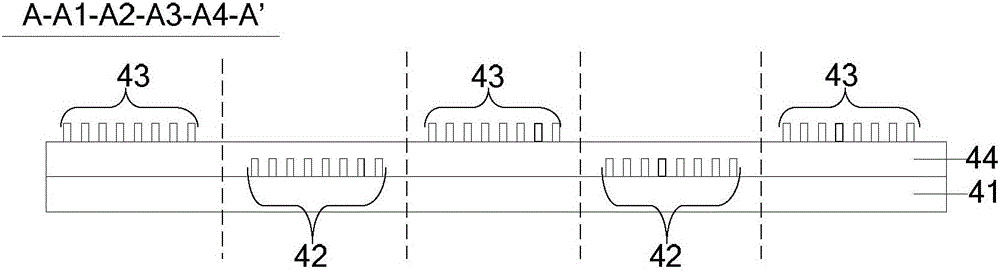

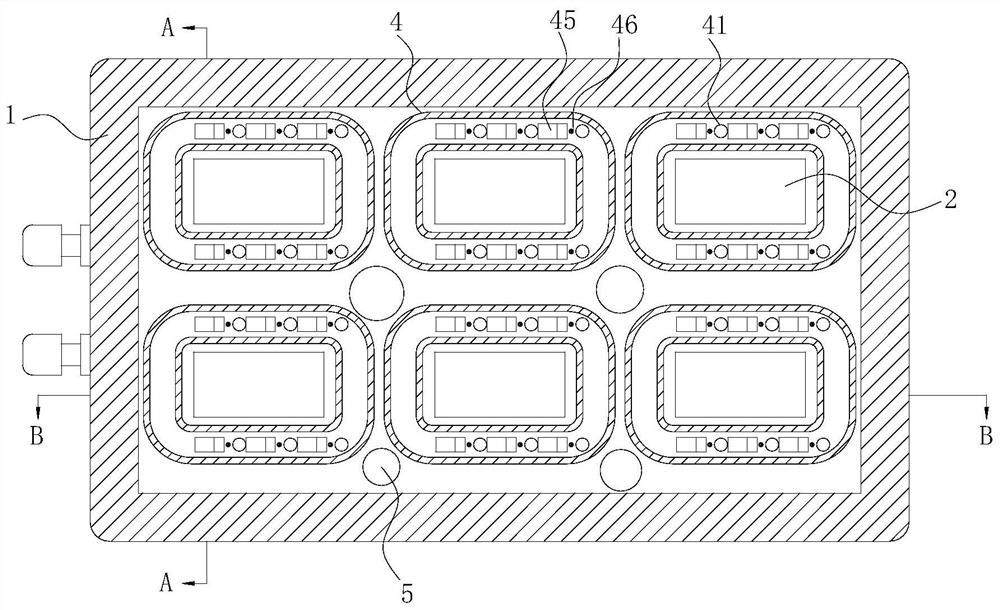

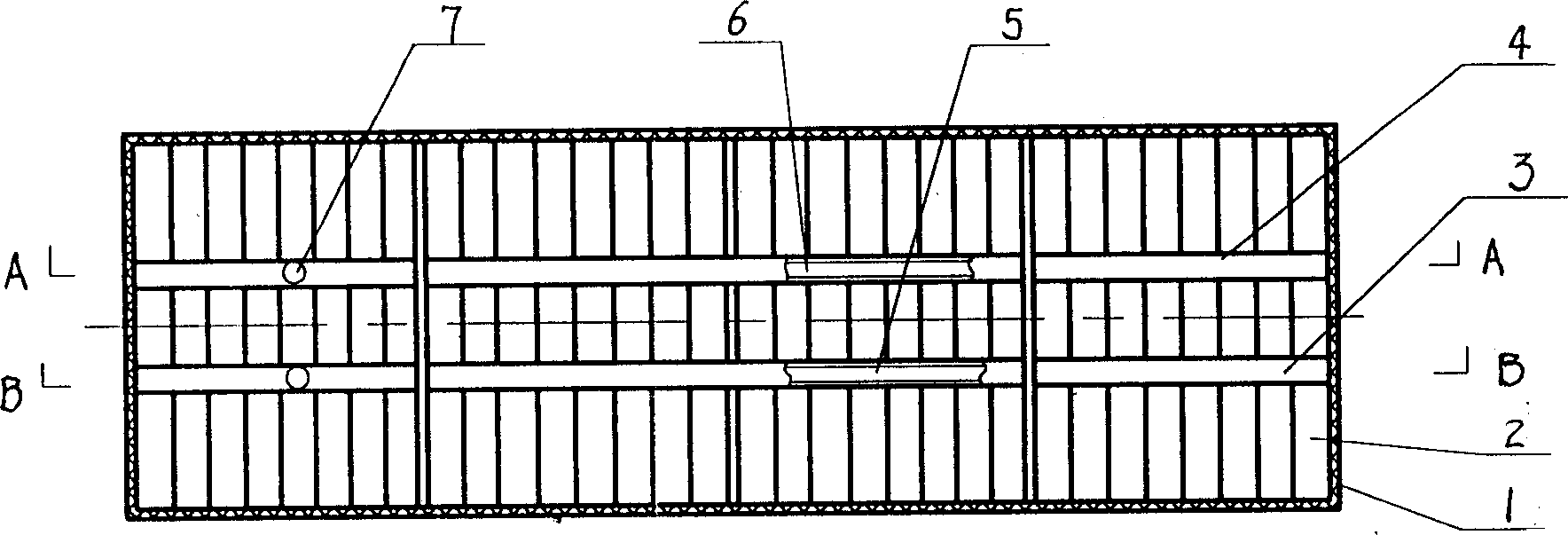

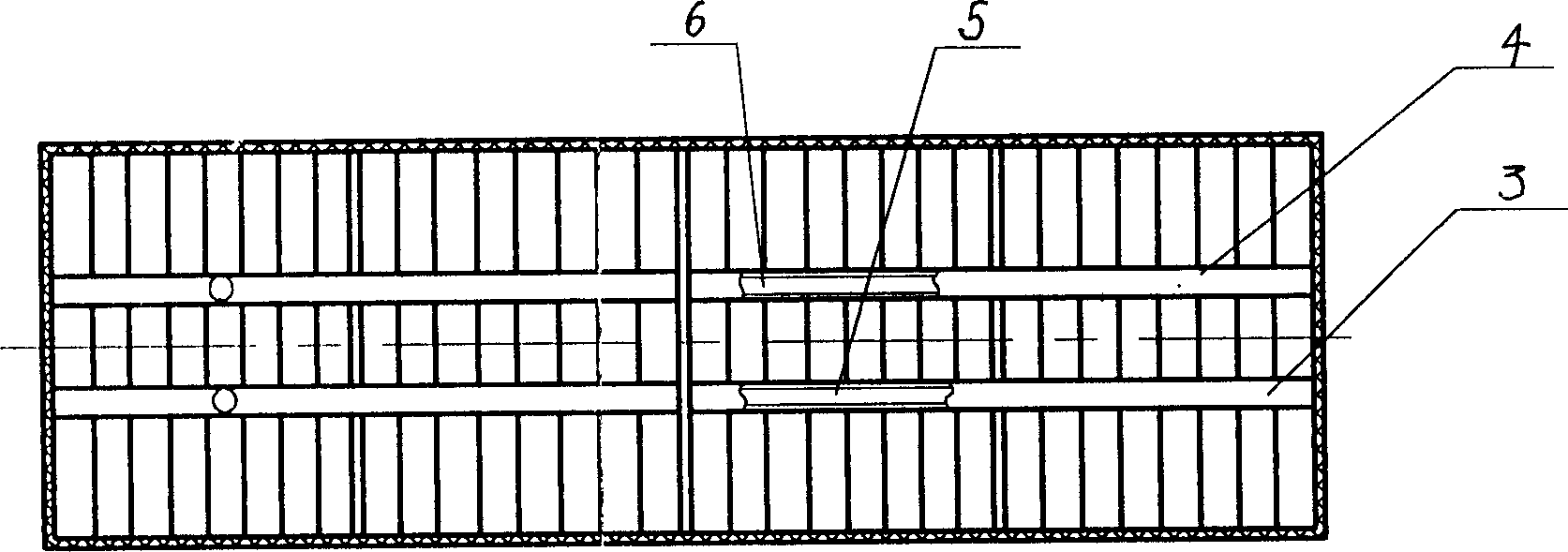

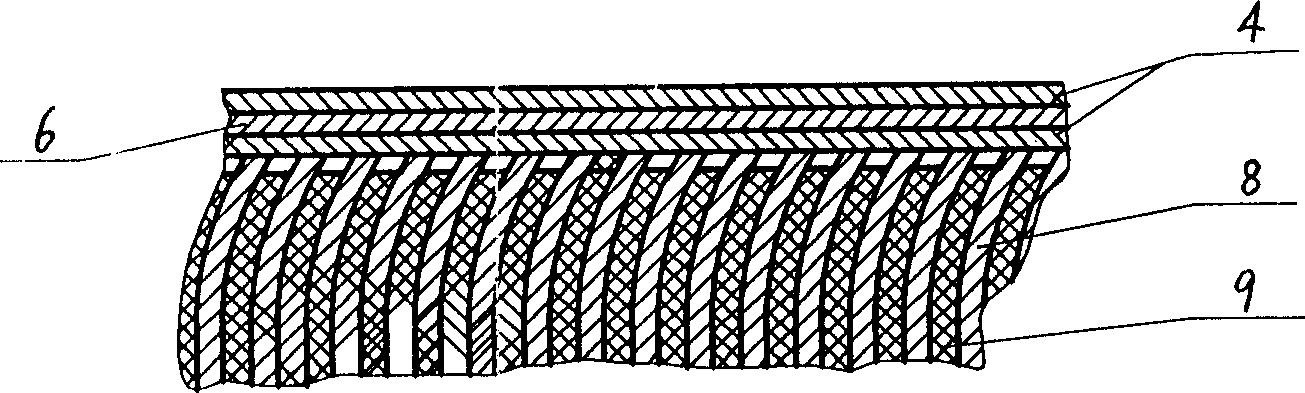

Acoustic surface wave filter and manufacturing method thereof

ActiveCN105490662AReduce field strengthImprove reliabilityImpedence networksField intensityAcoustics

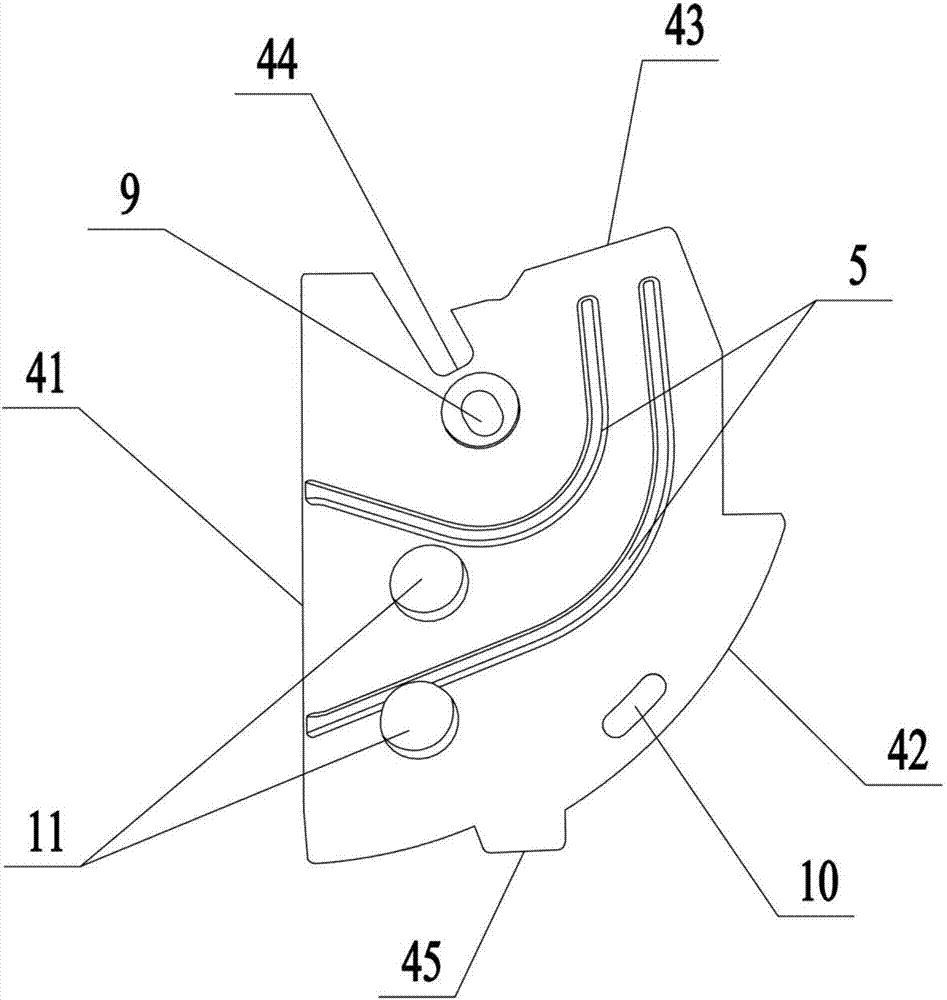

An acoustic surface wave filter comprises a base (2) and a cap (9), a filter pattern layer is arranged on the base (2), and the filter pattern layer comprises a sending interdigital transducer (3), a receiving interdigital transducer (4), ground wires (7), a signal input port (5) and a signal output port (6); the ground wires (7) comprise a first ground wire (71) connected with the sending interdigital transducer (3) and a second ground wire (72) connected with the receiving interdigital transducer (4); the sending interdigital transducer (3) and the receiving interdigital transducer (4) are rectangular interdigital electrodes formed by two comb electrodes which are interdigitated; corners of common terminals of the comb electrodes of the sending interdigital transducer (3) and the receiving interdigital transducer (4) are round corners. In order to effectively avoid a point effect, corner rounding treatment is adopted at joints of the ground wires and the interdigital electrodes, and the point field intensity is effectively reduced, thereby avoiding punch-through and improving reliability of a device.

