Nickel-based metal oxide ceramic inertia anode, preparing method and application

An oxide ceramic and inert anode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of expensive and unstable inert anode materials, and achieve strong resistance to molten salt chemical corrosion and electrochemical corrosion, and high temperature resistance. Strong oxidizing property and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

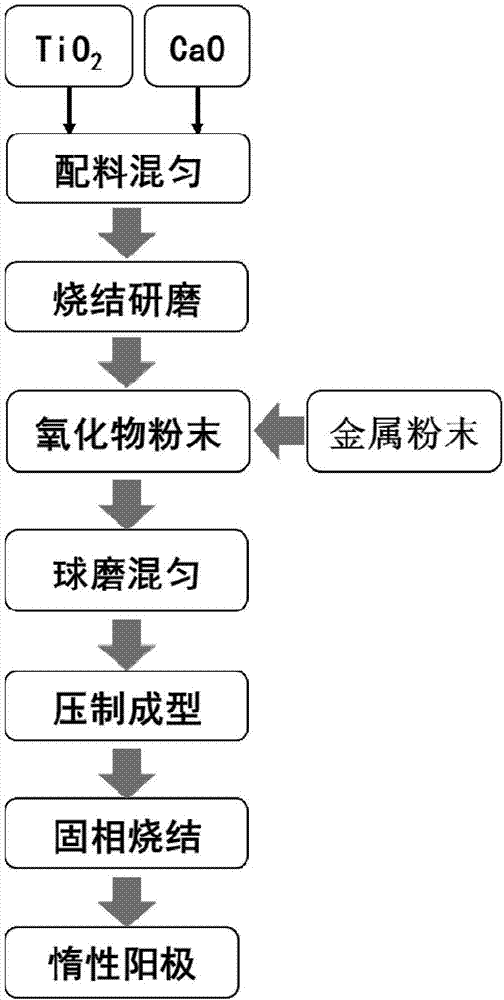

[0026] The embodiment of the present invention is a kind of preparation method of nickel-based metal oxide ceramic inert anode (for the preparation process see figure 1 ), including the following steps:

[0027] Step 1, CaO and TiO 2 Weigh and mix according to the ratio of (25.85~58.39wt%): (74.15-41.61wt%), and calcinate in a muffle furnace at 900°C for 4-6 hours, and grind the sintered block to obtain the oxide phase powder;

[0028] Step 2. Prepare metal oxide uniform mixed powder by ordinary ball milling method: weigh the metal mixed powder mentioned above, and mix it with the oxide powder prepared in step 1 according to the ratio of (40-60 wt%): (60-40 wt%) , and put them into the ball mill together for 12 hours of dry grinding; the ordinary ball mill not only has two functions of mixing and grinding, but the metal and oxide mixed powder after more than 12 hours of ball milling not only plays the role of further grinding and mixing, but also It also promotes the mutual...

Embodiment 1

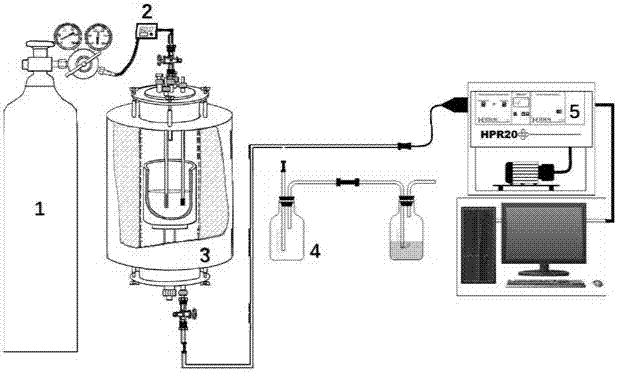

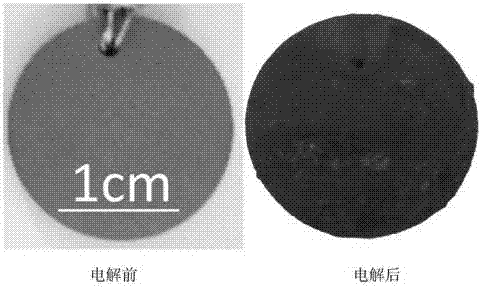

[0038] Using metallic nickel as the metal phase raw material, CaO and TiO 2 (the mass ratio of the two is 41.23%:58.77%) is the oxide phase raw material, the mass ratio of the two is 50%:50%, the raw material is carried out as described in the previous preparation steps, and the prepared inert anode is connected to the metal guide rod , as the working anode; the cathode uses a nickel rod, and the electrolyte uses CaCl 2 -LiCl-CaO (molar ratio is 0.35:0.65:0.05), the experimental atmosphere is CO 2 , the reaction temperature is 600°C. After the molten salt system was stabilized, the system was subjected to constant current electrolysis with a current density of 0.36 A / cm 2 , the schematic diagram of the electrolytic structure is shown in figure 2 As shown, in the self-made reaction resistance furnace 3, the left block is the inert anode, the right is the nickel cathode, and the black substance is the deposited carbonaceous material. After more than 16 hours of continuous e...

Embodiment 2

[0040] Using metal nickel and iron (the mass ratio of the two is 75.92%:24.08%) as the metal phase raw material, CaO and TiO 2 (The mass ratio of the two is 41.23%:58.77%) is the oxide phase raw material, the mass ratio of the two is 55%:45%, the raw material is carried out as described in the preparation steps, and the prepared inert anode is connected to the metal guide rod, As a working anode; the cathode uses a nickel rod, and the electrolyte uses CaCl 2 -LiCl-CaO (molar ratio is 0.35:0.65:0.05), the experimental atmosphere is CO 2 , the reaction temperature is 600°C. After the molten salt system was stabilized, the system was subjected to constant current electrolysis with a current density of 0.5 A / cm 2 . After more than 20 hours of continuous electrolysis, the anode released oxygen during the electrolysis process and showed good and stable electrical conductivity, and a large amount of amorphous carbonaceous materials were prepared at the cathode. After electrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com