Method for preparing metal ceramic composite powder body suitable for hot spraying

A metal-ceramic composite, thermal spraying technology, applied in the direction of coating, can solve the problems of reducing coating hardness, low friction coefficient, low shear strength, etc., to achieve improved surface activity, high bulk density, good wearability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

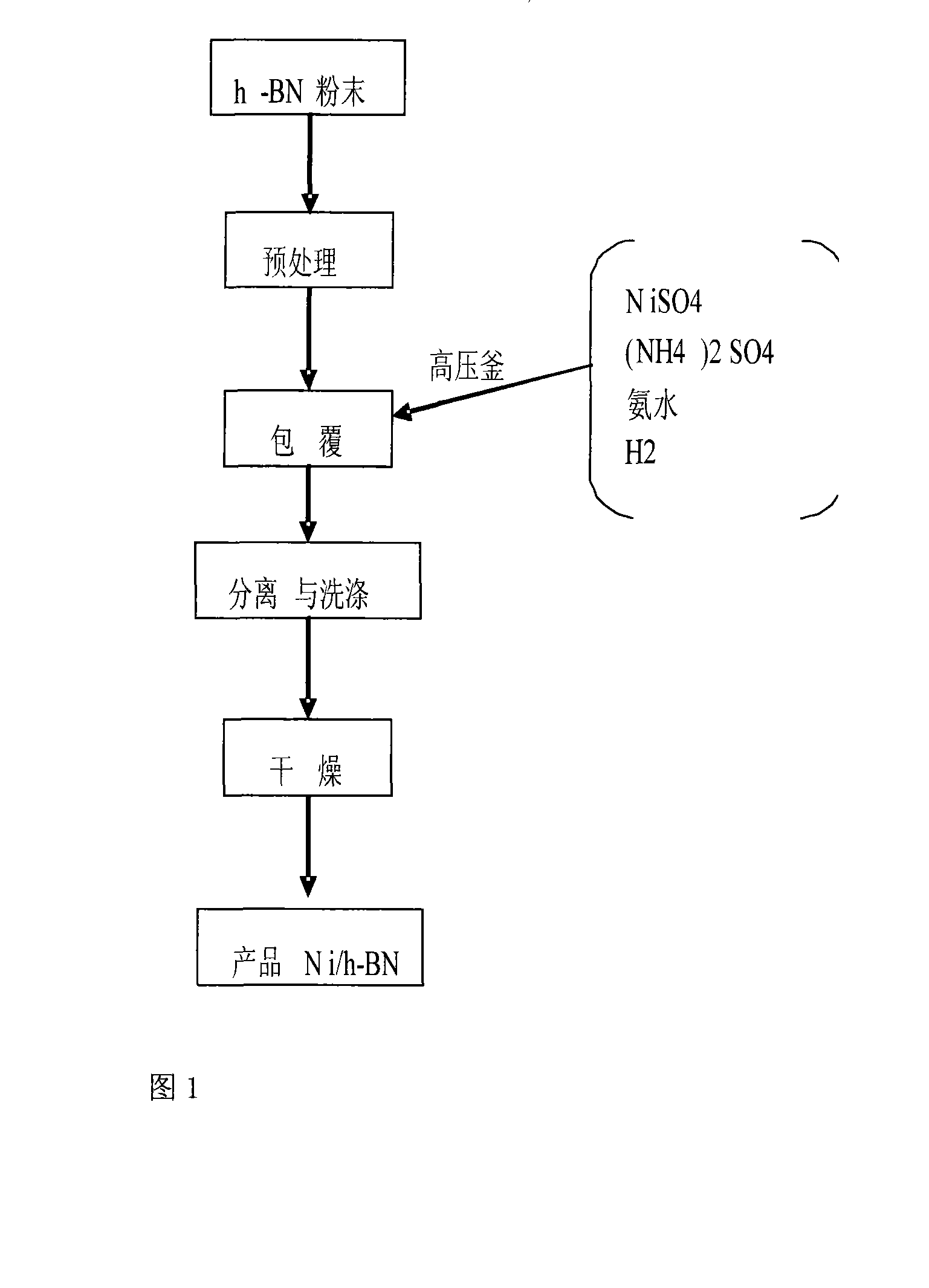

Method used

Image

Examples

Embodiment 1

[0026] The preparation method for producing nickel-coated boron nitride cermet composite powder comprises the following steps: take 26.3g of hexagonal boron nitride powder for pretreatment, add 200ml of 10% NaOH solution to boil for 30 minutes, and then wash several times, Add 200ml of sensitizing solution and stir, sensitize for about 5 minutes, after washing several times, add 5ml of activating solution for about 20 minutes, wash several times, dry and set aside.

[0027] Account for 95% of the total mass of the powder in which nickel metal accounts for 95% of the nickel sulfate solution with a concentration of 50g / l, the ammonium sulfate solution with a concentration of 150g / l, and the ammoniacal liquor according to the ratio of nickel to ammonia 1:2, totally 10L.

[0028] Weigh 2g of anthraquinone as an active agent, put it into a 10L autoclave together with the prepared mixed solution and activated hexagonal boron nitride for coating, capping, exhaust, and heating. When t...

Embodiment 2

[0031] The preparation method for producing nickel-coated boron nitride cermet composite powder comprises the following steps: take 55.6g of hexagonal boron nitride powder, add 200ml of 10% NaOH solution and boil for 30min, then wash several times, add sensitizing 200ml of activating solution and stirred, sensitization treatment for about 5min, after washing several times, add 5ml activation solution for about 20 minutes, wash several times, dry and set aside.

[0032] According to the ratio of metallic nickel accounting for 90% in the total mass of the powder, prepare a nickel sulfate solution with a concentration of 50g / l, an ammonium sulfate solution with a concentration of 150g / l, and ammoniacal liquor according to the ratio of nickel and ammonia 1:2, totally 10L.

[0033] Weigh 2g of anthraquinone as an active agent, put it into a 10L autoclave together with the prepared mixed solution and activated hexagonal boron nitride, seal the lid, exhaust, and heat. When the temper...

Embodiment 3

[0036] The preparation method for producing nickel-coated boron nitride cermet composite powder comprises the following steps: take 88.2g of hexagonal boron nitride powder, add 200ml of 10% NaOH solution and boil for 30min, then wash several times, add sensitizing 200ml of activating solution and stirred, sensitization treatment for about 5min, after washing several times, add 5ml activation solution for about 20 minutes, wash several times, dry and set aside.

[0037] According to the ratio of metallic nickel accounting for 85% in the total mass of the powder, prepare a nickel sulfate solution with a concentration of 50g / l, an ammonium sulfate solution with a concentration of 150g / l, and ammoniacal liquor according to the 1:2 ratio of nickel and ammonia, totally 10L.

[0038]Weigh 2g of anthraquinone, put it into a 10L autoclave together with the prepared mixed solution and activated hexagonal boron nitride, cover, exhaust, and heat. When the temperature rises to 145°C, 4 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com