Owner:BEIJING MXTRONICS CORP +1

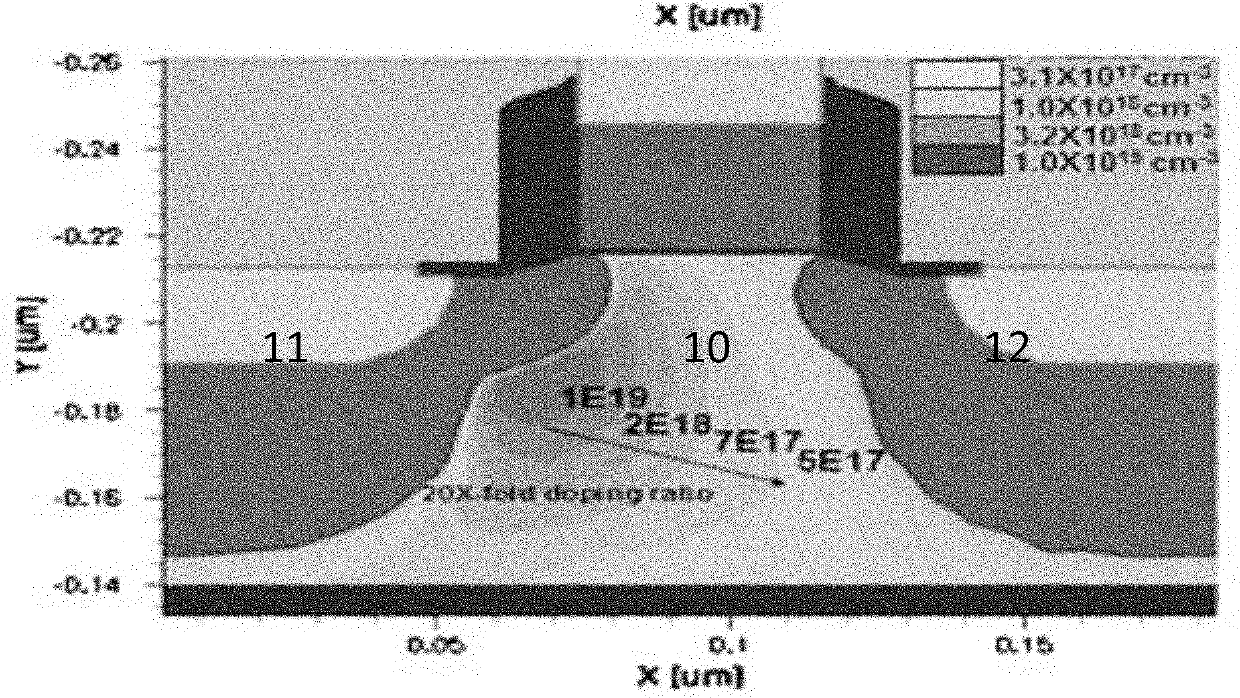

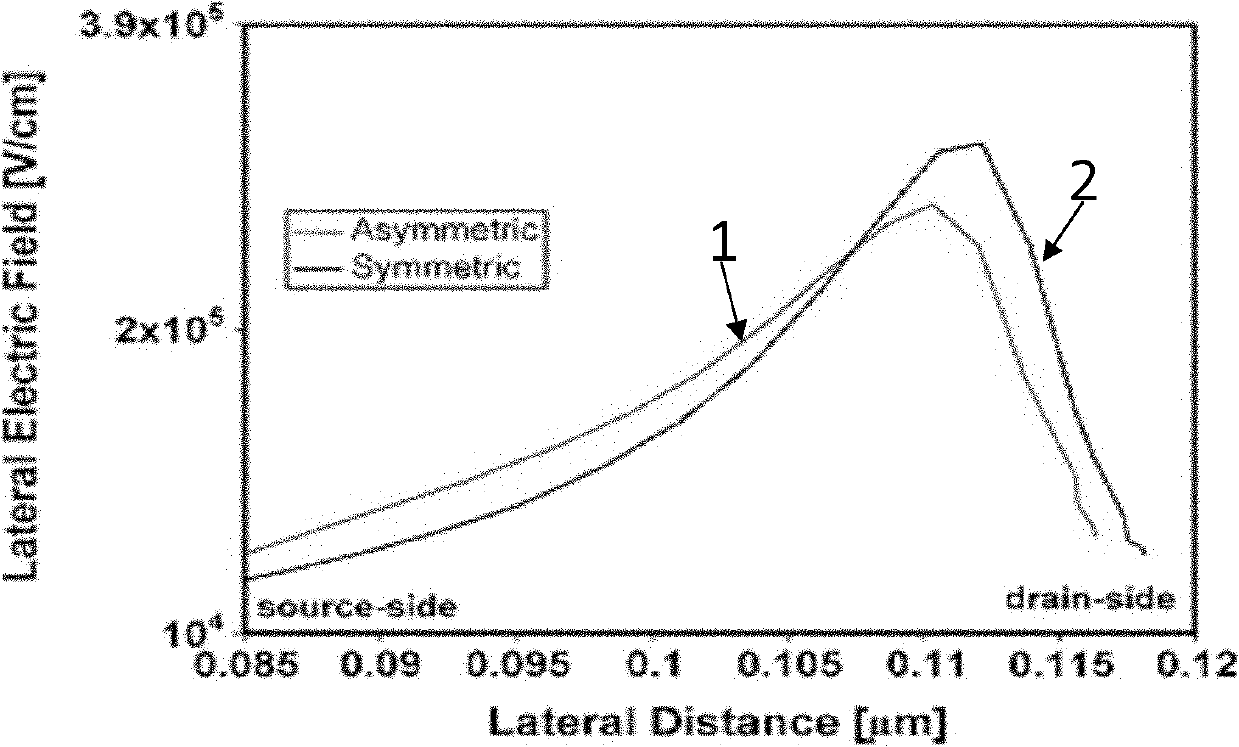

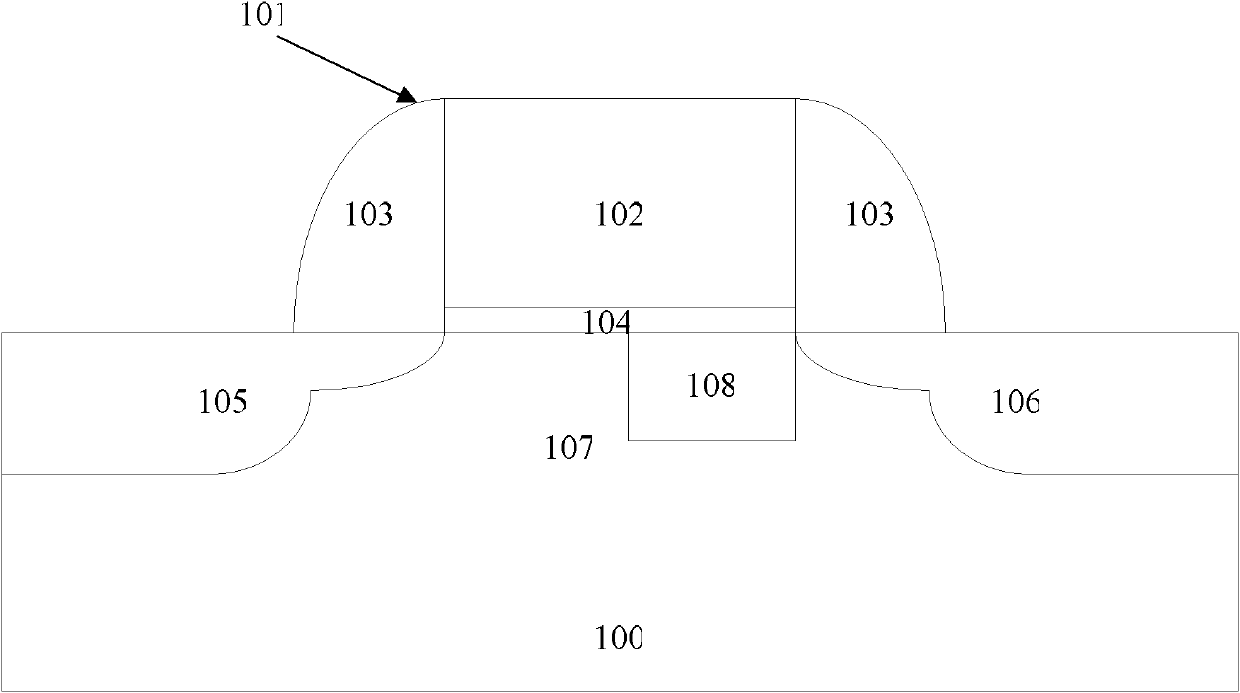

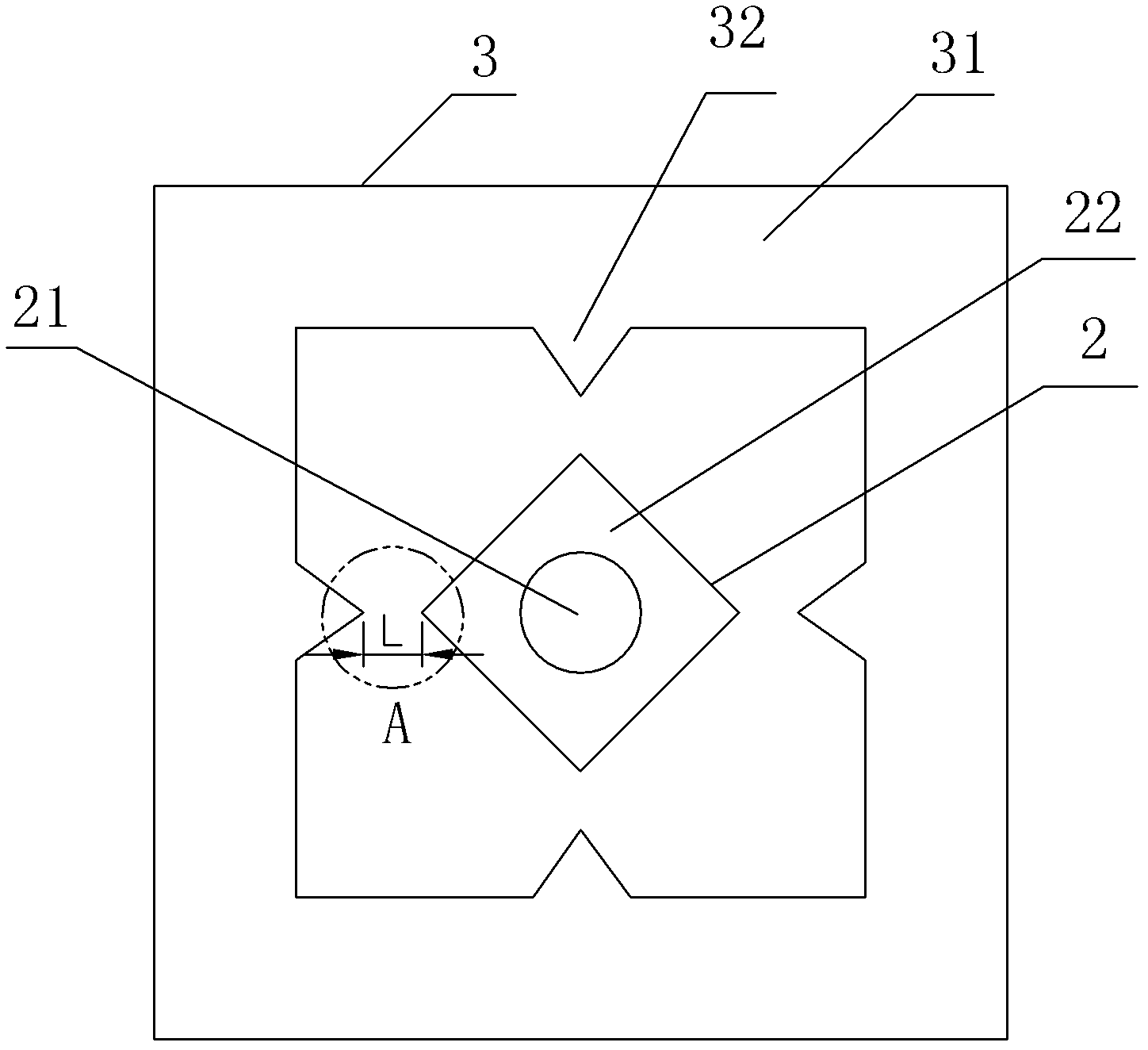

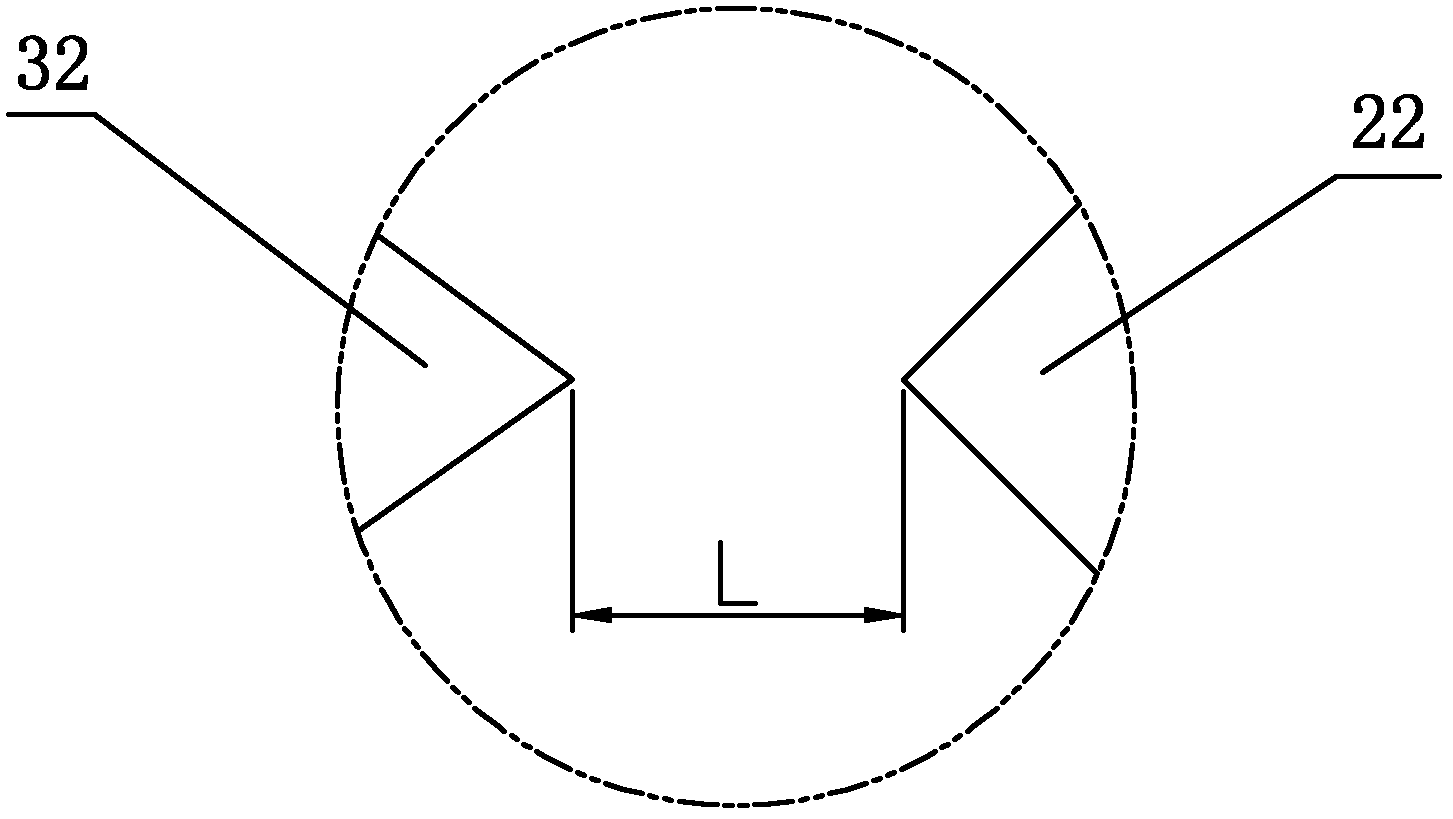

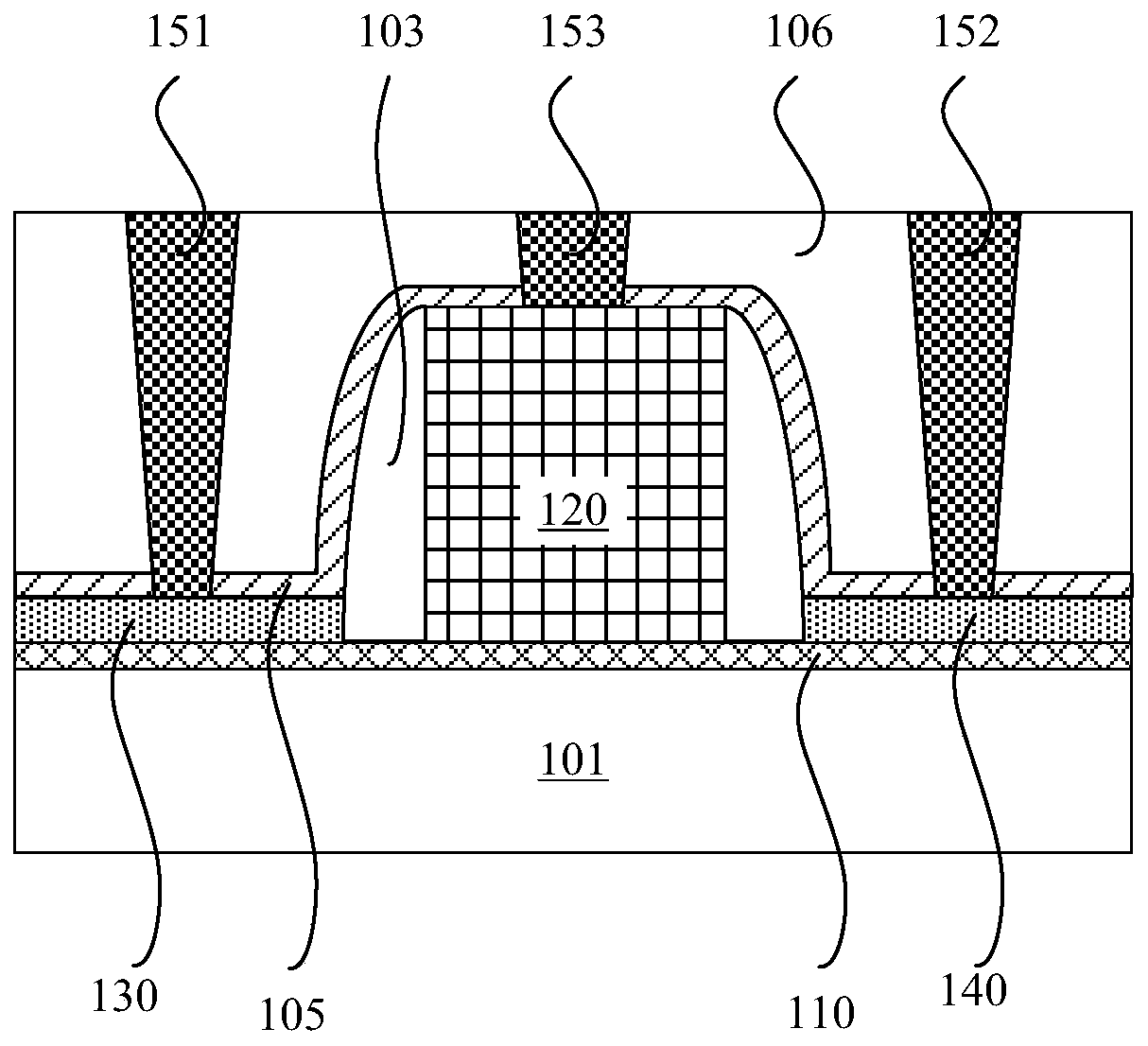

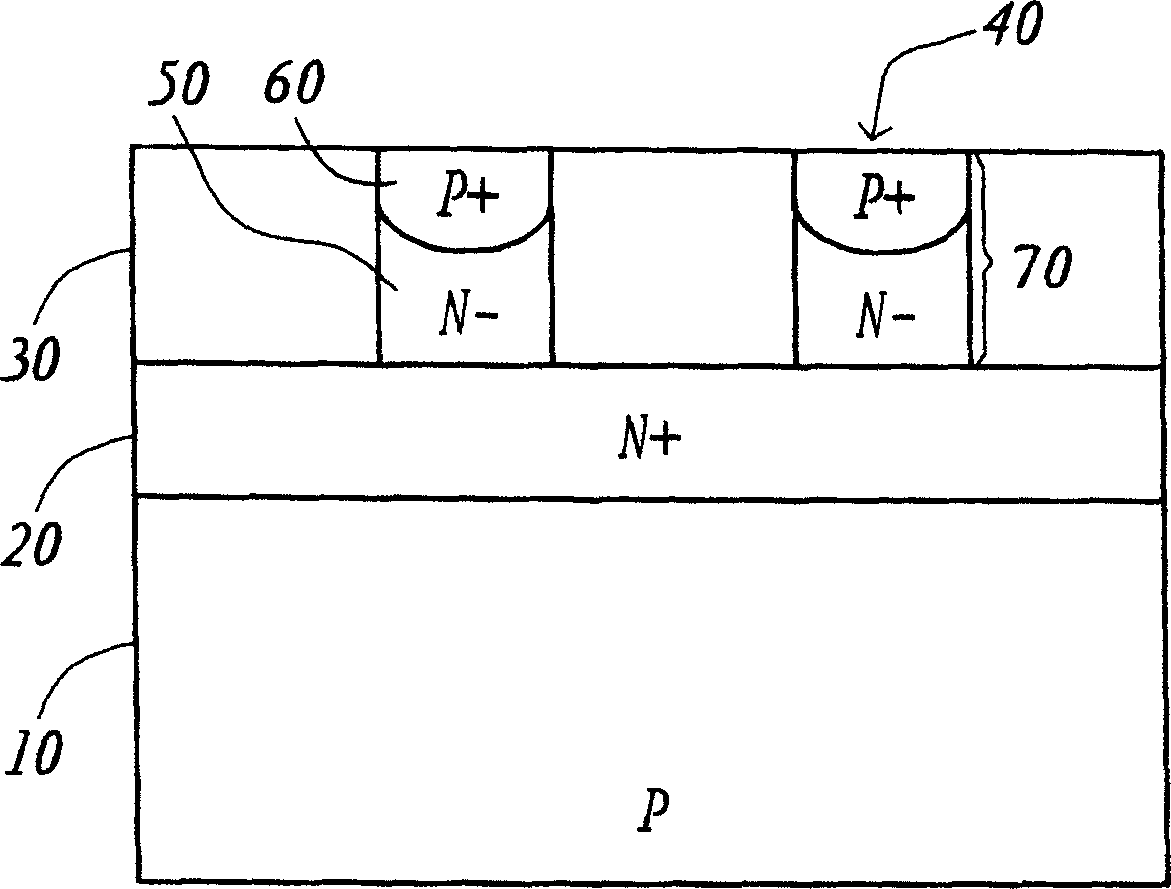

MOS (Metal Oxide Semiconductor) transistor and manufacturing method thereof

ActiveCN102569391AHigh carrier mobilityIncrease drive currentSemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorElectric field

The invention provides an MOS (Metal Oxide Semiconductor) transistor and manufacturing method thereof. The MOS transistor comprises a semiconductor substrate, a grid structure, a source region, a drain region and a channel, wherein the grid structure is formed on the semiconductor substrate; the source region and the drain region are formed in semiconductor substrate surfaces on both sides of the grid structure; and the groove is formed below the grid structure. The MOS transistor is characterized in that: one end in the channel close to the drain region is provided with a heterogeneous region; and the dielectric constant of the heterogeneous region is higher than those of other regions in the channel. The drain end of the channel of the MOS transistor is provided with the heterogeneous region, and the heterogeneous region is made of a semiconductor material of which the dielectric constant is higher than those of other regions in the channel and is positioned at a drain end, so that a drain end electric field is reduced relatively, and a source end electric field is enhanced relatively. Compared with the conventional asymmetrical groove MOS transistor, the MOS transistor has the advantages that: the carrier mobility of the source end is further increased, so that the driving current of a device can be raised; and the transverse electric field of the drain end is low, so that the phenomenon of drain end breakdown can be further avoided.

Owner:锐立平芯微电子(广州)有限责任公司

Cover plate, preparation method of cover plate and display device

InactiveCN106293200AImprove transmittanceAvoid breakdown phenomenonOpticsInput/output processes for data processingComposition processDisplay device

Owner:BOE TECH GRP CO LTD +1

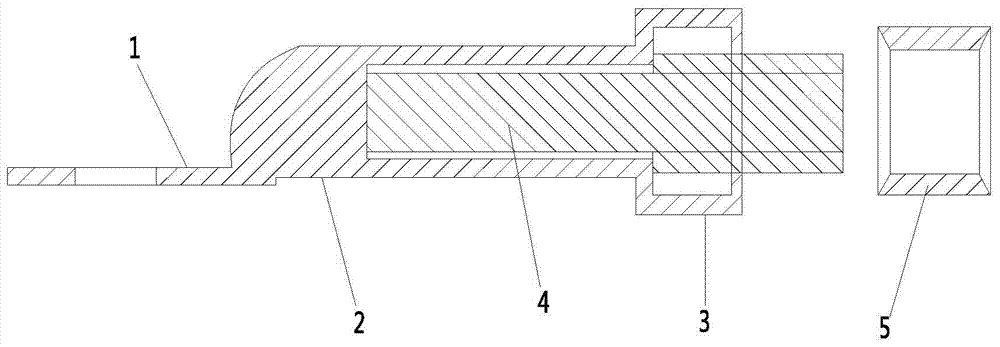

Dry-type capacitor type composite insulating sleeve pipe production method

ActiveCN104900350AReduce generationAvoid breakdown phenomenonInsulating bodiesLead-in/lead-through insulatorsHeat-shrinkable sleeveVacuum pumping

The present invention relates to a dry-type capacitor type composite insulating sleeve pipe production method which comprises a step of taking a metal tube conductor and winding a layer of glass fiber cloth belt around the surface of the conductor, a step of sleeving outer side wall of the conductor wound by the cloth belt with a heat-shrinkable sleeve pipe, carrying out vacuum pumping processing on the space between the heat-shrinkable sleeve pipe and the conductor and pouring epoxy resin into the cavity between the heat-shrinkable sleeve pipe and the conductor from the resin poring port on the conductor, and a step of heating, drying and curing the conductor and winding a layer of semiconductor glass fiber on the outer wall of the heat-shrinkable sleeve pipe. The method has the advantages that an original glass fiber cloth belt layer is replaced by the staggered winding of glass fiber cloth belt and a semiconductor conformal material, and a breakdown phenomenon can be avoided well.

Owner:江苏沃能高压电气有限公司

Insulated pipe type bus production method

ActiveCN104900340AReduce generationAvoid breakdown phenomenonCable/conductor manufactureHeat-shrinkable sleeveGlass fiber

The present invention relates to an insulated pipe type bus production method which comprises a step of taking a metal tube conductor and winding a layer of glass fiber cloth belt around the surface of the conductor, a step of sleeving the conductor with a heat-shrinkable sleeve pipe, carrying out vacuum pumping processing on the space between the heat-shrinkable sleeve pipe and the conductor and pouring epoxy resin into the cavity between the heat-shrinkable sleeve pipe and the conductor from the resin poring port on the conductor until the resin is full, a step of curing the epoxy resin, a step of winding a layer of shielding copper tape around the outer side wall of the heat-shrinkable sleeve pipe, and a step of packaging an insulating sheath around the outer side wall of the shielding copper tape layer to obtain the prepared product. The method has the advantages that when the used is used to make an insulated pipe type bus, the heat-shrinkable sleeve pipe is added, firstly the vacuum pumping processing is carried out, then the epoxy resin is poured and the drying is carried out, by using the characteristic that the heat-shrinkable sleeve pipe shrinks in the condition of heating, redundant epoxy resin and air are discharged, through the processing method, the generation of pores can be effectively reduced, and a breakdown phenomenon is avoided.

Owner:JIANGSU WONEN ELECTRIC TECH

Printed circuit bard (PCB) for preventing electrostatic discharge

InactiveCN103140016AEasy to useImprove test accuracyPrinted circuit detailsElectrical measurement instrument detailsCopperPrinted circuit board

The invention discloses a printed circuit board (PCB) for preventing electrostatic discharge. The PCB comprises a substrate and circuit patterns, wherein the substrate is made of insulating materials. The PCB is characterized in that at least one discharging pin for connecting external electric signals is arranged on the substrate, at least one tip is arranged on the discharging pin, copper skin is overlaid on the periphery of the discharging pin on the substrate and provided with sharp tips with the same quantity of sharp tips on the discharging pin, the sharp tips on the copper skin correspond to the sharp tips on the discharging pin, discharging spaces are arranged between tip ends of the corresponding sharp tips on the copper skin and the discharging pins, and the copper skin is electrically connected with the ground. The PCB has the advantages that during testing, damage and punch-through on electrical elements in a scanning card caused by an external electro spark detector (ESD) can be avoided, well protection on the inner circuit can be achieved, and interference on channel signals (namely a testing point channel) caused by the ESD of the PCB can be reduced.

