Novel preparation process for thermal barrier coating

A technology of thermal barrier coating and preparation process, which is applied in the direction of metal material coating process, coating, fusion spraying, etc., to achieve the effect of improving density and selective oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

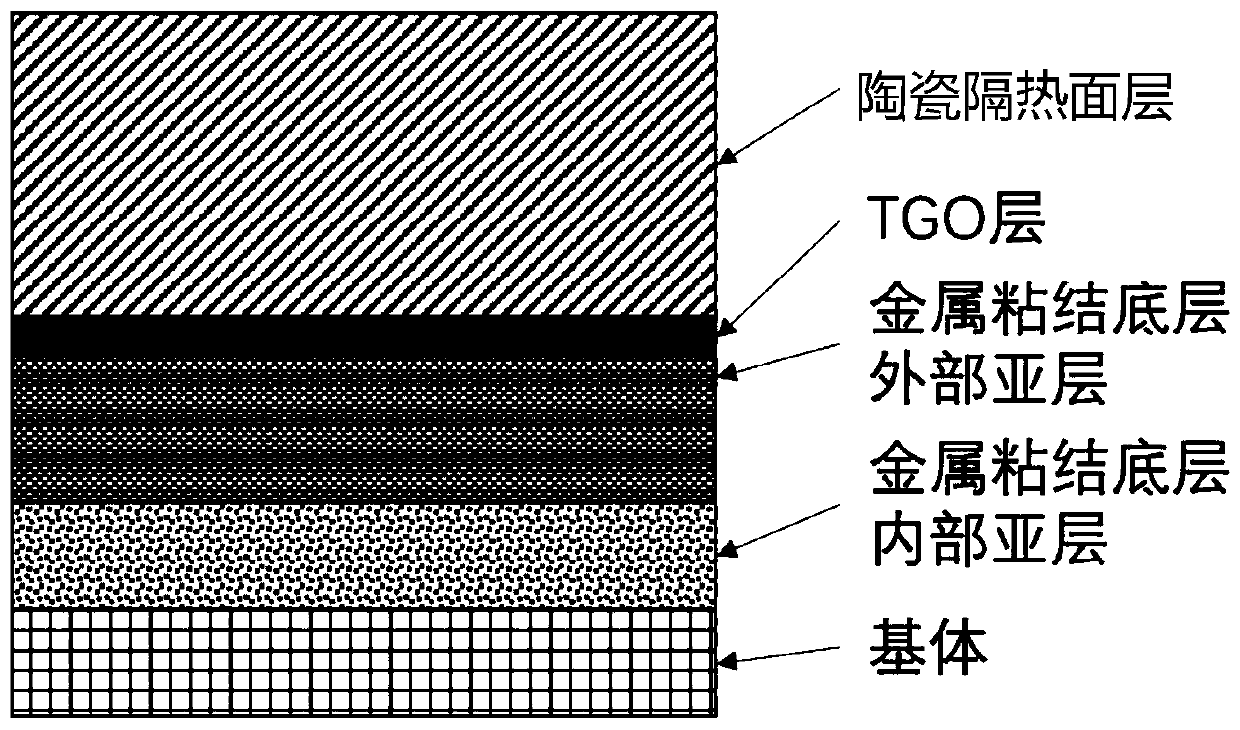

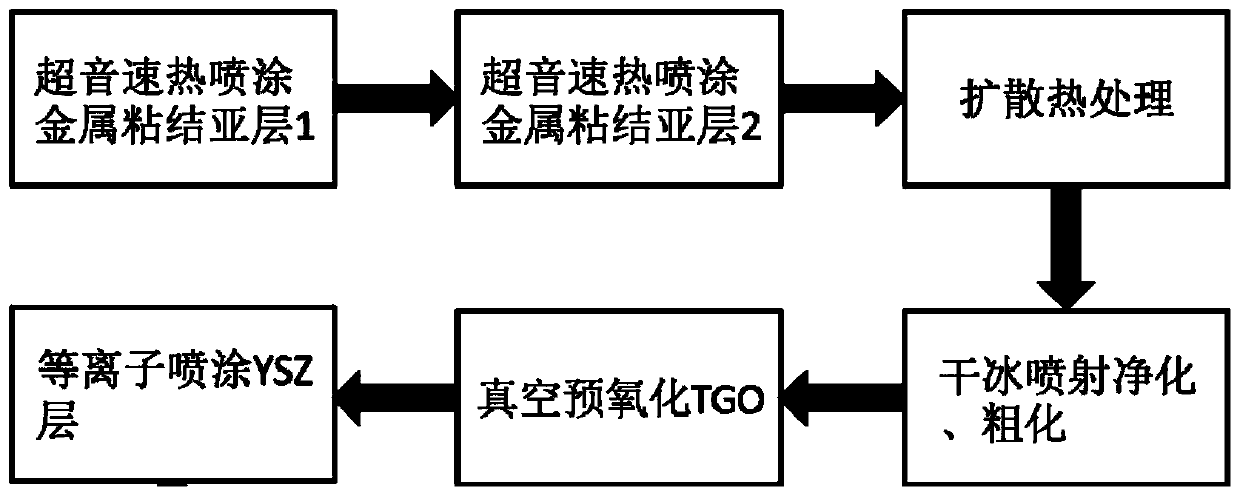

[0051] Step 1. Generate a composite metal bond primer on the surface of the substrate. Specifically include:

[0052] Step 11. Prepare a first metal bonding primer layer of about 50 μm on the surface of the substrate by a supersonic flame spraying process.

[0053] Step 12. Prepare a second metal bonding primer layer of about 50 μm on the surface of the substrate by a supersonic flame spraying process.

[0054] Both the first metal bond primer and the second metal bond primer were made of MCrAlY powder. The second metallic bond primer has a greater aluminum content than the first metallic bond primer.

[0055] Step 13. Vacuum diffusion heat treatment. Interdiffusion occurs between the first metal bonding primer and the second metal bonding primer, forming a layer on the surface consisting of an outer sublayer that is relatively aluminum-rich and has a higher elastic modulus and an inner layer that is relatively chromium-rich and has a lower elastic modulus Composite metal ...

Embodiment 2

[0061] Step 1. Generate a composite metal bond primer on the surface of the substrate. Specifically include:

[0062] Step 11. Prepare a first metal bonding primer layer with a thickness of about 100 μm on the surface of the substrate by a supersonic flame spraying process.

