High-concentration Re/Ru nickel-based single crystal superalloy with high temperature bearing capacity and high creep resistance

A nickel-based single crystal, high-concentration technology, applied in the field of high-temperature alloys, can solve the problems of high-temperature strength and durability that cannot fully meet the needs of advanced aero-engines with high propulsion ratios, and achieve improved temperature resistance, increased initial melting temperature, and wide heat treatment window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

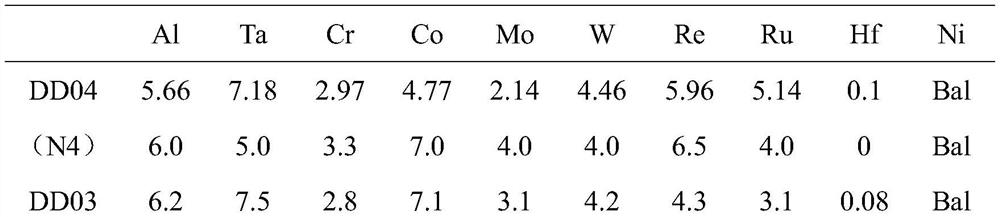

[0043] Table 1 lists the chemical composition (mass percent) comparison of nickel-based superalloy DD04 of the present invention and reference alloys N4 and DD03

[0044] Table 1

[0045]

[0046] In Table 1, DD04 is the chemical composition of the alloy of the present invention, and N4 and DD03 are the chemical composition of the comparative alloy.

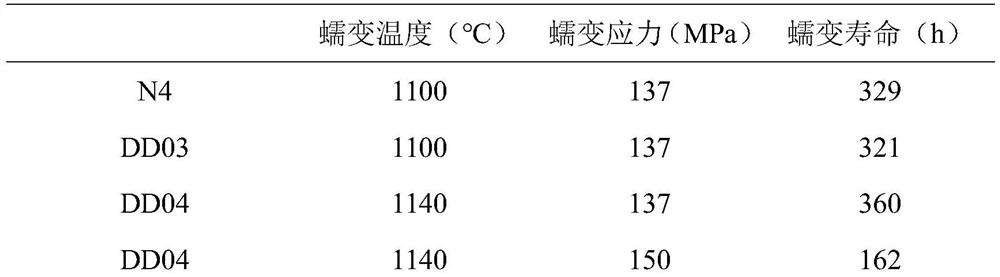

[0047] The above three fully heat-treated alloys were cut into sheet samples with a cross-section of 2.5mm × 4.5mm by wire cutting technology, and were placed in a testing machine for durability test. The calculation results are listed in Table 2.

[0048] Table 2

[0049]

[0050]

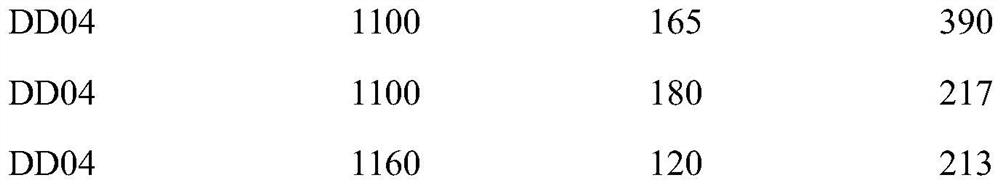

[0051] The fully heat-treated alloys of DD03 and DD04 were cut into sheet samples with a cross section of 2.5mm × 4.5mm by wire cutting technology, and were placed in a testing machine for long-term life testing under medium temperature and high stress conditions. The calculation results are listed in Table 3 .

[0052] table 3

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com