Owner:SHENZHEN MASONE ELECTRONICS

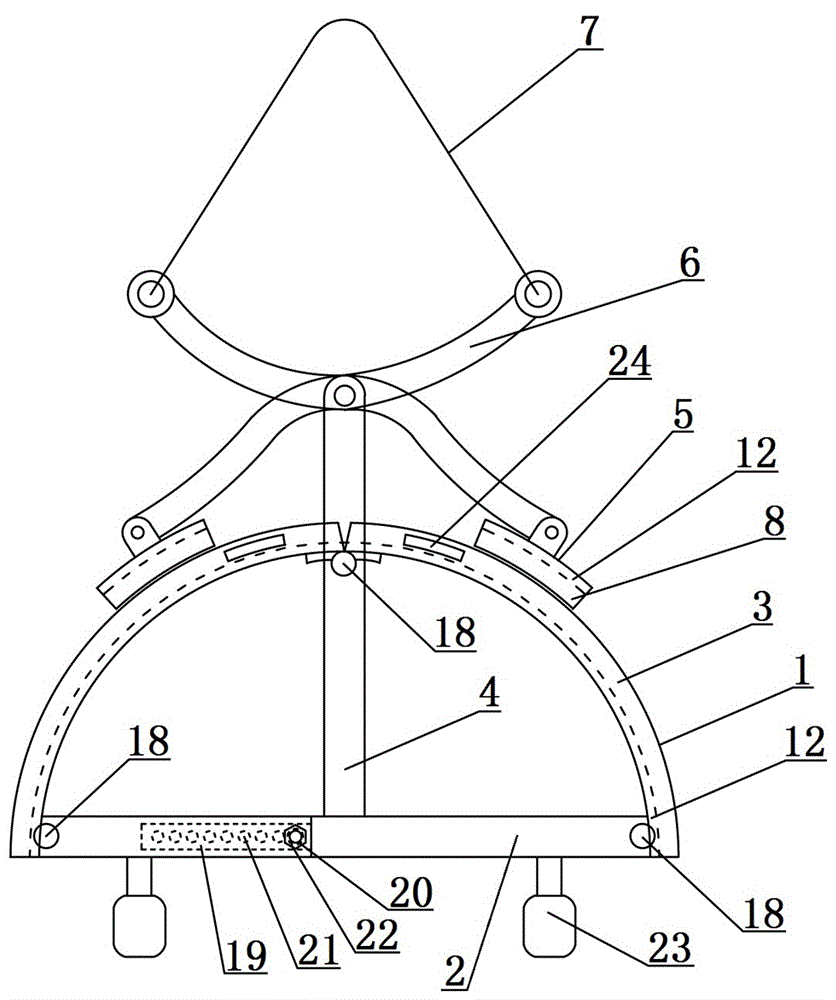

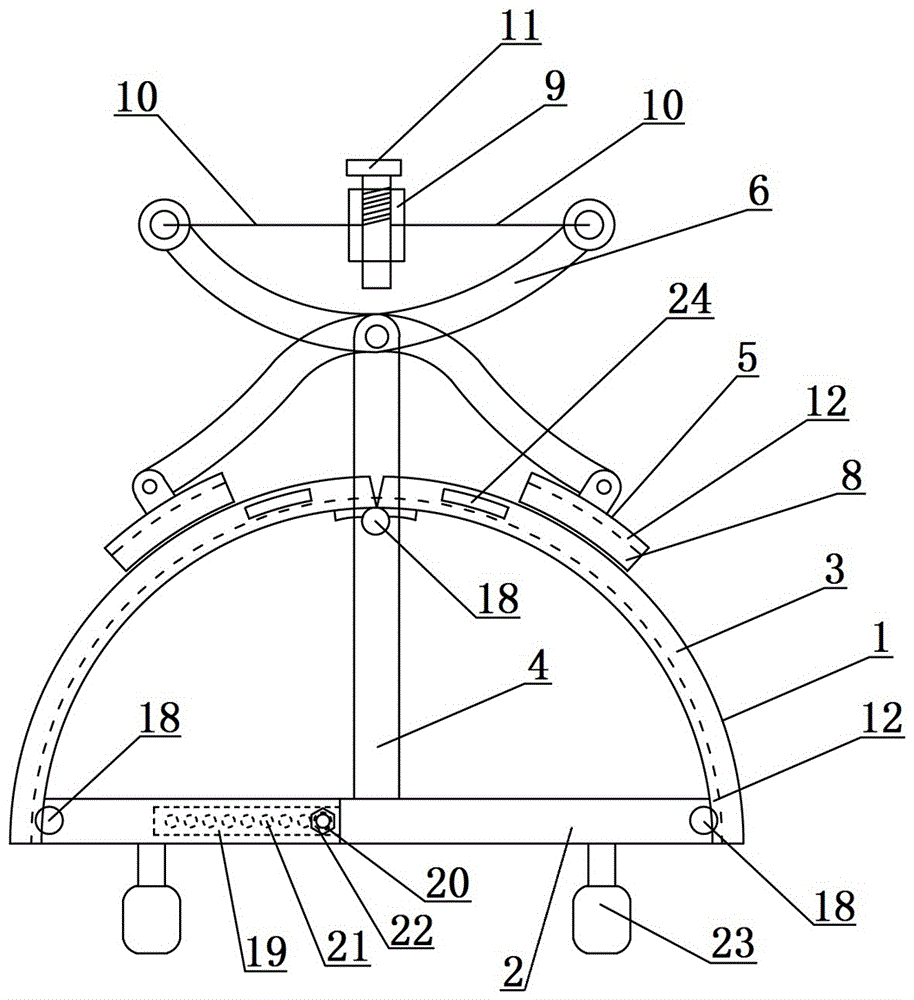

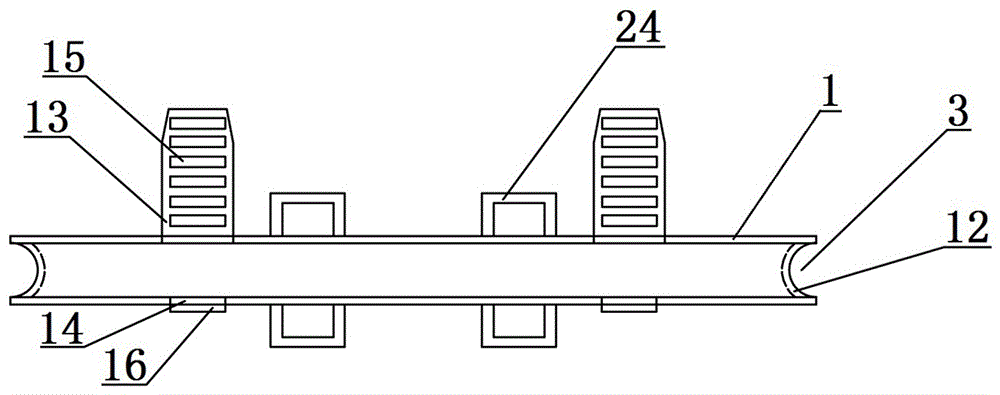

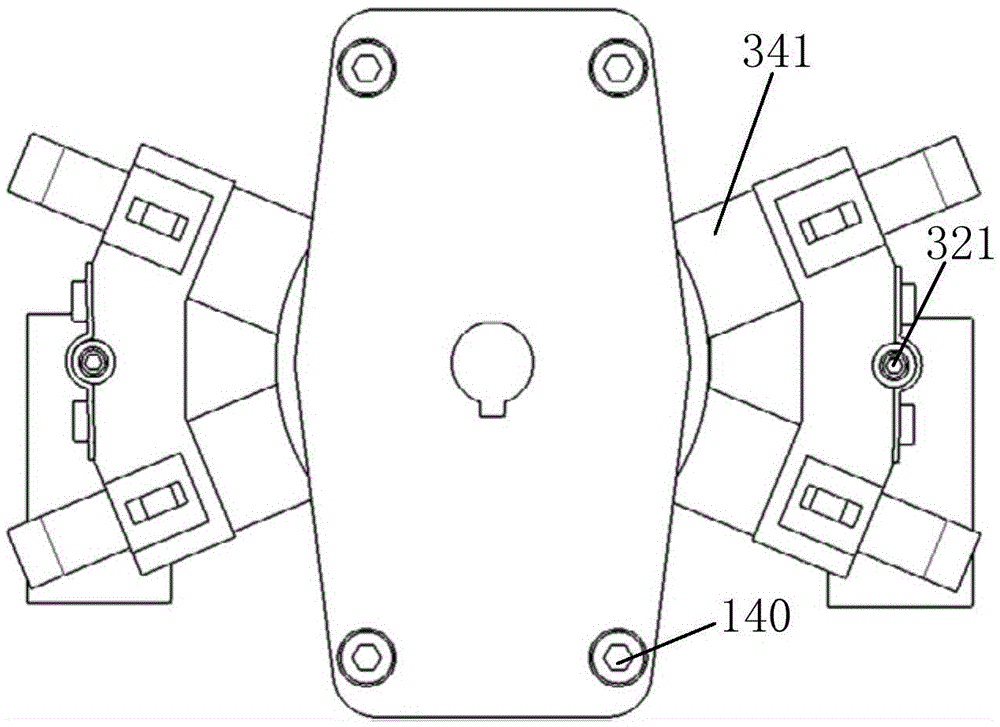

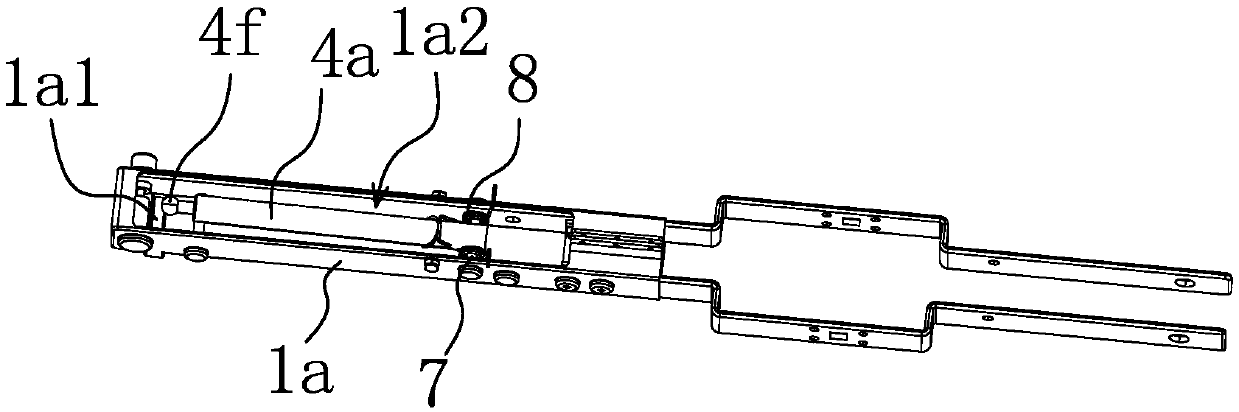

Cable dragging and moving device

ActiveCN105870840AEasy to dragEasy to drag and moveCable arrangements between relatively-moving partsApparatus for laying cablesBreakdown phenomenonEngineering

The invention discloses a cable dragging and moving device. The cable dragging and moving device comprises a cable supporting plate and a supporting plate. The bottom of the cable supporting plate is fixedly connected with the supporting plate. The cable supporting plate is in a semi-arc shape. A cable clamping groove matched with a cable is formed in the cable supporting plate. The bending radius of the cable supporting plate is larger than the minimum bending radius of the cable. A cable fastening device is arranged on the cable supporting plate. The cable dragging and moving device has the advantages that when the cable is dragged and moved, the cable does not slide or disengage in the cable clamping groove, and the cable is more conveniently and rapidly dragged and moved; the bending radius of the cable supporting plate is larger than the minimum bending radius of the cable, the bending radius of the cable is guaranteed, therefore, the damage degree of an insulating layer of the cable is reduced, the frequent occurrence of the cable breakdown phenomenon is avoided, the service life of the cable is prolonged, the labor intensity of workers is relieved, time and labor are saved, the working efficiency is improved, and normal digging work cannot be affected.

Owner:JINCHUAN GROUP LIMITED

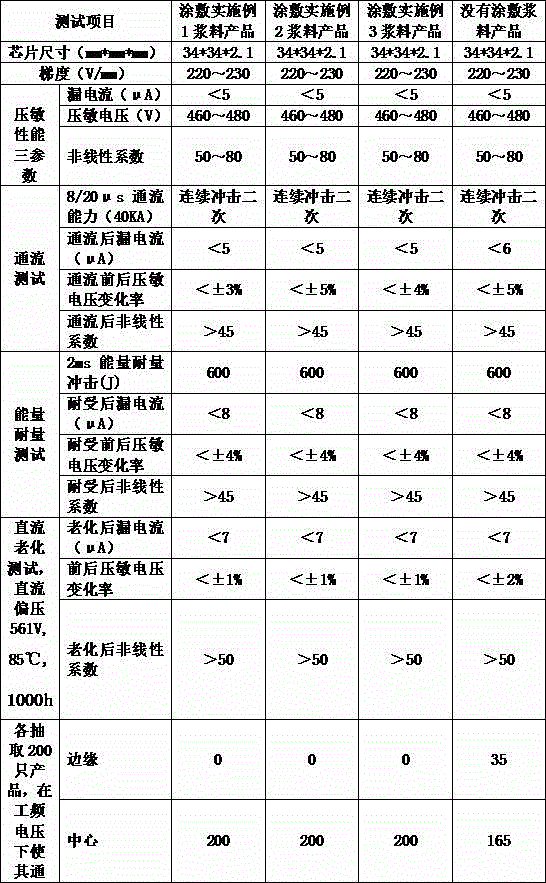

Voltage-sensitive resistor edge coating slurry material and preparation method thereof

The invention discloses a voltage-sensitive resistor edge coating slurry material and a preparation method thereof. The slurry material mainly comprises the following components in percentage by mass: 55%-65% of composite powder, 10%-20% of glass powder and 23%-28% of an organic carrier, wherein the composite powder is ultrafine composite powder prepared by fully and uniformly mixing the following raw materials in percentage by mass: 3%-10% of ZnO, 25%-35% of Sb2O3, 32%-43% of Y2O3, 20%-34% of Bi2O3 and 0.1%-0.5% of H3BO3, pre-sintering at 850 DEG C-1000 DEG C, fully crushing and sieving; and the glass powder comprises the following raw materials in percentage by mass: 15%-25% of ZnO, 50%-70% of Bi2O3, 2%-5% of B2O3, 5%-10% of SiO2, 0.5%-2% of K2CO3 and 5%-10% of ZrO2. The edge and circumferential circular wall of a green body of disintegrated voltage-sensitive resistor ceramic are mainly coated with slurry and the phenomenon that the lower edge is broken down due to power frequency over-voltage can be effectively solved.

Owner:GUANGXI NEW FUTURE INFORMATION IND

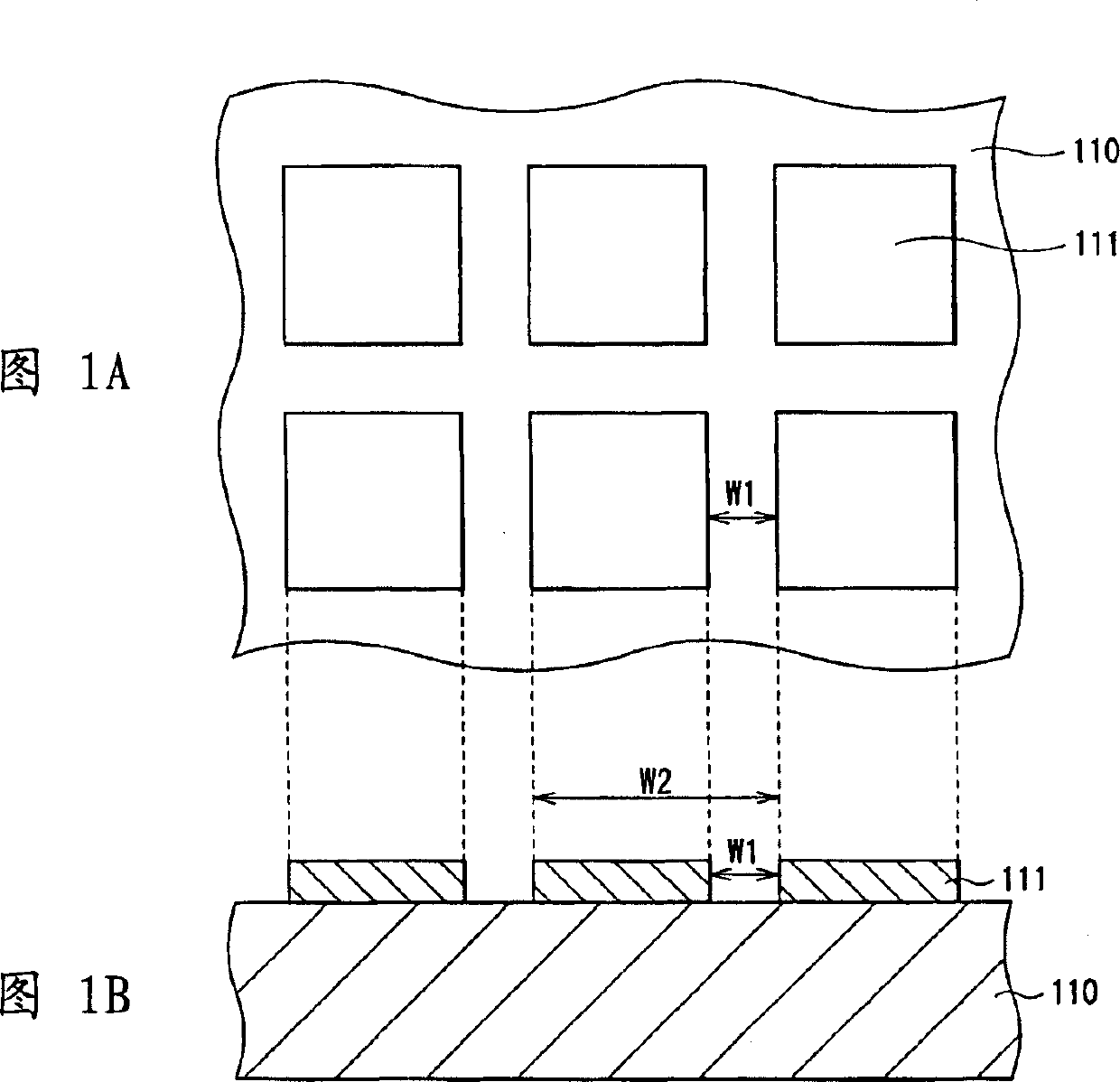

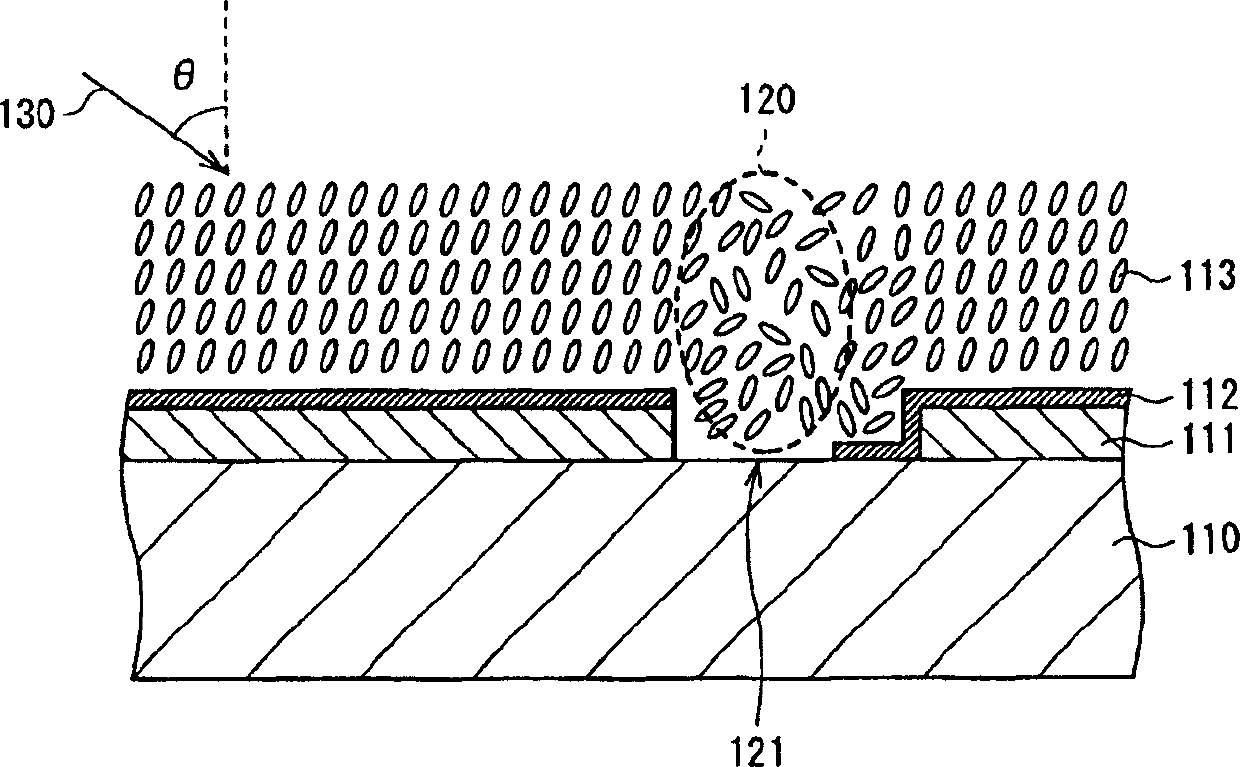

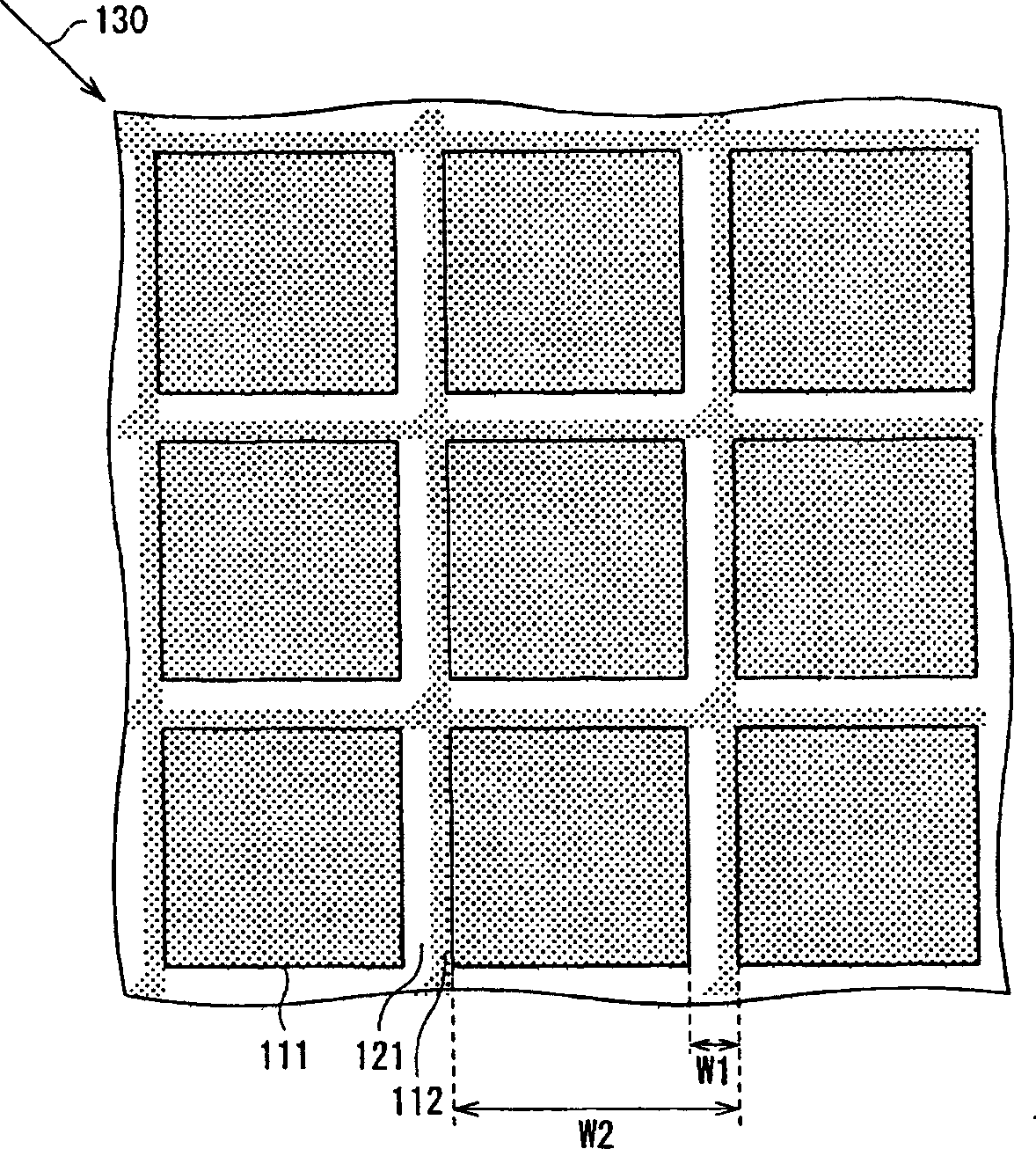

Reflective liquid crystal display device and method of manufacturing the same

InactiveCN1607440AAvoid breakdown phenomenonChange the angle of incidenceStatic indicating devicesNon-linear opticsLiquid-crystal displayBreakdown phenomenon

In a reflective liquid crystal display device according to the present invention, the breakdown phenomenon in long-term driving due to the asymmetric structure of the groove side surfaces between pixels can be avoided, and the reliability of long-term driving can be obtained. In the thickness direction, on the first side of the inter-pixel groove on the cross-section of the pixel electrode substrate, a first oblique vapor deposition alignment film is formed by vapor deposition, and on the second side facing the first side, a first oblique vapor deposition alignment film is formed by vapor deposition. The second oblique vapor deposition alignment film. Thereby, the film structure of the two sides of the inter-pixel groove in cross-section becomes symmetrical, so that the breakdown phenomenon in long-term driving due to the asymmetric structure of the side of the inter-pixel groove can be avoided.

Owner:SONY GRP CORP

Distributed feedback injection amplification semiconductor laser

InactiveCN101237121AGuaranteed stabilityReduce line widthLaser detailsLaser optical resonator constructionPhotovoltaic detectorsGaussian beam

The invention discloses a distributed feedback injection amplifying semiconductor laser, consisting of a main laser, a first light isolator, a taper laser amplifier, a second light isolator, a tiny light exploring laser power stabilization system and a laser shaping system, wherein, the main laser adopts a distributed feedback semiconductor laser tube, the collimated laser beam is injected into a taper laser amplifying chip passing through the first light isolator, the amplified laser adopts the beam splitting technique passing through the second light isolator, an electrophotonic detector detects the fluctuation of power of the amplified laser, the error signal is sent to a current control interface of the taper laser amplifier through a feedback circuit, the power stability of the laser is outputted after the error signal is amplified by a reverse feedback mechanism, the light outputs the collimated Gaussian beam through the laser shaping system. The distributed feedback injection amplifying semiconductor laser has compact structure, convenient adjustment, wide and narrow laser rays, high power, good stability and strong practicability.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

Insulation tube bus generation method

InactiveCN107731417AUniform density distributionIncrease short circuit currentApparatus for heat treatmentManufacturing rigid-tube cablesCopper wireEngineering

The invention relates to the technical field of transmission equipment, in particular to an insulation tube bus generation method. The method comprises the steps of insulating material pouring, solidifying and shielded copper wire winding. The invention provides the bus production method capable of cutting off static electricity and shielding electromagnetism, thereby solving the problems of extrapower loss and economic loss.

