Heat regenerator coupled with microminiature heat pipes and working method

A micro-sized, regenerator technology, applied in superheaters, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of unused regenerators, achieve good heat storage capacity, regular layout, and stress uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

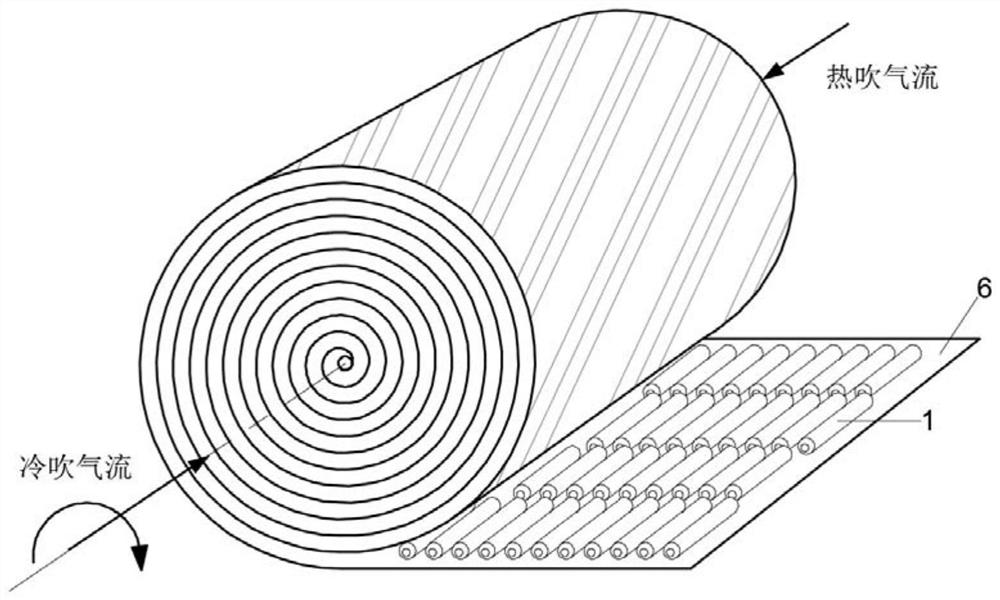

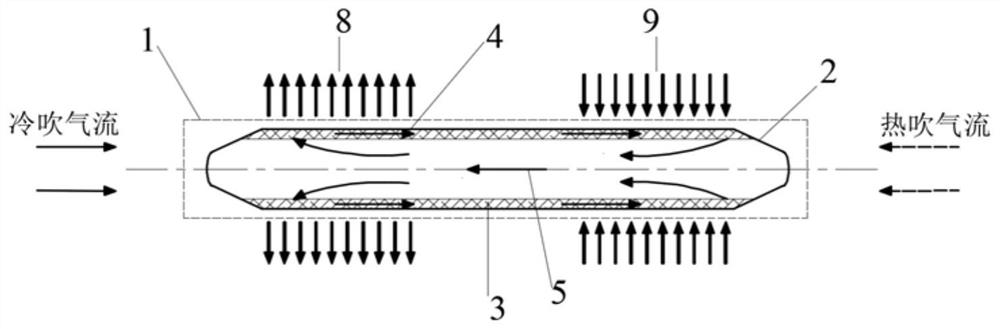

[0047] like image 3 As shown, the miniature heat pipe 1 includes a tube shell, a heat pipe capillary structure 3 and a liquid phase change working medium 4. The tube shell tube length is preferably 30 mm, the tube diameter is 3 mm, the tube wall thickness is 0.2 mm, and the axial center distance is 4 mm. The interval between segments is 4mm. The tube shell is made of seamless metal material with high thermal conductivity, which plays a role in quickly transferring heat. The capillary structure 3 of the heat pipe is composed of several layers of fine copper mesh arranged on the inner wall of the heat pipe, and the capillary holes between the multilayer meshes are used to guide the liquid. The liquid phase-change working medium 4 is composed of organic or inorganic substances with a boiling point of 300K-700. like Figure 5 Shown is a partial schematic diagram of the staggered arrangement of heat pipes. In the heat blowing stage of the heat recovery process, the high-tempera...

Embodiment 2

[0049] like Figure 8 As shown, the miniature heat pipe 1 is a triangular tube (the triangular tube means that the cross section of the heat pipe is a triangle), including a tube shell and a liquid phase change working medium 4, the length of the heat pipe is preferably 30 mm, and the equilateral length of the triangle is 3 mm. The wall thickness is 0.2mm, the axial center distance is 4mm, and the interval between segments is 4mm. The tube shell is made of seamless metal material with high thermal conductivity, which plays a role in quickly transferring heat. The capillary structure 3 of the heat pipe is composed of sharp-angle grooves on the inner wall of the triangular tube, and uses the capillary suction of the sharp corners to guide liquid. The liquid phase-change working medium 4 is composed of organic or inorganic substances with a boiling point of 300K-700. Image 6Shown is a partial schematic diagram of the staggered arrangement of triangular heat pipes. In the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com