Vacuum high temp. electric heating pipe and product tech. thereof

A production process and technology of electric heating tubes, applied in the direction of ohmic resistance heating parts, heating element materials, heating element shapes, etc., can solve the problems of potential safety hazards, low insulation level, increased working time, etc., to prevent breakdown and bursting phenomenon, high insulation performance, and the effect of preventing breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

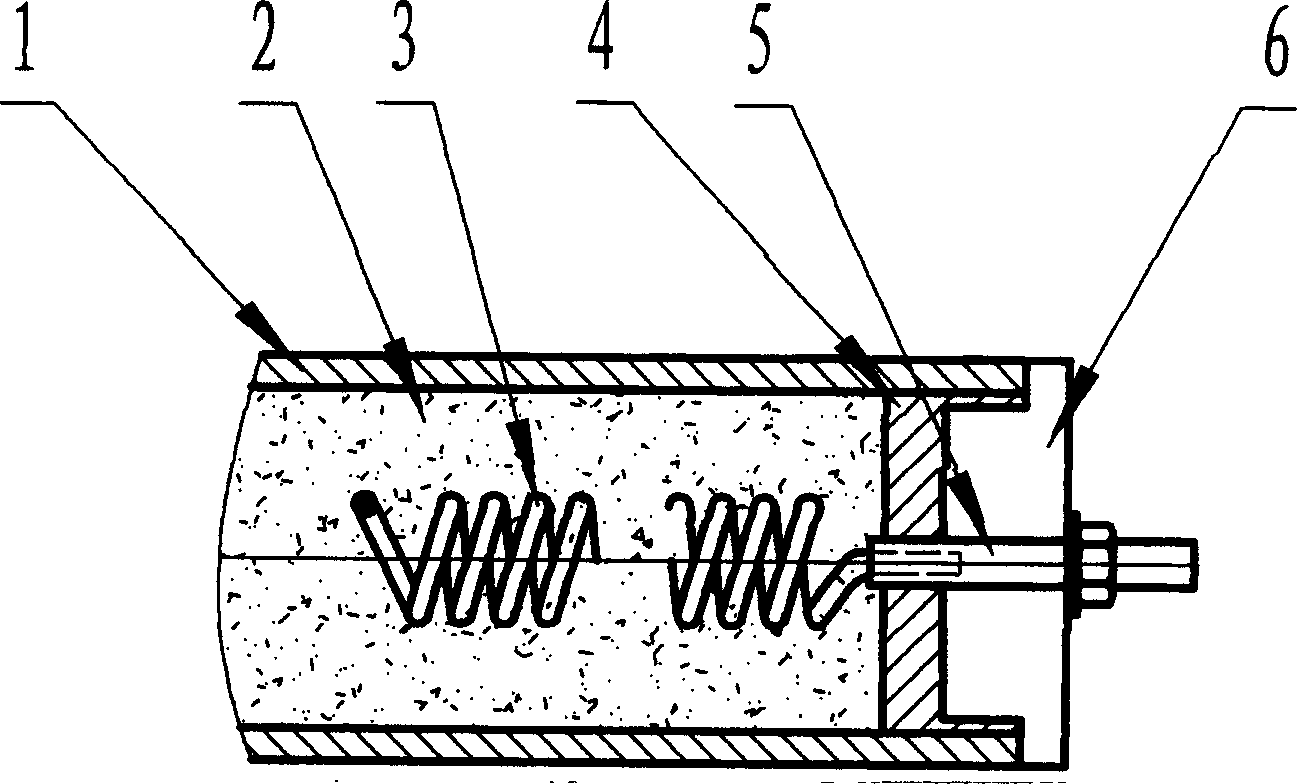

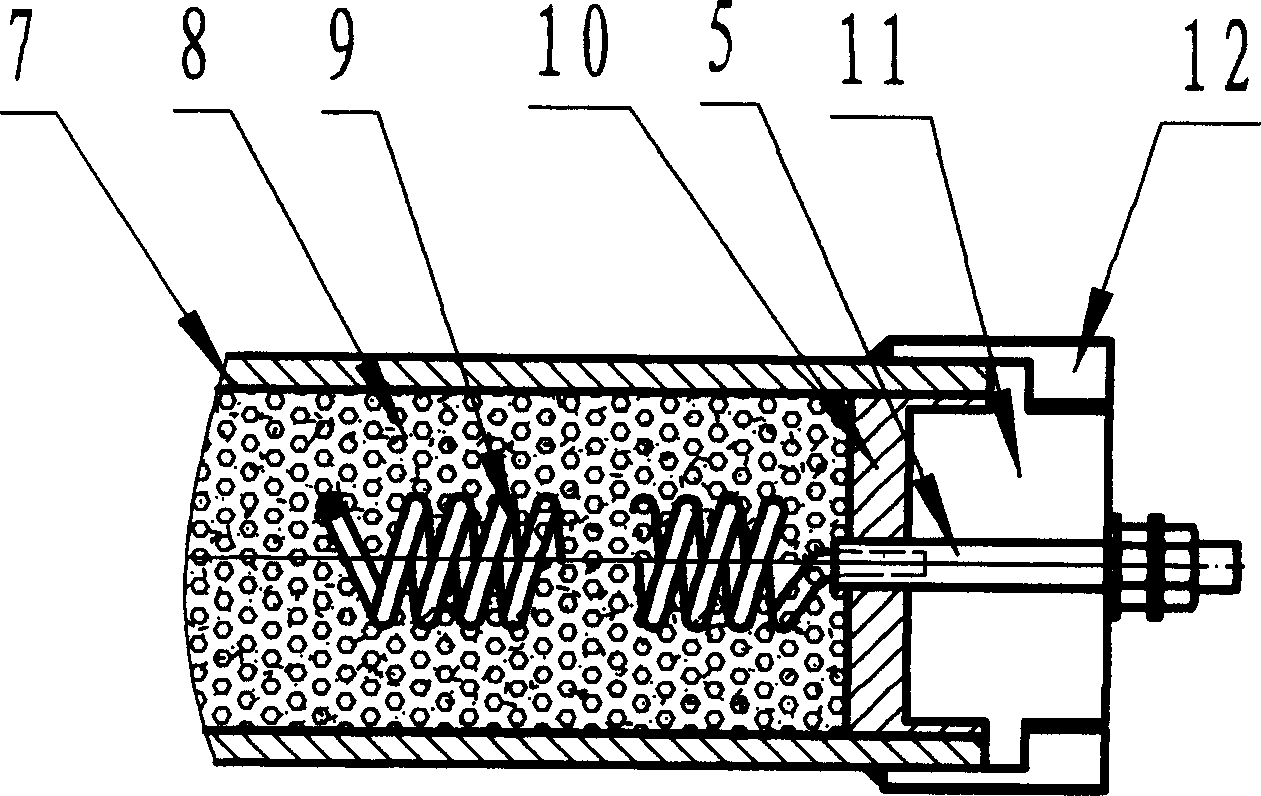

[0025] Specific embodiments of the present invention are described with reference to the accompanying drawings.

[0026] as attached figure 2 As shown: the present invention includes a heat-resistant steel outer protective tube 7, a thick and fine magnesia mixed filler layer 8 and a heating wire. The heating wire of this embodiment is a carbon fiber heating wire 9, which is located at the center of the heat-resistant steel outer protective tube. Coarse and fine magnesium oxide mixed filler layer 8 is filled around the carbon fiber heating wire 9 and between the heat-resistant steel outer protective tube 1, and the particle size of the fine magnesium oxide powder is 200M / cm 2 , the particle size of coarse magnesium oxide is 30M / cm 2 , the mixing ratio of fine magnesium oxide powder and coarse magnesium oxide particles is 1:4. A sealing plug 10 is arranged at the outlet end position, and the sealing plug 10 is made of a particle diameter of 150M / cm 2 It is made by mixing alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com