Owner:江苏众众热能科技有限公司

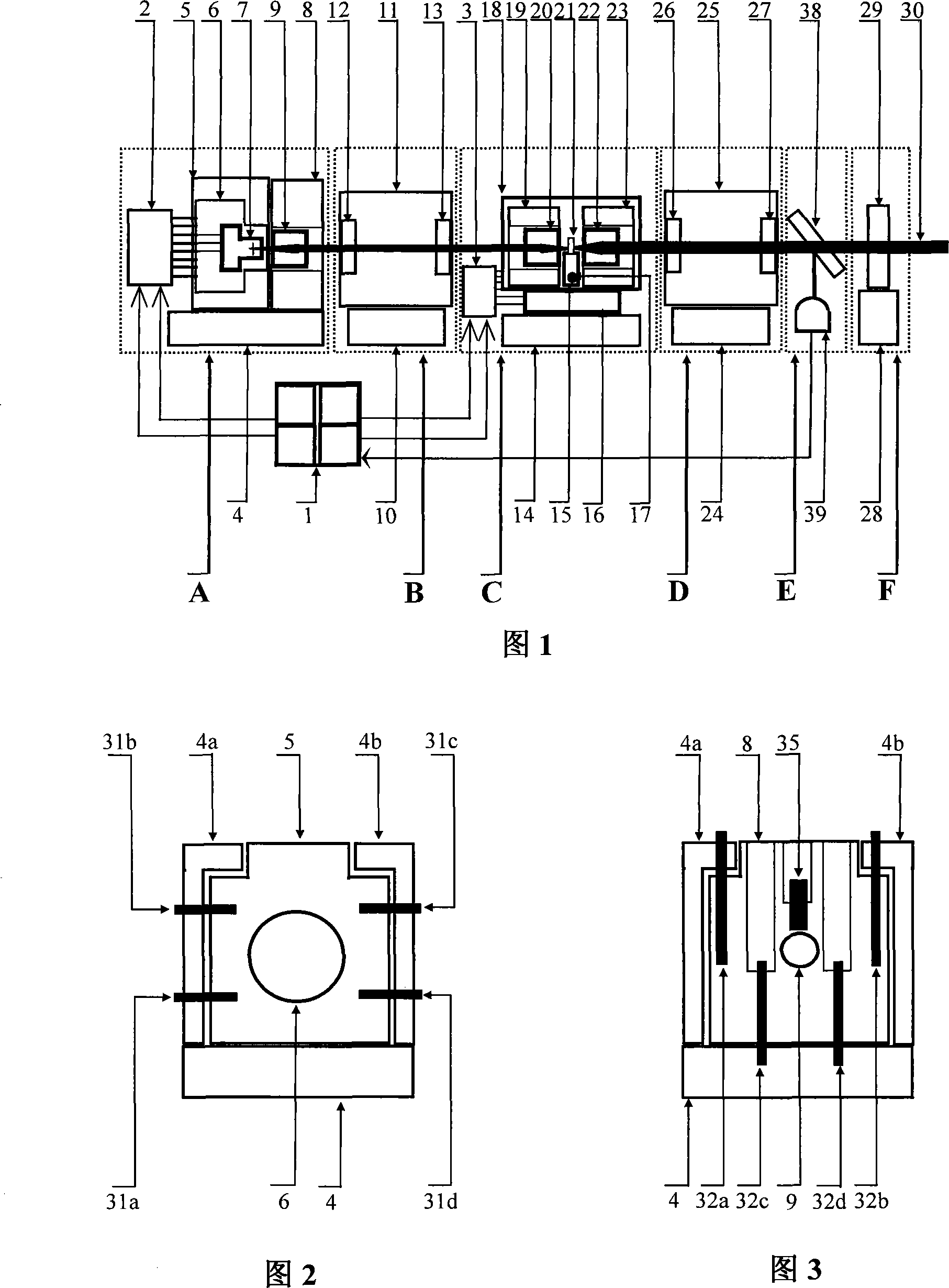

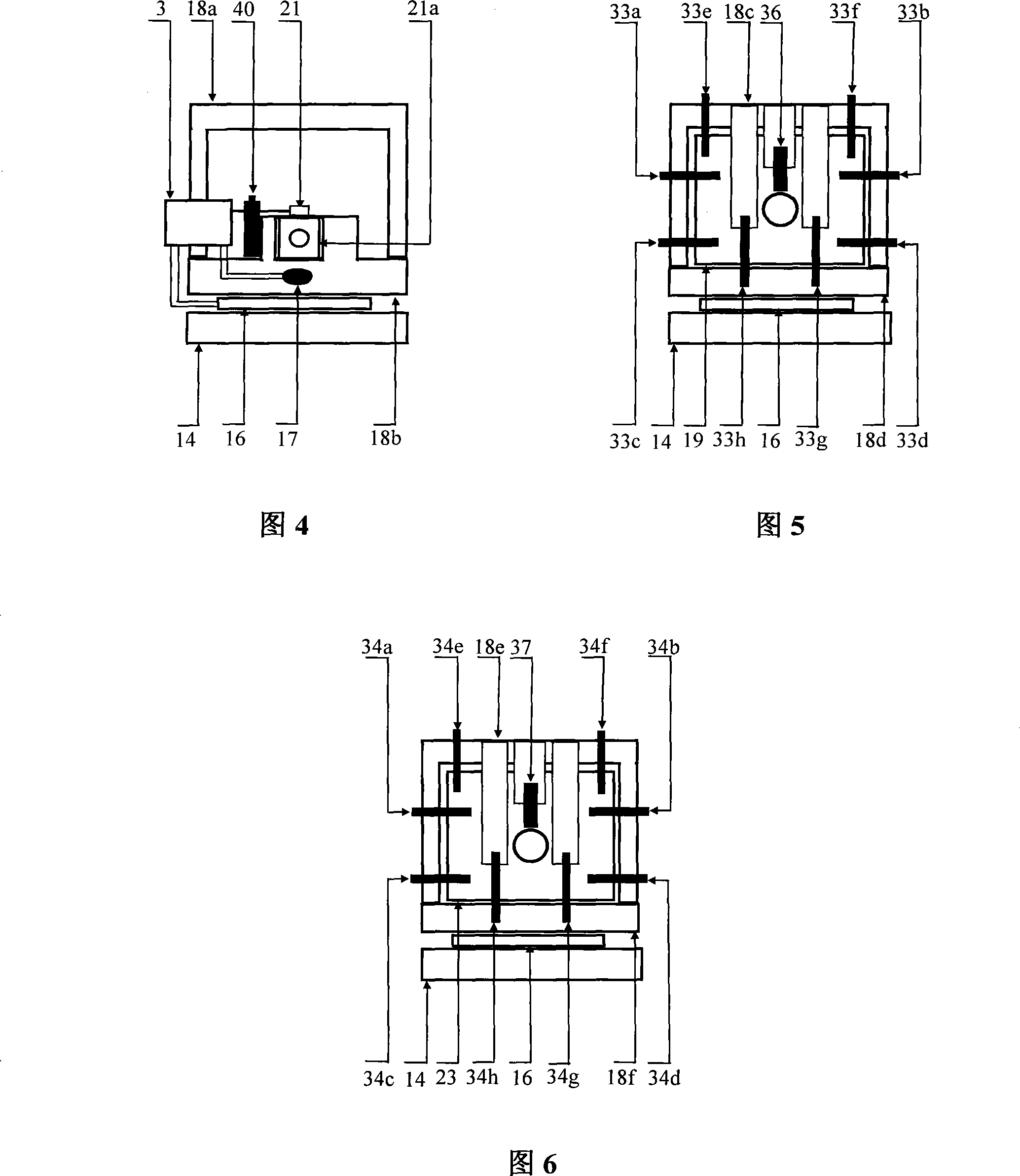

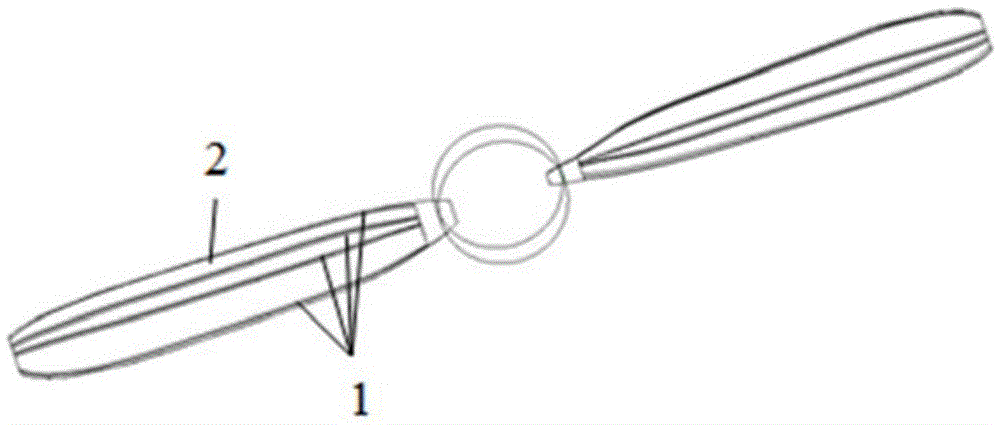

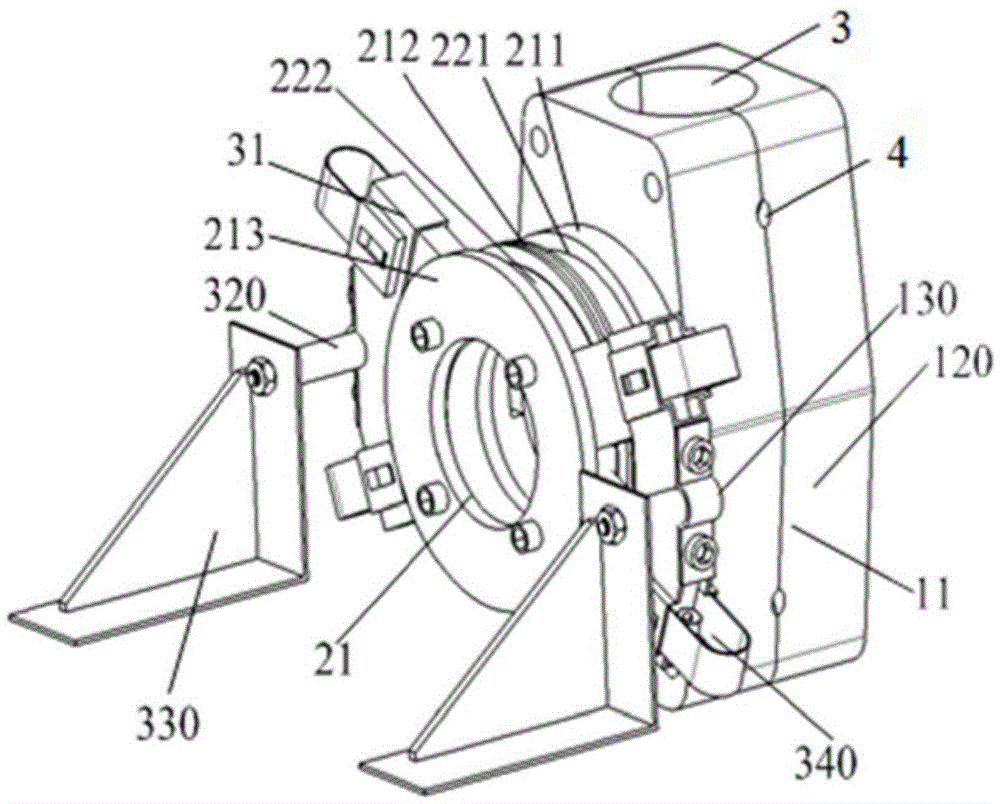

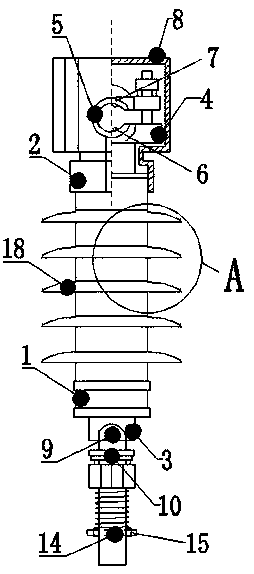

High-voltage transmission slip ring device for plasma flow control of propeller

ActiveCN105428949ADoes not affect breakdown resistanceImprove reliabilityRotary current collectorCouplings bases/casesRing devicePropeller

The invention relates to a high-voltage transmission slip ring device for plasma flow control of a propeller, and belongs to the technical field of plasma flow control. The high-voltage transmission slip ring device comprises a propeller hub, a synchronous rotating slip ring and two carbon brush brackets, wherein carbon brushes on the two carbon brush brackets are connected with a high-voltage output end and an earth terminal of an excitation power supply respectively; an insulating sleeve is arranged on each carbon brush bracket, so that the carbon brushes are insulated from an external experiment platform; and meanwhile, the carbon brushes slide along the axial directions of the sleeves and can be adjusted. The synchronous rotating slip ring is provided with two electrode rings, which are a high-voltage electrode ring and an earth electrode ring respectively; two sides of each electrode ring are provided with insulating gaskets; and insulating inner rings are arranged at the inner sides of the electrode rings to be assembled with the electrode rings. The electrode rings are connected with a plasma exciter of a paddle through high-voltage leads; and notches are formed in the insulating inner rings, so that each electrode ring can be communicated with two leads. The high-voltage transmission slip ring device is compact in structure, simple in processing of parts, convenient to dismantle and assemble, high in reliability, good in dynamic balance and convenient to maintain.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Cable pressure resistant test device and cable pressure resistant test method

ActiveCN103336229AUniform charge distributionAvoid breakdown phenomenonTesting dielectric strengthEngineeringSemiconductor

Owner:宁联电缆集团有限公司

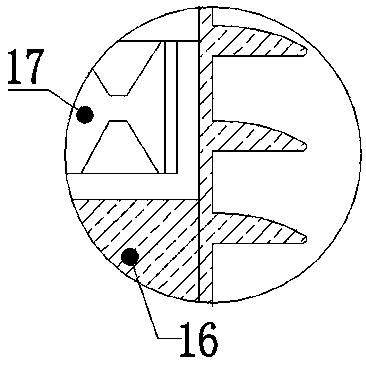

Pin type insulator

InactiveCN109741887AAvoid damageFacilitate the formation of short-circuit channelsPin insulatorsSocial benefitsMechanical engineering

The invention discloses a pin type insulator. The pin type insulator comprises an insulating pin body; the insulating pin body comprises a connecting end part and a fitting end part; the fitting end part is located below the connecting end part; a clamping seat is arranged at the top end of the connecting end part; a wire clamping groove is formed in the clamping seat; a puncture electrode and a puncture tooth pressing block are arranged in the wire clamping groove; the puncture tooth pressing block is located above the puncture electrode; an insulating cover is arranged outside the clamping seat; a steel leg is connected to the bottom end of the fitting end part; a spring washer and a locking nut are arranged on the steel leg in a sleeving mode; one side of the locking nut is connected with a spring; a through hole is formed in one side, located at the spring, of the steel leg; and a limiting clamp is inserted in the through hole. The pin type insulator is reasonable in structure, safe and reliable in performance and easy to install and use, and has relatively high economic and social benefits.

Owner:江西省萍乡市宇翔电瓷制造有限公司

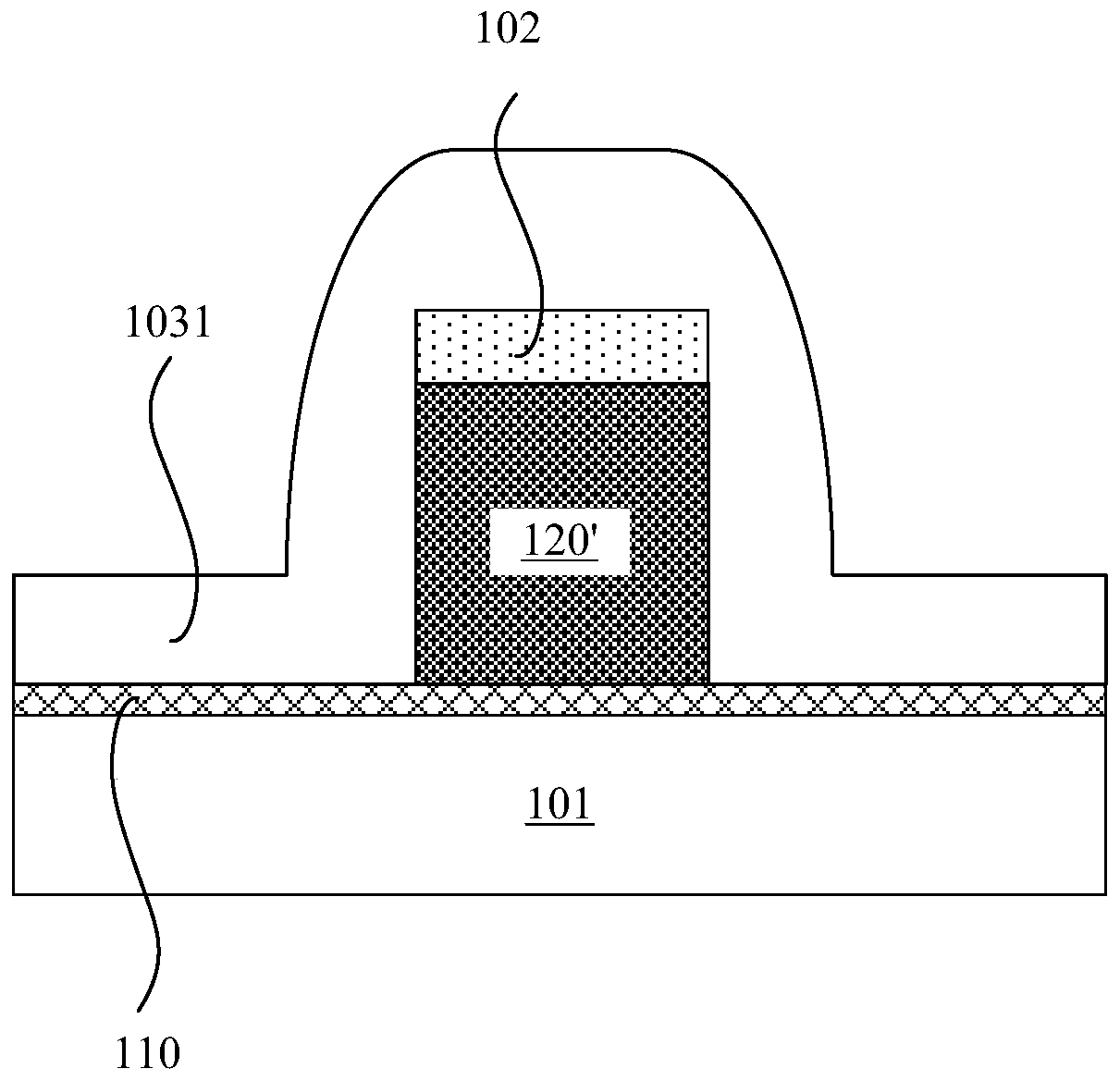

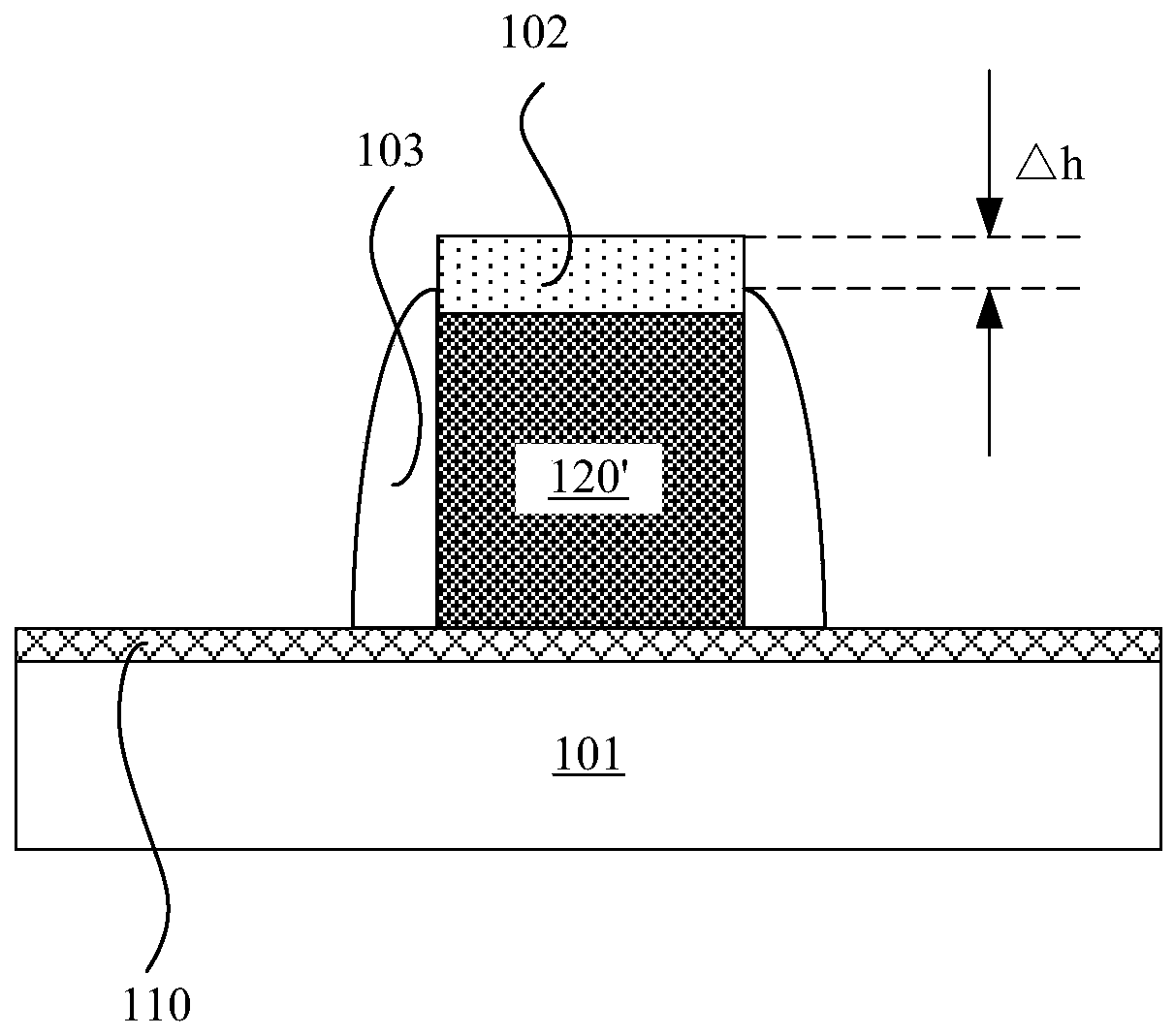

Transistor and manufacturing method thereof

PendingCN111180583AAvoid breakdown phenomenonAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringGate stack

The invention discloses a transistor and a manufacturing method thereof. The manufacturing method mainly comprises the following steps: sequentially forming a carbon nanotube, a dummy gate electrode and a mask layer on a substrate; forming a side wall covering the side wall of the dummy gate; forming an electrical contact on the carbon nanotubes; forming a sacrificial layer at least covering the side walls; carrying out planarization processing on the sacrificial layer to enable the height difference between the dummy gate and the side wall to be within a preset range; replacing the dummy gatewith a gate stack structure; removing the sacrificial layer; forming an etching barrier layer covering the electric contact, the gate stack structure and the side wall; forming an interlayer dielectric layer covering the etching barrier layer; and forming a plurality of contact holes penetrating through the interlayer dielectric layer and the etching barrier layer. The sacrificial layer is subjected to planarization processing, so that the height difference between the dummy gate and the side wall is within a preset range, and then the remaining sacrificial layer is removed, and the etching barrier layer is deposited, so that the whole gate stack structure and the source-drain contact area can be surrounded, and the breakdown phenomenon of the edge of the gate stack structure and the contact hole electric connection structure can be prevented.

