Manufacturing method of oriented film and LCD panel

A technology of liquid crystal display panels and manufacturing methods, applied in the direction of nonlinear optics, instruments, optics, etc., can solve problems such as lowering the qualified rate, increasing production costs, and circuit damage on the substrate, so as to avoid static electricity problems, simplify the manufacturing process, and pass rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for manufacturing an alignment film for a liquid crystal display panel and a method for manufacturing a liquid crystal display panel according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same symbols.

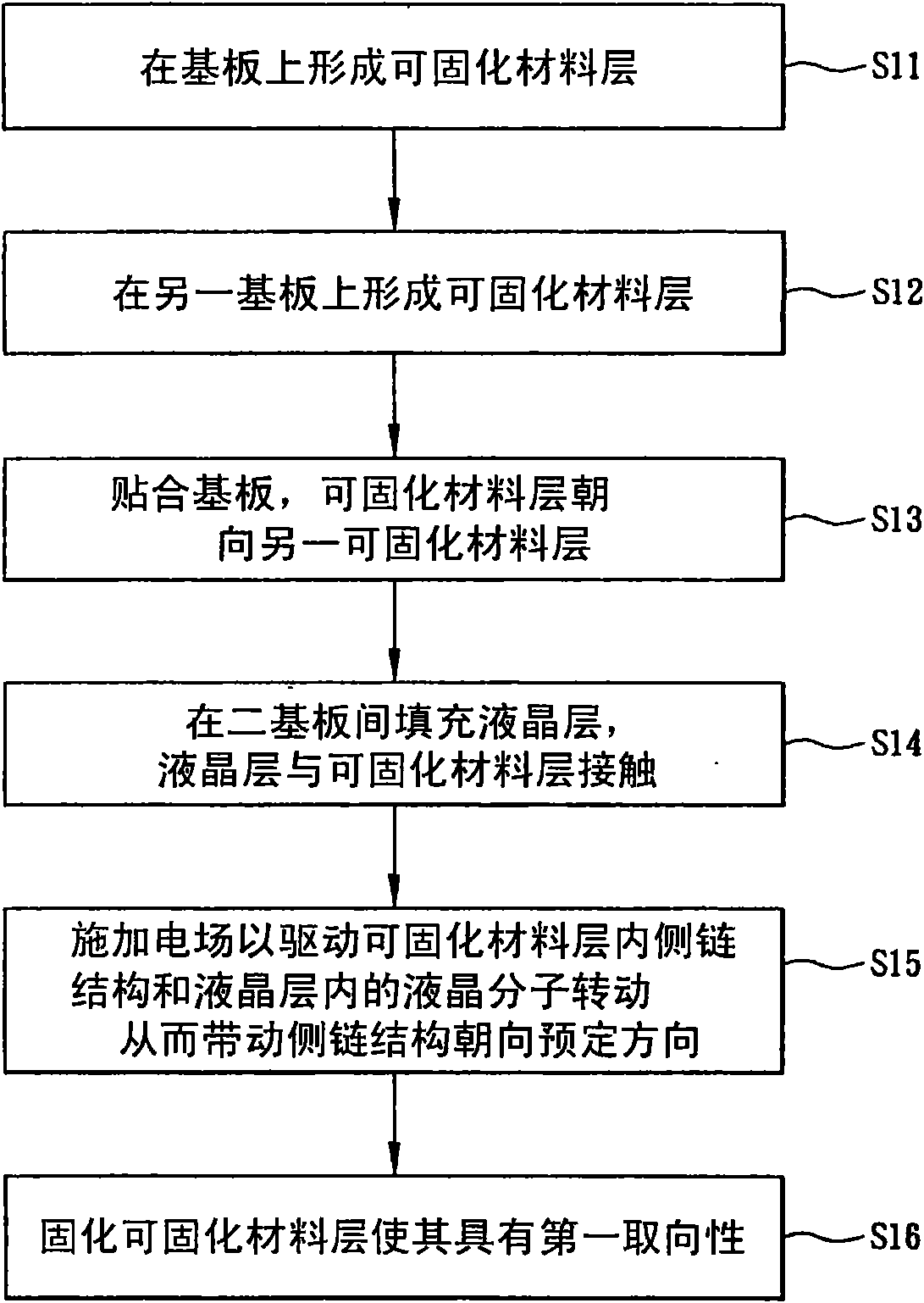

[0024] figure 2 It is a flow chart of a method for manufacturing a liquid crystal display panel in a preferred embodiment of the present invention. In this embodiment, the manufacturing method mainly includes step S11 to step S16. The following fit Figure 3A to Figure 3D The manufacturing method of this example will be described.

