Acoustic surface wave filter and manufacturing method thereof

A surface acoustic wave and manufacturing method technology, applied in the direction of electrical components, impedance networks, etc., can solve problems such as tip effect, surface acoustic wave damage, and interdigital strip breakage, so as to avoid breakdown phenomenon, reduce field strength, The effect of increasing the center frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

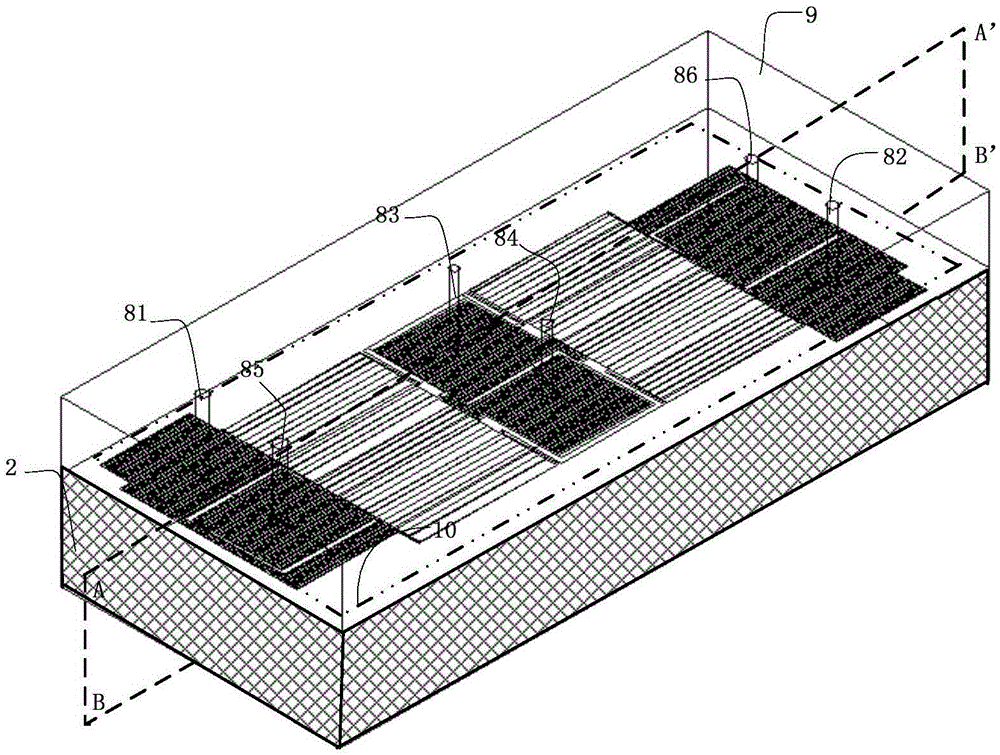

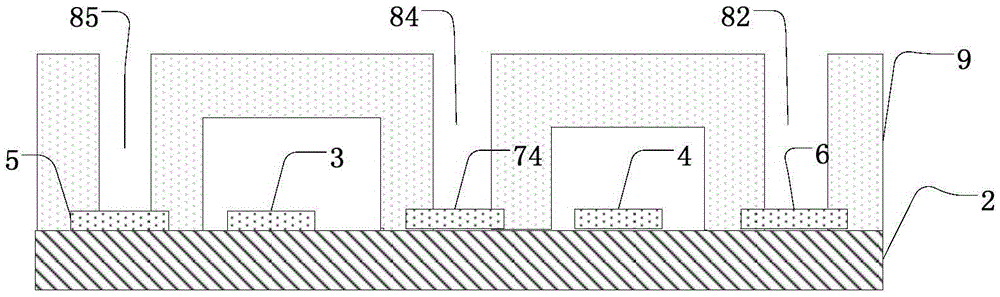

[0034] Such as figure 1 As shown, a surface acoustic wave filter includes a base 2 and a cap 9 .

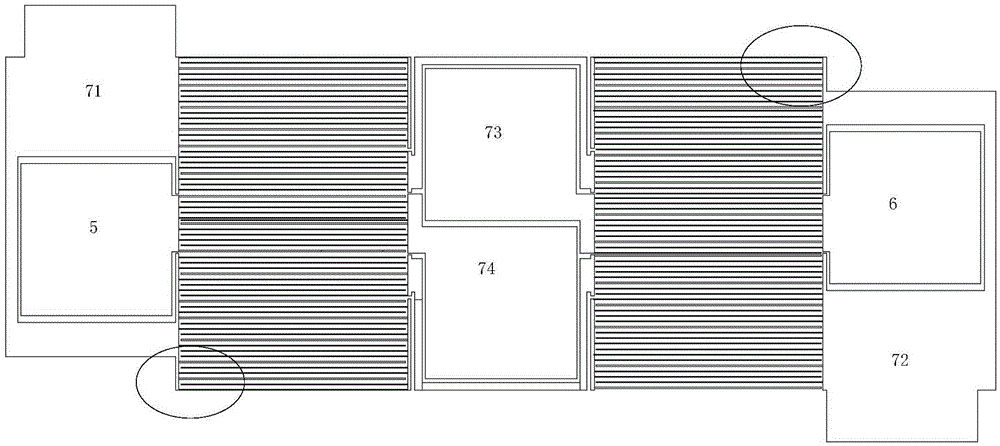

[0035] The substrate 2 has a transmitting IDT 3, a receiving IDT 4, a ground wire 7, a signal input port 5 and a signal output port 6, such as figure 2 is a top view of the structure on the substrate 2. The ground wire 7 includes a first ground wire 71, a second ground wire 72, a third ground wire 73 and a fourth ground wire 74;

[0036] The transmitting IDT 3 and the receiving IDT 4 are rectangular interdigital electrodes, which are composed of two interdigitated comb electrodes, and the shape of each interdigital generally adopts a rectangle. The line width of the interdigital transducer used in the present invention is 1 μm to 2 μm, the interdigital distance is 1 μm to 2 μm, and the length of the aperture (the part where two comb electrodes are inserted) is 300 μm to 350 μm. The corners of the common electrodes of the comb electrodes of the transmitting IDT 3 and the recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com