Owner:BEIJING INST OF CARBON BASED INTEGRATED CIRCUIT +1

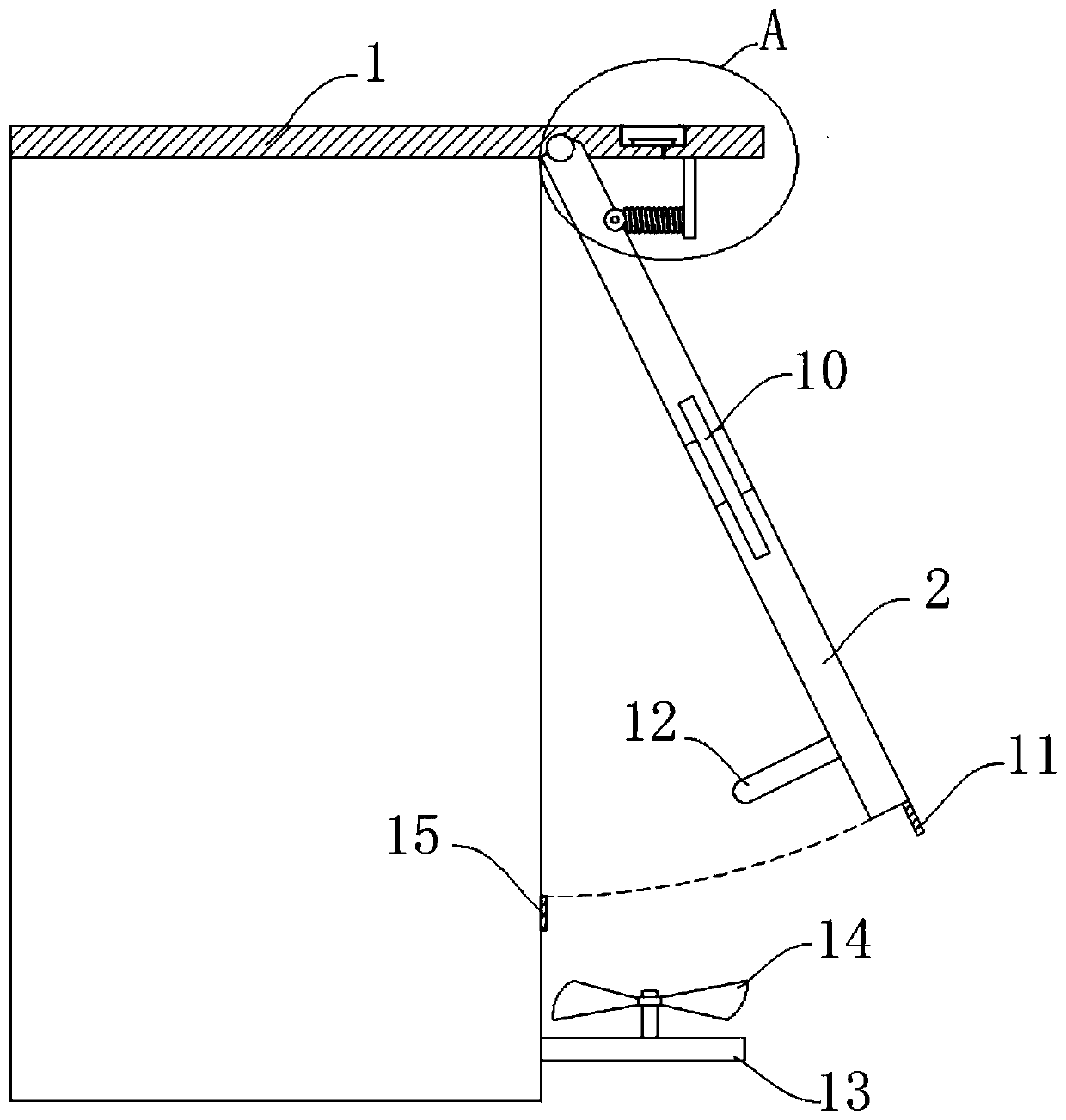

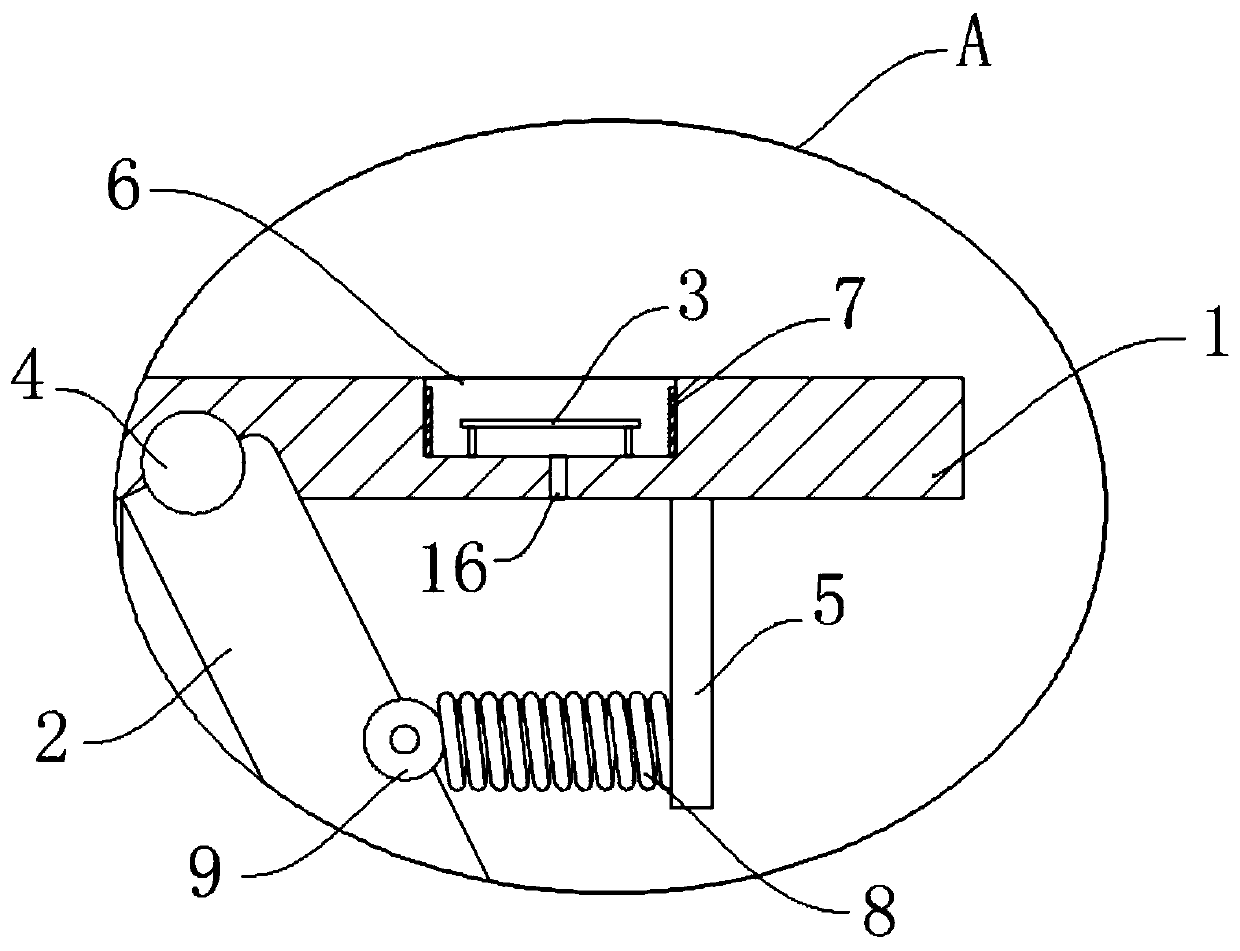

Ventilating window capable of avoiding noise influence

InactiveCN110952872AOperation without ventilationReduce distractionsBatteries circuit arrangementsVentilation arrangementWindow openingEngineering

The invention discloses a ventilating window capable of avoiding noise influence. The ventilating window comprises a window top platform and a window body, wherein a water trough is formed in the topof the window top platform; conducting layers are arranged on the two sides of the water trough; a piezoelectric ceramic piece is fixedly connected into the water trough through a clamping plate and is electrically connected with the conducting layers; a fixed plate is welded to the bottom of the window top platform; a spring is welded to the fixed plate and is horizontally arranged; a hinge is fixedly connected with the end, far away from the fixed plate, of the spring; the other working end of the hinge is rotatably connected with the window body through a hinge pin; and a push rod is fixedly connected onto the window body. The ventilating window has the following advantages: an oxygen concentration apparatus is adopted to detect the oxygen concentration differences in and out of the widow, so that spontaneous ventilating operation is carried out, the ventilating efficiency is improved when the window is opened, and the situation that the life is affected by noise due to long-time opening of the window is avoided; and when it rains, the window-opening time is adjusted according to the rain quantity, and the ventilating window has the smart home effect.

Owner:刘远远

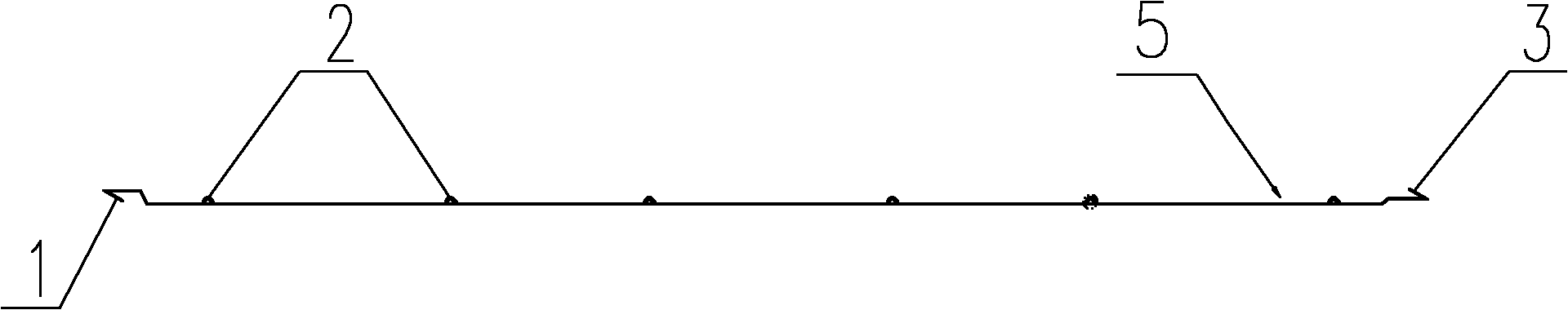

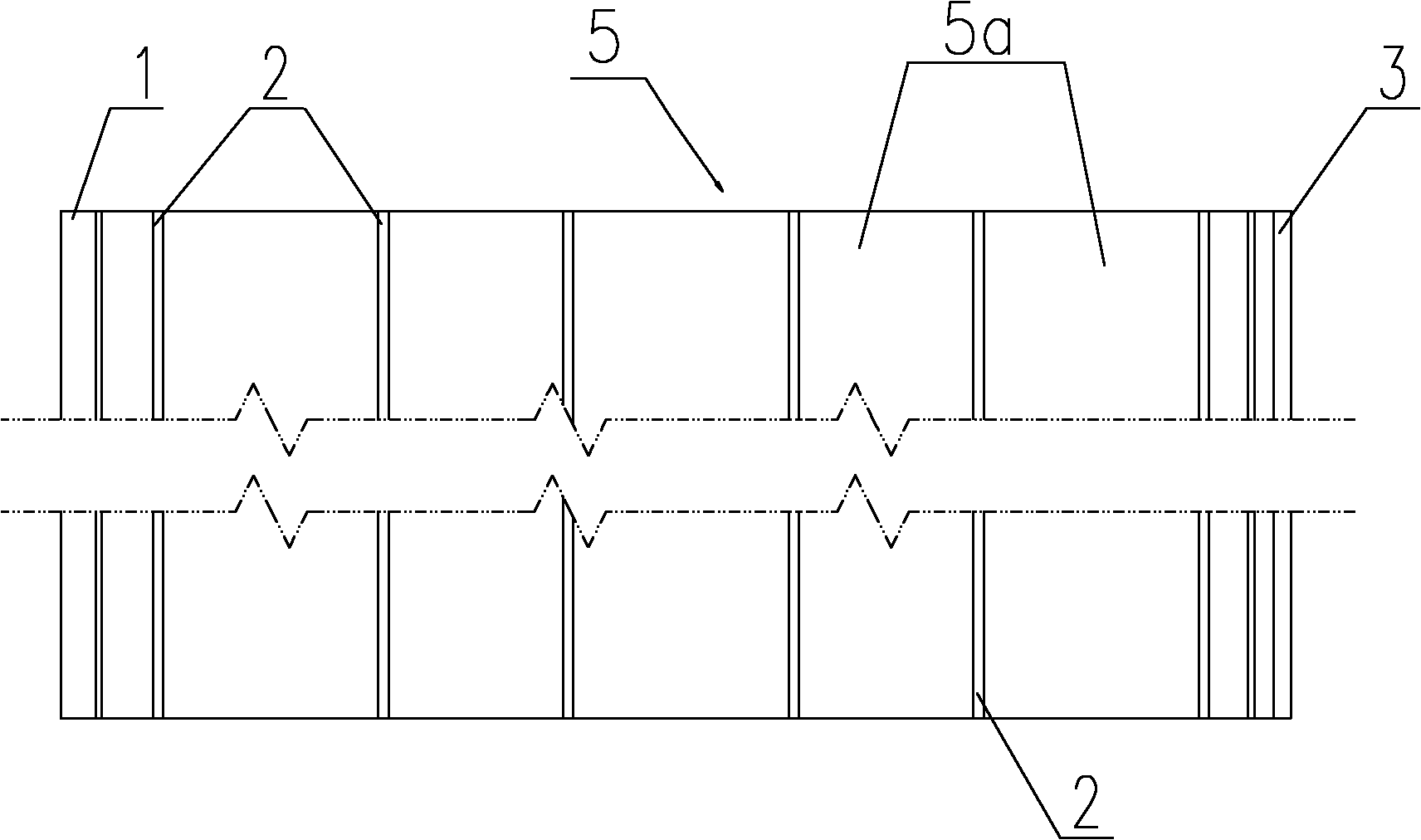

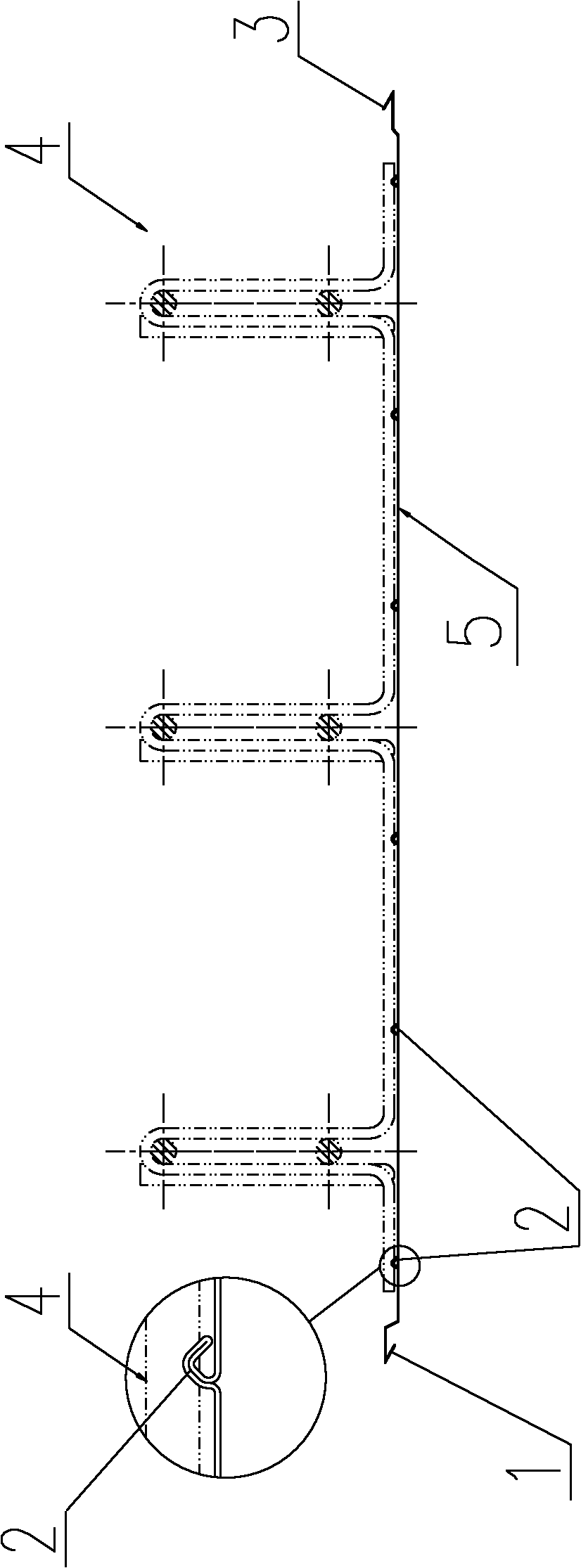

Composite pressed template for conveniently welding truss

ActiveCN102031867AAvoid breakdown phenomenonEliminate oar leakageForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringMetal sheet

The invention discloses a composite pressed template for conveniently welding a truss, which is a sheet metal. A plurality of raised lines are extruded in parallel at intervals on one lateral surface of the template, and are bumps formed by extruding and overlapping two sheets and bending the tops of the raised lines towards the plane section of the template. The composite pressed template has the advantages that: the shortcomings of the prior art are overcome; the raised lines formed on the template are the bumps formed by extruding and overlapping the two sheets and bending the tops of the raised lines towards the plane section of the sheet, have thicknesses remarkably more than that of the sheet, strong strength, high rigidity, improved pressure resistance and improved shearing resistance, avoid the template being broken down when the truss is welded on the template and avoid the leakage of grout at welding joints of the raised lines when concrete is poured; and the template provided by the invention can bear heavier construction loads and has high stability.

