Water sublimator water supply control method for coping with overload and back pressure

A technology of a water sublimator and a control method, applied in the fields of aerospace and heat transfer, can solve the problems of inability to cope with overload and back pressure environment, and achieve the effects of improving flexibility, stabilizing heat dissipation, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

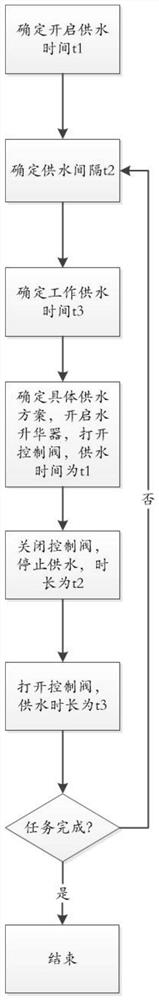

[0030] Such as figure 1 As shown, the specific flow of a water supply control method for a water sublimator to cope with overload and back pressure provided by the embodiment of the present invention includes the following main steps:

[0031] S1. When the water sublimator is supplied with water for the first time, there is no working fluid inside the water sublimator and it is in an empty state. Therefore, t1 should satisfy the two conditions of Formula 1 and Formula 2, that is, the first constraint condition. The first constraint is:

[0032] t1≤t tol Formula 1

[0033]

[0034] Among them, t tol is the high pressure withstand time, P' w.in is the actual water supply pressure, DIM fw is the structural parameter of the water supply channel, T pc is the phase transition interface temperature, P pc,0 is the phase change interface back pressure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com