Antioxidant and long-life heat absorption and storage integrated corundum-mullite ceramic and preparation method thereof

A long-life, anti-oxidation technology, applied in the field of ceramics, can solve the problems of high-temperature oxidation resistance, low service life, and reduced heat absorption/storage performance, and achieve excellent high-temperature oxidation resistance, long service life, and improved The effect of heat absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

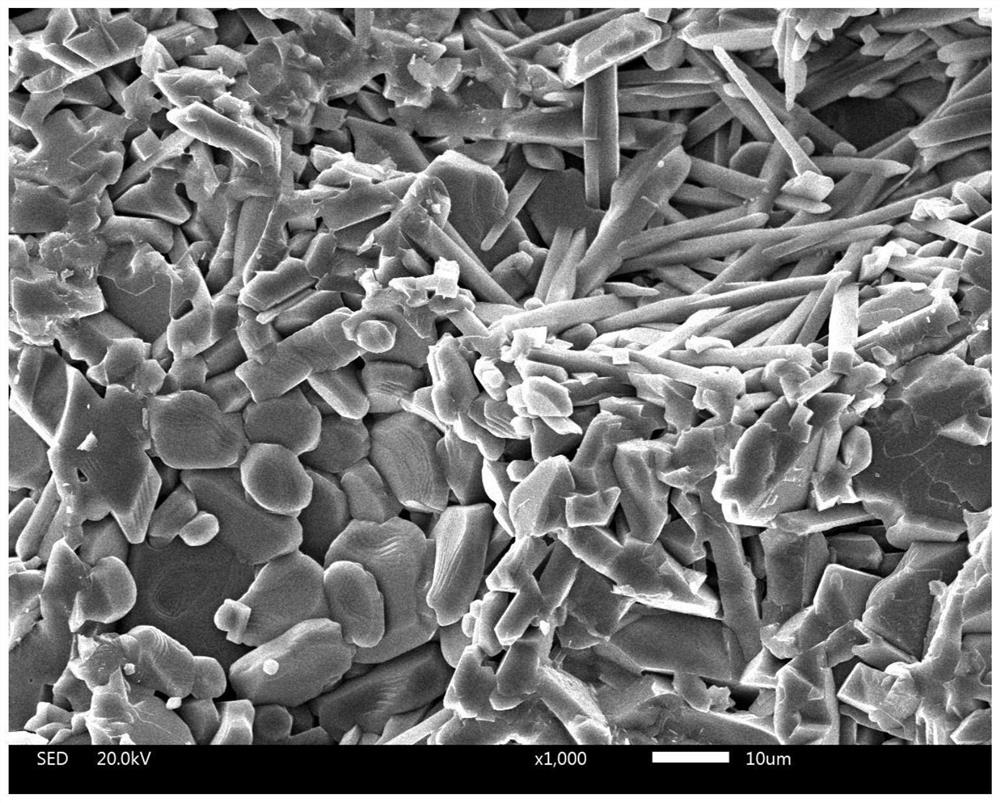

Image

Examples

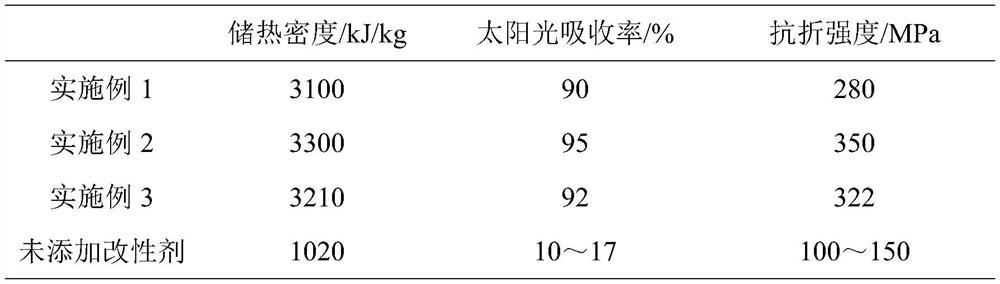

Embodiment 1

[0025] The present embodiment prepares described ceramics, comprises the following steps:

[0026] (1) Raw material processing: pass alumina powder and Suzhou soil through a 250-mesh sieve to prepare powder for later use;

[0027] (2) Proportioning and mixing of raw materials: Add a modifying agent to the raw materials. After each raw material and modifying agent are proportioned according to a certain mass percentage, they are evenly mixed with a ball mill for 1 hour to obtain a mixture, wherein the ball mass ratio is 1: 2;

[0028] (3) Granulation and staling: adopting spray drying method to add water with a mass of 3% to the mixture, and stale for 48 hours after granulation to obtain a blank;

[0029] (4) Semi-dry pressing molding: use a hydraulic press to press the stale blank to obtain a cylindrical solar heat storage ceramic green body, wherein the size of the green body is 800mm, the height is 100mm; the molding pressure is 90kN;

[0030] (5) Drying: place the shaped ...

Embodiment 2

[0038] The present embodiment prepares described ceramics, comprises the following steps:

[0039] (1) Raw material processing: pass alumina powder and Suzhou soil through a 250-mesh sieve to prepare powder for later use;

[0040] (2) Proportioning and mixing of raw materials: Add a modifier to the raw materials. After each raw material and modifier are proportioned according to a certain mass percentage, mix them uniformly with a ball mill for 3 hours to obtain a mixture, wherein the mass ratio of the balls is 1: 2;

[0041] (3) Granulation and staling: add 5% water by spray drying method to the mixture, and stale for more than 48 hours after granulation to obtain a blank;

[0042] (4) Semi-dry pressing molding: use a hydraulic press to press the stale blank to obtain a cylindrical solar heat storage ceramic green body, wherein the size of the green body is 800mm, the height is 100mm; the molding pressure is 120kN;

[0043] (5) Drying: place the shaped green body in a dryin...

Embodiment 3

[0051] The present embodiment prepares described ceramics, comprises the following steps:

[0052] (1) Raw material processing: pass alumina powder and Suzhou soil through a 250-mesh sieve to prepare powder for later use;

[0053] (2) Proportioning and mixing of raw materials: Add a modifying agent to the raw materials. After each raw material and modifying agent are proportioned according to a certain mass percentage, they are evenly mixed with a ball mill for 2 hours to obtain a mixture, wherein the ball mass ratio is 1: 2;

[0054] (3) Granulation and stale: adopt spray-drying method to add the water that quality is 4% to the mixture, after granulation, stale for more than 48h to obtain the billet;

[0055] (4) Semi-dry pressing molding: use a hydraulic press to press the stale blank to obtain a cylindrical solar heat storage ceramic green body, wherein the size of the green body is 800mm, the height is 100mm; the molding pressure is 105kN;

[0056] (5) Drying: place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com