Owner:TJK MACHINERY TIANJIN

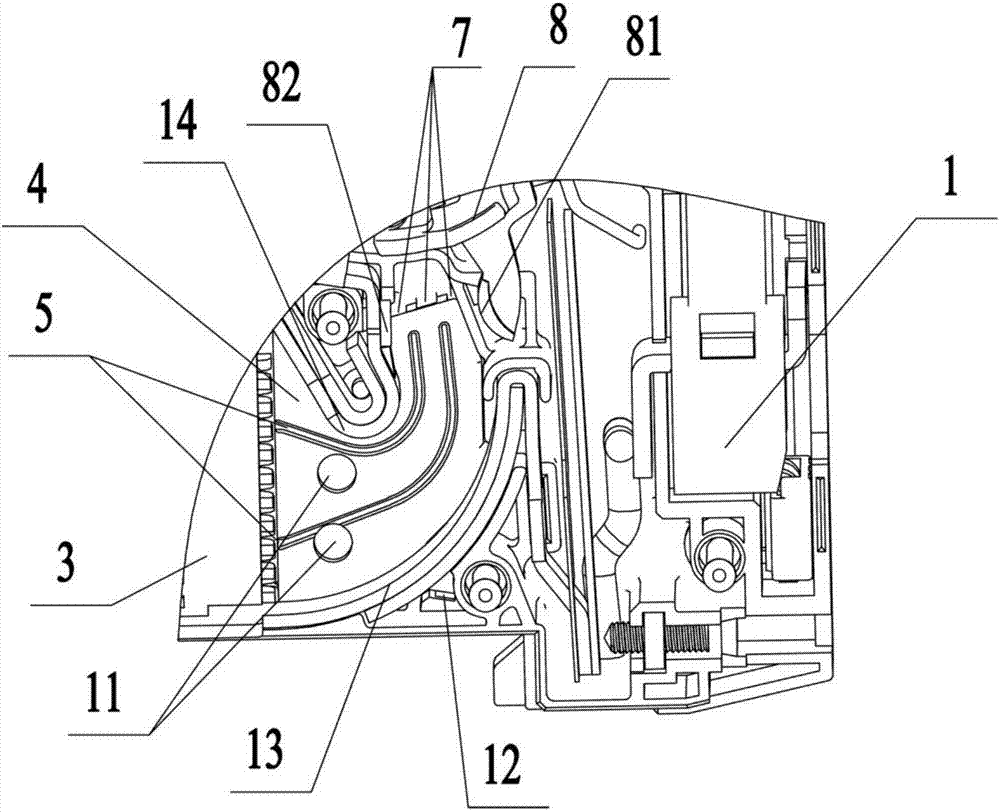

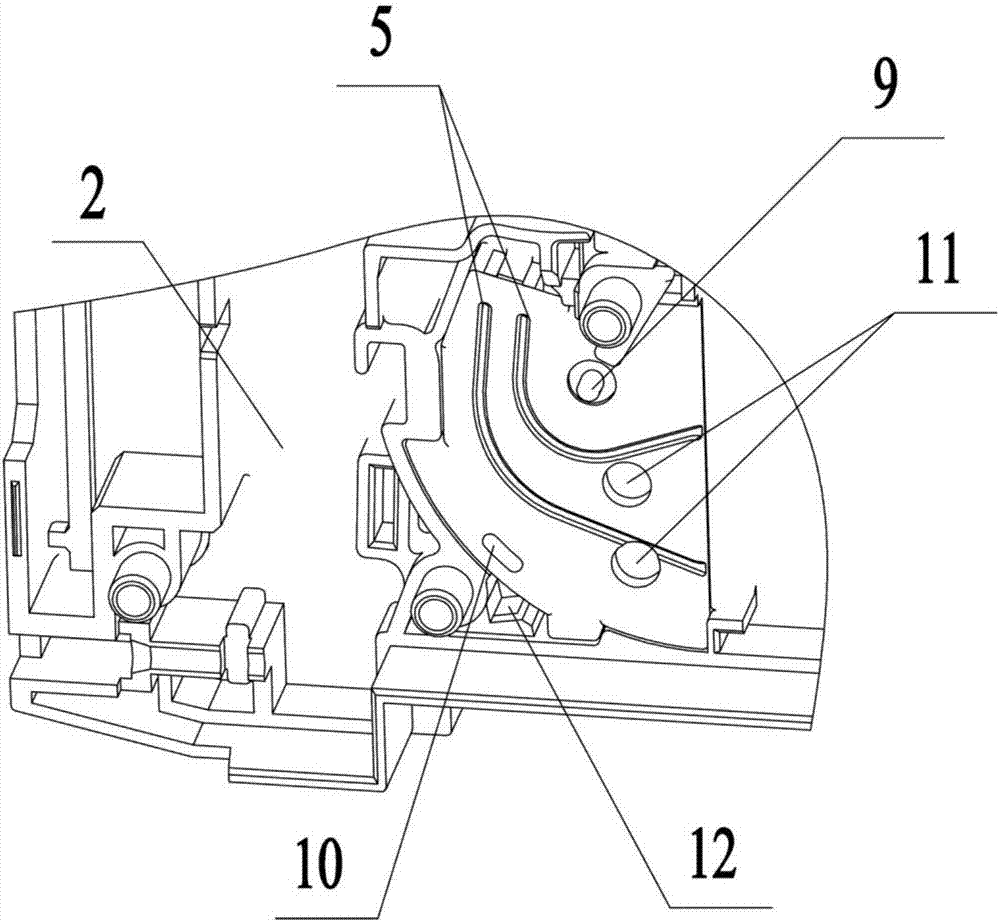

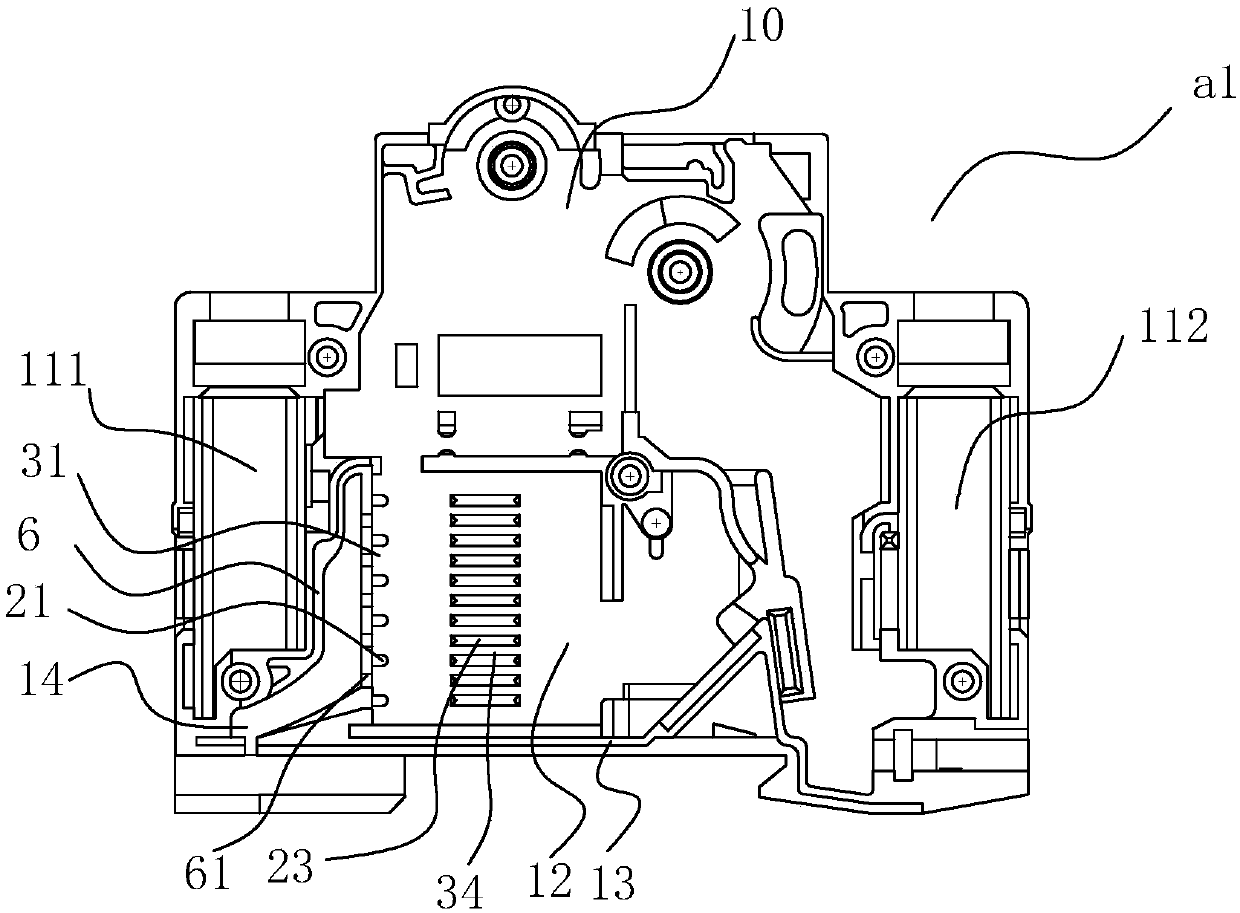

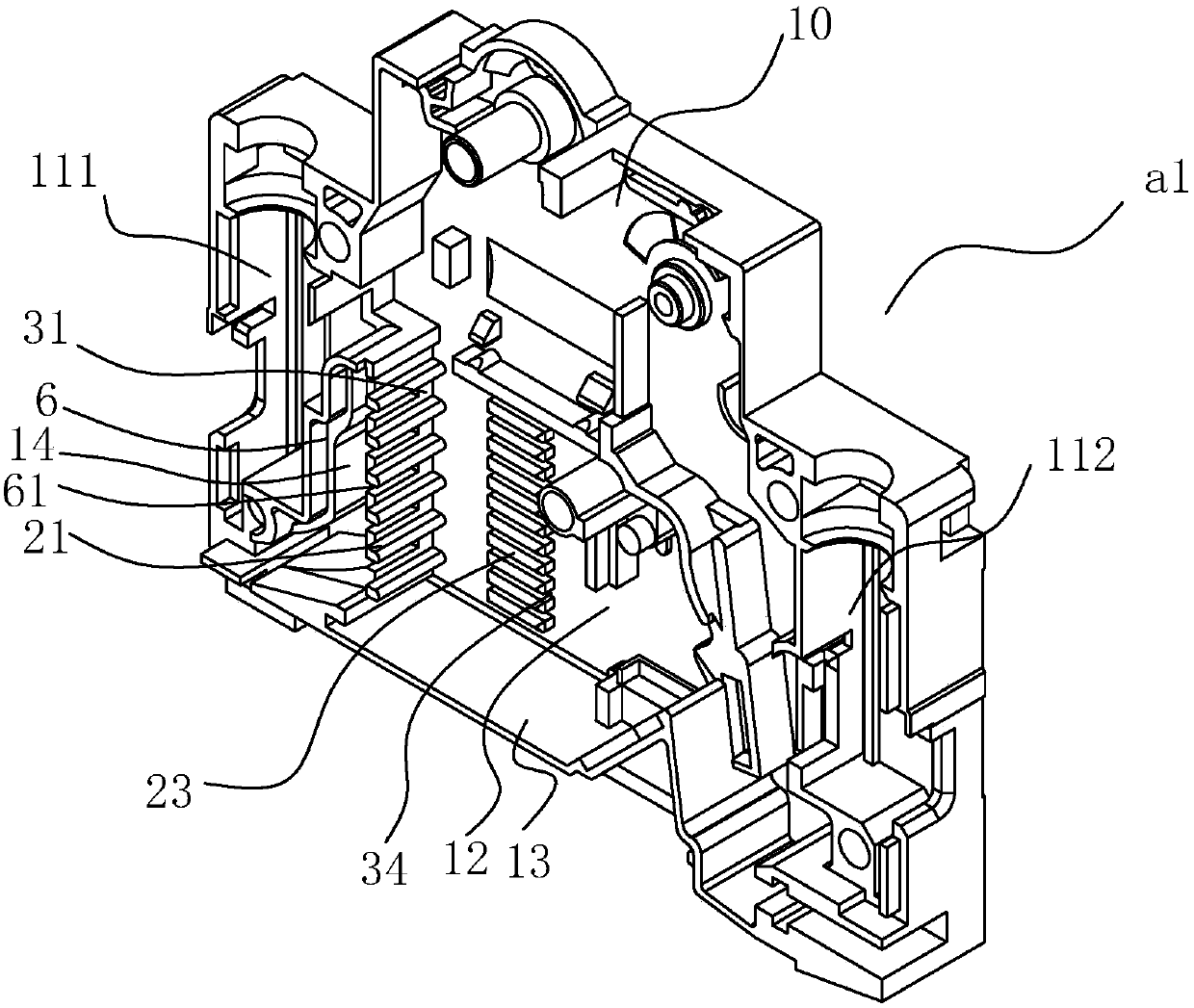

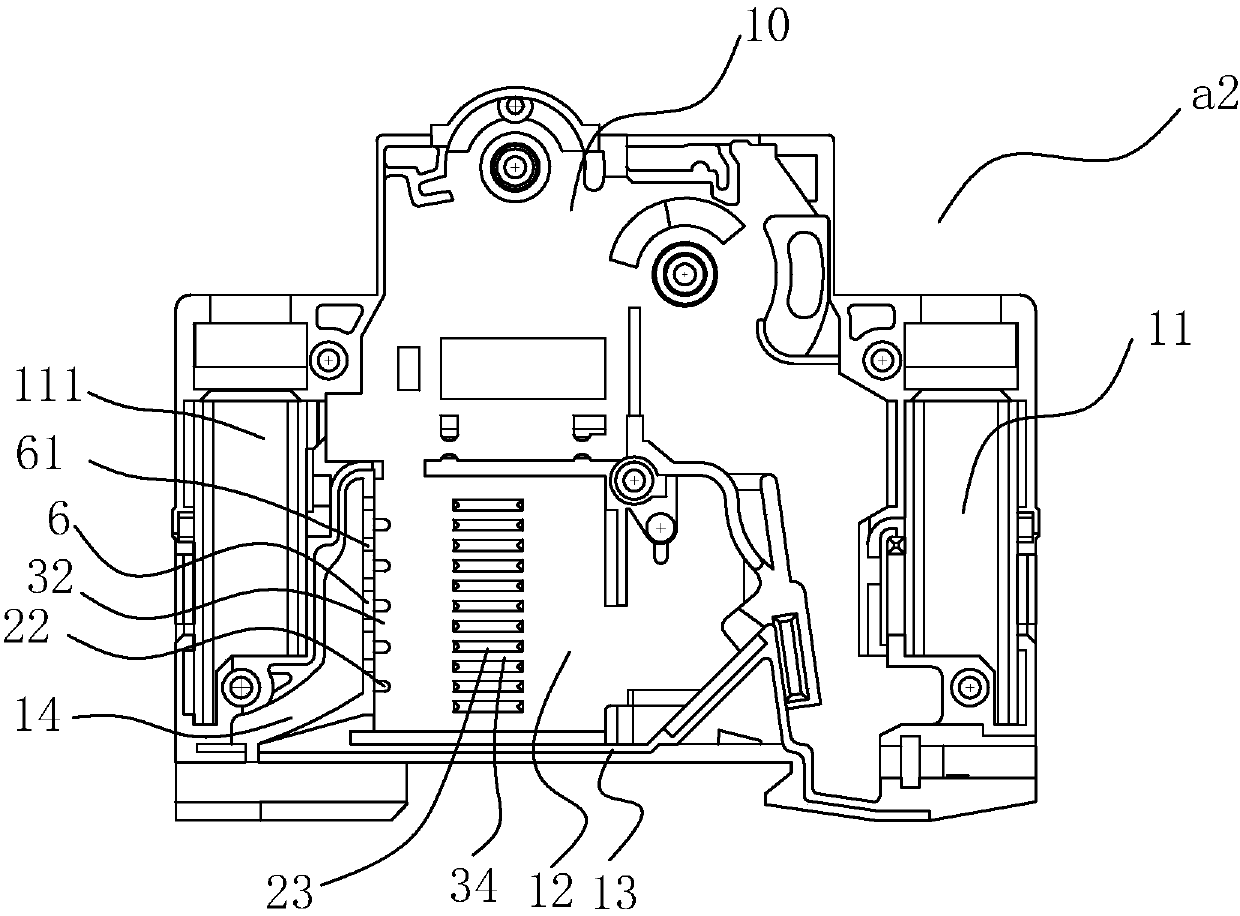

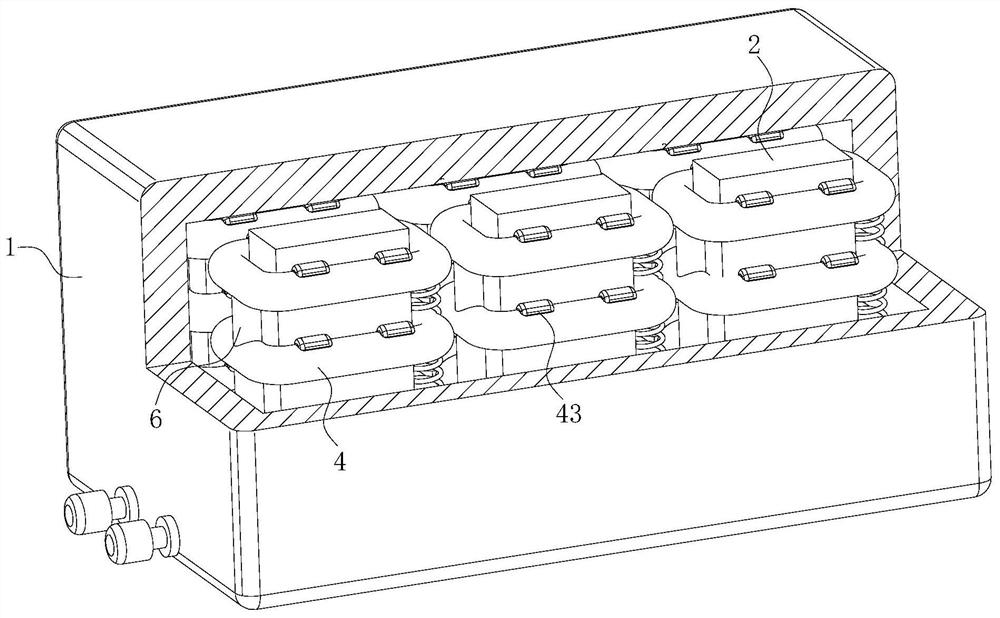

Circuit breaker

ActiveCN107993905AImprove breaking capacitySuppress breakdown phenomenonCircuit-breaking switch detailsCurrent limitingBreakdown phenomenon

The invention discloses a circuit breaker. The circuit breaker comprises a base, a cover plate, an arc extinguishing device and a contact system, wherein the arc extinguishing device and the contact system are arranged in a shell comprising the base and the cover plate, the arc extinguishing device comprises an arc extinguishing chamber and an arc isolation wall, the arc isolation wall is made ofa gas generation material and comprises a front surface and a rear surface, a diversion groove is formed in the rear surface of the arc isolation wall and is corresponding to an arc inlet side of thearc extinguishing chamber, and a diversion groove boss is arranged on the diversion groove and is used for guiding gas flow and cooling the gas flow. In the circuit breaker, the energy of the arc andthe space of the circuit breaker are effectively utilized, hot gas flowing out of regions of the contact system and the arc extinguishing device is returned to a region of the contact system through agas flow through groove in the back surface of the circuit breaker, a back breakdown phenomenon is prevented, and the current-limiting and breaking capability of the circuit breaker are improved.

Owner:HANGZHOU TAIMU ELECTRICAL

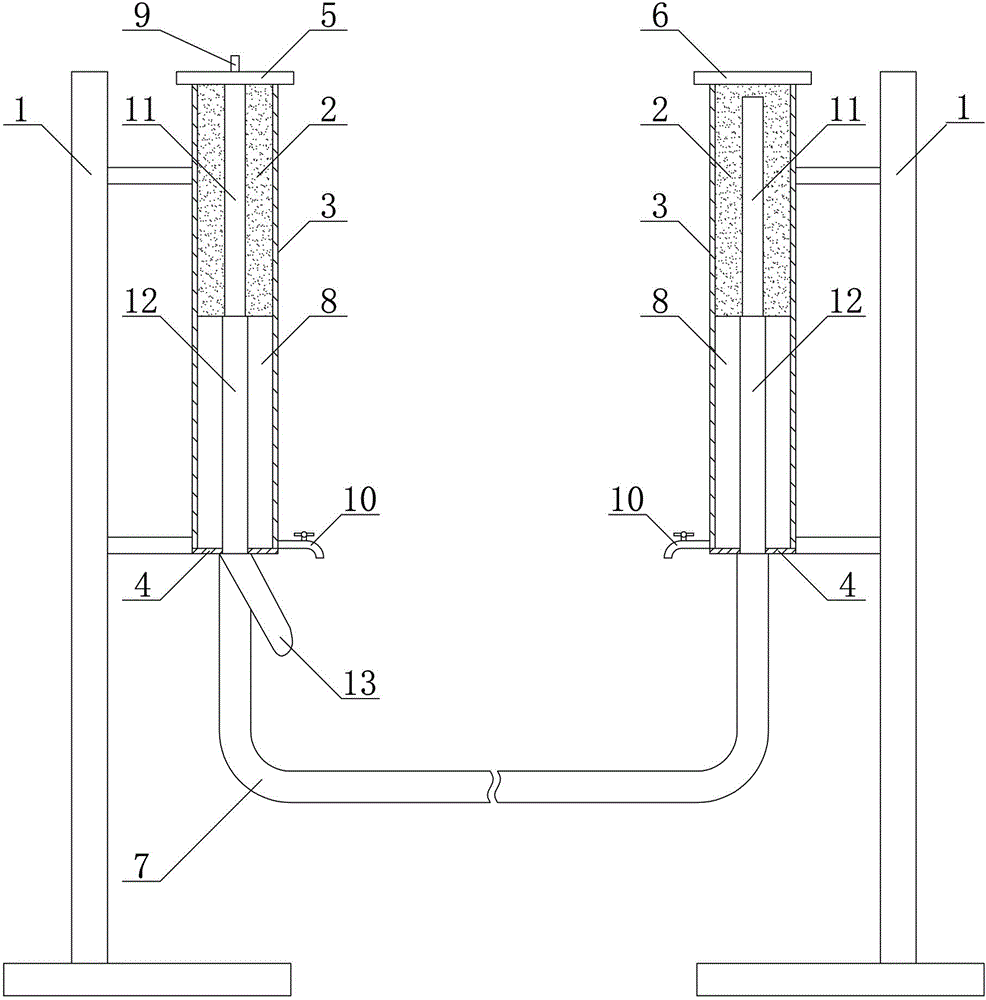

Water sublimator water supply control method for coping with overload and back pressure

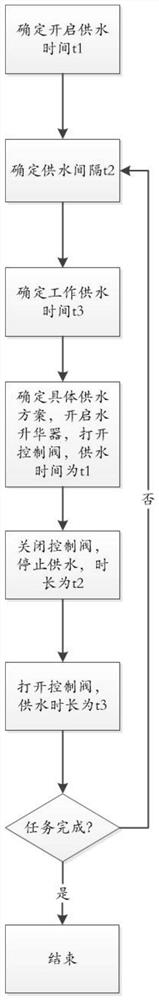

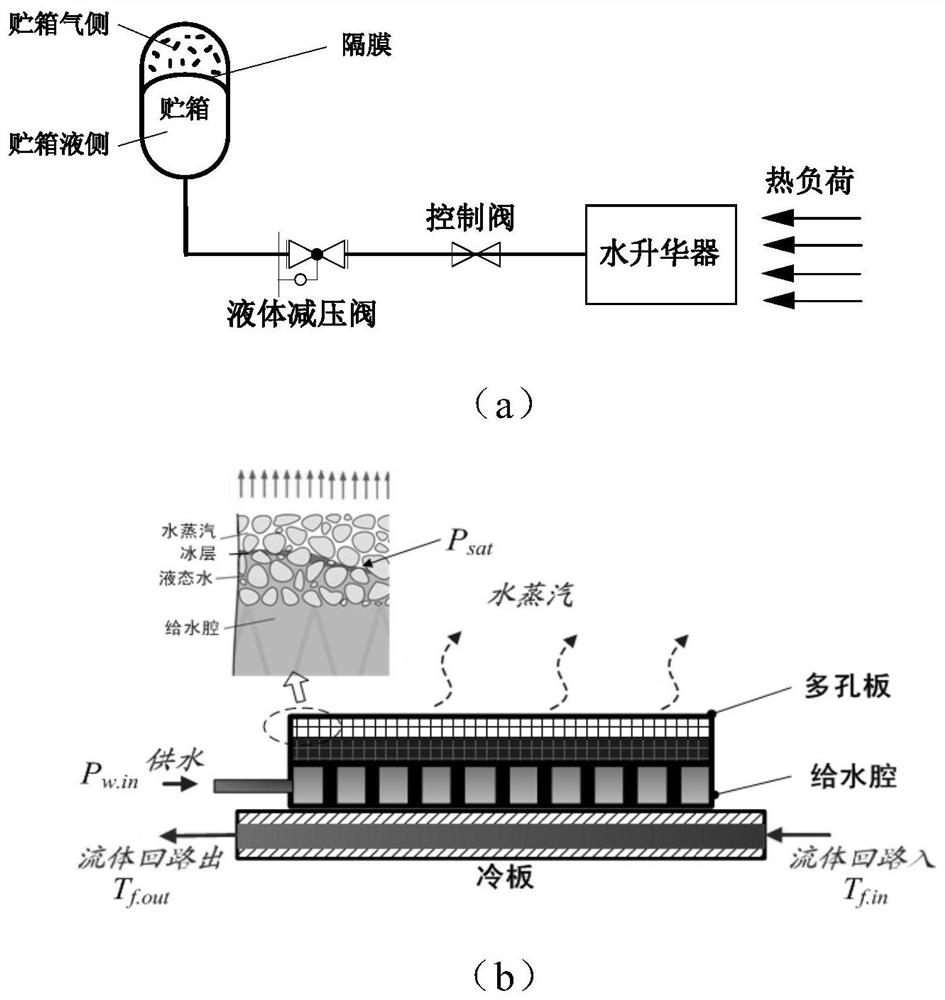

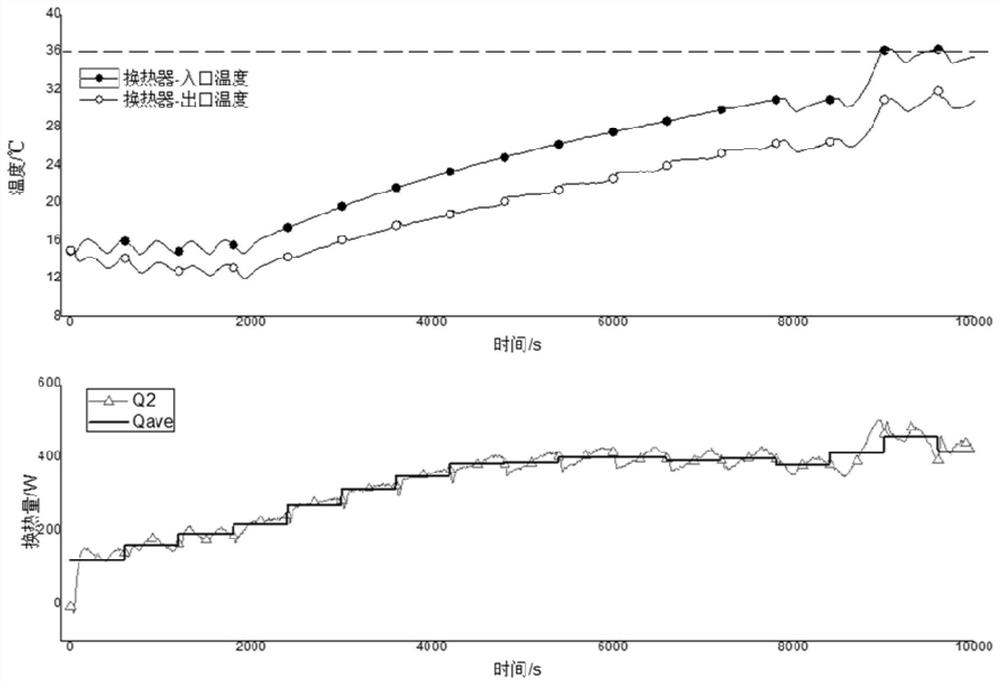

ActiveCN112661214AIncrease heightIncrease heat loadWater/sewage treatment by heatingSublimationControl valvesBack pressure

The invention discloses a water sublimator water supply control method for coping with overload and back pressure. The method can achieve a purpose that a water sublimator avoids a breakdown phenomenon under the conditions of complex heat, overload and back pressure factors in space, and achieves a higher heat dissipation capacity at the same time. Firstly, the water supply starting time t1 of the water sublimator is determined according to a first constraint condition; a water supply interval t2 is determined according to the task demand and a second constraint condition; and the working water supply time t3 of the sublimator is determined according to the third constraint condition. Then, a specific water supply scheme is determined, a water sublimator is started, a control valve is opened to supply water to the water sublimator, and the duration is water supply starting time t1; the control valve is closed, water supply is stopped, and the duration is the water supply stopping interval t2; the control valve is opened again, and the duration is the working water supply time t3; and t2 and t3 are repeatedly calculated, the valve is turned off on time according to the result, and the control valve is turned on until the task is finished.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

