LCD technique

A technology, glass substrate technology, applied in the field of LCD technology, can solve the problems of increasing cost, high labor intensity, waste of labor cost, etc., and achieve the effect of reducing corrosion and toxicity, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

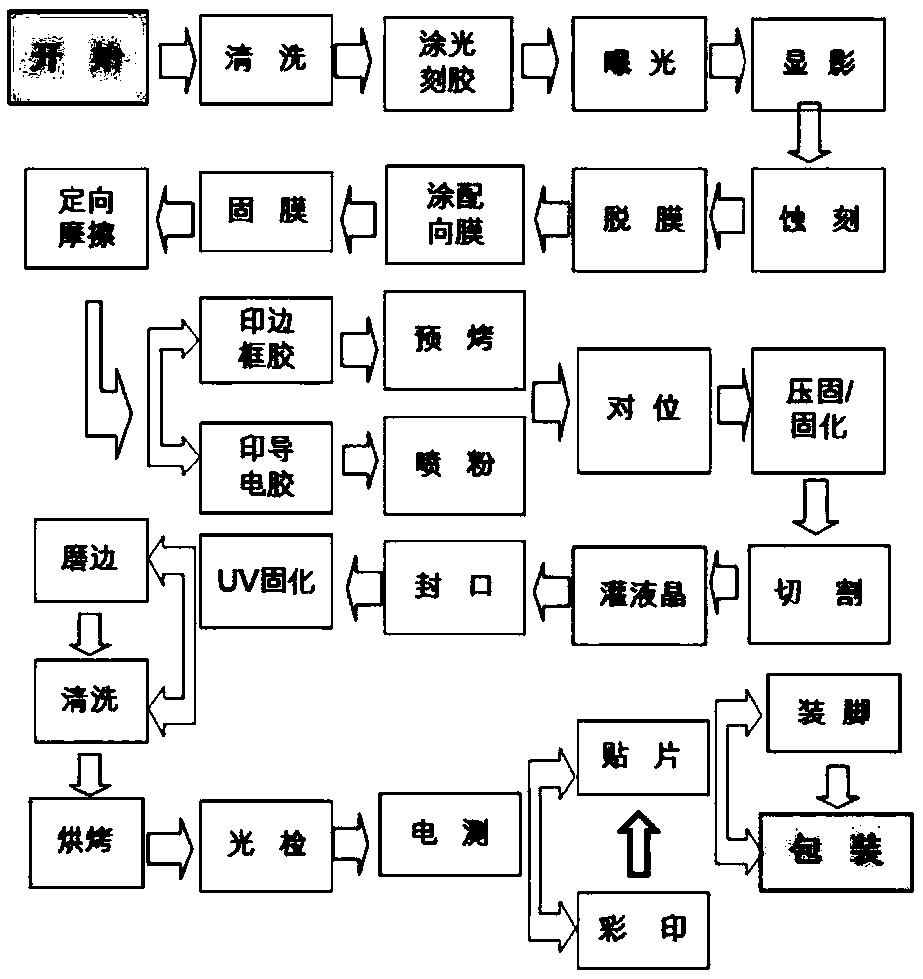

[0036] The present embodiment provides a kind of LCD technique, comprises the following steps:

[0037] S1. Pretreatment: After raw material inspection, the first cleaning, photoresist coating, exposure, development, film hardening, etching, stripping and second cleaning are carried out in order to obtain the ITO glass substrate;

[0038] S2. Applying an orientation layer and curing PI: finish coating an orientation layer and spraying powder before curing, and then curing to obtain a cured ITO glass substrate;

[0039] S3. Post-processing: The cured ITO glass substrate is rubbed with PI, silk screen, hot-pressed, cut, granulated, liquid crystal filled and sealed in sequence, and the initial production of the LCD display is completed after cleaning;

[0040] S4. Finished product processing: The preliminarily produced LCD display screen is inspected, edged, external silk screen, patched, and pinned, and finally packed into the warehouse.

[0041] Wherein, the photoresist coatin...

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, except that in step S2, an alignment layer is applied first, then powder spraying is performed, and then curing is performed to obtain a cured ITO glass substrate.

[0053] In this embodiment, the process sequence of powder spraying is changed from after curing to before curing, which can prevent static electricity.

Embodiment 3

[0055] This embodiment is basically the same as Embodiment 1, the difference is that the raw material of the ITO glass substrate described in step S1 is hard glass, and the diamond cutter wheel of a multi-knife machine is used for cutting in step S3, and the cutting is performed with a pressure of 3 to 4 kg .

[0056] In this embodiment, hard glass is used instead of ordinary glass, and the ITO glass substrate has higher hardness and is more heat-resistant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com