[0063] Step 12. Prepare a second metal bonding primer with a thickness of about 100 μm on the surface of the substrate by a supersonic flame spraying process.

[0064] Both the first metal bond primer and the second metal bond primer were made of MCrAlY powder. The second metallic bond primer has a greater aluminum content than the first metallic bond primer.

[0065] Step 13. Vacuum diffusion heat treatment. Interdiffusion occurs between the first metal bonding primer and the second metal bonding primer, forming a layer on the surface consisting of an outer sublayer that is relatively aluminum-rich and has a higher elastic modulus and an inner layer that is relatively chromium-rich and has a lower ela...

Embodiment 3

[0071] Step 1. Generate a composite metal bond primer on the surface of the substrate. Specifically include:

[0072] Step 11. Prepare a first metal bonding primer layer with a thickness of about 150 μm on the surface of the substrate by a supersonic flame spraying process.

[0073] Step 12. Prepare a second metal bonding primer with a thickness of about 150 μm on the surface of the substrate by a supersonic flame spraying process.

[0074] Both the first metal bond primer and the second metal bond primer were made of MCrAlY powder. The second metallic bond primer has a greater aluminum content than the first metallic bond primer.

[0075] Step 13. Vacuum diffusion heat treatment. Interdiffusion occurs between the first metal bonding primer and the second metal bonding primer, forming a layer on the surface consisting of an outer sublayer that is relatively aluminum-rich and has a higher elastic modulus and an inner layer that is relatively chromium-rich and has a lower ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| sublimation point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com