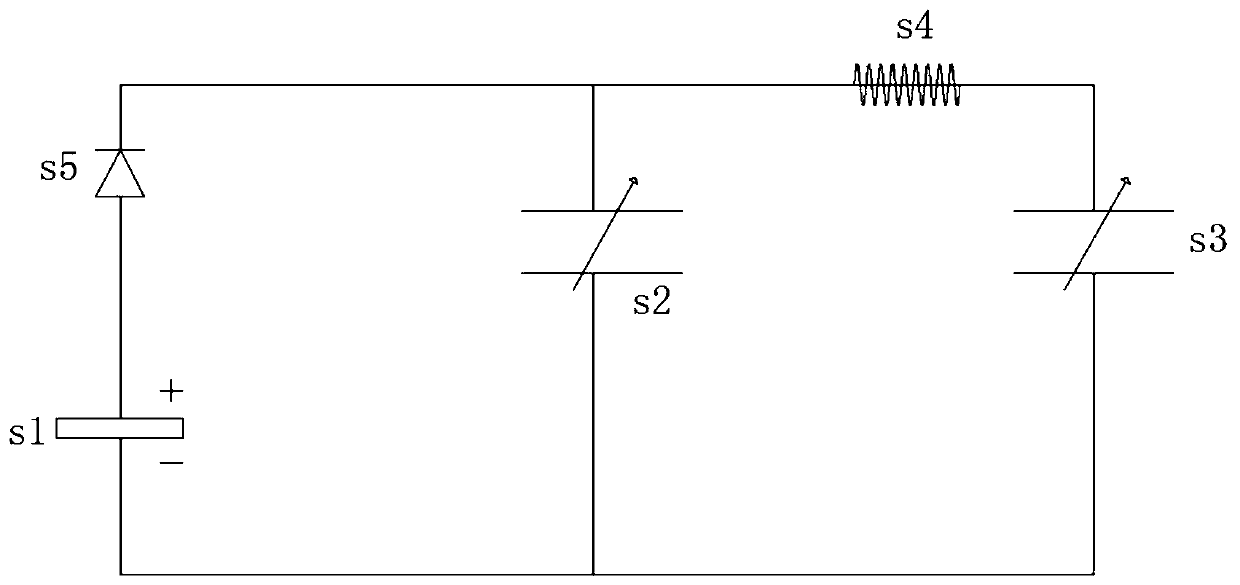

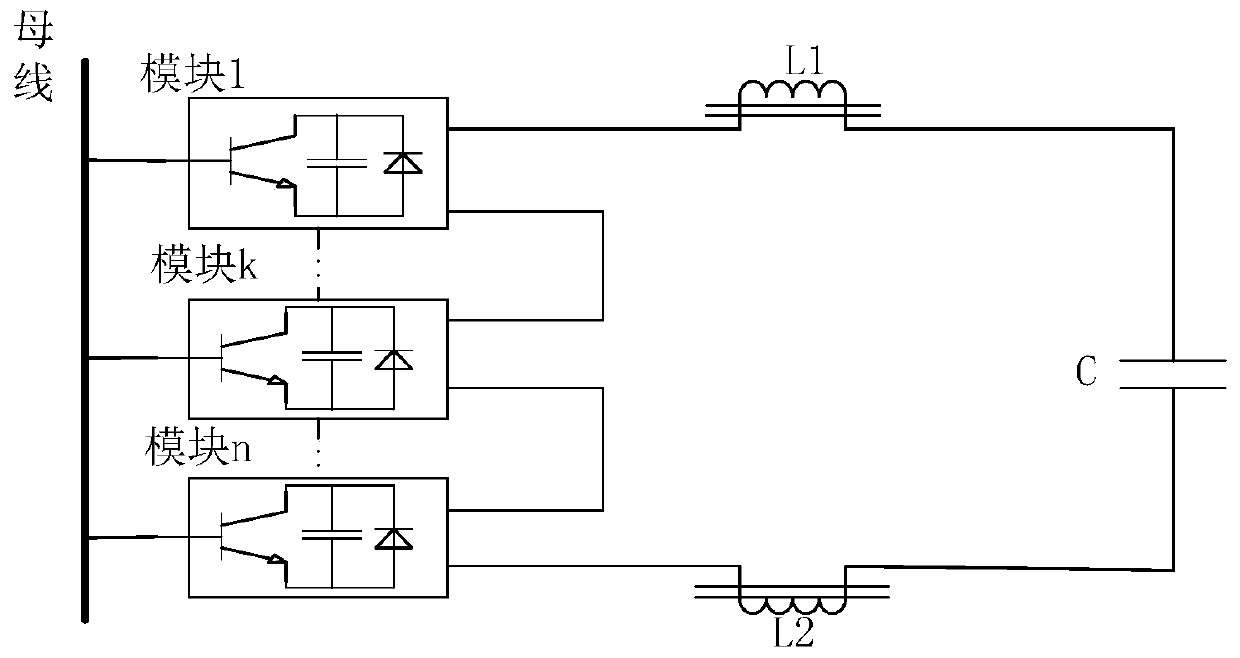

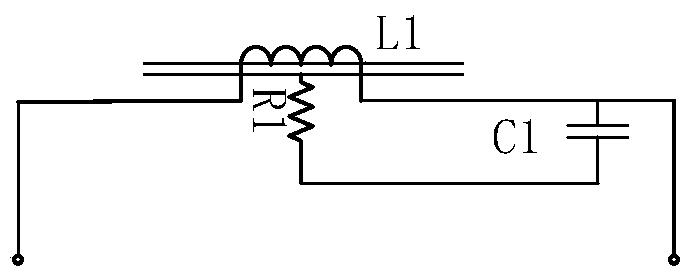

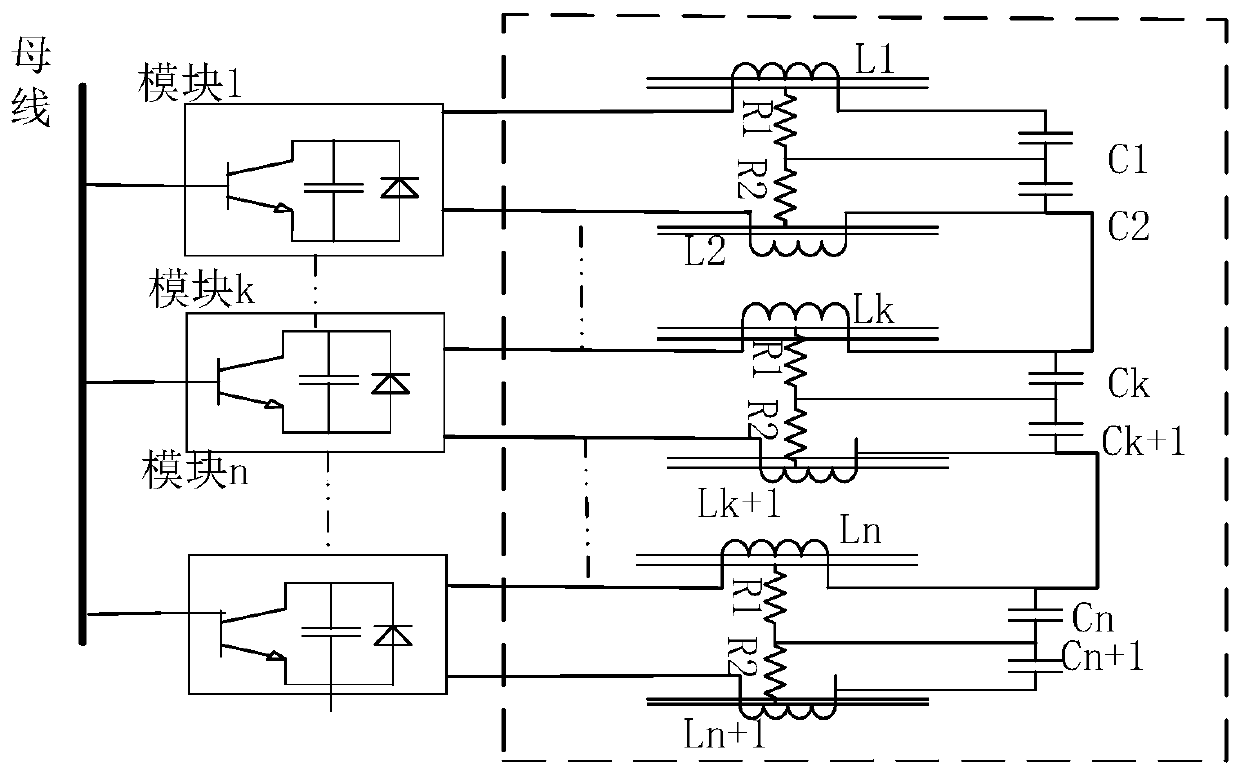

Suspension potential elimination circuit

PendingCN111064355ALevitation Potential ReductionAvoid Partial Discharge PhenomenaPower conversion systemsCapacitanceDc transformers

The invention relates to a suspension potential elimination circuit, which belongs to the technical field of direct current distribution networks. The circuit comprises a first winding with an iron core and an output end used for being connected with a DC / DC module in a direct current transformer, and a first capacitor. One end of the first capacitor is connected with the first winding, and the other end of the first capacitor is connected with a first resistor. The first resistor is connected with an iron core of the first winding. According to the suspension potential elimination circuit, the resistor is connected with the iron core of the first winding, and the resistor is connected with the capacitor, so that the iron core of the winding is electrically connected with the output side of the circuit; the suspension potential of the iron core in the direct current transformer is effectively reduced; the partial discharge phenomenon of the direct current transformer is avoided; and the safety and reliability of the direct current transformer are improved. The suspension potential elimination circuit is suitable for direct current transformers of various structures, such as directcurrent transformers of distributed cascaded topological structures, and can also be applied to power-frequency direct current transformers and high-frequency direct current transformers.

Owner:XIAN XJ POWER ELECTRONICS TECH +5

Circuit breaker shell and circuit breaker equipped with same

ActiveCN105957776AGood arc extinguishingRunning trajectory is stableProtective switch terminals/connectionsBreakdown phenomenonEngineering

The invention discloses a circuit breaker shell and a circuit breaker equipped with the same. At least two ventilating channels are formed between an access terminal accommodating region and an arc extinguish chamber accommodating region. Electric arc passes through the arc extinguish chamber and then enters the multiple ventilating channels through an electric arc inlet, so that the probability of re-arcing is lowered and the electric arc maintaining time is shortened; and therefore, the back breakdown phenomenon of the circuit breaker can be prevented fundamentally, and the breaking capability and the safety of the circuit breaker in use are improved.

Owner:欧迪森电气有限公司

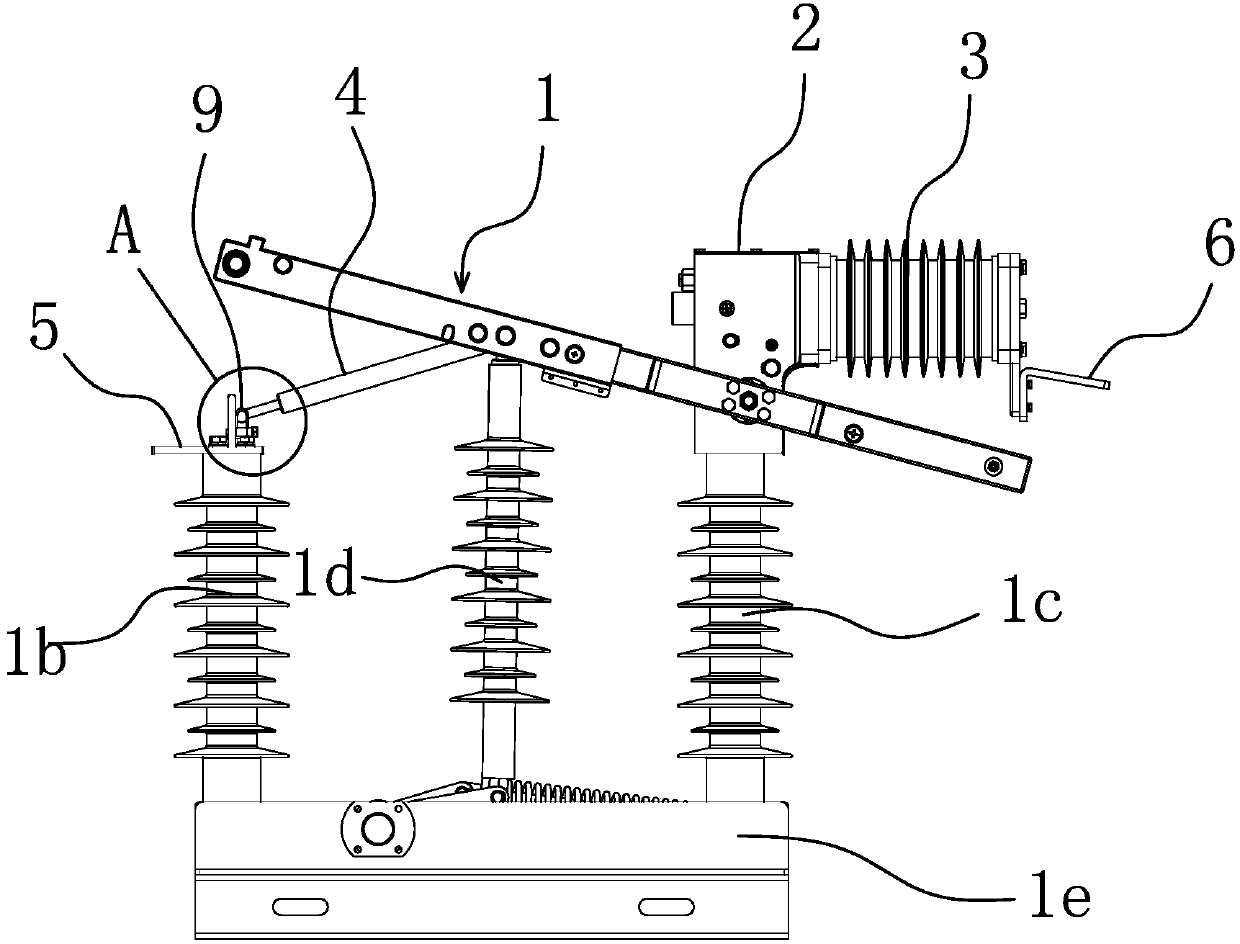

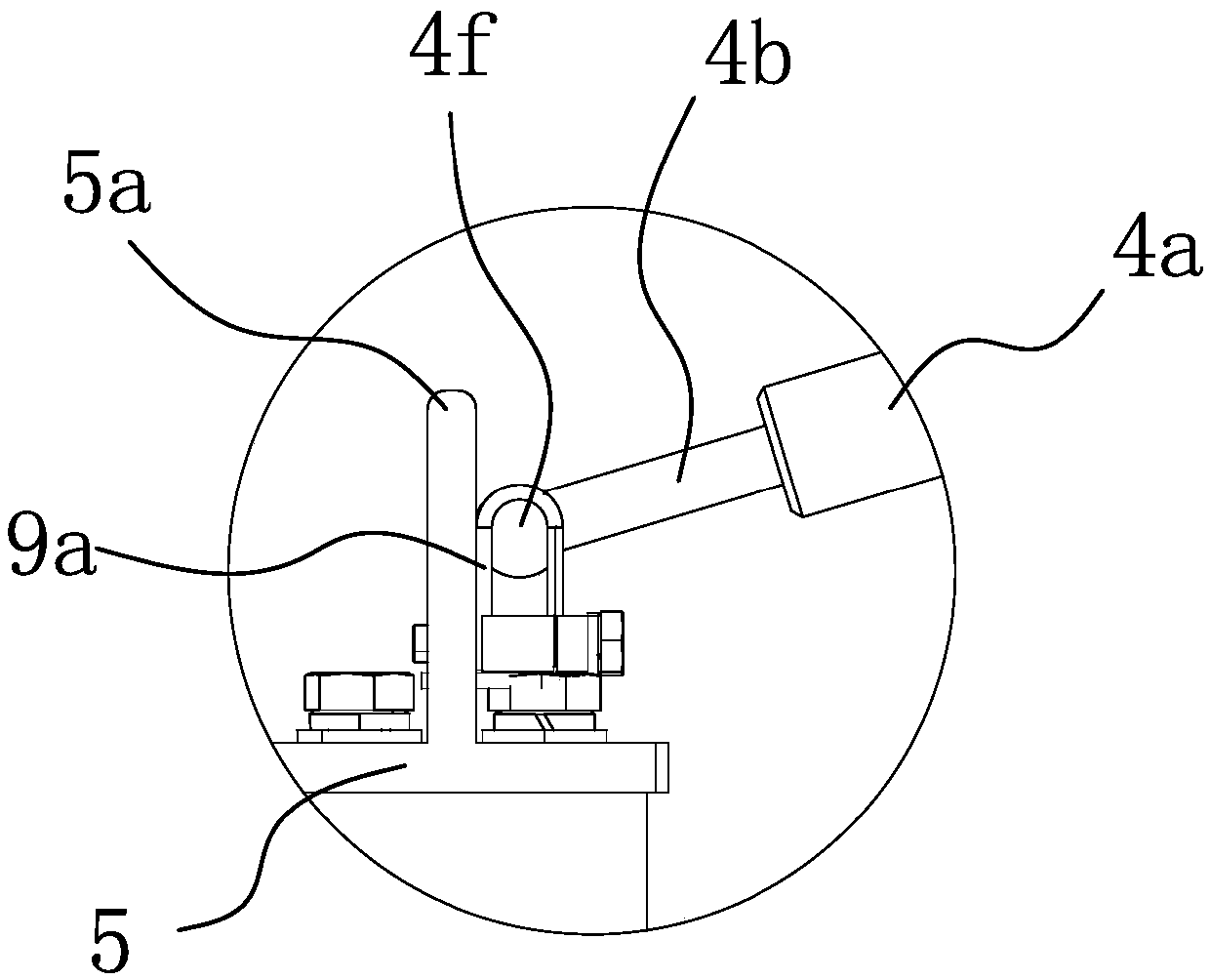

Vacuum isolating load switch

ActiveCN107833785AAvoid electrical breakdownEnsure safetyHigh-tension/heavy-dress switchesAir-break switchesEngineeringCircuit breaker

Owner:ZHEJIANG ZIGUANG ELECTRIC APPLIANCE

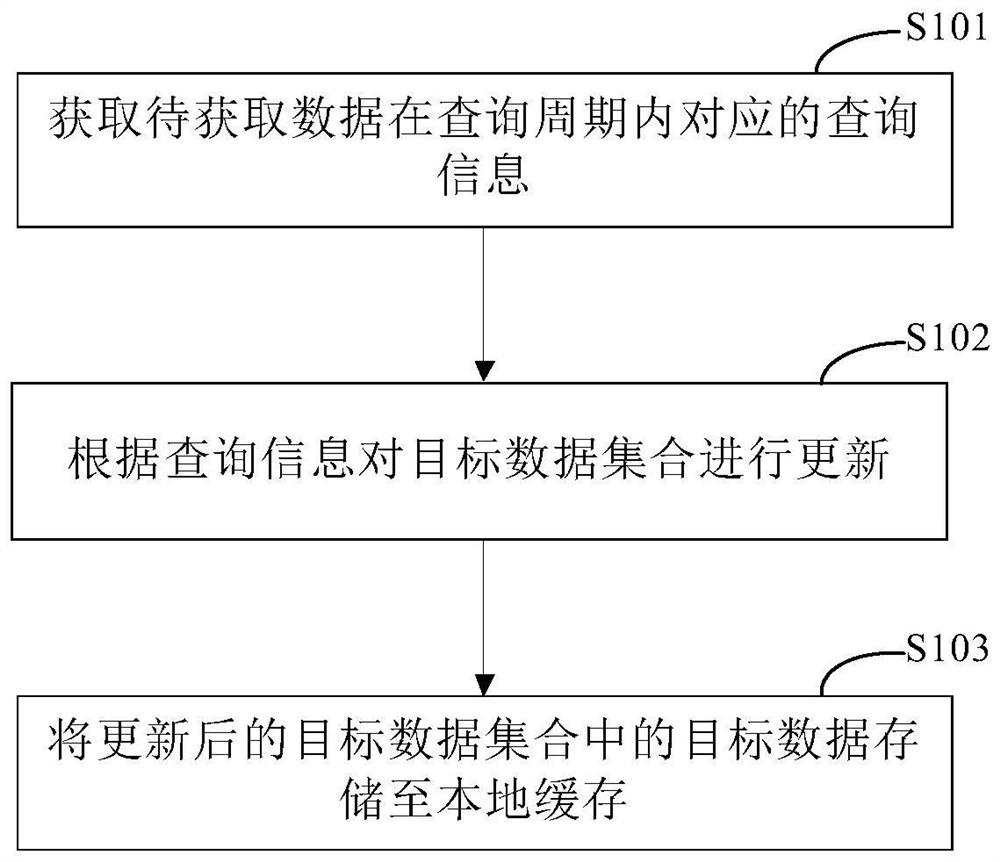

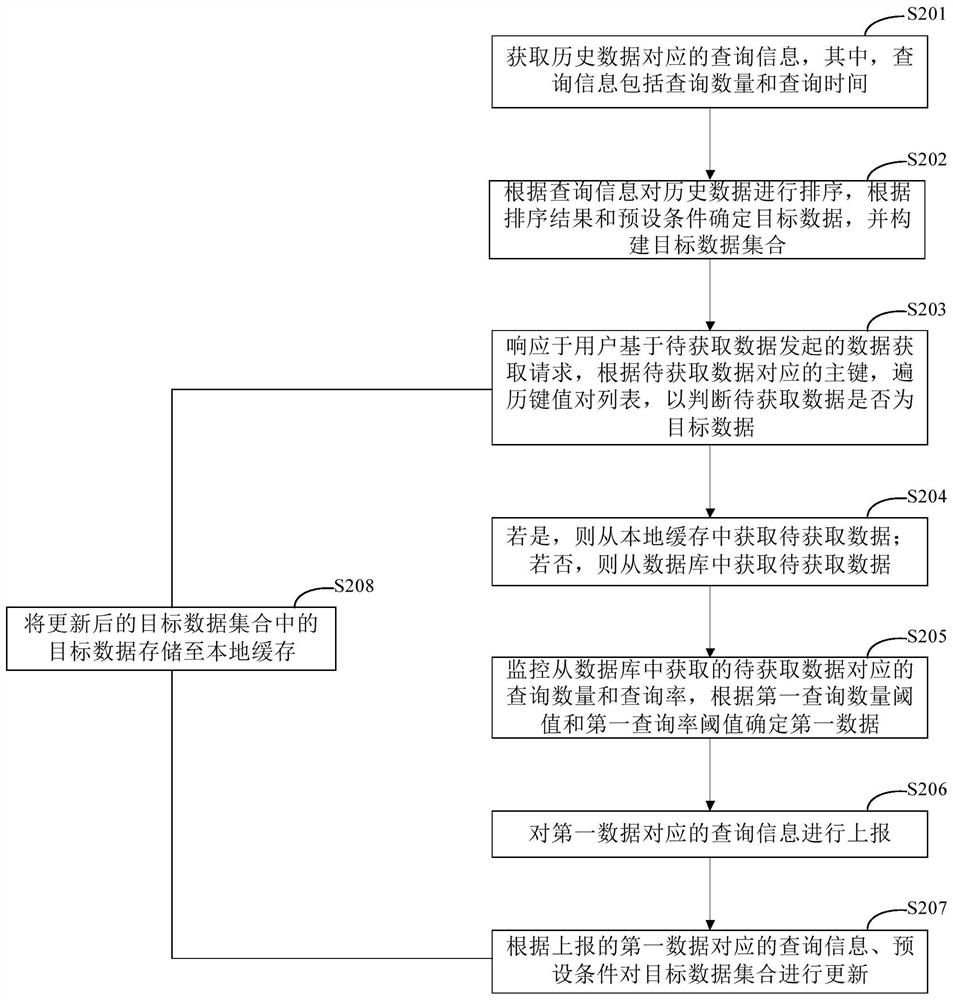

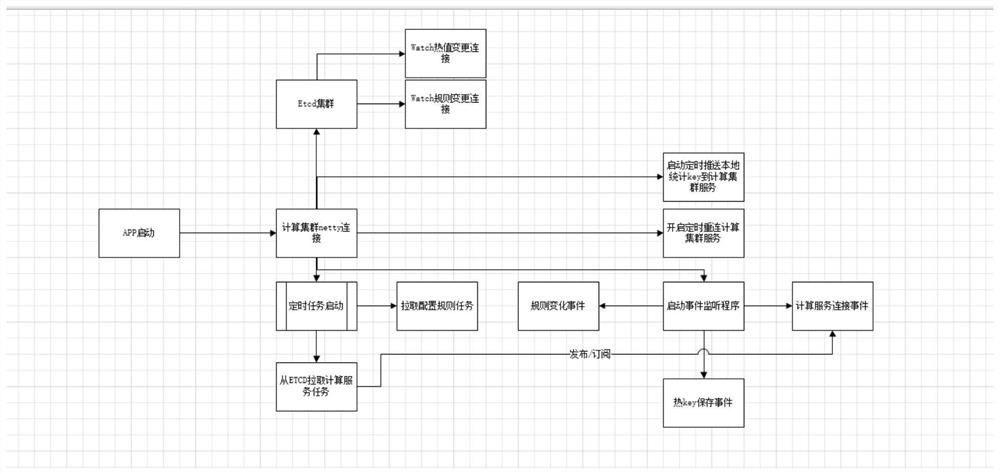

Data processing method and device

PendingCN113760982AImprove experienceAvoid breakdown phenomenonDatabase updatingDatabase distribution/replicationData setData mining

The invention discloses a data processing method and device, and relates to the technical field of computers. A specific embodiment of the method comprises the steps of obtaining corresponding query information of to-be-obtained data in a query period; updating a target data set according to the query information, wherein the target data set is constructed according to query information corresponding to historical data; and storing the target data in the updated target data set to a local cache. According to the embodiment, by updating the target data in real time, a cache breakdown phenomenon is effectively solved, application scenes are expanded, and the user experience is improved.