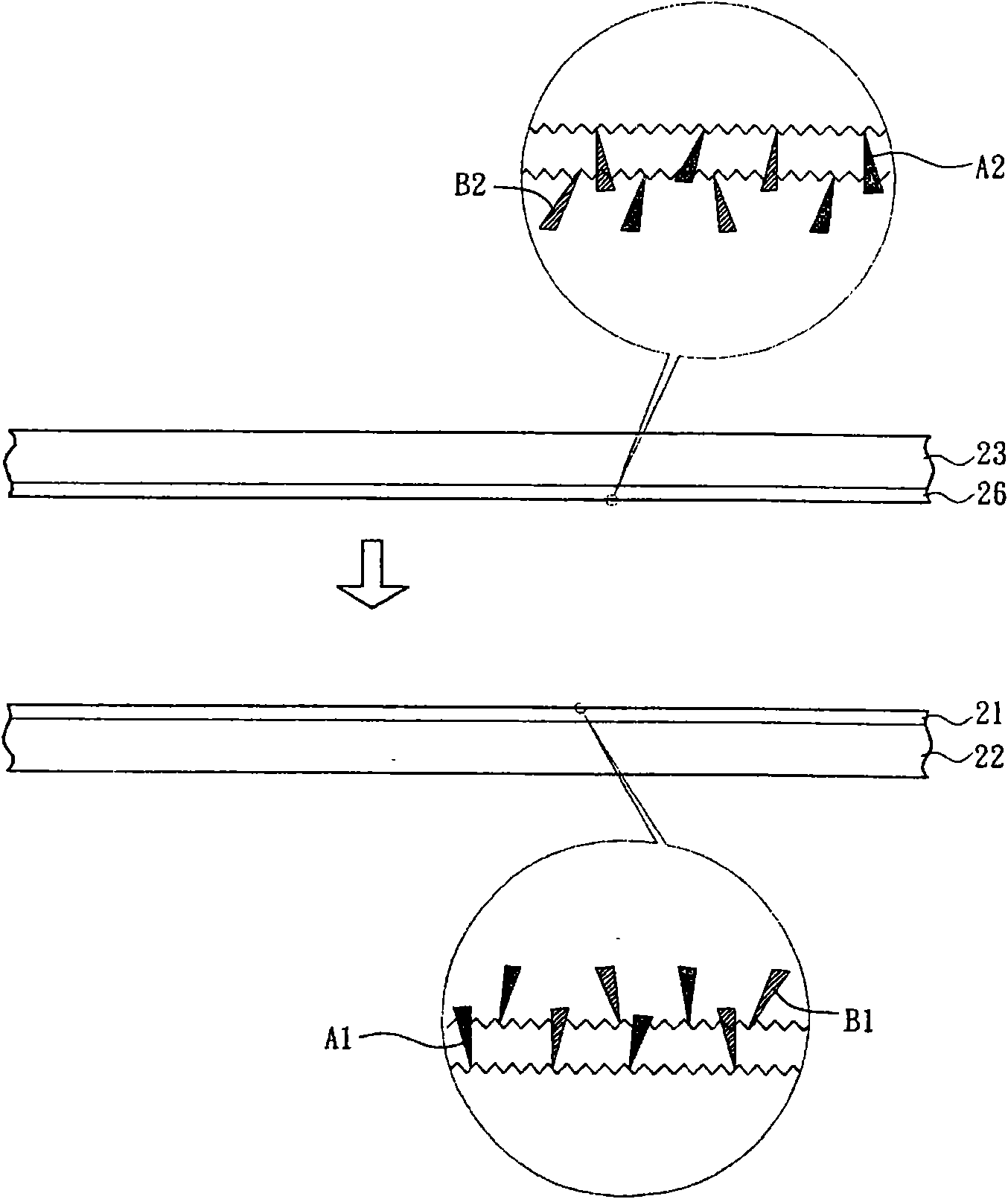

[0025] Such as figure 2 and Figure 3A As shown, step S11 is to form a curable material layer 21 on the substrate 22, wherein the curable material has a side chain structure A1. Step S12 is to form another curable material layer 26 on another substrate 23 , wherein the other curable material has another sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com