Honeycomb heat accumulator for shock resistance and high temperature oxidation resistance

A technology of anti-high temperature oxidation and heat storage body, applied in the direction of heat storage equipment, heat transfer modification, heat exchange equipment, etc., can solve the problem of poor high temperature oxidation resistance of the metal coating layer, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

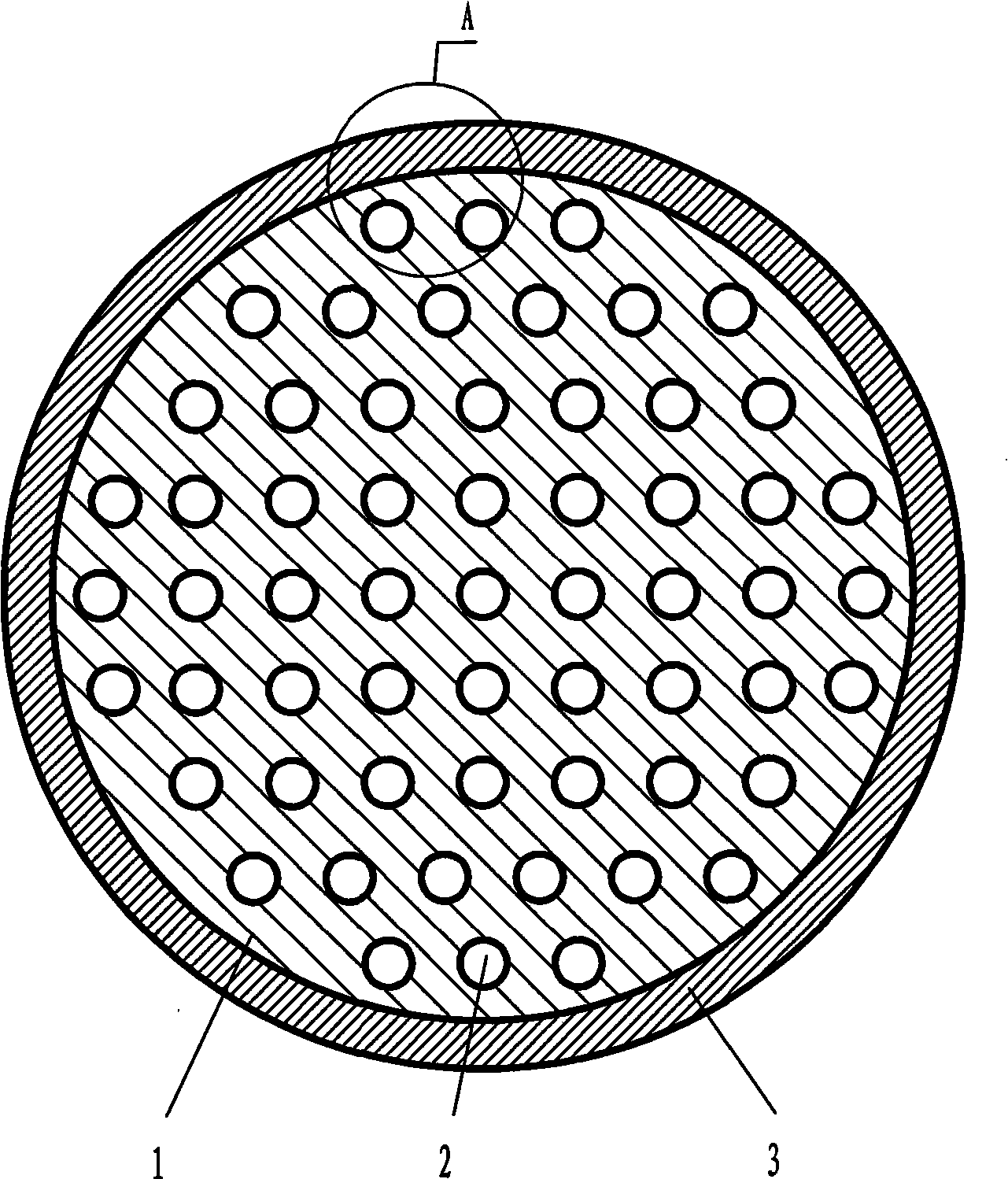

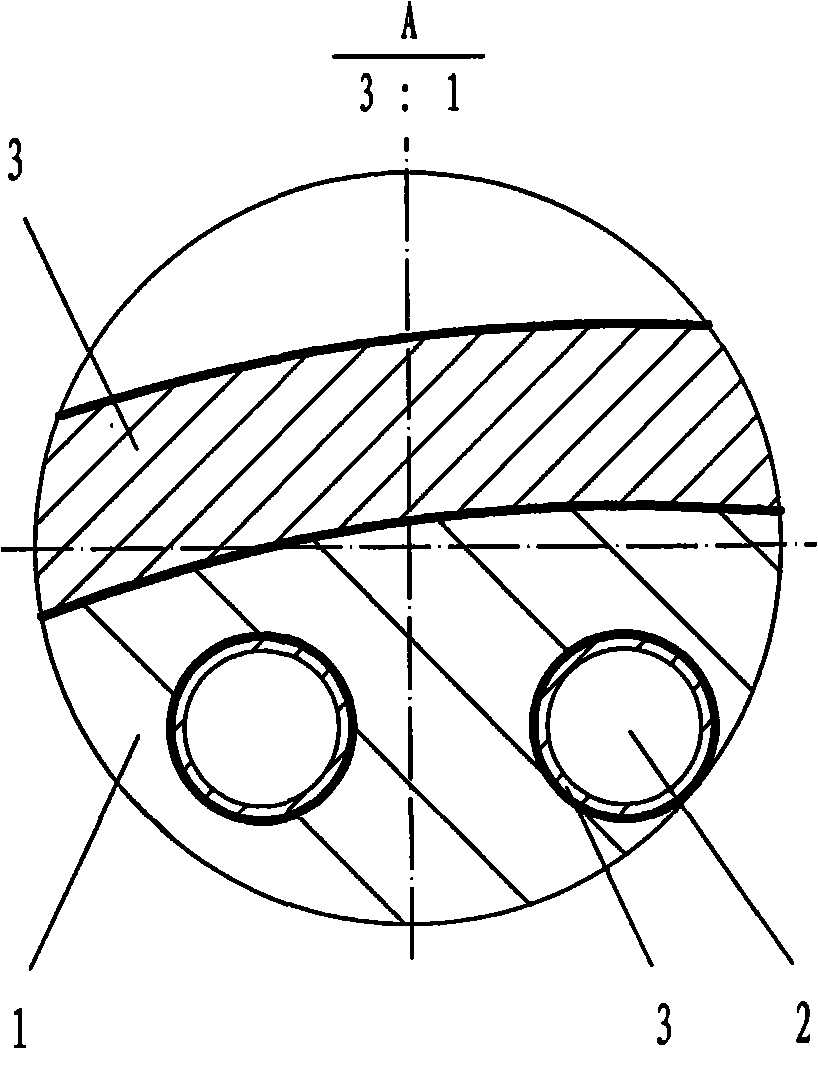

[0015] The honeycomb regenerator of this embodiment is shown in Figures 1 to 2. The cross section of the high-alumina honeycomb regenerator 1 is a circular shape, and a number of honeycomb through holes 2 with a circular cross section are regularly arranged on it. A layer of iron-chromium-aluminum heat-resistant alloy layer 3 with an average thickness of 1.2mm is tightly wrapped on the outer surface of the honeycomb regenerator 1 and the inner surface of the honeycomb hole 2. On the outer surface of the alloy layer 3, there is also infiltration Plated with a layer of molybdenum disilicide4.

[0016] In this embodiment, the material of the metal layer 3 can also be carbon steel, stainless steel or other heat-resistant steel, or other heat-resistant alloy; the regenerator 1 can also be made of cordierite, clay, silicon carbide and other refractory Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com