Owner:西安京迅递供应链科技有限公司

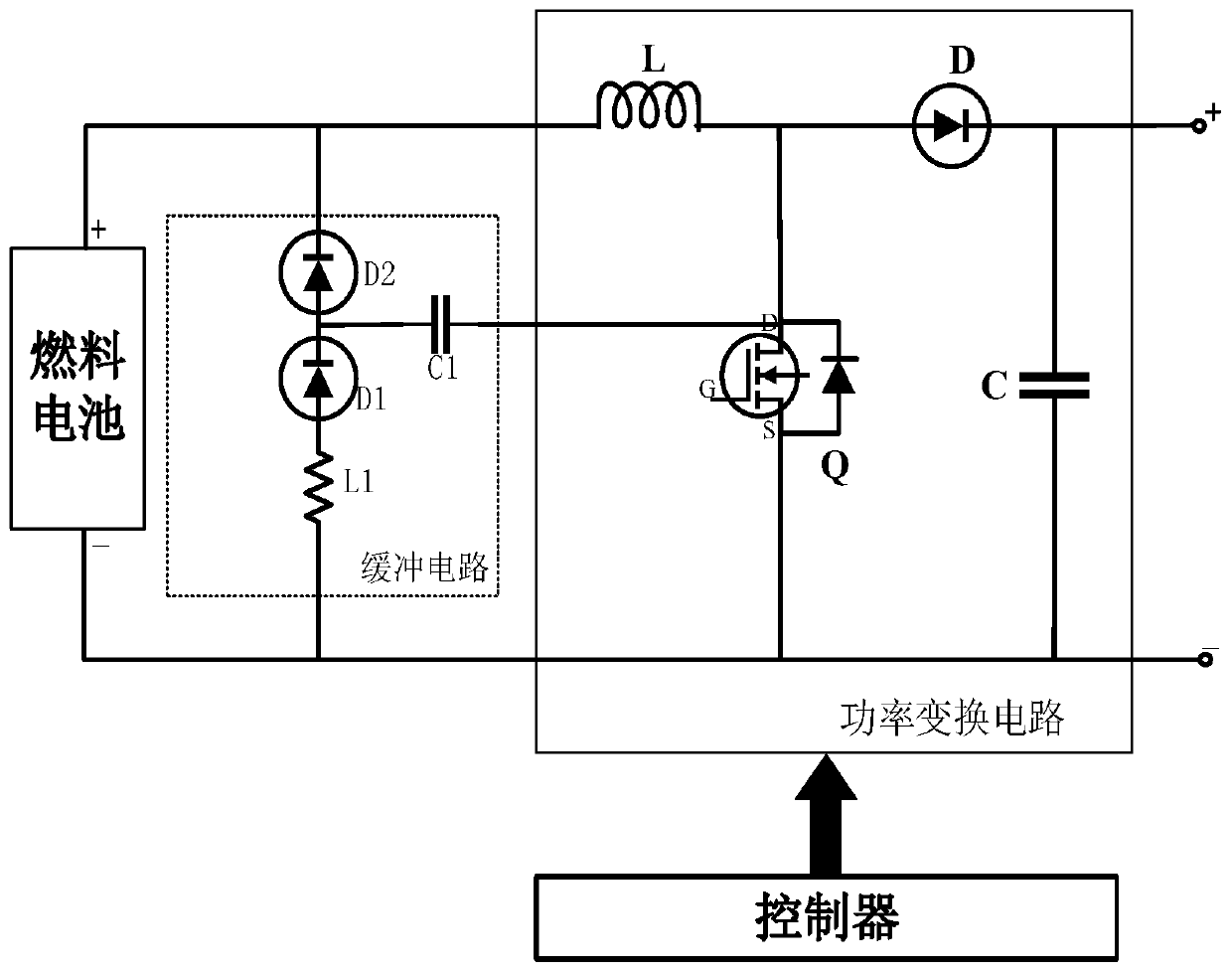

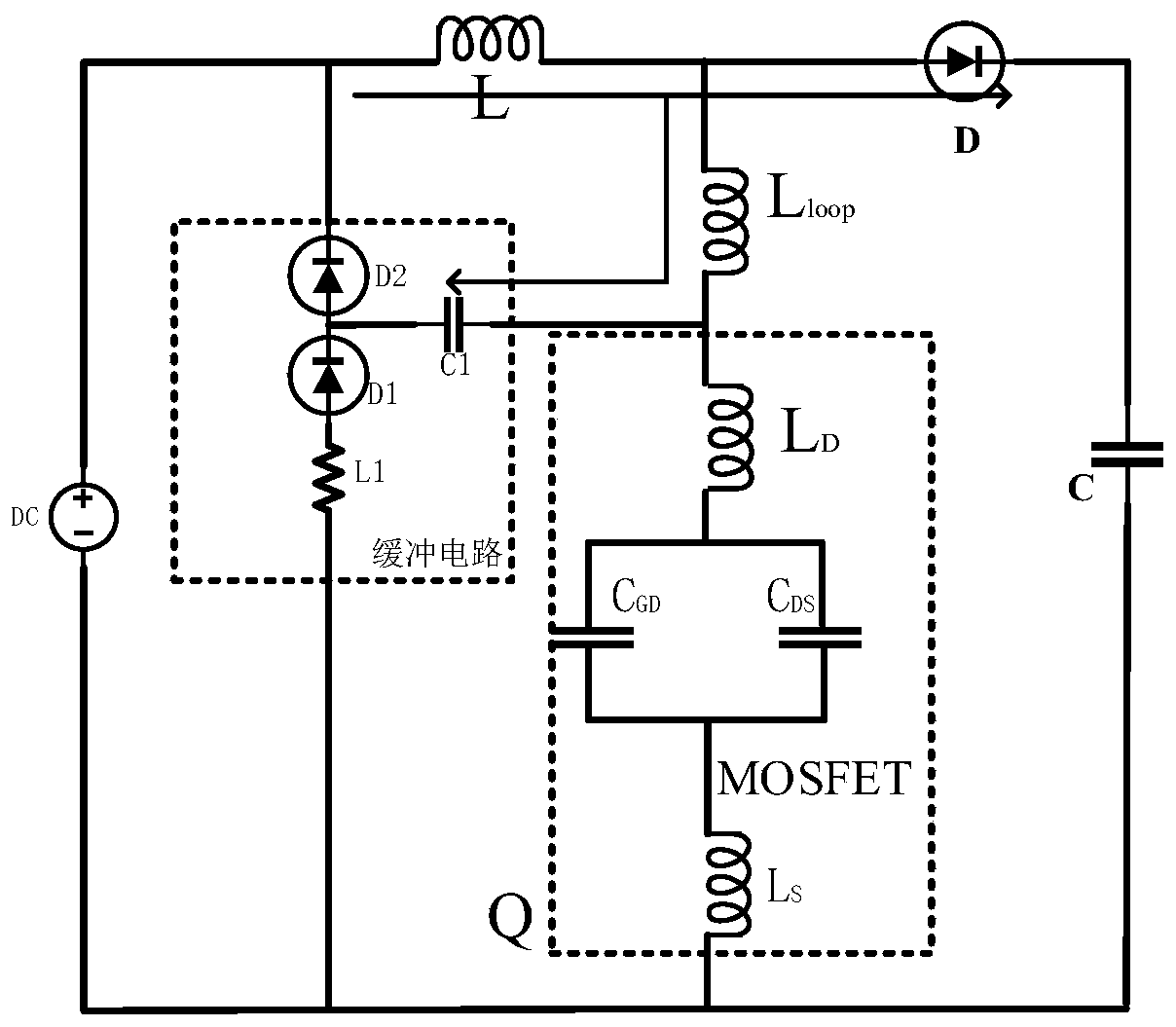

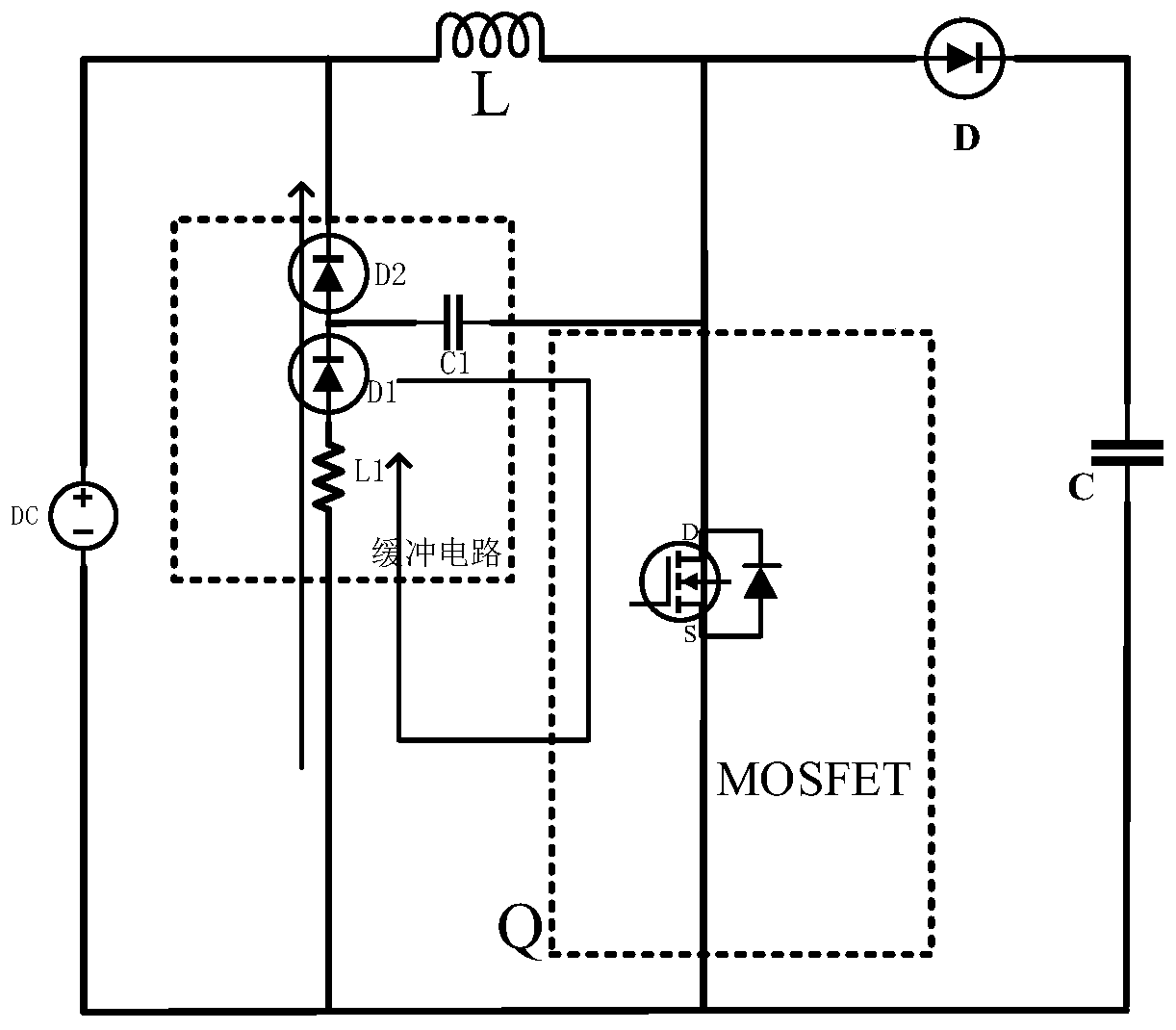

High efficiency DC/DC converter

InactiveCN111245226ASuppress voltage spikesAvoid breakdown phenomenonEfficient power electronics conversionDc-dc conversionPhysicsTerminal voltage

The invention relates to the field of power conversion of power electronics, in particular to a high-efficiency DC / DC converter which comprises a power conversion circuit, a controller and a buffer circuit. The buffer circuit is arranged between an input end and the power conversion circuit, the controller is connected with the power conversion circuit, the power conversion circuit comprises a switching tube and an LC oscillation circuit, and the buffer circuit is used for slowing down the rising speed of the voltages at the two ends of a source electrode and a drain electrode of the switchingtube. According to the invention, the voltage spike when the switching tube is turned off can be suppressed, thereby avoiding a breakdown phenomenon.

Owner:WUHAN UNIV OF TECH

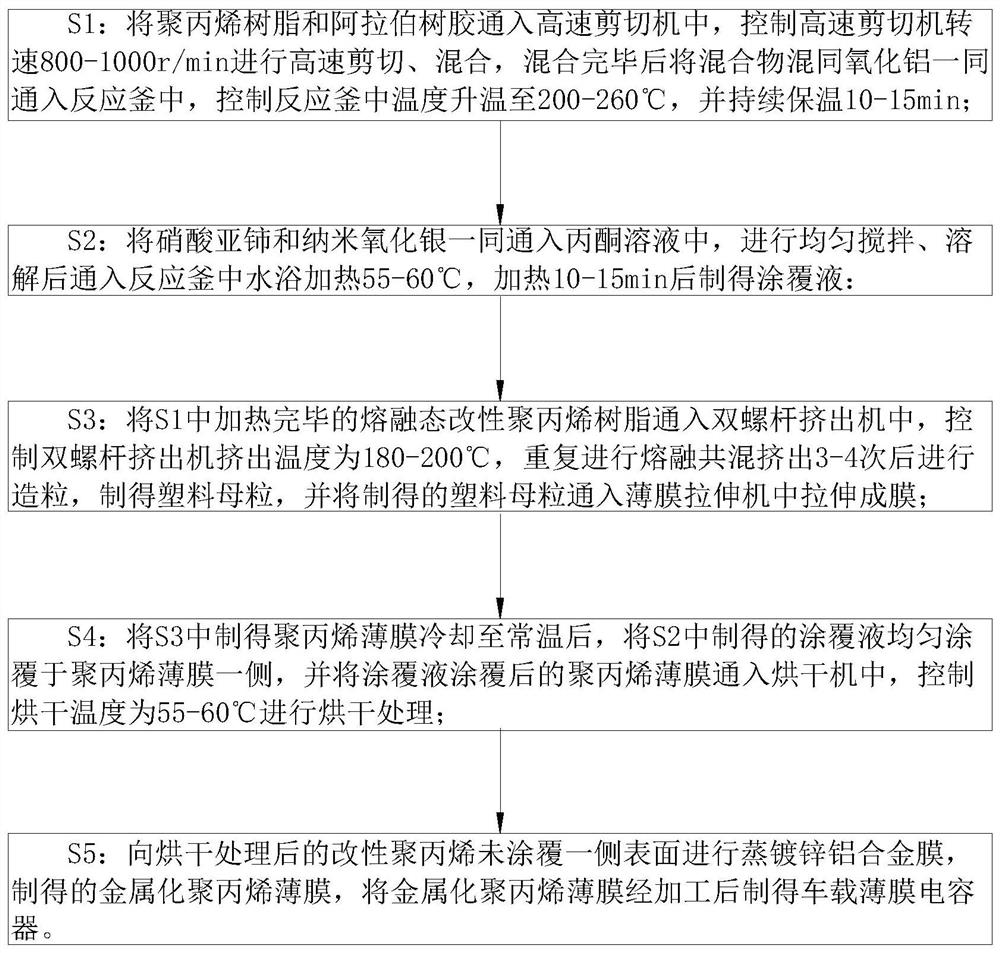

Polypropylene film

InactiveCN111635548ALow yieldLow cold shrinkageThin/thick film capacitorStacked capacitorsPolymer scienceManganese oxide

The invention belongs to the technical field of high polymer materials, and particularly relates to a polypropylene film which comprises a shell, a core and leading-out lines. The core comprises a substrate layers, metal film layers and a heat conduction layer. The two substrate layers are made of modified polypropylene resin films; the metal film layers are fixedly connected to both sides of thesubstrate layers through evaporation, and the area of the metal film layers is smaller than that of the substrate layers; the heat conduction layer is made of a heat conduction silicone grease material; the surfaces, away from the heat conduction layer, of the metal film layers are coated with an insulating paint layer; the metal film layers on two adjacent substrate layers are in a staggered state; the leading-out wires are respectively conducted with the metal film layers on the two substrate layers; the MAH graft modified polyethylene wax and the active manganese dioxide are added into thepolypropylene film, so that the softness of the prepared polypropylene film is effectively and remarkably enhanced, meanwhile, the active manganese dioxide is self-decomposed to release oxygen ions togenerate an aluminum oxide film, and the service life of a film capacitor is further prolonged.

Owner:孔维恒

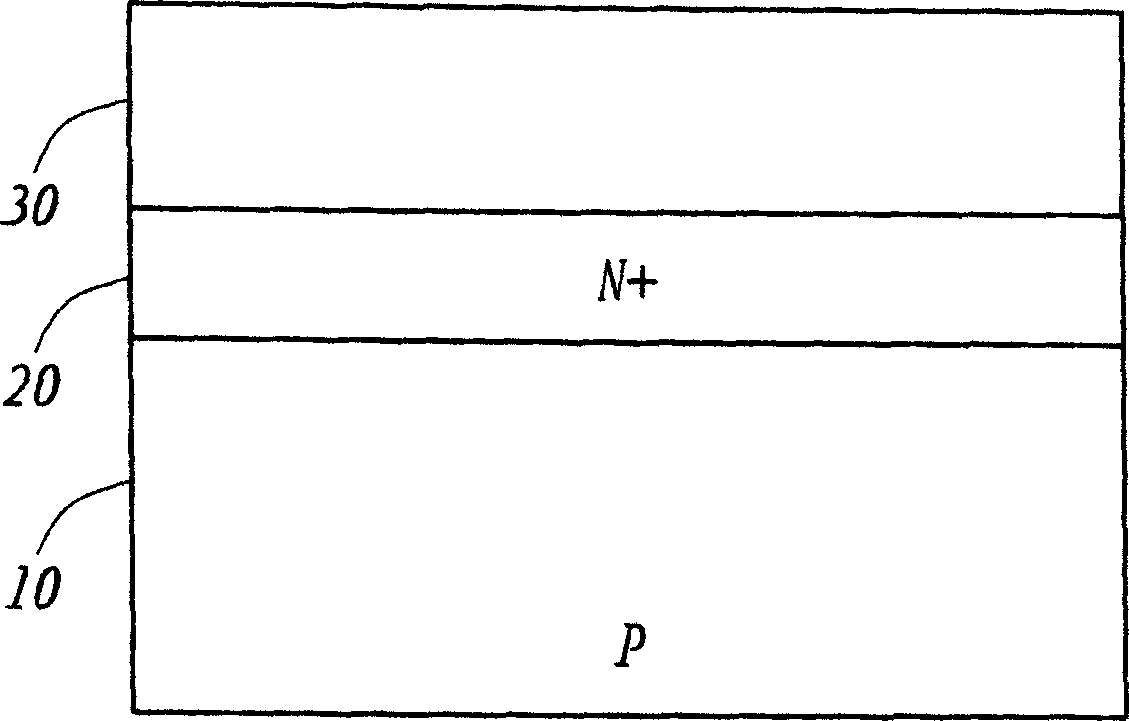

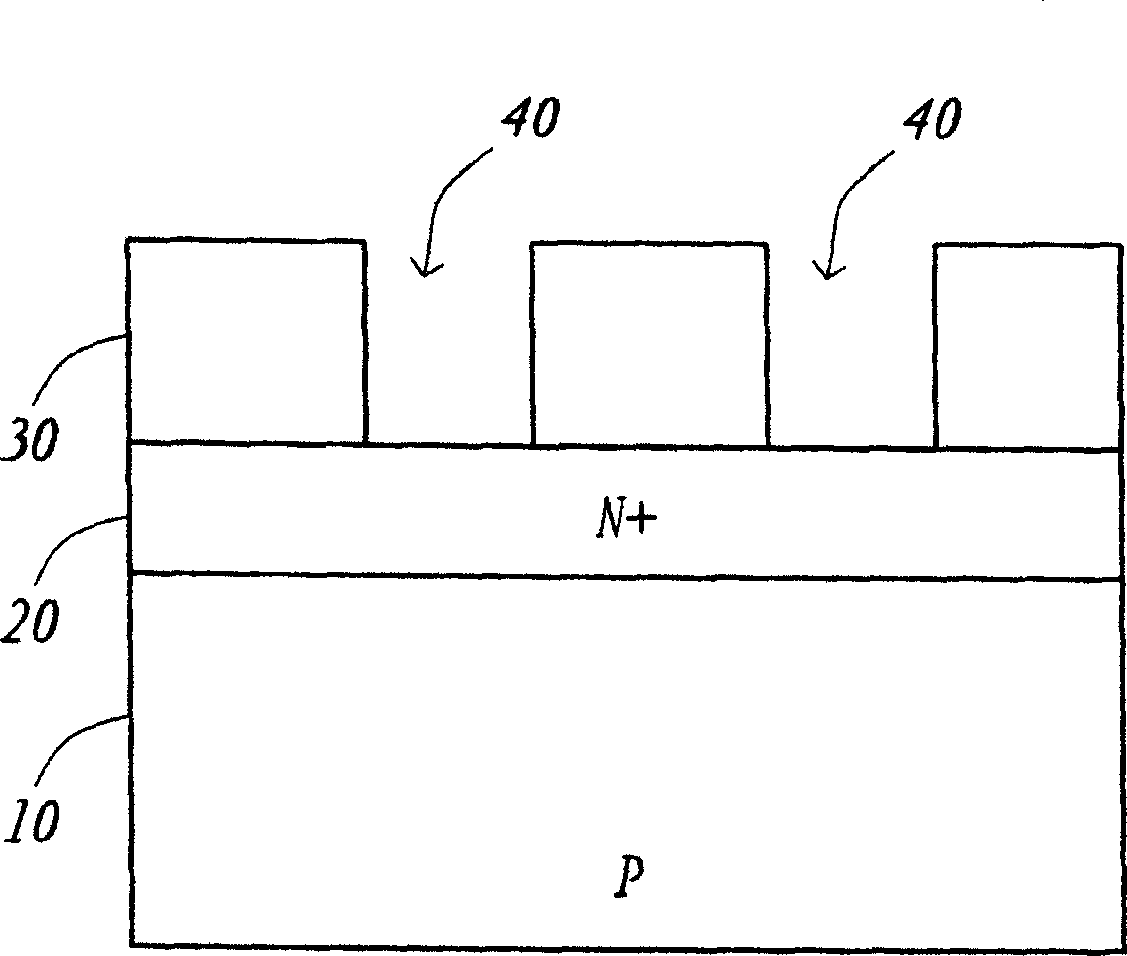

Memory element and its production method

InactiveCN1477699AAvoid breakdown phenomenonSolid-state devicesSemiconductor/solid-state device manufacturingDopantDielectric layer

Owner:MACRONIX INT CO LTD

Method for mfg. parallel capacitor core, and parallel capacitor core

InactiveCN1402278AAvoid melting and shrinkingGuaranteed compressive strengthMultiple fixed capacitorsCapacitor manufactureWeld seamAluminium foil

A parallel capacitor core is prepared through preparing aluminium foil and dielectric film, rolling, assembling core set, welding to form two welding seams, welding leading wire, and packing. its advantages are high oil-immersing speed and quality, improved local discharge performance and short period. Said parallel capacitor core is composed of core set and packing paper.

Owner:锦州电力电容器有限责任公司

Novel waterproof wiring terminal for on-column equipment cable terminals

InactiveCN104332936AAvoid enteringAvoid breakdown phenomenonConnection end capsMulticonductor cable end piecesOn columnCopper

A novel waterproof wiring terminal for on-column equipment cable terminals is mainly composed of two parts: a wiring terminal and an insulating nut. The wiring terminal part is composed of a semi-circular copper port, a press-fitting metal part, and a rainproof U-shaped port. The insulating nut is used as a separate component. The semi-circular copper port of the wiring terminal is connected with an equipment pile head. The press-fitting metal part is connected with a cable wire core. The invention provides the novel waterproof wiring terminal for on-column equipment cable terminals which is manufactured by a simple technology, and is corrosion-resistant, durable, and easy to use. Rainwater can be prevented from entering the wire core from the connector at the joint of the wiring terminal and the wire core and flowing into a cable branch box connector under a rod. Therefore, the phenomenon of discharge insulation breakdown caused by rainwater is prevented, and safe operation of equipment is ensured. The novel waterproof wiring terminal is suitable for wide popularization in the technical field to which the novel waterproof wiring terminal belongs.

Owner:ANHUI ELECTRIC POWER FUYANG POWER SUPPLY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com