Modified composite heat-resistant lithium ion battery diaphragm and preparation method thereof

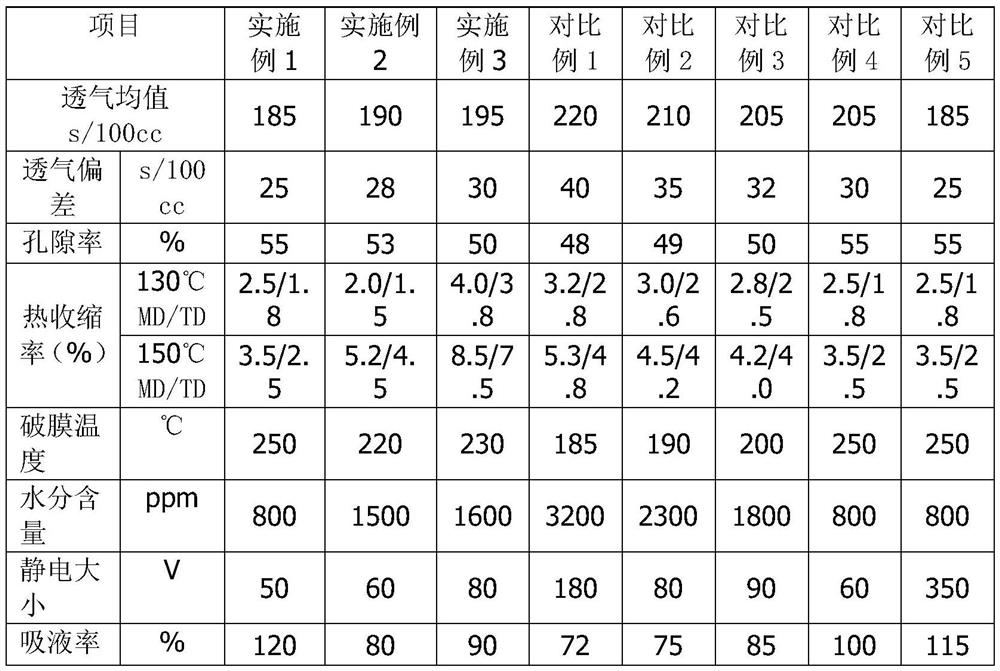

A lithium-ion battery, modified technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problems of large static electricity, high moisture, insufficient heat resistance, etc., to reduce surface energy, enhance compatibility and Dispersibility, the effect of improving the overall heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of a modified composite heat-resistant lithium-ion battery diaphragm, comprising the steps of:

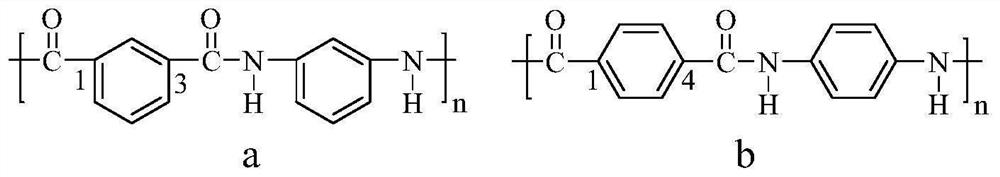

[0052] A. Modification of aramid fiber: select meta-aramid fiber, the structure is as follows figure 1 As shown in a, add a sodium hydroxide solution with a mass concentration of 4.5% to treat for 60 minutes at 60°C, carry out chemical modification, partially hydrolyze the meta-aramid fiber, open part of the polymer chain segment, and then add terephthalic acid to remove Excessive alkali, take a sample and monitor the pH of the solution with a pH meter, adjust the pH to a weak acid environment of 4.5, and finally cool down to 3°C and add p-phenylenediamine solution, add it while stirring rapidly, and carry out chemical copolymerization modification. After completion, use the above The sodium hydroxide solution adjusts the pH to 7.0 to obtain a modified aramid fiber slurry with a structure such as figure 2 shown.

[0053] B. Modification of inorganic n...

Embodiment 2

[0057] A preparation method of a modified composite heat-resistant lithium-ion battery diaphragm, comprising the steps of:

[0058] A. Modification of aramid fiber: select meta-aramid fiber, the structure is as follows figure 1As shown in a, add 0.1% sodium hydroxide solution at 30°C for 120 minutes to carry out chemical modification to partially hydrolyze the meta-aramid fiber, open part of the polymer chain segment, and then add terephthalic acid to remove For excess alkali, take a sample and monitor the pH of the solution with a pH meter, adjust the pH to a weak acid environment of 4.2, and finally cool down to 5°C and add p-phenylenediamine solution, add it while stirring rapidly, and carry out chemical copolymerization modification. After completion, use the above The sodium hydroxide solution adjusts the pH to 6.8 to obtain a modified aramid fiber slurry with a structure such as figure 2 shown.

[0059] B. Modification of inorganic nano-materials: Select spherical bau...

Embodiment 3

[0063] A preparation method of a modified composite heat-resistant lithium-ion battery diaphragm, comprising the steps of:

[0064] A. Modification of aramid fiber: select meta-aramid fiber, the structure is as follows figure 1 As shown in a, first add 10% sodium hydroxide solution at 100°C for 10 minutes to carry out chemical modification to partially hydrolyze the meta-aramid fiber, open part of the polymer chain segment, and then add terephthalic acid to remove Excessive alkali, take a sample and monitor the pH of the solution with a pH meter, adjust the pH to a weak acid environment of 4.8, and finally cool down to 0°C and add p-phenylenediamine solution, add it while stirring rapidly, and carry out chemical copolymerization modification. After completion, use the above The sodium hydroxide solution adjusts the pH to 6.0 to obtain a modified aramid fiber slurry with a structure such as figure 2 shown.

[0065] B. Modification of inorganic nanomaterials: select spherical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com